Installaon instrucons for the IMM'Ax automac immersed safety cover - 6/36

66

2. Delivery and recepon of

the roller

2.1 Delivery

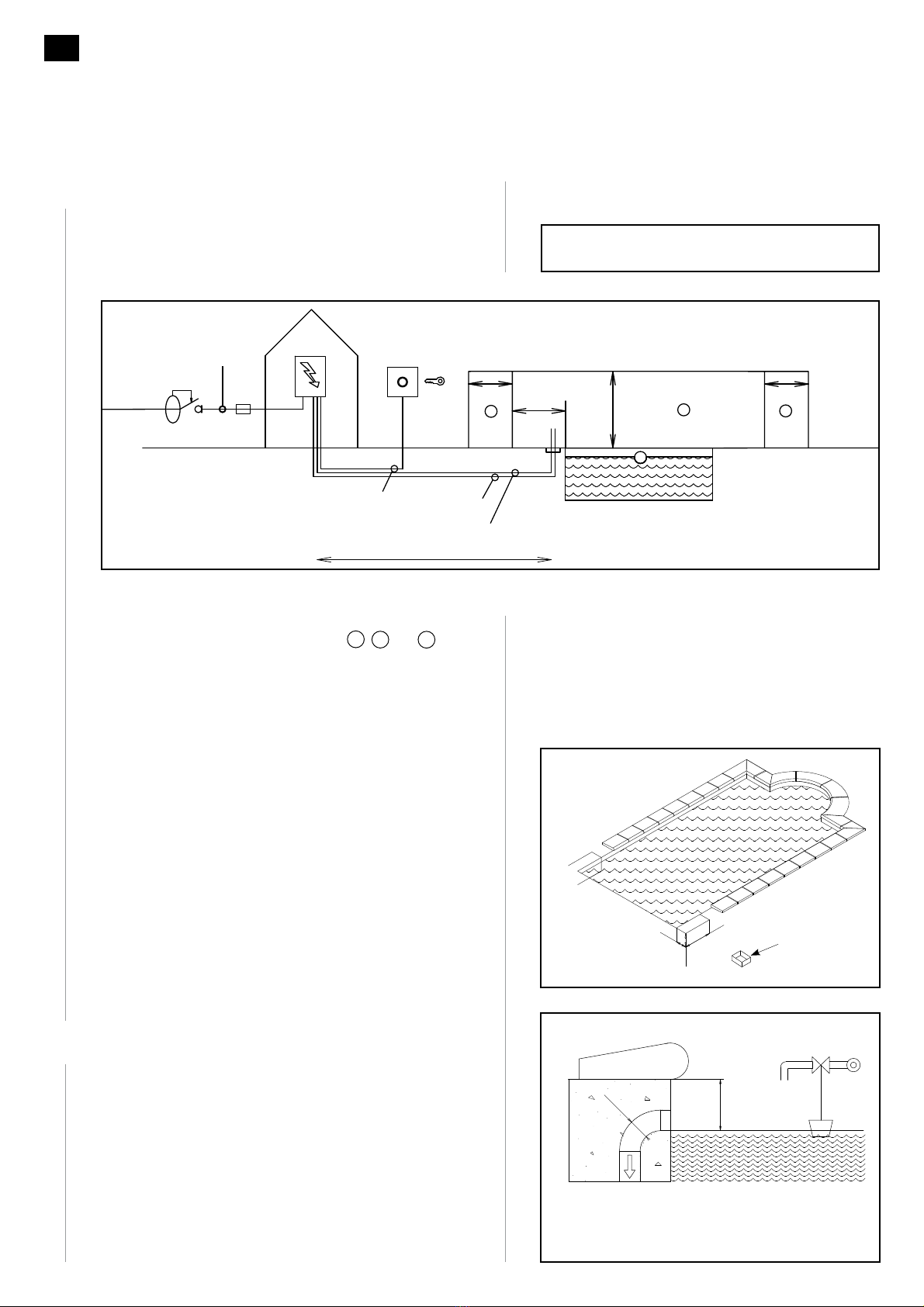

Fig. 6

- Plan the presence of 2 to 6 persons, or use a handling

device to handle the cover. The cover is delivered in a non-

recoverable wooden container measuring at least 40 cm

more than the width of the pool. It is heavy and fragile.

- For a 4 x 8 m pool, the container weighs 465 Kg and

measures 4.6 x 0.6 x 0.8 (h).

- For a 5 x 10 m pool, the container weighs 610 Kg and

measures 5.6 x 0.6 x 0.8 (h).

2.2 Recepon

- Open the container in the presence of the delivery staff

and check the condion of the goods and their compliance.

Keep the original packing.

- If there is any damage or missing parts, write down your

reserves on the transport documents (e.g.: container

open on delivery). The words "subject to unpacking"

alone are null and void. Send a registered letter (with

acknowledgement of receipt) to the transporter within

2 days. This letter must give an exact description of

the damage. Send a copy of the letter to AS POOL for

informaon.

- Store the parts in the container which should not be le

in full sunlight, but should be placed in a cool place if the

assembly is not carried out on the same day.

- Make the inventory compared to the order.

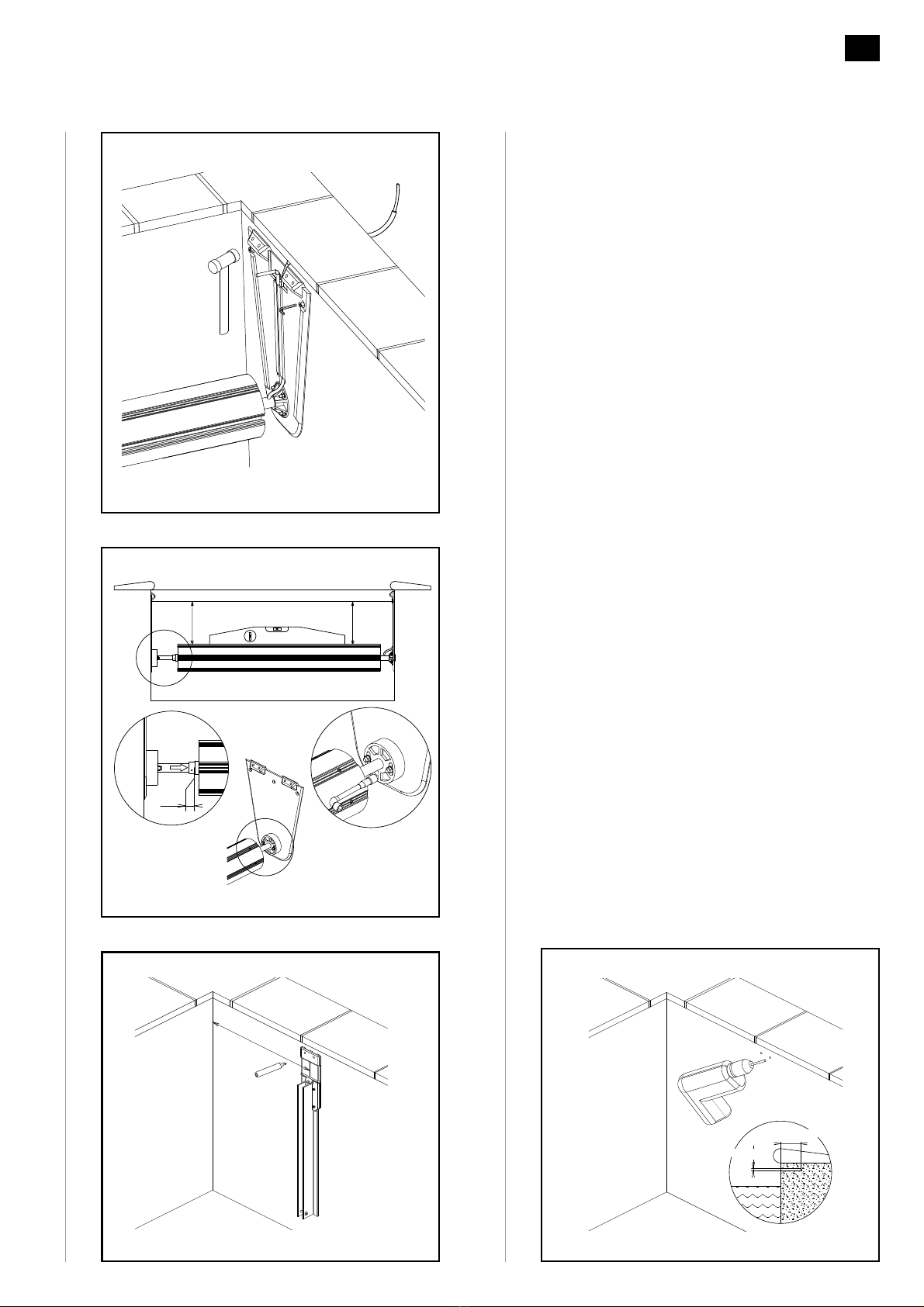

- Read the instructions completely before starting the

assembly.

- The installaon requires 2 persons for 7 hours.

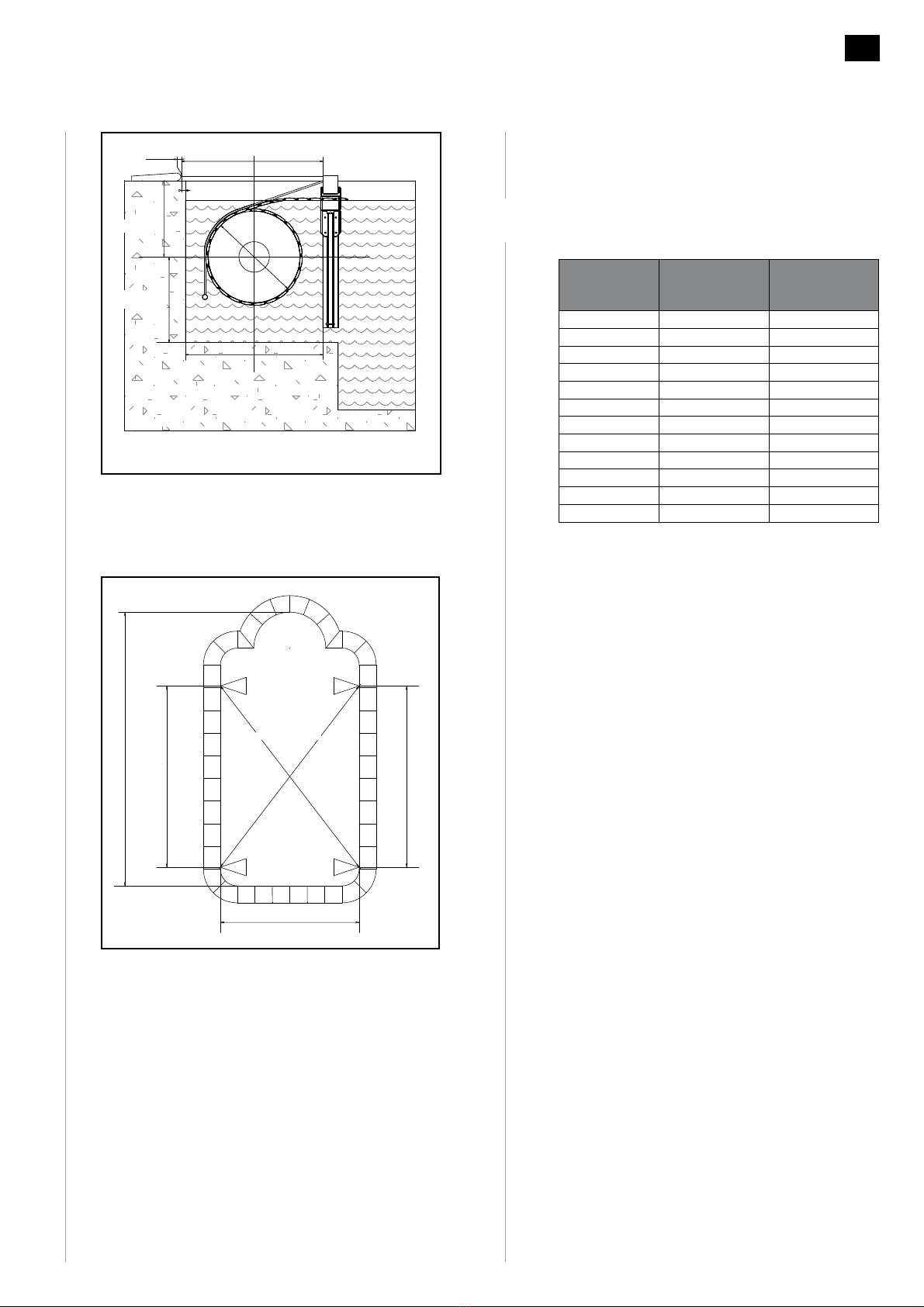

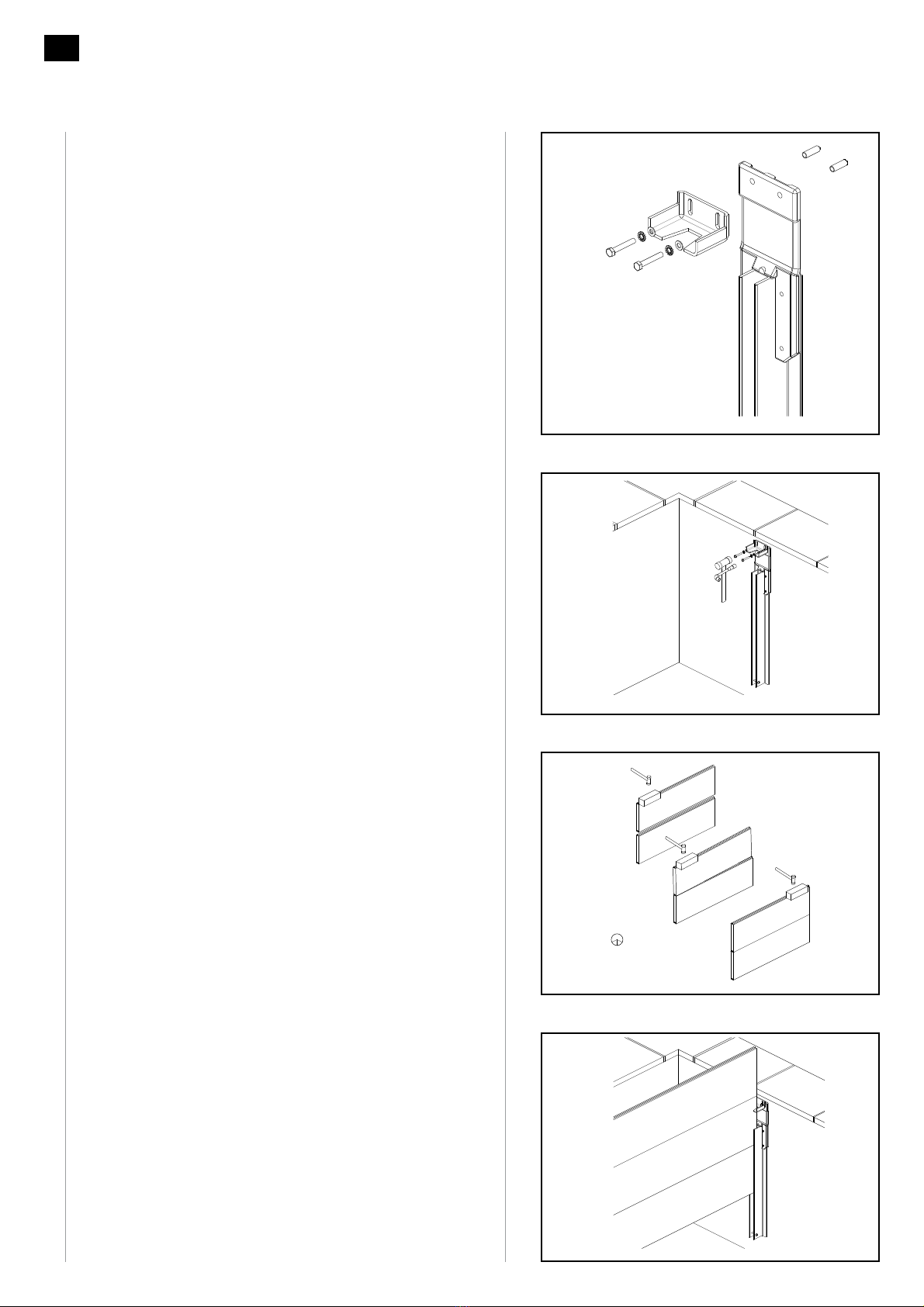

2.3 Items in the container

- A slat apron

- A motorised roller sha

-Twoflanges to support the sha

- A 23 x 32 cm box

- A slaed cover made up of a beam and duckboards (if

ordered).

- A paron wall (if ordered).

-Afixture kit

- Installaon instrucons

x 2 07:00

Fig. 6

0.8m

x

0.6m

Lx

4 290

5 300

6 310

7 320

I4.2 4.7 5.2 6.2 7.2 8.2 9.2 10.2 11.2 12.2

X4.6 5.1 5.6 6.6 7.8 8.6 9.6 10.6 11.6 12.6

0.6 m

0.8 m

x