3

INTRODUCTION

WELCOME

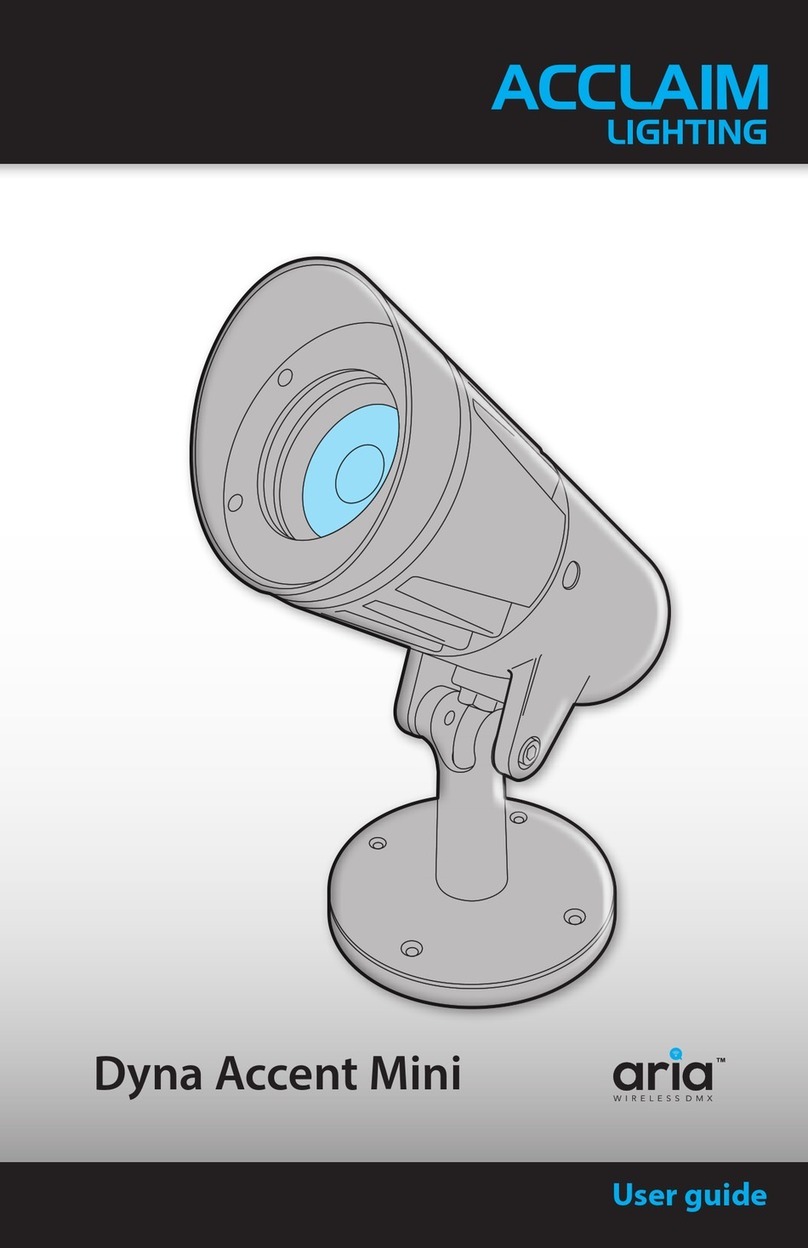

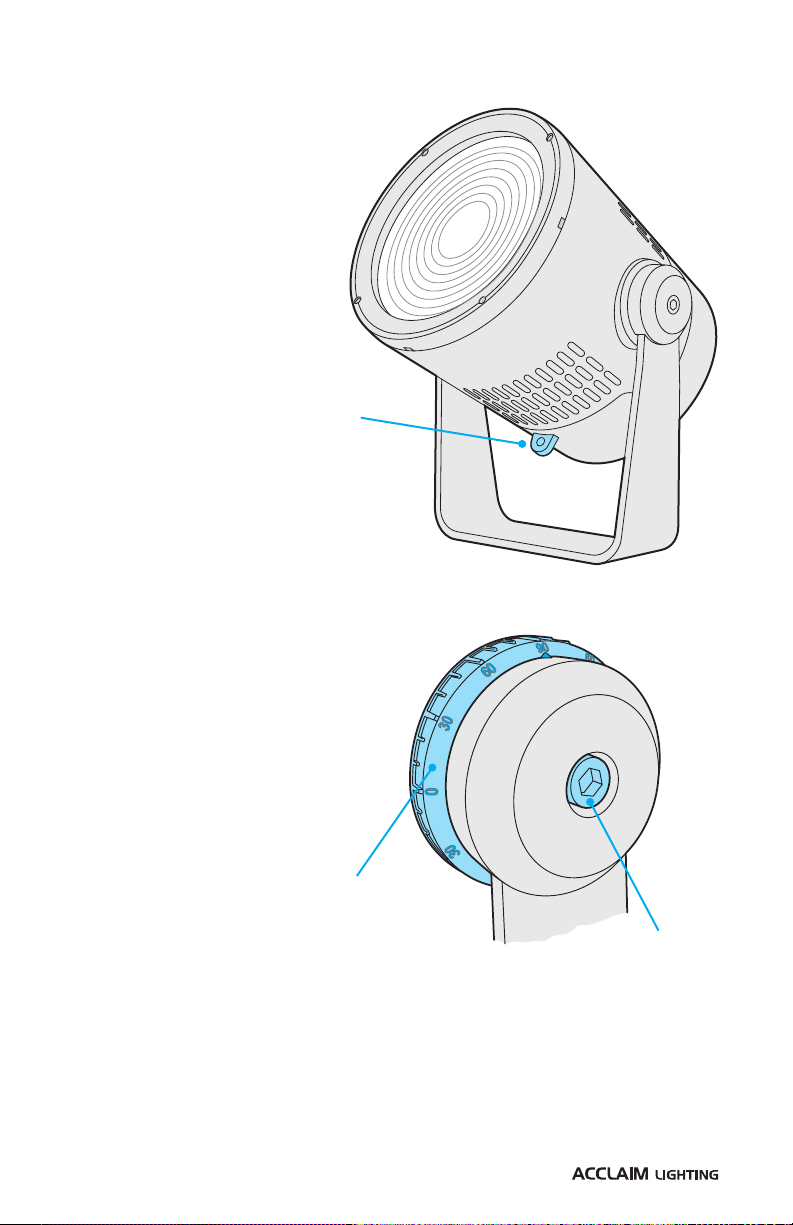

Welcome to Unity™ from Acclaim Lighting. This rugged fixture brings new levels of flexibility,

performance and refinement to exterior illumination. The Spectrum Five light engine

(red, green, blue, amber and lime) offers exceptional

brightness and clarity. In addition to RGBAL saturated

color mixing, a specially calibrated CCT control channel

allows you to dynamically configure any color temperature of white, from a warm 2500K

right up to an ultra cool 8000K. The advanced 7.5”polymer fresnel lens ensures the

10-degree native beam is fully homogenized and totally free of color striations.

External control using DMX-512A is supported either through direct cable connection or via

the built-in Aria™ wireless DMX receiver (transmitter available as an optional extra).

A clear daylight-readable OLED touch-screen user display provides access to a

comprehensive configuration menu system (see page 26). Alternatively, the industry

standard RDM (Remote Device Management) format can be used to configure numerous key

settings without the need to visit each fixture (see page 37).

For standalone applications, Unity provides an automation feature which will output a

predetermined color/white mix as the ambient light falls below a certain level, paired with

a configurable timer for auto shut off. The internal auto-sensing power supply can accept

mains inputs between 100 to 277VAC at 50 or 60Hz.

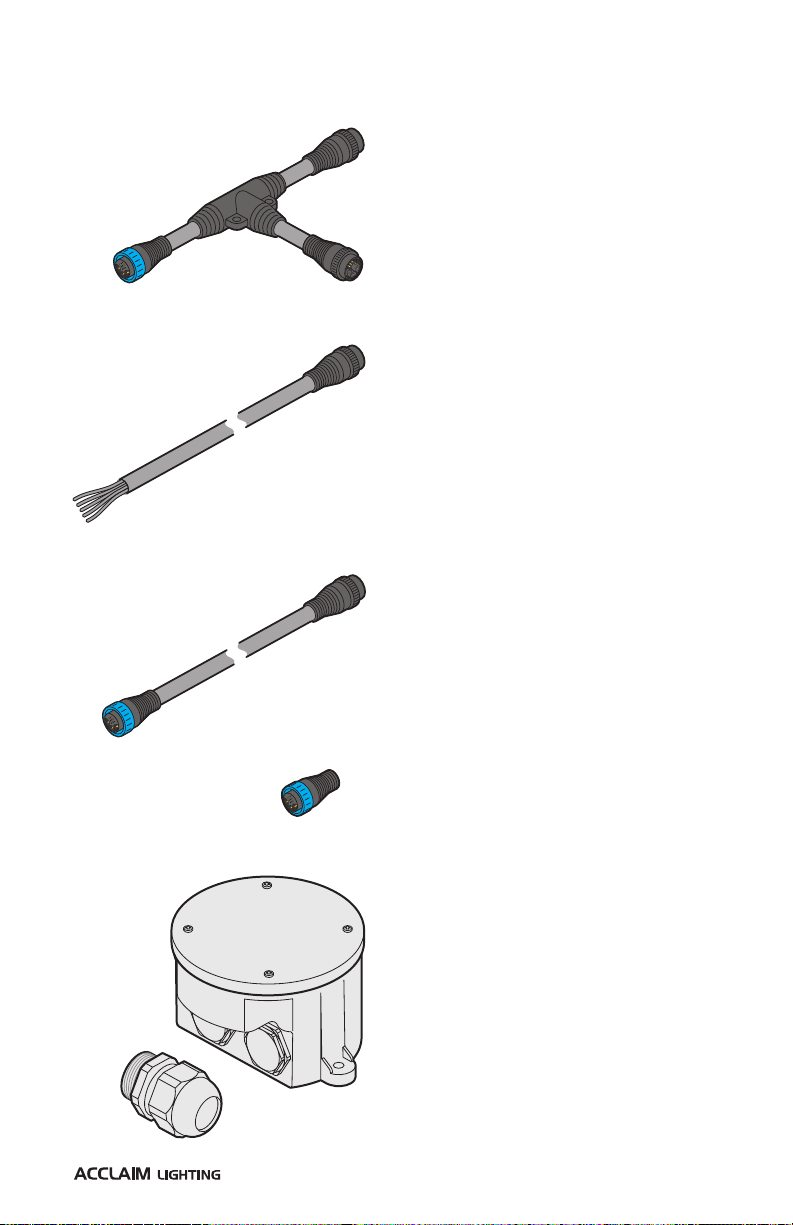

Each Unity fixture is supplied with a detachable 9’

(2.7m) control/power input cord (with bare-wire tails).

The corresponding input socket on the Unity rear

panel is also directly compatible with the Outdoor Link System, which greatly simplifies the

task of distributing power and control to multiple fixtures (see page 23).

A full range of mounting, suspension, connection and light shaping options are available to

allow Unity to easily adapt to the needs of any installation (see from page 4).

SAFETY

•When fixtures are mounted off-ground, ensure they are securely fitted to an appropriate

mounting surface.

•Ensure that the power input is supplied from a correctly fused, earthed and

environmentally protected location.

MAINTENANCE

CAUTION: Always isolate mains power before starting maintenance operations.

•Ensure that all mounting (and device) screws/bolts are fully tight and free of corrosion.

•Ensure there is no deformation to the housing, lenses or fixing points.

•Check that all power supply cables are free from physical damage or material fatigue.

•Use only genuine spare parts supplied by Acclaim Lighting.

CLEANING

•Use a moist, lint-free cloth when cleaning each fixture.

•Never use alcohol or solvents.

SAFETY, MAINTENANCE AND CLEANING