formlabs Form 3BL User manual

Manual Form 3BL

Installation and Usage Instructions

Form 3BL

Large-format Low Force Stereolithography

(LFS)™ 3D printer

Original English instructions

Read this manual carefully and keep it for future reference.

September 2020

REV 01

© Formlabs

Table of Contents

1Preface ..................................................................4

1.1 Read and retain instructions ................................................4

1.2 Obtaining documentation and information ...................................4

2Introduction ..............................................................6

2.1 Intended use..............................................................6

2.2 Technical specifications ....................................................7

2.3 Product elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.4 Understanding the display.................................................10

3Safety...................................................................11

3.1 Component and subsystem safety ..........................................11

3.2 Personal protective equipment (PPE) .......................................14

3.3 Specifications of tools to be used ..........................................14

3.4 Sensitive components ....................................................15

3.5 Emergency and exceptional situations ......................................16

4Preparation and setup....................................................17

4.1 Location and environs ....................................................17

4.2 Networking ..............................................................17

4.3 Unboxing the printer ......................................................17

4.4 Serial name ..............................................................18

4.5 Installing the printer.......................................................19

4.6 Connecting the printer to a network ........................................19

4.7 Leveling the printer ...................................................... 20

4.8 Inserting the resin tank and mixer ..........................................21

4.9 Inserting the build platform ............................................... 22

4.10 Inserting the resin cartridges ............................................. 23

4.11 Installing the Form 3BL Finish Kit .......................................... 24

4.12 Transporting the printer .................................................. 25

5Printing ................................................................ 27

5.1 Operational environment..................................................27

5.2 Designing for SLA ........................................................27

5.3 Setting up a print .........................................................27

5.4 Preparing the printer for printing .......................................... 29

Table of contents | 1

5.5 Finishing and post-processing a print...................................... 30

5.6 Managing the printer..................................................... 30

6Maintenance ........................................................... 32

6.1 Tools and supplies....................................................... 32

6.2 Inspecting and maintaining the printer ......................................33

6.3 Tasks between uses ......................................................33

6.4 Monthly maintenance .....................................................34

6.5 Periodic maintenance.................................................... 35

6.6 Planned maintenance.....................................................37

6.7 Maintaining the resin tank ................................................ 40

7Troubleshooting ........................................................ 43

7.1 Collecting diagnostic logs .................................................43

7.2 Performing a factory reset .................................................43

7.3 Cleaning after a failed print ................................................43

7.4 Troubleshooting errors or abnormal activity ................................ 45

8Disassembly and repair.................................................. 48

9Recycling and disposal .................................................. 49

9.1 Disposal of resin and accessories ......................................... 49

9.2 Disposal of solvent ...................................................... 50

9.3 Recycling of solvent ..................................................... 50

9.4 Disposal of electronic components........................................ 50

9.5 Disposal of packaging waste ..............................................51

10 Index................................................................... 52

11 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12 Product compliance ..................................................... 57

2

3

Read and understand this manual and its safety instructions before using the Form

3BL. Failure to do so can result in serious injury or death.

DISCLAIMER

Formlabs has made every eort to make these instructions as clear, complete, and correct

as possible. The information provided in this documentation contains general descriptions

and/or technical characteristics of the performance of the products contained herein. This

documentation is not intended as a substitute for and is not to be used for determining

suitability or reliability of these products for specific user applications. It is the duty of any

such user or integrator to perform the appropriate and complete risk analysis, evaluation, and

testing of the products with respect to the relevant specific application or use thereof. Neither

Formlabs nor any of its aliates or subsidiaries shall be responsible or liable for misuse of the

information that is contained herein. Notify us if you have any suggestions for improvements

or amendments or have found errors in this publication.

Copyright © 2020 by Formlabs. All rights reserved.

support.formlabs.com

TRADEMARKS

All product names, logos, and brands are property of their respective owners. All company,

product, and service names used in this manual are for identification purposes only. Use of

these names, logos, or brands does not imply endorsement.

DOCUMENT REVISIONS

Date Version Document changes

Sept 2020 REV 01 Initial publication

WARNING

4

1 Preface

Congratulations on purchasing the Form 3BL. On behalf of the Formlabs team, we thank

you for your purchase. The Form 3BL is a large-format Low Force Stereolithography (LFS)™

3D printer. The Form 3BL fabricates fully-supported parts by converting a 3D object into 2D

slices that can be traced layer by layer with two lasers. This manual explains how to set up,

use, and properly maintain the Form 3BL, as well as provides design guidance for optimizing

print results. The manual is intended for anyone who is installing, operating, maintaining, or

otherwise interacting with the Form 3BL. Supervise young or inexperienced users to ensure

enjoyable and safe operation.

1.1 Read and retain instructions

Read and understand this manual and its safety instructions before using the Form 3BL. Failure

to do so can result in serious injury or death. Keep all safety information and instructions for

future reference and provide them to subsequent users of the product.

Follow all the instructions. This will avoid fire, explosions, electric shocks, or other hazards that

may result in damage to property and/or severe or fatal injuries.

The Form 3BL shall only be used by persons who have fully read and understand the contents

of this manual. Ensure that each person who uses the Form 3BL has read these warnings and

instructions and follows them. Formlabs is not liable for cases of material damage or personal

injury caused by incorrect handling or non-compliance with the safety instructions. In such

cases, the warranty will be voided.

1.2 Obtaining documentation and information

Visit formlabs.com to:

• Access your Formlabs store (formlabs.com/store) and Dashboard accounts (formlabs.com/

dashboard).

• Find certified service providers in your region (formlabs.com/company/partners).

•

Access the Terms of Service (formlabs.com/terms-of-service) and the Privacy Policy

(formlabs.com/privacy-policy).

Visit support.formlabs.com to:

• Access the latest version of all Formlabs product documentation.

•

Contact Formlabs Support to request documentation, usage instructions, repair guides,

and technical information.

• Submit any comments or feedback regarding what is good and what can be improved.

Formlabs values comments from its users.

• Request additional training.

1.2.1 Support and service

Retain a record of the original purchase to request warranty services. Service options depend on

the status of the specific product’s warranty. Include the serial name of the product when contacting

Formlabs Support or a certified service provider for product support.

Instead of a serial number, Formlabs products have a serial name, which is a unique identifier to

track the history of manufacturing, sales, and repair, and to distinguish usage when connected

to a network. The serial name is on the back panel of the machine in the format AdjectiveAnimal.

Preface | 5

Service providers of Formlabs products also provide support and service. To the extent that

Formlabs or a certified service provider oers other or extended warranties, the terms of the

separate oer may apply. For products purchased from certified service providers, contact the

original service provider for assistance before contacting Formlabs Support.

For any support or service requests, including product information, technical assistance, or

assistance with instructions, contact Formlabs Support:

support.formlabs.com USA

Formlabs, Inc.

35 Medford St.

Somerville, MA, USA, 02143

Germany

Formlabs GmbH

Nalepastrasse 18-50

12459 Berlin, Germany

1.2.2 Warranty

This product is protected under warranty. Formlabs oers a warranty for all Formlabs branded

hardware. Unless otherwise expressly stated, the Terms of Service, including the Warranty,

constitute the entire agreement between you and Formlabs with respect to the Service and

any product you purchase from Formlabs and supersedes all prior or contemporaneous

communications, proposals, and agreements, whether electronic, oral, or written, between

you and Formlabs. Read the warranty for more details on the Formlabs warranty for your region:

US formlabs.com/support/terms-of-service

EU (EN) formlabs.com/eu/terms-of-service

EU (DE) formlabs.com/de/support/terms-of-service/eu

EU (FR) formlabs.com/fr/support/terms-of-service/eu

EU (ES) formlabs.com/es/terms-of-service/eu

EU (IT) formlabs.com/it/terms-of-service/eu

6

2 Introduction

2.1 Intended use

The Form 3BL is a commercial, precision tool intended for use in the additive manufacture

of end-user supplied designs from photopolymer resin. The final performance characteristics

of cured photopolymer resin may vary according to your compliance with the instructions

for use, application, operating conditions, material combined with, end use, or other factors.

In some cases, the additive manufacturing process may inherently result in variable

performance characteristics between manufacturing runs or within a specific part.

Such variances may not be apparent and may result in unexpected defects in

additively fabricated parts.

You shall independently verify the suitability of additive manufacturing, stereolithography

(SLA), the Form 3BL, and any specific designs or materials employed for the application

and intended purpose before use. In no event shall Formlabs be liable for any loss,

death, or bodily injury that you suer, or that you cause to any third party, in connection

with your use of Formlabs products. To the fullest extent legally permitted Formlabs

EXPRESSLY DISCLAIMS ANY IMPLIED OR EXPLICIT WARRANTY OF FITNESS for a

particular usage, the particular nature and circumstances of said usage being unforeseen

and unforeseeable to Formlabs.

Formlabs is not a manufacturer of medical devices. Formlabs provides tools and

materials that may be used in many applications, but makes no claims as to the safety or

eectiveness of any specific devices made using Formlabs products. Certain Formlabs

products, such as those commonly known in the industry as “biocompatible” materials,

have been engineered to comply with relevant industry standards. The specific standards

and most relevant technical specifications may be identified within the technical data

sheets and have been tested according to relevant testing protocols for those standards

and specifications. Biocompatible materials are a speciality product, developed for use by

medical professionals, and should be used in accordance with the instructions for use.

Do not modify. The Form 3BL is intended for use as-is. Modifying the machine without

explicit approval and directions from Formlabs will invalidate the warranty, and could

potentially ruin the machine and cause you bodily harm.

NOTICE

WARNING

WARNING

WARNING

Introduction | 7

2.2 Technical specifications

Parameter Unit

Printer Form 3BL

3D printing technology Low Force Stereolithography (LFS)™

Minimum dimensions for convenient

access (W × D × H)

90 × 96 × 104 cm | 35.4 × 37.8 × 41 in

Printer dimensions (W × D × H) 77 × 52 × 74 cm | 30.3 × 20.5 × 29.1 in

Printer weight 54.4 kg | 120 lb

Build volume (W × D × H) 33.5 × 20 × 30 cm | 13.2 × 7.9 × 11.8 in

Layer thickness (Axis resolution) 25–300 microns | 0.001–0.012 in

XY resolution 25 microns | 0.001 in

Laser spot size (FWHM) 85 microns | 0.0033 in

Resin cartridges 2

Resin dispensing system Automated

Biocompatible materials No

Supports Auto-generated, Light-touch removal

Operating environment 18–28 °C | 64–82 °F

Low ambient humidity

Operating temperature Auto-heats to 35 °C | 95 °F

Temperature control Air heated print chamber

Power requirements 100–240 VACMaximum 8.5 A

50/60 Hz

650 W

Laser specifications IEC 60825-1:2014 | EN 60825-1:2014

Class 1 laser product

2 Light Processing Units (LPUs)

In each Light Processing Unit (LPU):

405 nm violet laser | Maximum 250 mW

Radiation information The Form 3BL is a Class 1 laser product. Accessible radiation

is within Class 1 limits.

Connectivity Wi-Fi: 2.4, 5 GHz

Ethernet: 1000 Mbit

USB: 2.0

Wi-Fi connectivity Protocol: IEEE 802.11 b/g/n

Frequency: 2.4 GHz, 5 GHz

Supported security: WPA/WPA2

Ethernet connectivity RJ-45 Ethernet (10BASE-T/100BASE-TX/1000BASE-T) LAN Port

Connect with a shielded Ethernet cable (not included):

minimum Cat5, or Cat5e or Cat6 for 1000BASE-T.

USB connectivity USB (rev 2.0) B port with a USB A-B cable

Sound emission Does not exceed 70 dB(A).

Printer control Interactive touchscreen

Alerts Touchscreen alerts, SMS/email via Dashboard,Two LED status

indicators, Speaker for audio alerts

Print preparation PreForm desktop software

File type STL or OBJ

8

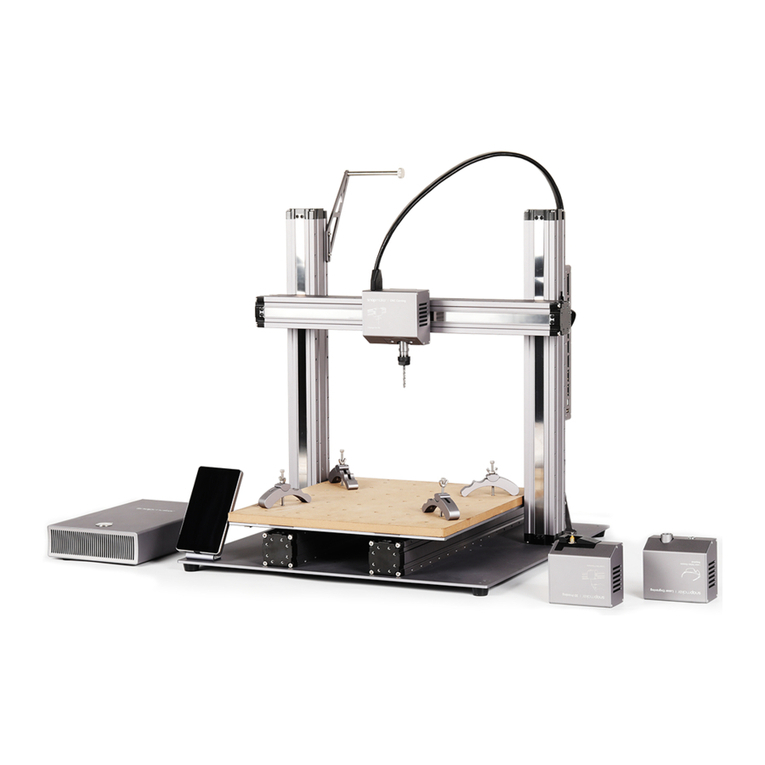

2.3 Product elements

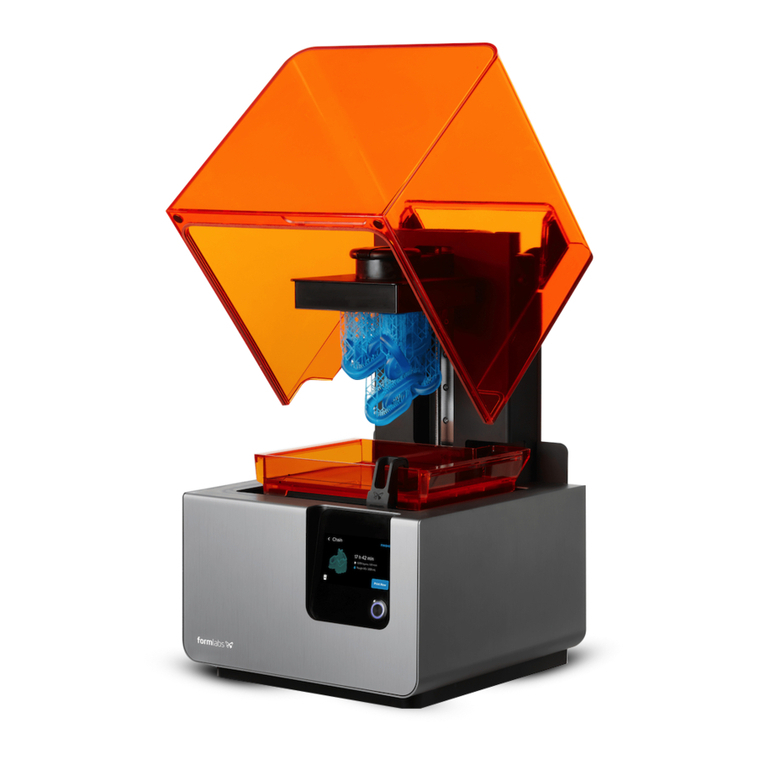

2.3.1 Form 3BL

Resin cartridge: Two containers hold the resin before dispensing into the resin tank. Shake

the resin cartridges periodically to keep resin well mixed.

Cover: The printer lid, made of metal and a strong, orange-tinted material, blocks exposure

to the lasers and protects the resin from curing due to ambient light.

Build platform: The aluminum base provides a surface for prints to attach to.

Resin tank: Resin is dispensed out of the resin cartridges into the resin tank. During a print,

two lasers pass upwards through the flexible film and cure resin onto the build platform

to form a printed part.

Mixer: Each resin tank includes a mixer that improves print consistency by clearing the

build area and circulating the resin.

Touchscreen: The LCD capacitive touch user interface displays print information, settings,

and error messages.

Leveling disc: Slide the leveling disc included around one of the leveling feet and rotate

to raise or lower the printer.

Status light: Two interior lights (vertical strips along the left and right walls) and an

illuminated logo (on the front panel) that pulse to indicate the printer is active, a print has

completed, or the printer has encountered an error.

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Introduction | 9

2.3.2 Form 3BL Finish Kit

Rinse bucket: Fill the rinse bucket with solvent to the FILL TO HERE marking before

washing prints. The rinse bucket includes a ground wire to prevent static discharge.

Formlabs recommends isopropyl alcohol or tripropylene glycol monomethyl ether.

Rinse basket: Place prints in the rinse basket, place the rinse basket into the rinse bucket,

and agitate to clean.

Rinse bottle: Remove resin trapped in cavities and internal channels of prints. Use clean

solvent. Formlabs recommends isopropyl alcohol.

Non-reactive nitrile gloves: Wear gloves when handling liquid resin, resin-coated surfaces,

or solvent. Wash skin with plenty of soap and water.

Battery operated solvent pump: Fill and empty the rinse bucket.

Build platform jig: Stabilize the build platform for the secure removal of prints.

Drying tray: Place washed prints on the drying tray to drip dry.

Flush cutters: Snip to separate prints from their supports. Cut with the flat side on the prints’

surface for minimal support marks.

Scraper: Remove prints from the build platform. Do not use the scraper to clean the resin

tank interior.

Removal tool: Pry under the raft to remove prints from the build platform. Do not use the

removal tool to clean the resin tank interior.

Tank tool: A two-part scraper for inspecting and cleaning the resin tank interior. Separate

tool for scraper function or combine for tongs.

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

910

11

10

2.4 Understanding the display

The Form 3BL’s display includes a touchscreen and speaker for audio notifications. The

touchscreen displays print information (job name, time remaining, layers printed), settings,

and error messages. The touchscreen serves as the user interface for the printer. The audio

notifications indicate the printer’s state. Refer to messages on the printer’s touchscreen to

understand the meaning of the audio notifications. For detailed guidance and visual assistance,

visit support.formlabs.com.

Tap the home icon in the left sidebar to access the Home screen. Current or upcoming print

jobs appear here.

Tap the collapsed menu icon in the left sidebar from Home to access the Queue screen. A list

of print jobs that have been uploaded to the printer appears here.

Tap the printer icon in the left sidebar from Home to access the printer status screen.

Information about the inserted consumables, such as resin types, resin cartridge levels, and

resin tank temperature appear here.

Tap the wrench icon in the left sidebar from Home to access the Settings screen. Network

connectivity, maintenance, and other options can be accessed here.

Safety | 11

3 Safety

Read and understand this manual and its safety instructions before using the Form

3BL. Failure to do so can result in serious injury or death.

Supervise young or inexperienced users to ensure enjoyable and safe operation.

The instructions contain warnings and safety information, as explained below:

DANGER indicates a hazard with a high level of risk which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard with a medium level of risk which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazard with a low level of risk which, if not avoided, could result in minor or

moderate injury.

NOTICE indicates information considered important, but not hazard-related.

DANGER: Isopropyl alcohol is a flammable chemical.

WARNING: The laser beam is harmful to the eyes. Avoid direct contact.

ENVIRONMENTAL HAZARD: Uncured photopolymer resin is classified as hazardous to aquatic life.

3.1 Component and subsystem safety

3.1.1 General

Lifting hazard: Due to its size and weight, do not move or reposition the Form 3BL alone. If the

machine needs to be moved, at least two individuals should use the lifting straps provided with the

Form 3BL.

Do not lift or reposition the Form 3BL:

• By the cover or any other movable part of the printer.

• When the printer is connected to a power source.

• When the printer is connected to an Ethernet or USB cable.

The Form 3BL requires an operating environment that is low in ambient humidity

and static electricity. Due to the sensitive nature of its components and the printing

mediums, system reliability and print quality may fluctuate if the ambient temperature

and moisture are outside the recommended ranges. Refer to section 4.1 Location and

WARNING

DANGER

WARNING

CAUTION

NOTICE

CAUTION

NOTICE

NOTICE

12

environs for the recommended operating environs.

3.1.2 Laser

Radiation exposure: The laser beam is extremely harmful to the eyes and skin,

capable of causing permanent blindness. Avoid direct contact at all times. The Form

3BL contains an interlock system to automatically shut o the lasers when the cover

is open. If this system is tampered with or fails, there is a risk of exposure to Class 3B

laser light. Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Unauthorized maintenance: Class 1 laser product. Only remove the shells of the

printer with authorization from Formlabs Support or a certified service provider.

Disconnect the machine from its power source before removing the shells.

Accessible radiation is within Class 1 limits. The laser diodes used inside the device have the

following specifications:

Diode Violet (405 nm)

Maximum output 250 mW

Certification IEC 60825-1:2014

EN 60825-1:2014

FDA performance standards for laser products except for deviations

pursuant to Laser Notice No. 56, dated May 8, 2019.

3.1.3 Sharp tools

Cutting hazard: Using sharp tools on slippery surfaces (such as a resin-coated build

platform) can result in sudden movement. Orient sharp tools away from yourself,

especially when cutting or scraping.

The accessories include sharp tools such as: a removal tool , flush cutters , and a scraper .

3.1.4 Resin

Poison hazard: Never ingest resin in liquid or solid form. If swallowed, immediately

call a poison center or medical professional. Contact Chemtrec at +1 800 424 9300

for global 24-hour emergency assistance.

WARNING

CAUTION

1

2

3

1 2 3

WARNING

Safety | 13

Refer to the safety data sheet (SDS) and local authorities for guidance on disposing of

resin and solvent. Liquid resin (whether pure liquid, dissolved in solvent, or partially cured)

may be classified as hazardous waste in your region and shall be disposed of with care.

ENVIRONMENTAL HAZARD:

Uncured photopolymer resin is classified as hazardous to aquatic life.

Consult the safety data sheet (SDS) as the primary source of information to

understand safety and handling of Formlabs materials. Respect Formlabs resin like

any household chemical. Follow standard chemical safety procedures andFormlabs

resin handling instructions. In general, Formlabs resin is not approved for use with

food, drink, or medical applications on the human body. However, biocompatible

resins, such as Dental SG Resin, are biologically safe for specific types and lengths

of exposure to the human body. Refer to the safety data sheet (SDS) for each specific

resin as well as support.formlabs.com for more detail.

3.1.5 Radio interference

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to CFR Title 47, Part 15 of FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at their own expense.

Changes or modifications to this product not authorized by Formlabs could void the electromagnetic

compatibility (EMC) and wireless compliance and negate your authority to operate the product.

This product has demonstrated EMC compliance under conditions that included the use of

compliant peripheral devices and shielded cables between system components. It is important

that you use compliant peripheral devices and shielded cables between system components to

reduce the possibility of causing interference to radios, televisions, and other electronic devices.

3.1.6 Isopropyl alcohol (IPA)

Fire hazard: Isopropyl alcohol is a flammable chemical. Keep away from ignition

sources, including open flames, sparks or concentrated sources of heat.

Formlabs does not manufacture isopropyl alcohol. Consult the chemical manufacturer

or supplier for detailed safety information. Carefully follow the safety instructions

provided with the isopropyl alcohol that you purchase. Isopropyl alcohol can be

flammable, even explosive, and should be kept away from heat, fire, or sparks. Any

containers holding isopropyl alcohol should be kept closed or covered when not in

use. We also recommend that you wear protective gloves and have good ventilation

when working with isopropyl alcohol.

CAUTION

NOTICE

NOTICE

14

3.1.7 Tripropylene glycol monomethyl ether (TPM)

Formlabs does not manufacture tripropylene glycol monomethyl ether. Consult the

chemical manufacturer or supplier for detailed safety information. Carefully follow

the safety instructions provided with the tripropylene glycol monomethyl ether you

purchase. We also recommend that you wear protective gloves when working with

tripropylene glycol monomethyl ether.

3.2 Personal protective equipment (PPE)

Safe operation of the Form 3BL can be achieved by implementing the following equipment:

• Non-reactive nitrile gloves

• Safety glasses

Skin irritant: Resin and solvent may cause skin irritation or an allergic skin reaction.

Wear gloves when handling liquid resin, resin-coated surfaces, or solvent. Wash skin

with plenty of soap and water.

Risk of eye injury: Some methods of support removal may cause small pieces of

supports to break away. Beware of flying debris. Wear eye protection and gloves to

protect the skin and eyes.

3.3 Specifications of tools to be used

The Form 3BL shall only be used with supplied accessories and additional tools recommended

by Formlabs. Third-party accessories and materials may cause damage. Refer to sections 3.1

Personal protective equipment (PPE) and 6.1. Tools and supplies for more information.

Purchase additional supplies:

• Cotton swabs

For cleaning the cartridge ID chips.

• General purpose cleaner (e.g., glass cleaner)

For cleaning the printer’s cover, outer shells, and display.

• Isopropyl alcohol (IPA), 90% or higher

° Recommend washing solvent for rinsing prints.

° For cleaning the printer’s optical components, build platform, and cartridge ID chips.

° For cleaning the work surface and tools.

• Lithium grease for ball bearings

For lubricating the X-and Z-axis screws.

• Low-fiber paper towels

° For cleaning the work surface and tools.

° For protecting sensitive components.

° For wiping residue grease, resin, or solvent.

• Non-abrasive microfiber cloth

For cleaning the printer’s cover, outer shells, and display.

NOTICE

WARNING

CAUTION

Safety | 15

• PEC*PADs

Disposable lint-free, non-woven microfiber cloths for cleaning the printer’s optical

components. Do not reuse a PEC*PAD; dispose of after each use.

• Rubber bulb air blower

For removing dust from the glass optical window.

• Tripropylene glycol monomethyl ether (TPM)

Alternative washing solvent to isopropyl alcohol for rinsing prints.

3.4 Sensitive components

The Form 3BL has multiple sensitive components that are vulnerable to permanent damage

if not periodically inspected and properly maintained. Using any tools, cleaning agents, or

methods not mentioned in this manual may result in permanent damage to these components.

Follow the maintenance instructions outlined in this manual and on support.formlabs.com

when servicing the following components or any other internal component of the machine.

For detailed guidance and visual assistance, visit support.formlabs.com.

• Glass optical window

A narrow piece of anti-reflective coated glass that is surrounded by the slider. It protects

the sensitive mirrors inside the LPUs from dust and other contamination. Maintain a clean

glass optical window to prevent print failures. Refer to section 6.6.5 Cleaning the glass

optical window for more information.

• Light Processing Units (LPUs)

These interchangeable assemblies each contain a laser and mirrors the control the path

of the laser, ensuring a clean, crisp laser spot. The Form 3BL has two Light Processing

Units , which are secured in the LPU housing. Refer to section 8 Disassembly and repair

for more information.

• Platform lock

A lever that is part of the locking mechanism that secures the build platform. Contact

Formlabs Support or a certified service provider before adjusting the platform lock, as

improper adjustment can lead to damage to the machine.

• Slider

A metal surface that allows for smooth movement of the LPU housing across the flexible

film interior. The slider surrounds the glass optical window. A clean slider protects the

flexible film and preserves print quality. To inspect and clean the slider, refer to section

6.6.4 Cleaning the slider.

• X-axis ball screw

Controls the horizontal (X-axis) motion of the Light Processing Unit (LPU) housing. Keep the

X-axis ball screw clean and well-lubricated so that the LPU housing can move smoothly

and accurately. To inspect and lubricate the ball screw, refer to section 6.5.5 Maintaining

the X- and Z-axis screws.

• Z-axis lead screw

Controls the vertical motion of the build platform carriage. Keep the lead screw clean

and well-lubricated so that the build platform carriage can move smoothly and accurately.

To inspect and lubricate the lead screw, refer to section 6.5.5 Maintaining the X- and

Z-axis screws.

16

3.5 Emergency and exceptional situations

Formlabs has made every eort to provide updated safety data sheets (SDS) for every resin

product, in accordance with the latest government guidelines. Always consult the safety data

sheet (SDS) as the primary source of information to understand safety and handling of Formlabs

materials and required accessories.

3.5.1 Isopropyl alcohol (IPA)

Fire hazard: When handling isopropyl alcohol, always consult the safety data sheet

(SDS) from the isopropyl alcohol supplier as the primary source of information. Handle

isopropyl alcohol with gloves in a well-ventilated area. Keep away from heat, sparks,

and open flame. Isopropyl alcohol evaporates rapidly, so keep the rinse tub and

bottles closed whenever possible.

3.5.2 Resin

Poison hazard: Never ingest resin in liquid or solid form. If swallowed, immediately

call a poison center or medical professional. Contact Chemtrec at +1 800 424 9300

for global 24-hour emergency assistance.

Promptly clean and inspect the printer after a resin spill to minimize any cosmetic or

functional damage to the printer. If you have experienced an accidental resin spill,

document the problem with photos and clean the printer as best as possible. Contact

Formlabs Support or a certified service provider as soon as possible.

WARNING

NOTICE

Table of contents

Other formlabs 3D Printer manuals

formlabs

formlabs Fuse 1 User manual

formlabs

formlabs Form Wash User manual

formlabs

formlabs Form 3 User manual

formlabs

formlabs Form 3 User manual

formlabs

formlabs Form Wash L User manual

formlabs

formlabs Form 2 Setup guide

formlabs

formlabs FORM 1 User manual

formlabs

formlabs Form 2 User manual

formlabs

formlabs IBT Flex Resin User manual

formlabs

formlabs Form Cure User manual

Popular 3D Printer manuals by other brands

Josef prusa

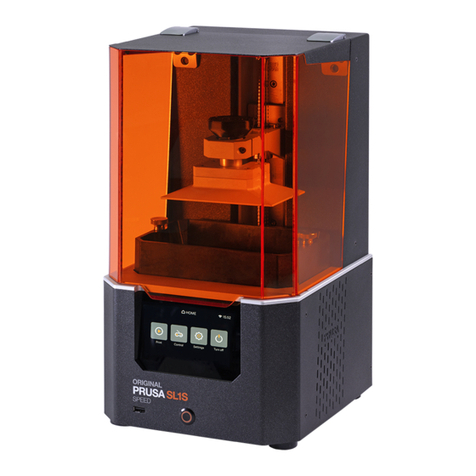

Josef prusa PRUSA RESEARCH SL1 KIT Printing handbook

W2P Engineering

W2P Engineering PowerVat 250 operating manual

3D Magic

3D Magic 3D Spinner FAIRY Series quick start guide

Printed Solid

Printed Solid Taz 6 Enclosure instructions

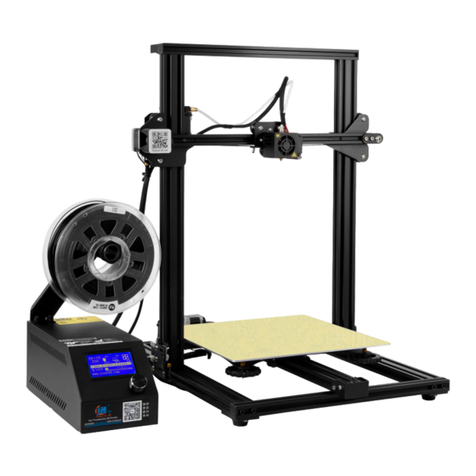

Creality

Creality CR-10 Series Guide book

LONGER

LONGER Cube2 Operating instruction