NFO Drives Sinus Optimal Specification sheet

www.nfodrives.se[email protected]

+4645437029TubbaTorg5SE‐37432Karlshamn,Sweden

Operating and

Installation Manual

NFO Sinus Optimal

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual2

Contents

1Safetyaspects........................................................................................................................................4

2Technicaldata.......................................................................................................................................5

3Mechanicalinstallation.........................................................................................................................7

3.1Mounting...................................................................................................................................7

4Electricalinstallation.............................................................................................................................8

4.1Signalterminalconnection........................................................................................................9

4.1.1Signalterminalsandtheiruse....................................................................................9

4.1.2Signalterminalsconfiguration..................................................................................11

4.1.3Analoguecurrentinput.............................................................................................11

4.1.4Negativelogic...........................................................................................................12

4.1.5SerialchannelRS485.................................................................................................12

4.1.6Connectingpotentiometer.......................................................................................12

4.2Powerterminalconnection.....................................................................................................13

4.2.1Connectorsandcables..............................................................................................13

4.2.2Powerterminaluse...................................................................................................13

4.2.3Connectingmainssupply..........................................................................................14

4.2.4Connectingmotor.....................................................................................................14

5Parametersettingsandoperation......................................................................................................15

5.1Generalnotes..........................................................................................................................15

5.2Keyboardanddisplay..............................................................................................................15

5.3IndicatorsandMotorstatus....................................................................................................17

5.4Operatingmodes.....................................................................................................................17

5.4.1ManualMode...........................................................................................................18

5.4.2AutoMode................................................................................................................18

5.4.3BusMode(Serialchannel/Fieldbus)......................................................................19

5.5Parameterspecifications.........................................................................................................20

5.5.1Parametersummary.................................................................................................20

5.5.2Parametertable........................................................................................................20

5.6Selectapplication....................................................................................................................24

5.7Autotuningandmotorparameters.........................................................................................24

5.7.1Fulltuning.................................................................................................................25

5.7.2Basictuning...............................................................................................................25

5.7.3Calculatedtuning......................................................................................................25

5.7.4Motorsinparallel.....................................................................................................26

5.8Settingcontrolparameters.....................................................................................................26

5.8.1Accelerationanddecelerationramps.......................................................................26

5.8.2Phaseorder...............................................................................................................26

5.8.3Stopmode................................................................................................................27

5.8.4Energysavefunction................................................................................................27

5.8.5PowerOn,StartandStopdelay................................................................................27

5.8.6Motorbrake,DC‐Brake.............................................................................................27

5.8.7Speedregulator,Kp‐speedandTi‐speed..................................................................27

5.8.8Frequencysleepsetting............................................................................................28

5.8.9Frequencybypass.....................................................................................................28

5.8.10Increasedstartcurrent(currentboost)....................................................................29

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual3

5.8.11ControlMode............................................................................................................29

5.8.12Autostart...................................................................................................................29

5.8.13Analoginputtype.....................................................................................................30

5.8.14Digitalinputconfiguration........................................................................................30

5.9Frequencycontrolwithoutloadcompensation,Frequencymode.........................................30

5.9.1SetpointsourceforFrequencyMode.......................................................................30

5.9.2Analoguefrequencysetpointrange,MinAinFrqandMaxAinFrq..........................30

5.10RPMregulationwithspeedestimation,Speedmode.............................................................31

5.10.1SetpointsourceforSpeedMode..............................................................................31

5.10.2Analoguespeedsetpointrange,MinAinSpdandMaxAinSpd...............................31

5.11Processregulation,PIregulator..............................................................................................32

5.11.1SetpointsourceforPI‐regmode...............................................................................33

5.11.2Regulatorsetting,RegAmp,RegKpandRegTi........................................................34

5.12Motorsafetyfunctions............................................................................................................34

5.12.1PTCinput...................................................................................................................34

5.12.2Electronicmotoroverloadprotection......................................................................35

5.13Outputsignals.........................................................................................................................36

5.13.1Relay1(Alarmrelay).................................................................................................36

5.13.2Relay2(Runindication)............................................................................................36

5.13.3Analogoutputs.........................................................................................................36

5.14Communicationinterfaces......................................................................................................36

5.15Displaysetup...........................................................................................................................37

5.16Status,Temperature,CountersandVersion...........................................................................37

5.17Resettofactorysettings..........................................................................................................37

5.18Alarmandfaultprocedures....................................................................................................38

5.18.1Faultlog....................................................................................................................38

5.18.2Faultmessages..........................................................................................................38

5.18.3Acknowledgefault....................................................................................................40

6CommunicationusingModbus...........................................................................................................40

6.1.1Readstatusandactualvalues..................................................................................41

6.1.2ControlinverterusingMODE/SMODE/InverterStatus.............................................41

6.1.3ControlinverterusingDriveControl/DriveStatus.....................................................42

7ControlusingProfinet/Profibus..........................................................................................................43

8Brakechopperandpowersurgeregulator.........................................................................................44

9Gettingstarted....................................................................................................................................45

9.1Installation...............................................................................................................................45

9.2RunninginManualmode........................................................................................................45

9.3RunninginAutomode.............................................................................................................45

9.3.1Setvalueselectioninautomode...............................................................................45

9.3.2Runningwithfixedfrequency...................................................................................45

9.3.3Runningwithanalogsetpoint...................................................................................46

9.3.4Processregulationwithfixedsetpoint.....................................................................46

9.3.5Processregulationwithanalogsetpoint..................................................................46

9.3.6Alternatingfixedfrequencyandprocessregulation................................................47

9.3.7Ventilationcontrolwithanalogsetpointandfirealarm..........................................47

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual4

Introduction

The frequency inverter described in this operating manual is used for frequency (Hz) or speed (rpm) control of

three-phase AC induction motors. This manual describes how to install and use the inverter.

Read the manual carefully before installing the inverter, to ensure you install it correctly and get the maximum

performance out of it.

The inverter has a patented switch circuitry that ensures the motor receives a sinusoidal voltage at all times, under

all operating conditions. This solves all problems related to conventional PWM based frequency inverters, e.g.

electromagnetic interference, ball bearing damage, high earth currents and high switching noise.

A 30mA rated RCD (earth leakage circuit breaker) can be used with this frequency inverter.

The inverter also uses the patent "Natural field orientation" which is a vector control method to give perfect speed

control of induction motors all the way from zero to full speed.

1 Safety aspects

Always disconnect the inverter from the mains supply before working on any electrical- or mechanical installation

components.

Installation, maintenance and repairs must always be conducted by staff adequately trained and experienced for

the purpose.

Modifying or replacing any components of the inverter or its accessories will render the inverter warranty null and

void. Should the need for any modifications or replacements arise, always contact NFO Drives AB.

Components in the power section and some components in the signal section are connected to the mains supply

when the inverter is powered.

WARNING! Touching any components with the mains supply connected can be fatal. Always disconnect the

mains supply before opening the cover.

WARNING! Even when disconnected from the mains supply, the inverter may still contain lethal voltages

due to its buffer capacitors. Always wait at least five minutes to make sure no voltage remains before

working with the inverter.

WARNING! The heat sink of the inverter may get hot, depending on operating conditions. Do not touch.

WARNING! Spontaneous start. When controlled from a communication bus or remote unit, the motor may

start at any moment. Pressing STOP on the inverter is not sufficient, as bus master or remote unit may re-

gain control over inverter and start motor again. Disconnect run signal at terminal DIN1 to safely inhibit start.

For connection of mains supply, the inverter shall be permanently connected to fixed wiring including a circuit

breaker which must be used to ensure all-pole disconnection under overvoltage III conditions.

The inverter shall always be connected to protective earth (P.E.) when the mains supply is connected.

If the motor temperature sensor (PTC/Klixon) functionality is used, the sensor and its wiring must supply

adequate isolation and comply with installation requirements for the equipment in use.

The level of integrity offered by the drive control input functions – for example stop/start, forward/reverse and

maximum speed, are not sufficient for use in safety-critical applications without independent channels of

protection. All applications where malfunction could cause injury or loss of life must be subject to a risk

assessment and further protection provided where needed.

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual5

2 Technical data

Table 1. Inverter ratings for 380-480V 3~ 50/60 Hz Type TN electrical supply network

Art. no.

Rated

output

power

Rated

output

current

[1]

Max

output

current

[2]

Apparent

output

power

[3]

Absolute

losses

[4]

P

L,CDM(90,100)

Efficiency

class

[5],[6]

Standby

power

[7]

Size (H×D×W)

[mm]

Weight

[kg]

NFO

3A4D3490D 2.2 kW 1.0-4.9 A 5.8 A 3.3 kVA 0.14 kW IE2 7.5 W 390x190x160 7.0

Notes:

[1] The inverter is optimized for use at a wide range of nominal motor currents in the power ranges of 0.37 kW to

2.2 kW.

[2]

The inverter application should not be dimensioned for higher continuous current than Rated output current.

However, it can supply Max output current for an infinite time, but it may be detrimental to its life span.

[3]

Apparent output power Sr,equ used for IE (International Efficiency) classification.

[4]

Measured at a load point corresponding to 90% of rated frequency and 100% of rated output current.

[5]

CDM (Complete Drive Module) efficiency class according to Commission Regulation (EU) 2019/1781 and

IEC 61800-9-2:2017.

[6]

Due to sinusoidal voltage output from the NFO inverter, the expected additional harmonic losses in the motor,

which are present when using a PWM inverter, are now absent.

IEC 61800-9-2:2017: “When [three-phase induction motors] are operated on a CDM, additional harmonic

losses PLHL = rLHL × PLTsin are caused by the non-sinusoidal voltage supply”. The increase of motor losses as a

result of PWM operation (rLHL) are estimated to 15% of the total losses. According to the reference model for a

2.2kW IE2 or IE3 induction motor, this corresponds to about 0,05 kW.

When determining the overall efficiency of the PDS (Power Drive System, i.e. inverter and motor together), it

should be taken into account that motor losses are approximately 15% lower when using an inverter with

sinusoidal voltage output, than it would be if using a conventional PWM inverter.

[7]

No external control equipment connected to the 24V supply output, and cooling fan regulator at low speed.

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual6

Table 2. Common data

Inverter output

Output volta

g

e waveform Sinusoidal

Output frequenc

y

0

–

150 Hz

Control modes

Frequenc

y

control 0

–

150 Hz, Vector control without slip compensation

Speed control 0

–

9000 rpm, Vector control with slip compensation

Re

g

ulators

Process control PI with extern analo

g

ue feedback in all control modes

Speed re

g

ulator Re

g

ulator for optimal d

y

namic performance

I/O No. Name Confi

g

urable levels

Di

g

ital control inputs 8 DIN1

–

DIN8

Analogue control inputs 2 AIN1, AIN2 0-10V, 2-10V, ±10V,

0-20mA, 4-20mA, ±20m

A

, Pot

Di

g

ital outputs 2 Re1, Re2 Rela

y

, max 50VDC

Analogue outputs 2 AOUT1, AOUT2 0-10V, 2-10V, ±10V,

0-20mA, 4-20mA, ±20m

A

Volta

g

e output 1 +24V max 200m

A

Serial control 2 USB 2.0 T

y

pe B, RS485

Serial protocols 2 Modbus RTU / ASCII, NFO

Fieldbus options Profinet, Profibus, Modbus TCP b

y

usin

g

An

y

Bus CompactCom module

Motor safet

y

Thermistor input PTC or Klixon

Electronic motor

overload protection Switch off if motor load is over rated power for a long time

Ambient conditions

Ambient operating temp. -10 – +45 C

Storage temp. -20 – +60 C

Humidit

y

0

–

90%, non-condensin

g

Protection class IP55 accordin

g

to SS-EN 60529

EMC certification

Emissions: EN 55011:2016 EN, 55011/A1:2017, EN 61000-3-3:2013

Immunity: EN 61000-6-2:2005, EN 61000-4-2, -3, -4, -5, -6, -11

Harmonics: EN 61000-3-2:2014 [1]

For use without shielded cables or additional EMC filter.

Electrical safety

Low Voltage Directive EN 61800-5-1:2007, EN 61800-5-1/A1:2017. Motor

terminal short circuit protection [2] according to IEC 60364-4-41:2005 / AMD1,

clause 411. Short circuit protection functionality operates regardless of motor

cable area, len

g

th or other properties, or mains power suppl

y

impedance.

Climatic tests

Dry heat test IEC 60068-2-2

Damp heat test IEC 60068-2-78

Vibration test IEC 60068-2-6

Notes:

[1] Compliance guaranteed up to 80% of nominal output power.

[2] If short circuit should occur, the inverter may get damaged. However, it will prevent damage of connected

equipment, fire and other hazards.

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual7

3 Mechanical installation

When unpacking the inverter, carefully inspect the product and make sure it has not been damaged during

transportation. Inverter with cracks, dents or other visual damage shall not be installed.

The inverter must not be installed such that outlet air from another inverter or other equipment blows directly

into the inverter air intake. A minimum of 80 mm clearance must be kept above and below the inverter, and a

minimum of 20 mm vertical gap must be kept between inverters, to ensure sufficient air flow.

All terminals are accessed by opening the plastic cover. To be able to use the snap-and-hold-open

functionality of the cover, a free space of 200 mm is required above the inverter.

During installation it is important that no foreign objects, such as cable strands or screws, fall into the inverter

as a short circuit may occur. Drilling in chassis or cover is not allowed.

After installation, make sure all grommets at the cable entries are mounted and the cover is closed and

secured with its screws to avoid contact with dangerous voltages.

3.1 Mounting

Unscrew the two lower captive screws and loosen the inverter from the backplate. Fasten backplate to a vertical

surface using four screws. Make sure that the top mounting screws are sufficiently strong to hold the entire weight

of the inverter. Place the inverter on the backplate by mating the chassis cut-out to the backplate hooks. Tighten

the lower captive screws on both sides.

The cover is opened by unscrewing the two captive screws in the plastic cover and fold up the cover until it snaps

tight. There are two possible positions for the cover. Close the cover by pulling it out and fold down. Be careful not

to break the snaps in the cover when folding down. Tighten the screws in the plastic cover.

The plastic cover can be removed by unscrewing the two upper screws after the cover is opened. The cable from

the cover to the control board must be carefully removed from the control board. Replace in reverse order.

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual8

4 Electrical installation

Connect mains power to terminals L1, L2, L3 and PE.

Connect motor cable to terminals U, V, W and PE using standard unshielded cable.

Never install contactors or switches between the inverter (terminals U, V and W) and the motor that

intentionally or unintentionally may be used to disconnect the motor from inverter output.

A motor safety switch can be mounted between the inverter (terminals U, V and W) and the motor, but it

must only be operated when the motor is not running.

First time powered up, the installer must select application, enter motor name plate data, and perform a

motor tuning.

Connect/install the necessary low voltage signalling that is required for your application, e.g. a run signal for

start/stop, analog input for setpoint, communication, etc.

Make sure run signal is not activated until installer has completed the setup of the inverter.

Make sure the low voltage signal wires have sufficient isolation when passing nearby power cables.

Fig.1. Default configuration

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual9

Terminals 11, 12, 30 and 31 (0V) are connected to PE with a 1MΩresistor but can be connected galvanically to PE

via an external jumper to terminal 19 or 36 (PE). These terminals may vary in terms of potential by up to 100 V from

PE. The USB contact is galvanically connected to 0V.

AIN1.N and AIN2.N are connected to 0V by jumpers J701 and J703.

Warning! If option Autostart is ON and there is a run signal to the inverter (DIN1, terminal 1), the inverter will

start the motor when power is applied.

An external brake-resistor must be fitted if the retardation time is less than 5 sec, see section 6.

If a Motor Safety Thermistor is to be used, jumper J802 must be set accordingly, see 5.12.1.

4.1 Signal terminal connection

The signal terminals are of type “tension clamp spring connection” with a usable cable cross-section of 0.13 - 2.5

mm² (AWG 26 - AWG 14). To connect the cable, carefully push the actuator downward. If a tool is used, make sure

it does not damage any components on the circuit board. The signal cables should be fixed to the PCB with at least

two straps.

Fig. 1. Signal line wiring.

Make sure the signal wires have sufficient isolation when passing power cables.

4.1.1 Signal terminals and their use

The following control signals with its default configuration are available:

Term. Name Function Default function description

1 DIN1 Di

g

ital input 1 Run si

g

nal Start/stop

2 DIN2 Di

g

ital input 2

A

nalo

g

selection

3 DIN3 Di

g

ital input 3 Direction of rotation

4 DIN4 Di

g

ital input 4 Process re

g

ulator activation

5 DIN5 Di

g

ital input 5 Select fixed frequency (see Table7)

6 DIN6 Di

g

ital input 6 Select fixed frequency (see Table7)

7 DIN7 Di

g

ital input 7 Select fixed frequency (see Table7)

8 DIN8 Di

g

ital input 8 PTC motor protection

9 +24V

+24V max 200mA regulated voltage for digital inputs or external

sensors. Short circuit protected. Can also be used for auxiliary

control power suppl

y

.

10 +24V

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual10

11 0V 0V, I/O Ground

12 0V

13 RE1.NO Rela

y

1 NO Fault relay, potential-free contact max 1 A, 50 V DC.

If fault present, terminals 14 are 15 closed.

14 RE1.COM Rela

y

1 COM

15 RE1.NC Rela

y

1 NC

16 RE2.NO Rela

y

2 NO Run indication, potential-free contact max 1 A, 50 V DC.

Terminals 16 and 17 are closed when motor is running.

17 RE2.COM Rela

y

2 COM

18 RE2.NC Rela

y

2 NC

19 PE Protective earth

20

A

IN1.P

A

nalo

g

ue input 1, pos

A

nalo

g

ue setpoint input, positive

21

A

IN1.N

A

nalo

g

ue input 1, ne

g

A

nalo

g

ue setpoint input, ne

g

ative

(

0V, I/O Ground

)

22

A

IN2.P

A

nalo

g

ue input 2, pos Process re

g

ulator actual value input, positive

23

A

IN2.N

A

nalo

g

ue input 2, ne

g

Process re

g

ulator actual value input, ne

g

ative

(

0V, I/O Ground

)

24

A

OUT1.I

A

nalo

g

ue output 1, I Current output 1

25

A

OUT1.U

A

nalo

g

ue output 1, U Volta

g

e output 1, impedance 50Ω

26

A

OUT2.I

A

nalo

g

ue output 2, I Current output 2

27

A

OUT2.U

A

nalo

g

ue output 2, U Volta

g

e output 2, impedance 50Ω

28 +24V +24V (same as terminal 9 and 10)

29 +24V

30 0V 0V, I/O Ground (same as terminal 11 and 12)

31 0V

32 RS485.

A

RS 485 +

33 RS485.

A

34 RS485.B

RS 485 -

35 RS485.B

36 PE Protective earth

Table 3. Signal terminals and their use

Digital inputs (terminals 1 - 8), positive logic:

Maximum input voltage: 30V

Switch level: 13V (input voltage higher than switch level is considered as active level)

Impedance: 10kΩ

Digital inputs (terminals 1 - 8), negative logic:

Maximum input voltage: 30V

Switch level: 9V (input voltage lower than switch level is considered as active level)

Impedance: 10kΩ

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual11

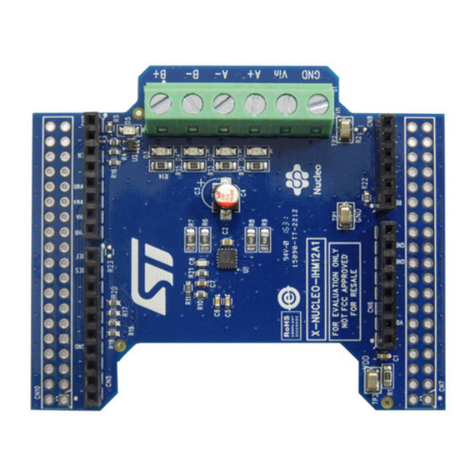

4.1.2 Signal terminals configuration

The jumpers on the control board are for the

configuration of the analogue- & digital-

inputs as well as the serial RS485 channel.

The placement and default settings of the

jumpers are seen in Fig. 2 and explanations

about their use are described in the following

sections.

Fig. 2. Jumper placement and default settings

4.1.3 Analogue current input

To use analogue current input 1, move J701

to “I” position. If more than one unit is

controlled by a single current input signal,

then J702 should be removed or moved to

position “X”. This allows the common-mode

voltage to vary by ±24V from 0V

The same applies for J703 and J704 when

using analogue current input 2.

Input resistance: 82Ω.

Note: When used as voltage inputs, J702 and

J704 must be mounted in “0” position.

Fig.3. Analogue current input configuration

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual12

4.1.4 Negative logic

The inverter can be configured to run the

digital inputs (DIN1 to DIN8) with negative

logic. This is done by moving jumper J801 to

the “NEG LOG” position. The inputs are then

made active by connecting them to the 0V

(terminals 11,12, 30 or 31), see Fig.4.

If the PTC function is to be used with

negative logic, an external resistor (1,5kΩ,

min 1/2W) must be connected between the

terminals DIN8 and 0V. And J802 must be in

the OFF position.

Fig.4. Connection via negative logic (jumper J801 moved)

4.1.5 Serial channel RS485

The inverter can be controlled via an RS485 type

serial channel. Connection is made through

terminals 32 (RS485.A) and 34 (RS485.B). If the

signals are to be bridged to further units, terminals

33 and 35 can be used as in Fig.5.

Termination of the serial channel with 124Ωresistor

is available by moving jumper J803 to position “485

TERM. ON”.

Fig.5. Connection RS485

4.1.6 Connecting potentiometer

If a potentiometer is to be used as the setpoint

source, it is connected between the analogue

voltage output AOUT2.U (27) and the analogue

voltage input AIN1.P (11 or 12).

Change parameter AinSet to Pot and this

automatically configures AOUT2.U to supply 10V.

The value of the potentiometer should be between

4,7kΩand 22kΩ. A lower value will give a lower

maximum frequency because of a 50Ωoutput

impedance in AOUT2.U.

Fig.6. Connecting potentiometer

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual13

4.2 Power terminal connection

4.2.1 Connectors and cables

The power terminals are of type “Push-Lock” with a cross section of 0.2 – 6mm2(AWG 24 – AWG 10). Use cable

type(-s) with operating temperature rating of at least 70C. The cable insulation shall be stripped 12 mm before

pushed into the connector, and then the lever shall be closed.

It is important that the lever is pushed to its fully closed position, as shown below:

Fig.7. The connection lever of the power terminals

4.2.2 Power terminal use

Terminal Function Description

L1

L2 Mains supply Mains supply 380–480V 3~

L3

PE Protective earth Power supply protective earth connector

B Brake resistor Connection for external brake resistor (between B and +)

- - Internal DC link voltage negative and positive terminals.

+ + Positive terminal also used for external brake resistor (option)

PE Protective earth Motor protective earth connector

U Motor phase connectors - To be connected to the

V Motor outputs correct poles of the motor. Incorrect connection can

W cause erratic/unwanted behaviour of the motor.

Table 4. Use of power terminals

When installing two or more inverters together, with one or more of their motors running regeneratively, the

inverters DC link terminals (+ and -) can be connected to each other (thus supplying energy to each other).

Note! As there are component tolerances in the inverters, the link voltage may vary slightly between units, so an

equalising resistor and ultra-fast fuse must be fitted to each line.

Contact NFO Drives AB for correct dimensioning.

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual14

4.2.3 Connecting mains supply

Three-phase feed inverters are connected to a three-phase mains network at a nominal voltage of 380

–

480 V

50/60 Hz between terminals L1, L2, L3 and PE. (PE = Protective Earth = ground).

Recommended slow-blow fuses for three-phase supply:

Model 2.2 kW

(

1.0

–

4.9

A

)

Fuse 10

A

Table 5. Recommended fuse

With the mains supply connected correctly and the motor running, the inverter draws less than 2 mA earth current

in the PE connection. An earth leakage circuit-breaker or RCD 30mA can be used with the inverter.

Turning on and off the mains supply too frequently can damage the inrush circuit of the inverter.

Wait at least 1 min between each power up. Do not use the mains supply for frequent on/off control

of the motor.

4.2.4 Connecting motor

Connect motor cables to terminals U, V, W and PE.

Nominal motor voltage for three-phase fed inverters is 400V. A motor with a nominal voltage of 400V–Y / 230V–D

must be configured for Y-connection, and a motor with nominal voltage of 690V–Y / 400V–D must be configured for

D-connection.

Setup of motor parameters and autotuning must always be performed before first motor start.

A motor safety switch can be mounted between the inverter (terminals U, V and W) and the motor, but it

must only be operated (switched off or on) when the motor is not running.

Never install contactors or switches between the inverter (terminals U, V and W) and the motor that

intentionally or unintentionally may be used to disconnect the motor from inverter output.

EMC standards is met without use of shielded motor cables, if the inverter is correctly installed.

There is no limit to the length of the motor cable as the inverter always supplies a sinusoidal voltage

to the motor. Of course, a slight drop in the voltage (resistance in cables) must be allowed for, which

is accounted for during the autotuning. Use cable with a resistance in each phase that is sufficiently

(and significantly) lower than the resistance in each motor phase winding (stator resistance).

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual15

5 Parameter settings and operation

5.1 General notes

The inverter can be used in the following modes of control:

Frequency regulation of an induction motor (motor speed is not compensated for load variations) with a fixed

digital or analogue setpoint. The motor's electrical frequency is shown on the display. This is the factory default

mode.

Speed regulation for an induction motor with speed calculation (motor speed compensated for load variations)

with a fixed digital or analogue setpoint. The motor's estimated speed is shown in the display.

In the above modes, the setpoint can also be the output from the internal PI-regulator with feedback from a process

controlled by an induction motor.

Setup of motor parameters and motor tuning must always be performed before first motor start.

5.2 Keyboard and display

The figure and table below shows the keyboard and general key functions.

Button Function

Enter into parameter or parameter-group.

Save parameter.

Enter/toggle between normal screen and setup

menu tree.

Leave parameter, parameter-group or leave

parameter unsaved.

Toggle Operating mode between Manual and Auto.

Starts motor in Auto mode if Run signal active.

Starts motor in Manual mode.

Stops motor in all modes.

NOTE: A bus master may start motor at any time

Increase parameter when changing values.

Moves between parameter-groups or parameters.

Decrease parameter when changing values.

Moves between parameter-groups or parameters.

Fig. 8. Keyboard Table 6. Button functions

After power up, the inverter enters the RUN screen. This screen shows the status of the inverter. Setup is reached

by pressing (Esc). From the Setup Screen, the RUN screen is entered again by pressing (Esc).

When a parameter or a parameter-group is selected, its text is inverted. By pressing (Enter) the parameter or

parameter-group is entered.

The value of a given parameter can be increased or decreased by pressing (Up) or (Down). When

adjusting parameters, the increment increases successively. When any parameter is changed but not yet saved, its

value is highlighted. To save the value, press (Enter).

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual16

The following flowchart Fig. 9 shows how different screens are reached, examples of appearance and explanation

of text:

Fig. 9. Programming flowchart and screen examples with explanations

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual17

5.3 Indicators and Motor status

The indicator lights below the display have the following meaning:

POWER The inverter is powered.

RUN The motor is running.

FAIL An alarm or error has been detected.

The Motor status, shown in the lower left corner of the display, has the following meaning:

Run Motor is running.

Stopping Motor is decelerating towards a stop.

Standby Inverter standby, waiting for Run signal (DIN1).

Disable Inverter is not ready or will not accept Run signal.

Waiting Inverter is waiting for an internal timer to finish.

5.4 Operating modes

The inverter has four operating modes, Inhibit, Manual, Auto and Bus. When starting and initiating the inverter it

enters the Auto mode and the RUN screen is shown. The Auto mode is used for controlling the inverter with an

external start signal from terminal 1 (DIN1). The Manual mode is normally used for test and programming, as well

as running the inverter, with the use of the keyboard.

The inverter will start the motor automatically when it is powered up if terminal 1 (DIN1 = run signal) is active

and parameter AutoStart=ON. Parameter AutoStart is factory set to OFF to prevent unintentional motor

starts during commissioning. If the inverter is powered up with an active run signal and AutoStart = OFF, the

inverter will remain in mode Inhibit until run signal goes inactive (or AutoStart is set ON).

The following flowchart Fig. 10 shows how to switch between Manual and Auto modes:

Fig. 10. Flowchart switching between modes and screen examples

You can toggle between Auto and Manual mode at any time by pressing .

The chosen mode is displayed in the right lower corner of the screen.

The inverter starts automatically, or continues to run if it is running, when entering Auto mode if terminal 1

(DIN1) is active.

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual18

5.4.1 Manual Mode

You can switch to Manual mode at any time by pressing . If the motor is running in Auto mode, it will continue

to run in Manual mode with the setpoint the same as the actual value at the time of the switch over.

The setpoint and actual value are shown on the screen. The setpoint is increased by pressing , decreased by

pressing and saved by pressing .

The motor is started by pressing and stopped by pressing . When the motor is running, Run is shown

in the lower left corner of the screen. When the motor is stopped, Stopping is shown.

5.4.2 Auto Mode

You can switch to Auto mode at any time by pressing . If terminal 1 (DIN1) is active the motor starts. Auto

mode can also be reached by toggling terminal 1 (DIN1 Run) with AutoStart = ON, or by serial channel command.

If the inverter is in Auto mode and run signal terminal 1 (DIN1) is not active, the Motor status shows Standby.

The source for the setpoint is selected by the parameter Op Mode (Setp Source) for the control mode concerned

see 5.9.1, 5.10.1 and 5.11.1.

If selecting Op Mode (Setp Source) to:

Terminal: enables the setpoint source to be selected from the digital input signal terminals as inTable 7. Setpoint

sources can be changed while inverter is running and apply immediately.

Analog 1 F - 2 F: runs clockwise with analog setpoint. The analog signal range and input type is selected using

parameter AinSet from the Control parameter group as in Table 8. The analog input value is then scaled between

the lowest setpoint (Min Ain Frq, Min Ain Spd or Set Min = lowest analog input value) and the highest setpoint (Max

Ain Frq, Max Ain Spd or Set Max = highest input value).

Analog 1 R - 2 R:as Analog F, but running counter-clockwise.

Fix-1 F - 7 F: runs clockwise with setpoint from corresponding fixed value parameter for the selected control mode

Fix-1 R - 7 R:as Fix-1 F – Fix-7 F, but running counter-clockwise.

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual19

Function Analog select Direction PI control Select A Select B Select C

Terminal

Function DIN2 DIN3 DIN4 DIN5 DIN6 DIN7

Analog 1 Forward 0 0 0 0

0

0

Analog 1 Reverse 0 1 0 0 0 0

Fix-1 F 0 0 0 1 0 0

Fix-1 R 0 1 0 1 0 0

Fix-2 F 0 0 0 0 1 0

Fix-2 R 0 1 0 0 1 0

Fix-3 F 0 0 0 1 1 0

Fix-3 R 0 1 0 1 1 0

Fix-4 F 0 0 0 0 0 1

Fix-4 R 0 1 0 0 0 1

Fix-5 F 0 0 0 1 0 1

Fix-5 R 0 1 0 1 0 1

Fix-6 F 0 0 0 0 1 1

Fix-6 R 0 1 0 0 1 1

Fix-7 F 0 0 0 1 1 1

Fix-7 R 0 1 0 1 1 1

Analog 2 Forward 1 0 0 x x x

Analog 2 Reverse 1 1 0 x x x

PI control F x 0 1 x x x

PI control R x 1 1 x x x

Table 7. Digital input control to select setpoint source. (0 = inactive, open, 1 = active, closed)

Parameter Ain Type Analogue value Input (terminal)

0-20 mA Current 0-20mA 20 and 21 (J701 at “I” position)

4-20 mA Current 4-20mA 20 and 21 (J701 at “I” position)

+/-20 mA Current +/- 20mA 20 and 21 (J701 at “I” position)

0-10 V Voltage 0-10V 20 (J701 at “U” position)

2-10 V Voltage 2-10V 20 (J701 at “U” position)

+/-10 V Voltage +/- 10V 20 (J701 at “U” position)

Pot Potentiometer 11, 20 and 27 (J701 at “U” position)

Table 8. Settings for analogue inputs AIN1 and AIN2.

5.4.3 Bus Mode (Serial channel / Field bus)

There are two built in communication protocols available: Modbus RTU/ASCII and NFO Classic (legacy NFO

protocol). Both communicate using either USB or RS485. For other fieldbus communication protocols, the inverter

also accepts an Anybus CompactCom module as an option. Please contact NFO Drives AB for more information.

For controlling the inverter or altering its parameters via Modbus or NFO Classic protocol, the Windows program

“NFO Sinus Manager” is available and can be downloaded from www.nfodrives.se

3006469-2022-04

NFODrivesAB2021201013‐2OperatingandInstallationManual20

5.5 Parameter specifications

5.5.1 Parameter summary

Parameters are divided into parameter groups, as shown in the table below. Please note that parameters,

selectable options and default values may change without notice.

Motor Ramp Run Control Freq. Speed PI-reg Output Comm. Status Temp. Display Count. Version Error

P-Nom Accel

Time

Phase

orde

r

Control

mode

Op

mode

Op

mode

Op

mode

Relay 1

Mode

RS485

bustype U-rms Motor

temp

Display

par.1

Operate

time

CoProc

version Error-log

U-Nom Decel

Time

Stop

mode

Auto-

start FixFrq1 FixSpd1 FixReg1 Relay 1

Freq

RS485

add

r

I-rms Power

module

Display

par.2 Run time DSP

version

Restart

Delay

f-Nom Ramp

Brkpoint

Energy

save

A.input

1 type FixFrq2 FixSpd2 FixReg2 Relay 2

Mode

RS485

baud P-out COP

temp

Display

par.3

Brake

time

GUI

version

Reset

Time

N-Nom Alt.

Accel

Pwr On

delay

A.input

2 type FixFrq3 FixSpd3 FixReg3 Relay 2

Freq

RS485

cha

r

PF Heat

sink 1

Bklight

level

Cur.lim

time

Prod

date AC Fail

I-Nom Alt.

Decel

Run

delay

D.input

config FixFrq4 FixSpd4 FixReg4 Aout 1

Mode

RS485

timeout DC Link Heat

sink 2

Bklight

timeout

DC low

time

Serial

numbe

r

Temp Hi

cos Stop

delay FixFrq5 FixSpd5 FixReg5

Aout 1

Max

RS485

autostop

Brake

chop

Heat

sink 3

Menu

readonly

Start

count PTC

Temp

Tuning DC

brake FixFrq6 FixSpd6 FixReg6

Aout 2

Mode

RS485

failsafe

Stator

freq.

Heat

sink 4 Alarm

count Over

load

R-stator Kp

speed FixFrq7 FixSpd7 FixReg7

Aout 2

Max

USB

bustype

Rotor

freq.

Fan 1

volt Output

Energy Ain Fail

R-rotor Ti

speed A.input

min freq

A.input

min rpm

Setpoint

min

Analog

1 out

USB

add

r

Control

freq.

Fan 2

volt Total

Energy DC Low

L-main Sleep

freq. A.input

max freq

A.input

max rpm

Setpoint

max

Analog

2 out

USB

timeout

Rotor

speed

Fan 3

volt DC High

Sigma

Bypass

freq.

Actual

min USB

autostop

Control

speed

Fan 4

volt

GND

Fail

I-magn Bypass

bandw.

Actual

max ABCC

interface

Actual

Torque EXT 24V Short

Circuit

I-limit Boost

time

Setp

min limit ABCC

bustype

Control

Torque

USB

5V

Imagn

Low

Pole

Count Boost

level

Setp

max limit ABCC

add

r

Actual

PI-reg

Current

Low

T-nom

Reg

sign ABCC

timeout

Setpoint

Pi-reg

Current

High

Tuned

status

Reg

Kp ABCC

autostop Ain 1 V Current

Limit

Reg

Ti Auto

reset Ain1 mA Run Fail

Min freq Ain 2 V

Max freq Ain2 mA

Unit Keybrd.

Off limit Terminal

Onlimit

Table 9. Parameter groups and parameters.

For parameter groups Frequency or Speed, only the menu/group for the selected control mode will be shown.

5.5.2 Parameter table

The table below shows all inverter parameters, divided into parameter groups.

3006469-2022-04

This manual suits for next models

1

Table of contents

Other NFO Drives DC Drive manuals