Niagara 56645 Assembly instructions

Visit our website at: http://www.harborfreight.com

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual (or month and year of purchase if product has no number). Keep this manual and the

receipt in a safe and dry place for future reference. 22b

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright©2021 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service ma y n o t b e i n c l u d e d .

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Page 2 For technical questions, please call 1-888-866-5797. Item 56645

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INFORMATION

Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in serious injury.

Work Area

1. Keep your work area clean and well lit.

Cluttered dark areas invite accidents.

2. The work area should have adequate

drainage to reduce the possibility of

a fall due to slippery surfaces.

3. Keep bystanders, children, and visitors

away while operating the Sprayer.

Distractions can cause you to lose control.

Personal Safety

1. Follow all guidelines regarding

chemicals sprayed, including MSDS

instructions and EPA regulations.

2. If the amount of weight you can lift safely

is limited, do not fill the Tank completely

to prevent strain and injury.

3. Stay alert. Watch what you are doing and use

common sense when operating the Sprayer.

Do not use the Sprayer while tired or under

the influence of drugs, alcohol, or medication.

A moment of inattention while operating the

Sprayer may result in serious personal injury.

4. Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

5. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enable better

control of the tool in unexpected situations.

6. Always wear eye protection.

Wear ANSI-approved safety goggles.

Page 3For technical questions, please call 1-888-866-5797.Item 56645

Use

1. Use only for water or water-based fertilizers,

herbicides, pesticides and sealers. Do not use

to spray combustible or corrosive chemicals.

2. Do not point the Sprayer at yourself,

other people or animals.

3. Industrial applications must follow

OSHA requirements.

4. Make sure the liquid used in the

Sprayer is not dirty or sandy.

5. This product is not a toy. Do not allow

children to play with or near this item.

6. Use as intended only.

7. Inspect before every use; do not use

if parts are loose or damaged.

8. Maintain product labels and nameplates.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

9. The warnings and cautions discussed in this

manual cannot cover all possible conditions

and situations that may occur. The operator

must understand that common sense and

caution are factors that cannot be built into this

product, but must be supplied by the operator.

Service

1. Have your Sprayer serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of

the tool is maintained.

2. Store idle tools and equipment out of

reach of children and other untrained

people. Tools and equipment are dangerous

in the hands of untrained users.

3. Maintain the Sprayer with care. Keep

this product clean. A properly maintained

Sprayer is easier to control.

SAVE THESE INSTRUCTIONS.

Page 4 For technical questions, please call 1-888-866-5797. Item 56645

Specifications

Tank Capacity 4 Gallons

Empty Weight 9 lb

Max PSI 90 PSI

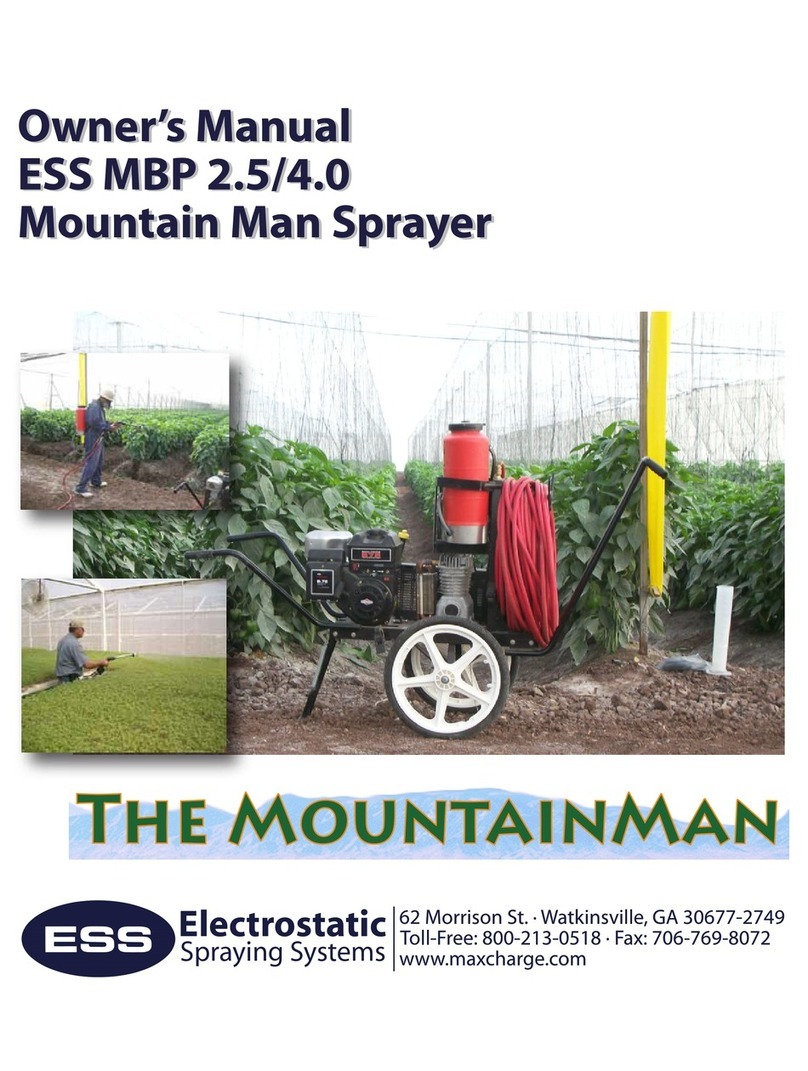

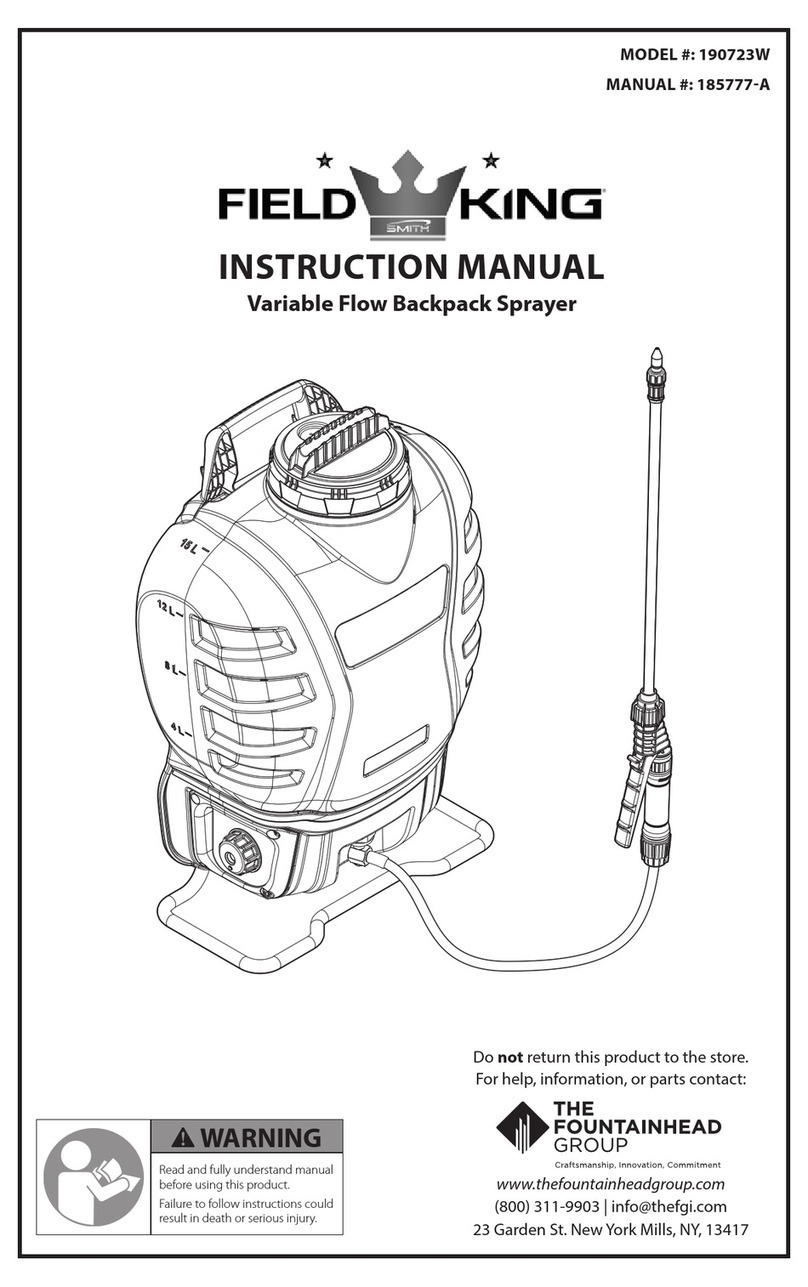

Components and Controls

Note: For additional information regarding the parts listed in the following

pages, refer to the Parts List and Diagram on page 10.

Stand

Nozzle

Tank

Hose

Pump

Handle

Tank

Lid

Wand

Trigger

Shoulder Strap

Wand Holder

Page 5For technical questions, please call 1-888-866-5797.Item 56645

Assembly Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this document

including all text under subheadings therein before set up or use of this product.

Attaching the Wand

1. Insert end of Wand into the end

of the Trigger Assembly.

2. Slide Nut over threaded end of Trigger Assembly,

then turn clockwise and tighten Nut securely.

Trigger Assembly

Nut

Wand

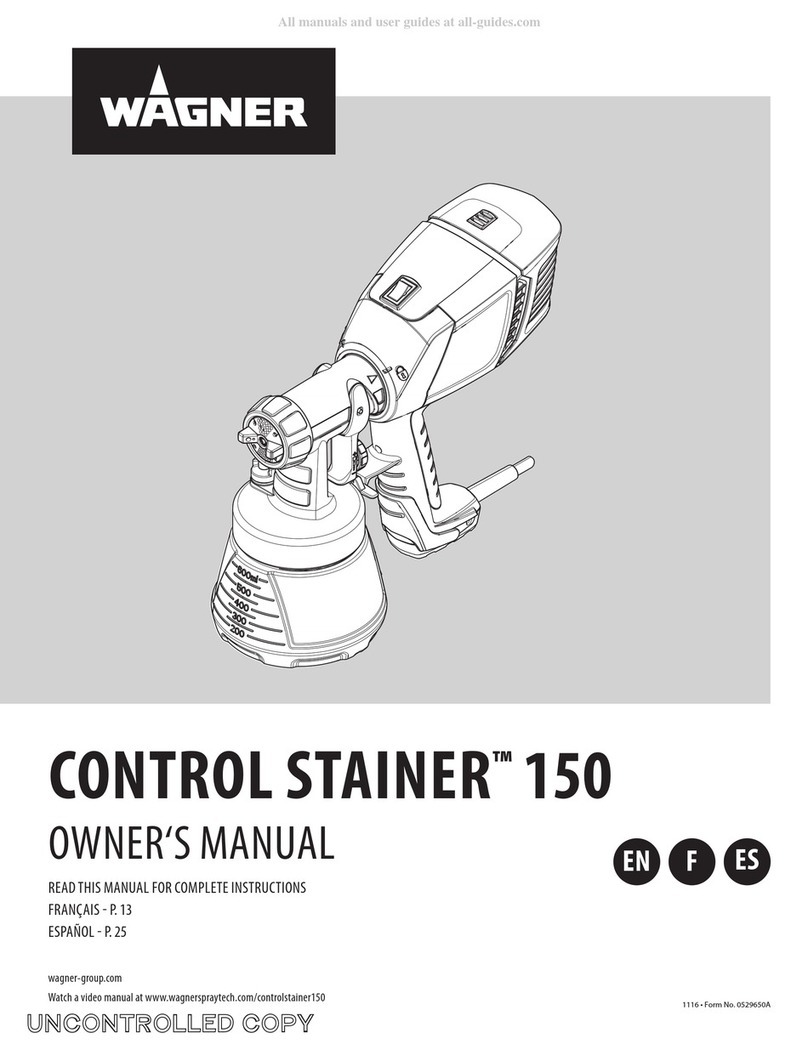

Changing the Nozzle

WARNING! TO PREVENT SERIOUS INJURY: Relieve

pressure and empty tank before changing Nozzles.

1. Loosen Nut by turning counterclockwise.

Remove Nozzle.

2. Replace Nozzle. Tighten Nut securely.

3. When using the Adjustable Nozzle, adjust the

output flow by turning the nozzle’s Cap.

Wand

Cone

Nozzle

Nut

Double

Cone Nozzle

Fan Nozzle Sprinkler

Nozzle

Adjustable Nozzle

Cap

Pump Handle Orientation

The Pump Handle can be installed on either side of

the Tank. To change the side that the Handle is on:

1. Remove the Butterfly Nut and M5 Screw. Save

these parts and remove the Pump Handle.

2. Move the Pump Handle to the other side

of the Tank and attach it to the other end of

the Turning Rod using the saved parts.

Pump

Handle

Turning

Rod

Butterfly

Nut

M5 Screw

Tank

Attaching the Shoulder Straps

Attach each Shoulder Strap to bottom

of Tank, one on each side.

Shoulder Strap Hook

Page 6 For technical questions, please call 1-888-866-5797. Item 56645

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this document

including all text under subheadings therein before set up or use of this product.

WARNING! TO PREVENT SERIOUS INJURY:

Follow all guidelines regarding chemicals sprayed,

including MSDS instructions and EPA regulations.

CAUTION! If the amount of weight you can lift

safely is limited, do not fill the Tank completely

to prevent strain and serious injury.

1. Remove Tank Lid and fill Tank, through the Tank

Filter, no higher than top fill line. Replace Tank Lid.

2. Strap the Sprayer to your back.

a. Put your arms though the Shoulder Straps

so the pads rest on your shoulders

with the Tank behind your back.

b. Wrap the waist strap around your waist

and connect the buckle to secure.

c. Adjust shoulder and waist straps as needed.

Waist Strap Buckle

Shoulder

Straps

3. Pump the Handle to build up sufficient pressure.

4. Remove the Wand from its holder

on the lid of the Tank.

5. Point the Nozzle toward the area to be sprayed,

then depress the Trigger to begin spraying.

Page 7For technical questions, please call 1-888-866-5797.Item 56645

6. For continuous spray, press the Trigger down and

pull the Trigger Lock back, then release the Trigger.

Trigger

Lock Trigger

Trigger Lock On

To stop continuous spray, press the

Trigger down and push the Trigger Lock

forward, then release the Trigger.

Trigger Lock Off

7. As you spray, the Sprayer will depressurize.

When decreased pressure is affecting spray

pattern, pump the Pump Handle until proper

pressure is achieved, then resume spraying.

8. When finished spraying:

a. Point Wand in safe direction and depressurize

the Tank by pressing down on the Trigger.

b. Dispose of liquid according to

manufacturer guidelines.

c. Clean the Sprayer according to

Maintenance Instructions.

d. Store Sprayer in a safe, dry, clean location

out of reach of children and out of sunlight.

Page 8 For technical questions, please call 1-888-866-5797. Item 56645

Inspection, Maintenance, and Cleaning

Procedures not specifically explained in this manual must

be performed only by a qualified technician.

TO PREVENT SERIOUS INJURY FROM PRODUCT FAILURE:

Do not use damaged equipment. If abnormal noise, vibration, or

leaking air occurs, have the problem corrected before further use.

Follow all guidelines regarding chemicals sprayed, including MSDS instructions and EPA regulations.

1. BEFORE EACH USE, inspect the general

condition of the Sprayer. Check for:

• loose hardware,

• misalignment or binding of moving parts,

• cracked or broken parts, and

• any other condition that may

affect its safe operation.

2. AFTER EVERY USE, clean the Sprayer:

a. Flush with water.

b. Clean Nozzle, Handle Filter, and Tank Filter.

c. Rinse with water and allow to air-dry

with the Tank open.

3. PERIODICALLY, lubricate all moving parts of

the pump assembly with petroleum jelly.

4. STORAGE

Store Sprayer in a safe, dry, clean location out

of reach of children and out of sunlight.

Cleaning the Handle Filter

1. Remove Trigger Assembly from the Wand

by turning it counter clockwise.

2. Remove the Wand Handle from the

Trigger Body by turning it counter clockwise.

3. Carefully remove the Handle Filter,

saving all pieces.

4. Flush Filter with clean water.

5. Reassemble Trigger Assembly.

Wand Handle

Handle Filter

Trigger Body

Trigger Sealing

Ring

Trigger Assembly

Page 9For technical questions, please call 1-888-866-5797.Item 56645

Troubleshooting

Problem Possible Causes Likely Solutions

Unit does not spray.

1. Not enough liquid in tank.

2. Sprayer not pressurized.

3. Nuts loose.

4. Spray fluid contains particles or

sand.

5. Nozzle and/or Filter clogged

with mineral buildup.

1. Add liquid to tank.

2. Pump Handle to pressurize Sprayer.

3. Tighten Nuts.

4. Disassemble, clean, then reassemble Nozzle

and/or Handle and Tank Filters. Empty, clean,

then refill Tank with properly strained fluid.

5. Disassemble, clean, then reassemble

Nozzle and/or Handle and Tank Filters.

Spray pattern is

undesirable.

1. Spray fluid contains particles or

sand.

2. Nozzle and/or Filter clogged

with mineral buildup.

1. Disassemble, clean, then reassemble Nozzle

and/or Handle and Tank Filters. Empty, clean,

then refill Tank with properly strained fluid.

2. Disassemble, clean, then reassemble

Nozzle and/or Handle and Tank Filters.

Follow all safety precautions whenever diagnosing or servicing the Sprayer.

Record Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts. Specify UPC 792363566452 when ordering parts.

Page 10 For technical questions, please call 1-888-866-5797. Item 56645

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS DOCUMENT AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Parts List and Diagram

Parts List

Part Description Qty

1 Nozzle Cap 1

2 Nozzle O-Ring 1

3 Joint 1

4 Wand O-Ring 2

5 Split Sleeve 2

6 Wand Nut 2

7 Wand 1

8 Trigger 1

8-1 Trigger Lock 1

8-2 Trigger Lever 1

8-3 Trigger Nut 1

8-4 Trigger Spring 1

8-5 Valve Core 1

8-6 Valve Core O-Ring 1

8-7 Trigger Sealing Pad 1

8-8 Trigger Pin 1

8-9 Trigger Body 1

8-10 Trigger Sealing Ring 1

8-11 Wand Handle Filter 1

8-12 Wand Handle 1

9 Hose Nut 1

10 Hose 1

11 Hose Locking Ring 1

12 Tank Lid 1

13 Air Intake Plug 1

14 Tank Gasket 1

15 Tank Filter 1

16 Tank 1

17 Back Pad 1

19 Screw, M6 x 12 2

20 Screw, M6 x 18 2

21 Nut, M6 2

22 Air Chamber O-Ring 1

Part Description Qty

23 Air Chamber 1

24 Pump O-Ring Ø29 1

25 Pump O-Ring Ø49 1

26 Screw ST4×8 2

27 Flat Gasket 2

28 Pump Valve Gasket 2

29 Pump Cylinder 1

30 Piston Spring 1

31 Piston Bowl 1

32 Piston 1

33 Connecting Rod Clamp 1

34 Connecting Rod Calibre 1

35 Operation Arm 1

36 Inner hex Screw, M8 x 25 2

37 Nut, M5 2

38 Pump Locking Ring 1

39 Screw, M5 1

40 Piston Cover 1

41 Screw, M5 x 25 1

42 Screw, ST3 x 10 2

43 Pump Handle Cover 1

44 Pump Handle 1

45 Nut, M5 1

46 Turning Rod 1

47 Flat Gasket 2

48 Turning Rod Sleeve 2

49 Split Pin 1

50 Screw, M5 x 25 1

51 Shoulder Strap 1

52 Cone Nozzle 1

53 Fan Nozzle 1

54 Double Cone Nozzle 1

55 Adjustable Jet Nozzle 1

Page 11For technical questions, please call 1-888-866-5797.Item 56645

Assembly Diagram

26677 Agoura Road • Calabasas, CA 91302 • 1-888-866-5797

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for the

period of 90 days from the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity, improper

installation, normal wear and tear, or to lack of maintenance. We shall in no event be liable for death, injuries

to persons or property, or for incidental, contingent, special or consequential damages arising from the use of

our product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise.

If our inspection verifies the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will

return repaired products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

Table of contents

Other Niagara Paint Sprayer manuals