F5 Paint Shaker

877-862-7049 www.F5PaintShaker.com

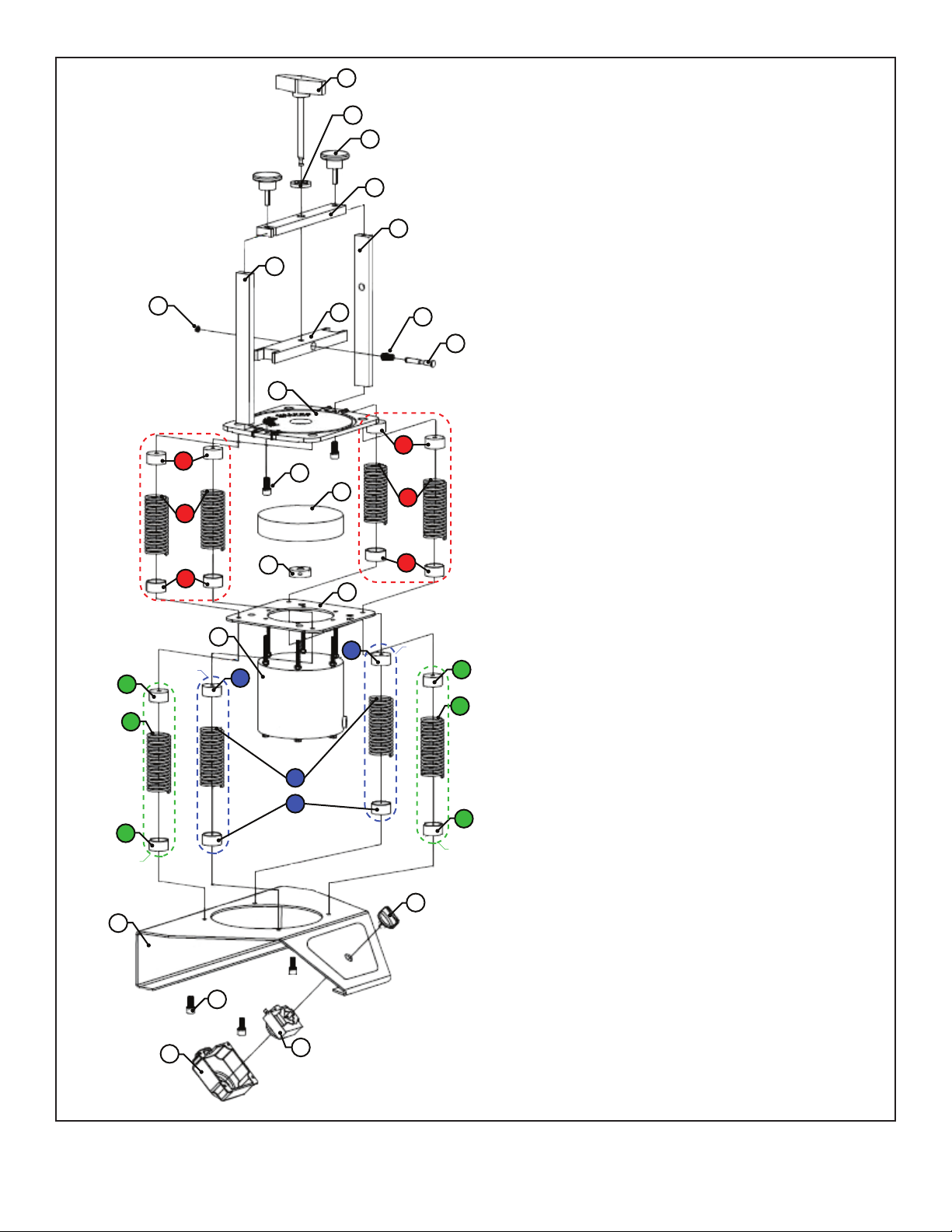

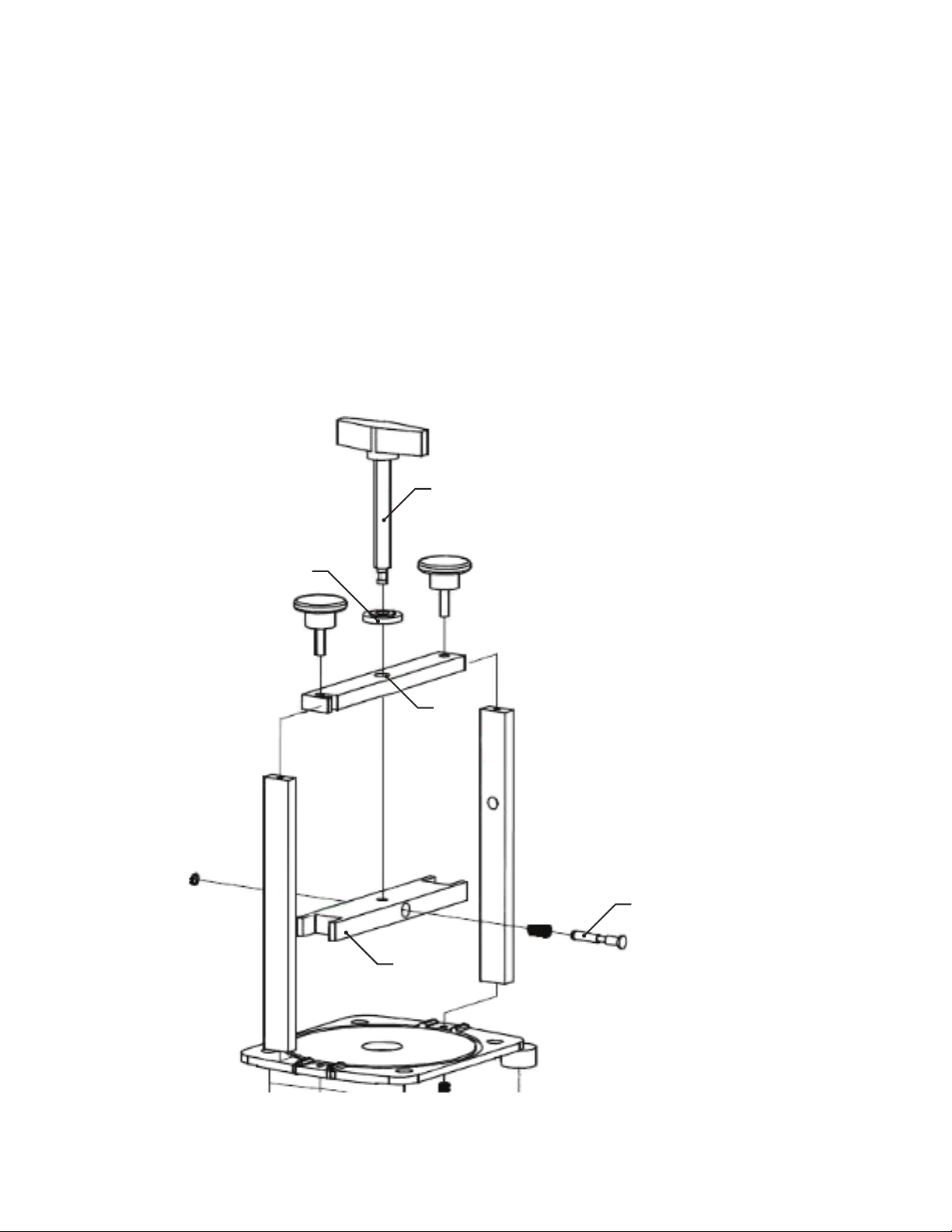

Before proceeding to back off springs, ensure that you have fully installed the springs and

platform.

1. Carefully use a pair of pliers to grasp the top of the spring until the jaw catches onto the

end of the spring coil, making sure you do not gouge the spring wire. This will slightly

open the spring so that you can back it off the mount.

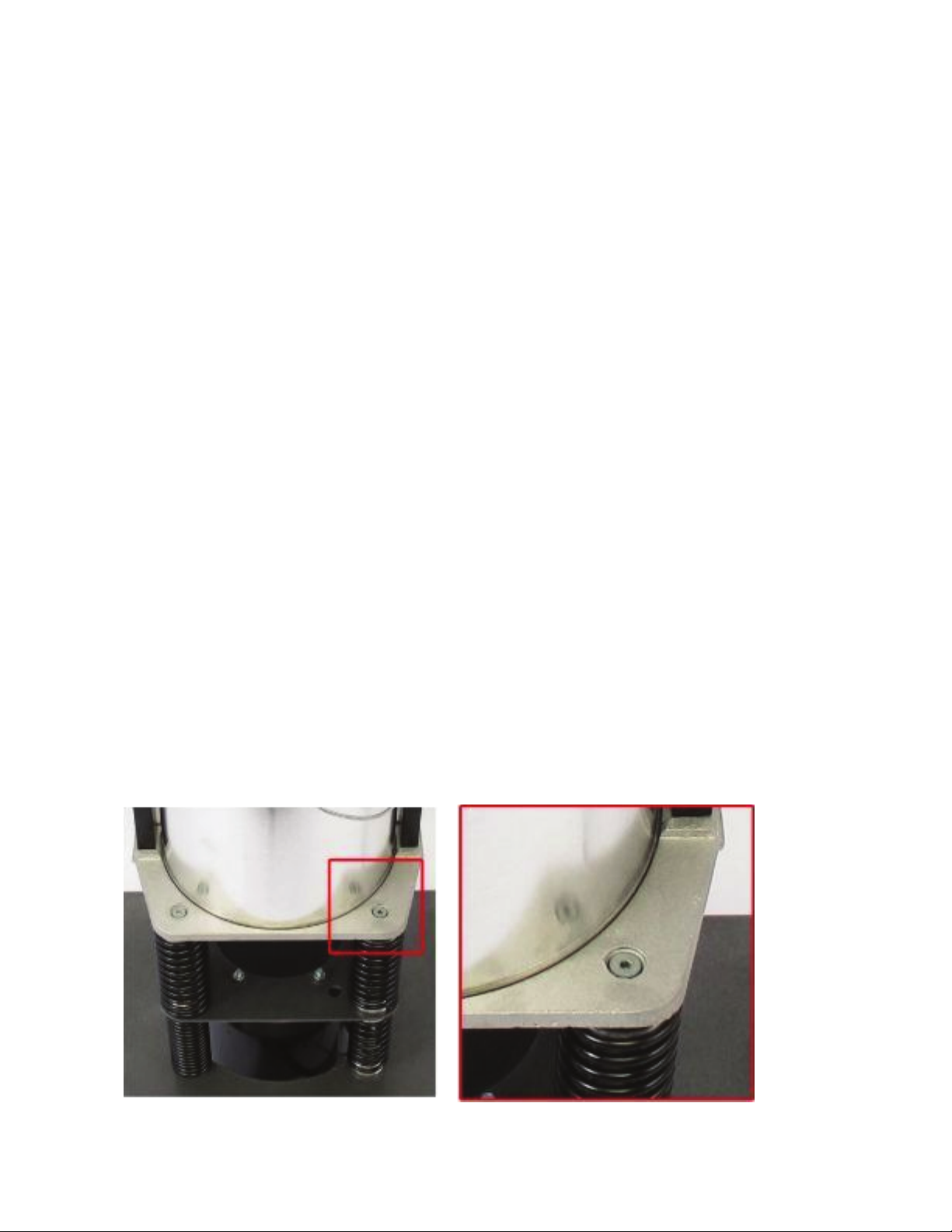

2. Back each spring off about ¹⁄4 turn and loosen the four flat head cap screws on the

platform. The springs will then snap back.

3. Retighten the four screws. Continue this until the end of each spring is ¹⁄4” away from

the platform. DO NOT BACK THE SPRINGS COMPLETELY OFF THE MOUNTS.

How to Back Off the Springs

1. To check if the springs need adjustment, place a full can of paint onto the platform,

secure it, and turn on the paint shaker. If you hear any clattering, there are loose

springs that need adjustment. If not, proceed to the next step (”How to Check the

Spring Adjustment”).

2. To determine which springs need adjustment, observe how the shaker’s mid-plate

moves while it’s on. If the right side moves more, tighten the right front and left back

springs (Fig. H). If the left side moves more, tighten the left front and the right rear

springs. If both sides move, tighten all four springs.

3. Turn off the machine before you tighten the springs. Take hold of the loose spring

and tighten it ¹⁄4 turn into the end mount. Then tighten that spring’s diametrically

opposite spring the same amount. Loosen the flat head cap screws on the springs

you have tightened, let the spring snap back, and then retighten the screws.

4. Turn on the machine again and once again observe if either side moves more than

the other. If so, repeat the procedure (always going ¹⁄4 turn at a time) until the

machine operates evenly on both sides.

How to Adjust the Springs

Fig. H: