Nichia 144 Series User manual

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

1/12 SP-QR-C2-210575-1

Jul. 9, 2021

Application Note

Assembly Precautions

for the Nichia 144 Series LEDs

Table of contents

・・・・・・・・・・2

・・・・・・・・・・・・・・・・・3

・ ・ ・ ・ 4

・ ・ 5-8

・ ・ ・ ・ ・ ・ ・ ・ ・ ・ ・ ・ 8

・・・・・・・・・9-10

・ ・ ・ ・ ・ ・ ・ ・ 10-11

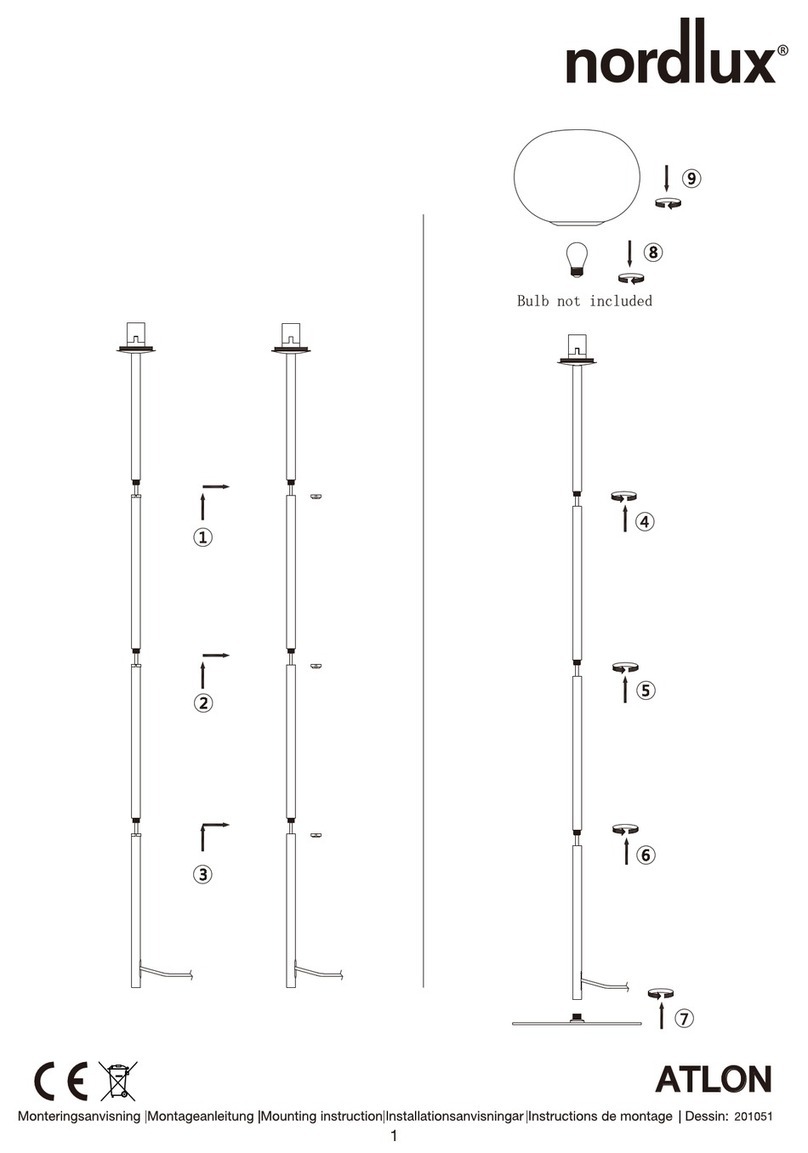

1. LED Outline Dimensions/Tape Dimensions

2. Handling Precautions

3. Design Recommendations for Optimal Amount of Solder

4. Precautions for Setting Up a Pick-and-Place Machine/Nozzle

5. Precautions When Reflow Soldering

6. Evaluation of the Effect of Solder Volume

7. Evaluation of Self-Alignment Performance

The part number NV4L144AR,NV4W144AR,NV4L144AM,NV4W144AM in this document are the part number of our

products, and do not have any relevance or similarity to other companies' products that may have trademark rights.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

2/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

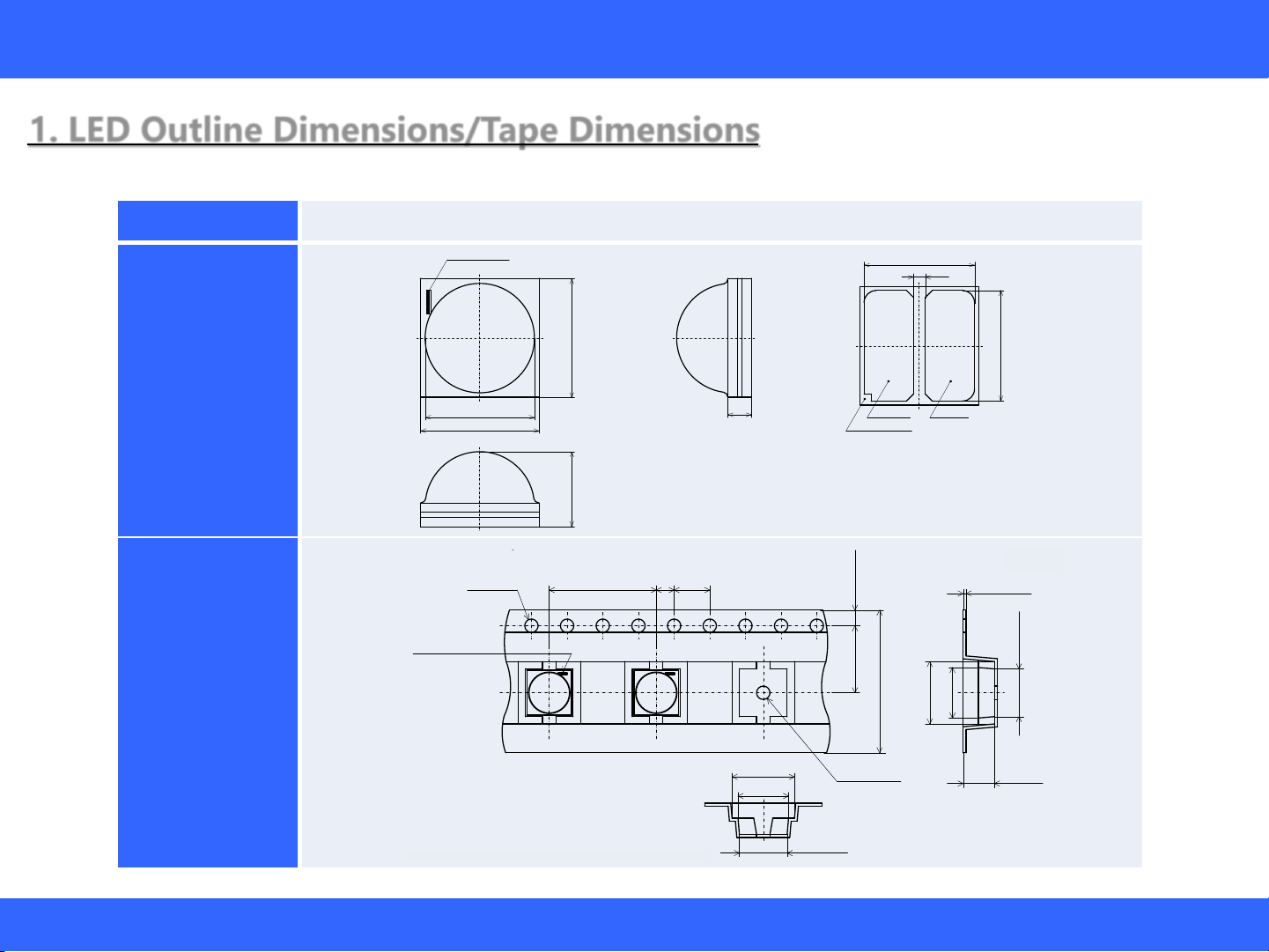

1. LED Outline Dimensions/Tape Dimensions

Table 1. Product Specifications

Part Number NV4L144AR, NV4W144AR, NV4L144AM, NV4W144AM

LED

[unit: mm, Tolerance: ±0.2mm]

Embossed

Carrier

Tape

Reel Size: 1,500 LEDs

[unit: mm]

Nxxx144x

STS-DA7-9282

(単位 Unit: mm)

管理番号 No.

テーピング部 Tape

2±0.1 4±0.1

Φ1.5+0.1

-0

1.75±0.1

7.5±0.1

16+0.3

-0.1

12±0.1

5.35±0.1

0.35±0.05

3.5±0.1

トレーラ部/リーダ部 Trailer and Leader トップカバーテープ

引き出し方向

Embossed Carrier Tape

エンボスキャリアテープ

Top Cover Tape

Feed

Direction

Trailer 160mm MIN(Empty Pockets)

リーダ部最小400mm

Leader without Top Cover Tape 400mm MIN

LED装着部

Loaded Pockets

引き出し部最小100mm(空部)

Leader with Top Cover Tape

100mm MIN(Empty Pocket)

トレーラ部最小160mm(空部)

* 数量は1リールにつき 1500個入りです。

Reel Size: 1500pcs

* 実装作業の中断などでエンボスキャリアテープをリールに巻き取る場合、

エンボスキャリアテープを強く(10N以上)締めないで下さい。

LEDがカバーテープに貼り付く可能性があります。

When the tape is rewound due to work interruptions,

no more than 10N should be applied to

the embossed carrier tape.

The LEDs may stick to the top cover tape.

* JIS C 0806電子部品テーピングに準拠しています。

The tape packing method complies with JIS C 0806

(Packaging of Electronic Components on Continuous Tapes).

リール部 Reel

Φ13±0.2

330±2

ラベル

Label

Φ21±0.8

21.5±1

17.5±0.5

Φ100±1

-0

Φ1.5+0.2

(5.86)

(7)

Cathode Mark

5.35±0.1

(5.86)

(7)

STS-DA7-9306A

NV4L144AM

管理番号 No.

(単位 Unit:mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

*

(単位 Unit:mm, 公差 Tolerance:±0.2)

K A

保護素子

Protection Device

0.5

4.65

4.65

AnodeCathode

Cathode Mark

3.15 5

4.6

5

Cathode Mark

1

パッケージ材質

Package Materials

セラミックス

Ceramics

項目 Item 内容 Description

プリコート材質

Pre-coating

Materials

シリコーン樹脂

(拡散剤+蛍光体入り)

Silicone Resin

(with diffuser and phosphor)

レンズ材質

Lens Materials

シリコーン樹脂

Silicone Resin

電極材質

Electrodes Materials

質量

Weight

金メッキ

Au-plated

0.093g(TYP)

STS-DA7-9306A

NV4L144AM

管理番号 No.

(単位 Unit:mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

*

(単位 Unit:mm, 公差 Tolerance:±0.2)

K A

保護素子

Protection Device

0.5

4.65

4.65

AnodeCathode

Cathode Mark

3.15 5

4.6

5

Cathode Mark

1

パッケージ材質

Package Materials

セラミックス

Ceramics

項目 Item 内容 Description

プリコート材質

Pre-coating

Materials

シリコーン樹脂

(拡散剤+蛍光体入り)

Silicone Resin

(with diffuser and phosphor)

レンズ材質

Lens Materials

シリコーン樹脂

Silicone Resin

電極材質

Electrodes Materials

質量

Weight

金メッキ

Au-plated

0.093g(TYP)

STS-DA7-9306A

NV4L144AM

管理番号 No.

(単位 Unit:mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

*

(単位 Unit:mm, 公差 Tolerance:±0.2)

K A

保護素子

Protection Device

0.5

4.65

4.65

AnodeCathode

Cathode Mark

3.15 5

4.6

5

Cathode Mark

1

パッケージ材質

Package Materials

セラミックス

Ceramics

項目 Item 内容 Description

プリコート材質

Pre-coating

Materials

シリコーン樹脂

(拡散剤+蛍光体入り)

Silicone Resin

(with diffuser and phosphor)

レンズ材質

Lens Materials

シリコーン樹脂

Silicone Resin

電極材質

Electrodes Materials

質量

Weight

金メッキ

Au-plated

0.093g(TYP)

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

3/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

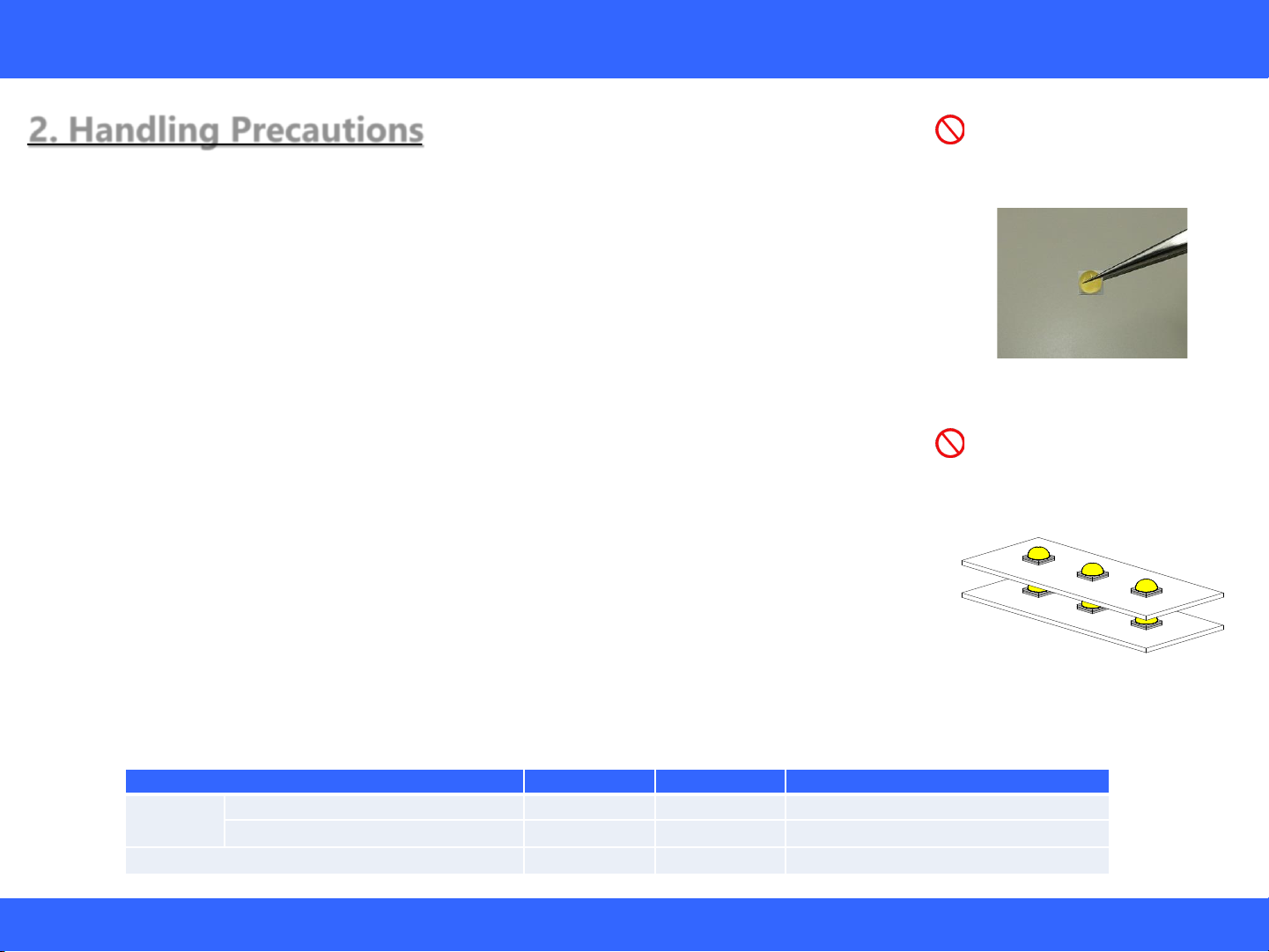

2. Handling Precautions Incorrect

Incorrect

Figure 1. Example of an Improper

Holding Position

Caution: Do not grab/hold the LEDs

with tweezers around the

encapsulating resin.

Figure 2. Example of Improper

Stacking

Caution: Do not stack assembled

PCBs on top of each other.

Handling with bare hands

Do not handle the LEDs with bare hands:

- this may contaminate the LED surface and have an effect on the optical characteristics,

- this may cause the LED to deform and/or the wire to break causing a catastrophic failure (i.e. the LED

not to illuminate),

- the lead frame may cause injuries when the LED is handled with bare hands.

Handling with tweezers

Ensure that when handling the LEDs with tweezers, excessive force is not applied to the LED. Otherwise, it

may cause damage to the resin (e.g. cut, scratch, chip, crack, delamination and deformation) and the

internal connection to fail causing a catastrophic failure (i.e. the LED not to illuminate).

ESD Precautions

LEDs are sensitive to transient excessive voltages (e.g. ESD, lightning surge). If this excessive voltage

occurs in the circuit, it may cause the LED to be damaged causing issues (e.g. the LED to have a reduction

in the radiant flux or not to illuminate [i.e. catastrophic failure]). When handling the LEDs, ensure that

necessary measures have been taken to protect them from transient excess voltages. Refer to the

applicable specification for more details.

Stacking assembled PCBs together

Do not stack assembled PCBs together. Otherwise, it may cause damage to the resin (e.g. cut, scratch,

chip, crack, delamination and deformation) and the internal connection to fail causing a catastrophic

failure (i.e. the LED not to illuminate).

Baking

The storage/packaging requirements for the Nichia 144 Series LEDs are comparable to JEDEC Moisture

Sensitivity Level (MSL) 3 or equivalent. Nichia used IPC/JEDEC STD-020 as a reference to rate the MSL of

this LED. If the “After Opening” storage time has been exceeded or any pink silica gel beads are found,

ensure that the LED are baked before use. Baking should only be done once.

Conditions Temperature Humidity Time

Storage

Before Opening Aluminum Bag

≤ 30°C ≤ 90% RH Within 1 Year from Delivery Date

After Opening Aluminum Bag

≤ 30°C ≤ 70% RH ≤ 168 hours

Baking 65±5°C - ≥24 hours

Table 2. Storage/Baking Conditions

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

4/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

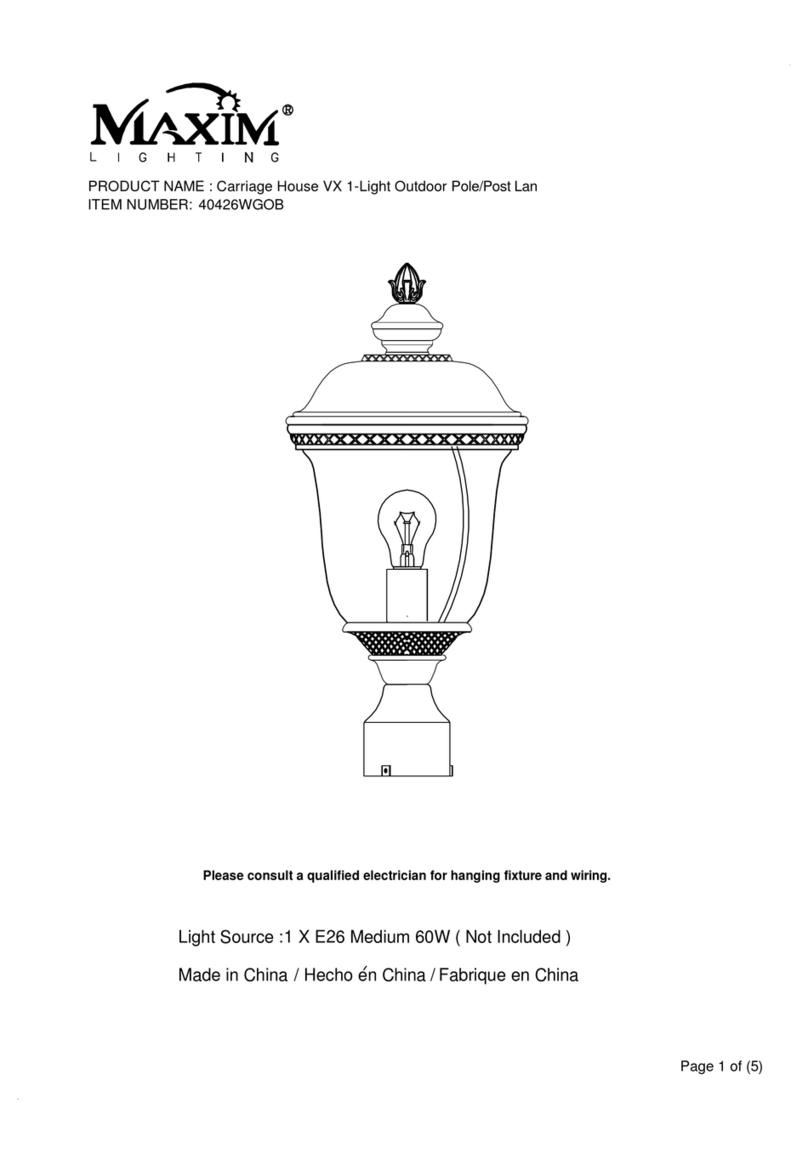

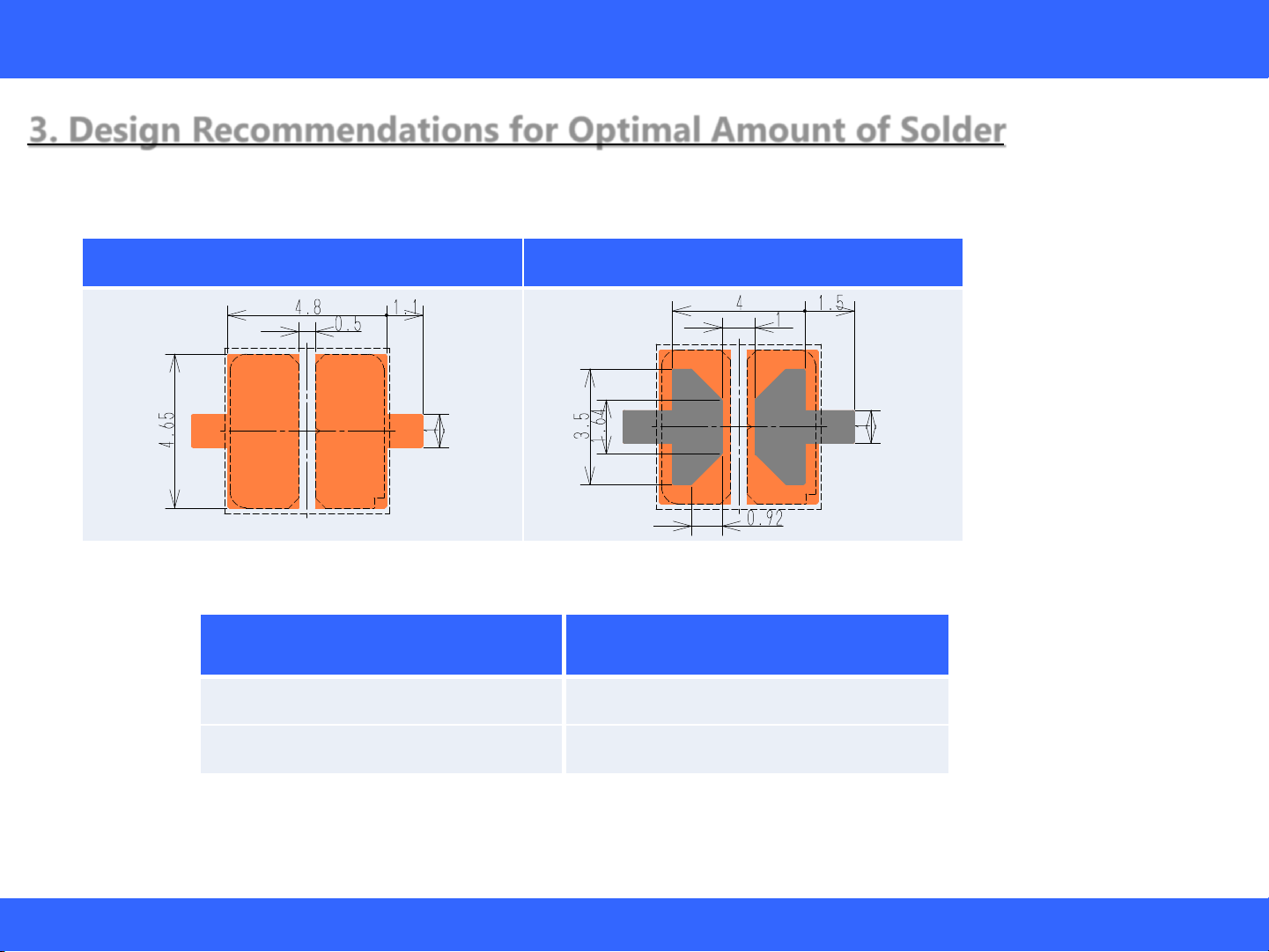

3. Design Recommendations for Optimal Amount of Solder

Soldering Pad Pattern/Metal Solder Stencil Aperture

Table 3. Recommended Soldering Pad Pattern/Metal Solder Stencil Aperture

Table 4. Recommended Solder/Metal Solder Stencil Conditions

Soldering Pad Pattern Stencil Aperture

[unit:mm] [unit:mm]

⋯LED outline

■Soldering Pad Pattern

■Stencil Aperture

Item Recommended

Condition

Solder Stencil Thickness 120 [μm]

Solder Paste Sn-3.0Ag-0.5Cu

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

5/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

4. Precautions for Setting Up a Pick-and-Place Machine/Nozzle

Table 5. Cautions/Suggestions for setting up equipment

Item Recommended Conditions/Specifications Cautions/Suggestions

Pick-and-place machine1Modular mounter

Pick-and-place nozzle Specially designed nozzle

(see Figure 3)

See “Pick-and-Place Nozzle” on

Page 6 for the details.

Tape-and-reel feeder

Electrical (motorized) feeder

Tape width: 16mm

Feed length: 12mm

See “Tape-and-Reel Feeder” on

Page 6 for the details.

Nozzle height for pick-up

operations

The contact surface of the nozzle head for pick

operations should be adjusted to 1.7mm below the edge

of the embossed carrier tape pocket.

See “Recommended Nozzle Height

for Pick-up Operations” on Page 7

for the details.

Nozzle height for placement

operations (i.e. placement depth) 0.2mm for placement depth

See “Recommended Nozzle Height

for Placement Operations

(Placement Depth)” on Page 7 for

the details.

Imaging-based Automatic

Inspection

Using the electrode as a reference is recommended to

locate the center of the LED.

See "Imaging-based Automatic

Inspection" on Page 8 for the

details.

Note:

1The recommended conditions/specifications above have been determined under the following verification conditions:

Pick-and-place machine (modular mounter):

- YS100 High-Speed General-Purpose Modular (manufactured by Yamaha Motor Co., Ltd.)

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

6/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

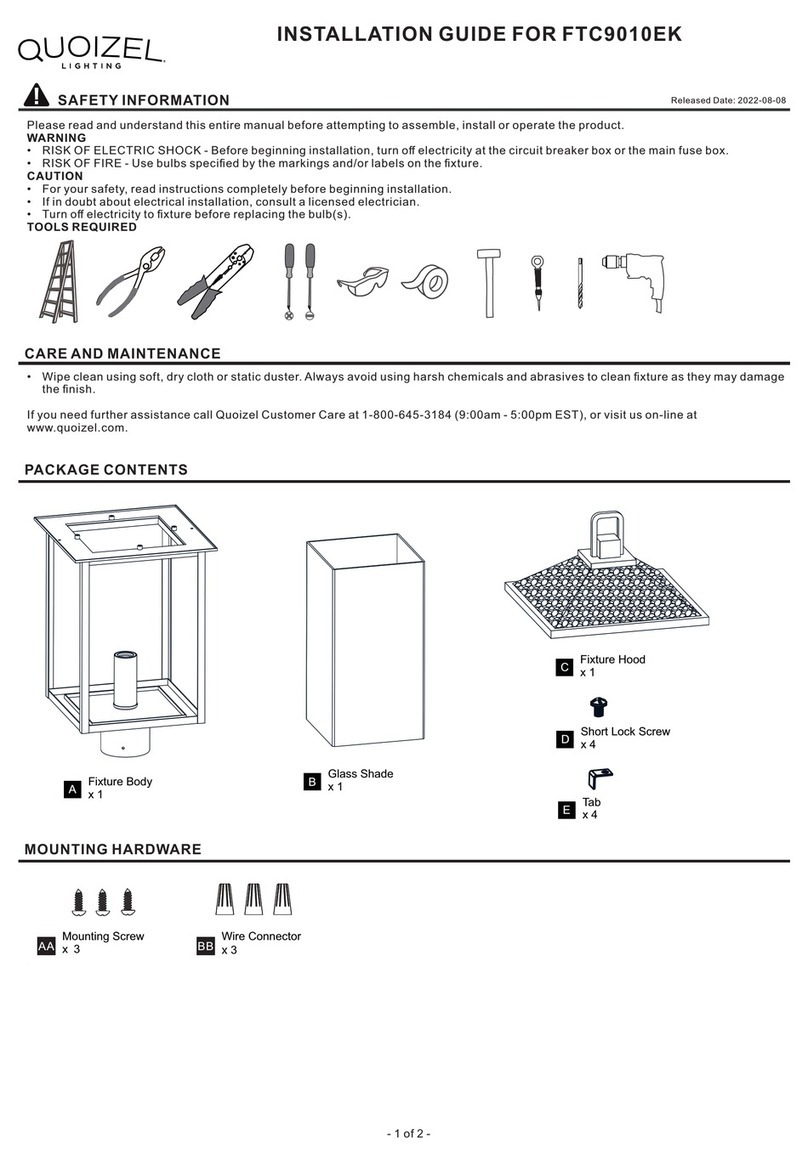

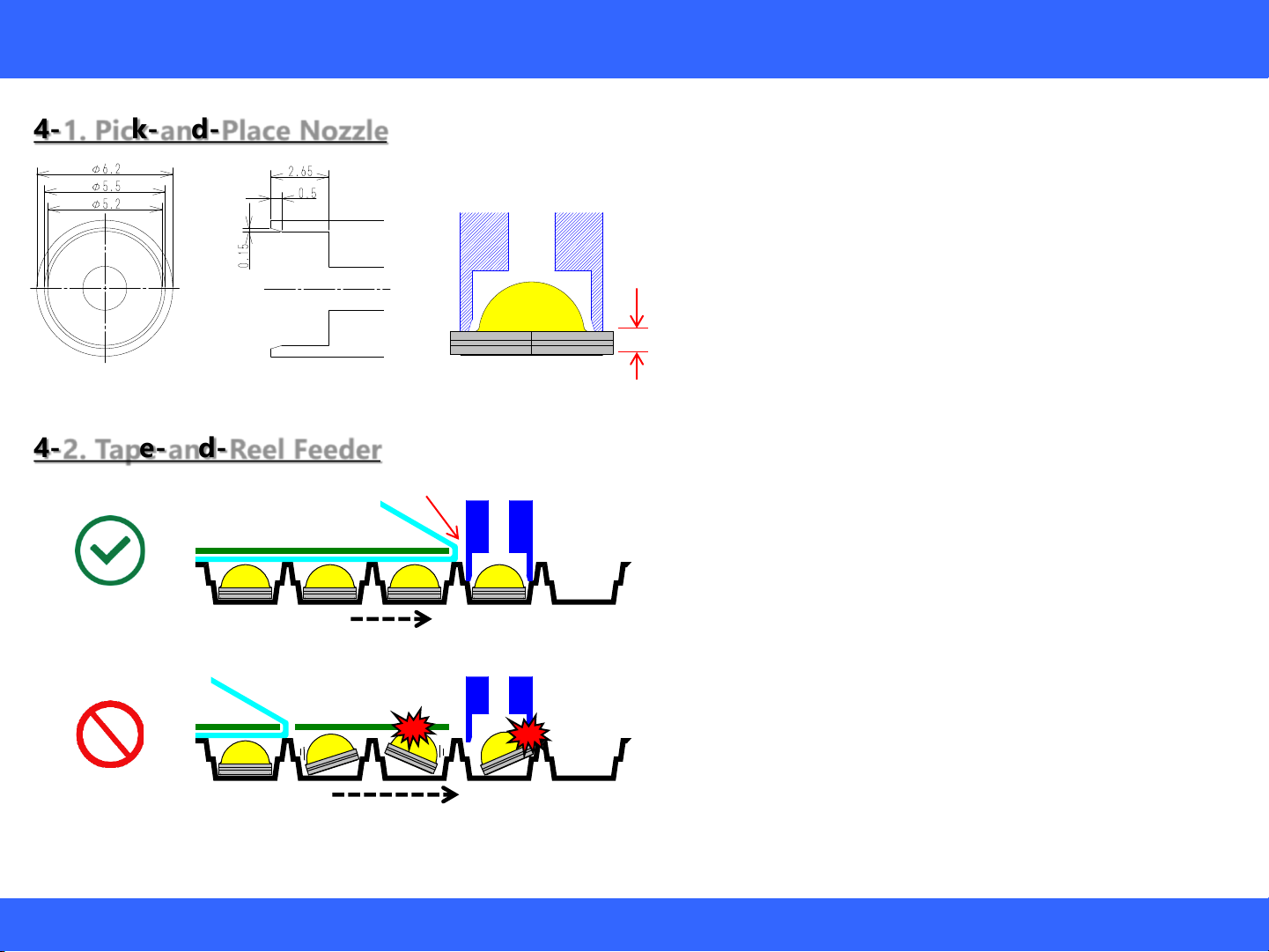

4-2. Tape-and-Reel Feeder

4-1. Pick-and-Place Nozzle

[Unit: mm]

Figure 3. Recommended Nozzle

Dimensions

Figure 4. part Height

Correct

Incorrect

Figure 5. Examples of Correct/Incorrect Top Cover Tape Removal Positions

1.0mm

•The nozzle must not have any direct contact with

the encapsulating resin.

•The nozzle touches on the top of LED substrate.

(see Fig. 4)

Therefore input value of the Part Height should

be 1.0mm.

•Tape width:16mm / Feed length:12mm

•The chosen tape feeder should be one that has a

slower feeding speed (e.g. electrical feeders).

•The recommended tape removal position is right

next to where the pick-and-place nozzle picks up

the LEDs to prevent the LEDs from tilting within the

tape pocket and becoming damaged by the feeder

shutter and/or nozzle.

Tape Removal Position

Slower feeding speed = Less vibration

LED position stays stable.

Faster feeding speed = More vibration

LED tilts within the tape pocket.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

7/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

4-4. Recommended Nozzle Height for Placement

Operations (Placement Depth)

4-3. Recommended Nozzle Height for

Pick-up Operations

Figure 6. Recommended Nozzle Height for Pick-up Operations

Figure 7. Recommended Nozzle Height for Placement (Placement Depth)

Pickup Point

1.7mm from

the top of the

carrier tape

Pick-and-Place

Nozzle

Carrier Tape

Press

0.2[mm]

PCB

Pick-and-Place

Nozzle

•After the LED is mounted onto solder paste on the PCB,

the nozzle should further press the LED 0.2mm into the

PCB.

•Pick-and-place nozzle should be 1.7mm inside from the top of

carrier tape to pick up the LED. (see Fig. 6)

•Some LED mounters may not be stabilize the operation. In

that case, adjusting the height for LED pickup is needed until

the operation is stabilized.

☞If the pickup point is higher than the recommended

point, the LED may tilt, and poor suction may occur

which will cause a suction error.(e.g. diagonal

positioning within the nozzle)

☞If the pickup point is lower than the recommended

point, poor suction may occur due to carrier tape

deformation.

☞If the press force is too weak, assembly failure may

occur since the LED may float on top of the PCB or it

may not separate from the nozzle.

☞If press force is too strong, LED may receive

excessive stress which may cause the LED to be

damaged.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

8/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

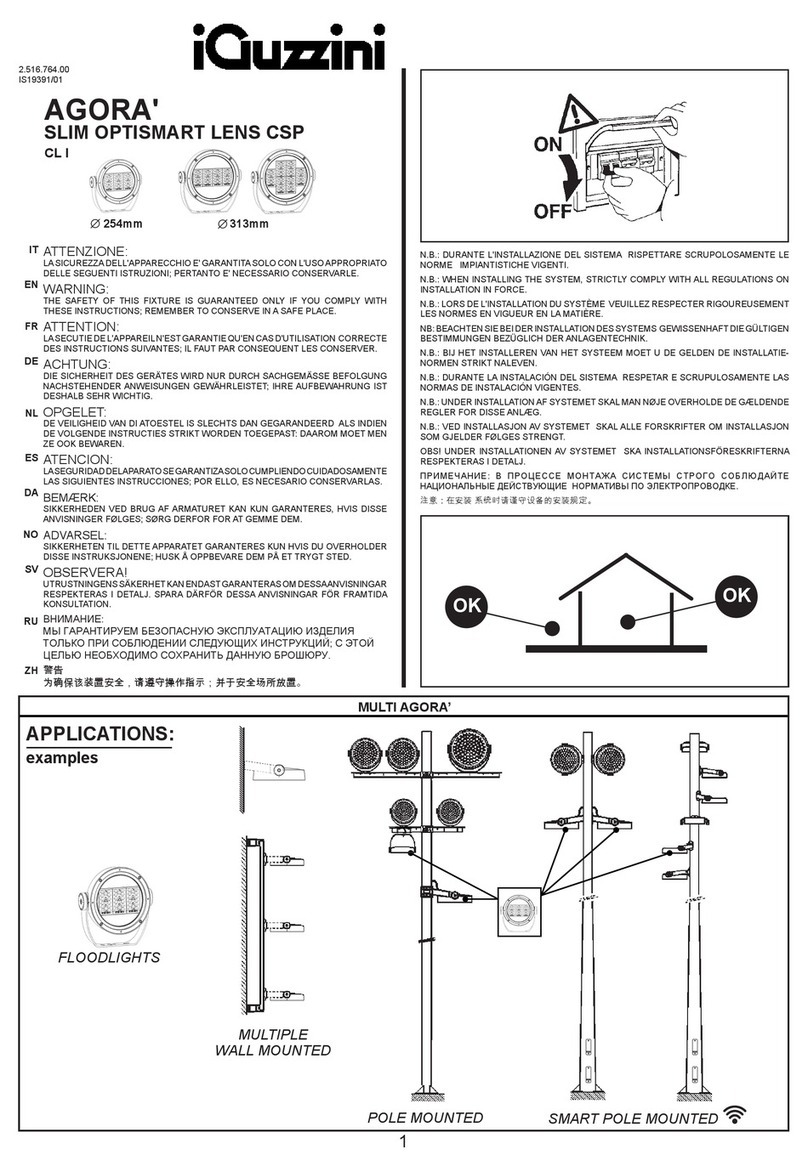

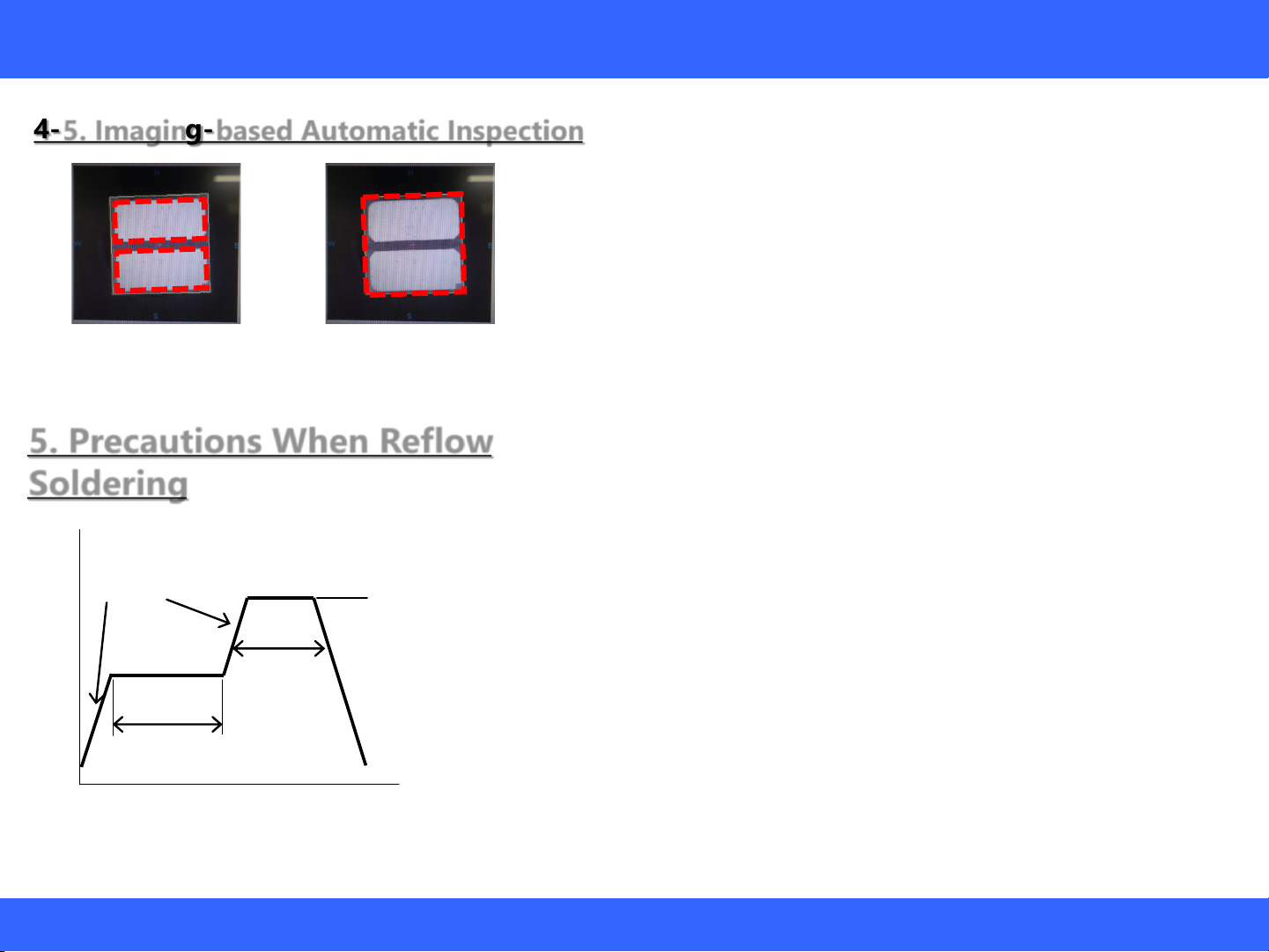

4-5. Imaging-based Automatic Inspection

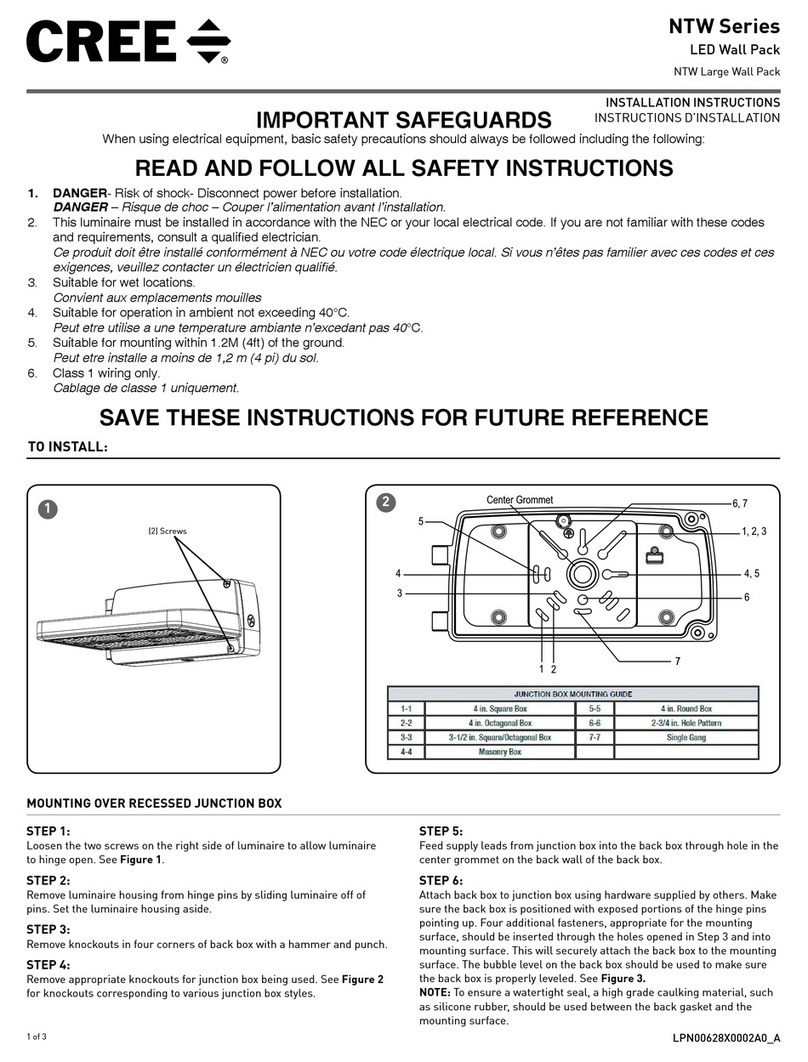

5. Precautions When Reflow

Soldering

Figure 8. Electrical Pads

(Recommended)

Figure 10. Recommended Reflow Soldering

Condition (Lead-free Solder)

120sec Max

Pre-heat

180 to 200°C

260°CMax

10sec Max

60sec Max

Above 220°C

1 to 5°C per sec

•Reflow soldering must not be performed more than twice.

•Using the recommended reflow soldering conditions (See Figure 10 to

the left) as a reference, modify if necessary, the recommended reflow

conditions specified by the manufacturer of the solder paste being used.

Note:

To ensure that these reflow conditions have no negative effect on the

LEDs, perform sufficient verification prior to use.

•When cooling the LEDs from the peak temperature a gradual cooling

slope is recommended; do not cool the LEDs rapidly.

•During reflow soldering, the heat and atmosphere in the reflow oven may

cause the optical characteristics to degrade. In particular, reflow soldering

performed with an air atmosphere may have a greater negative effect on

the optical characteristics than if a nitrogen atmosphere is used; Nichia

recommends using a nitrogen reflow atmosphere.

•Using image recognition and adjusting the pickup

position for each LED should be implemented to

maintain assembly accuracy. It is recommended to

have the adjustment based on the position of the

electrical pads for higher assembly accuracy.

Figure 9. Outline

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

9/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

6. Evaluation of the Effect of Solder Volume

The amount of solder paste was evaluated and compared with the recommended solder stencil conditions (section3).

Lighting, wettability, solder ball and floating were inspected after the reflow process.

Table 6. Evaluation Result(Lighting Check, Solder Wettability, Solder Ball)

Stencil

Aperture Rate

※Stencil Aperture Area

/Electrode Area

30% 50% (Recommend) 70%

Stencil Thickness

100μm

Lighting check

OK Lighting check

OK Lighting check

OK

Solder Ball

0/24 pcs Solder Ball

0/24 pcs Solder Ball

0/24 pcs

120μm

(Recommend)

Lighting check

OK Lighting check

OK Lighting check

OK

Solder Ball

0/24 pcs Solder Ball

0/24 pcs Solder Ball

2/24 pcs

150μm

Lighting check

OK Lighting check

OK Lighting check

OK

Solder Ball

0/24 pcs Solder Ball

2/24 pcs Solder Ball

6/24 pcs

•Solder wettability performance was good enough to light the LED in all conditions. However,

solder ball occurrence was increased if solder paste volume (area, thickness) is increased.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

10/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

•Amount of tilt (avg.): 60μm

Angle of incline: around 0.7 degree

Solder volume does not affect to the amount of

tilt and angle of incline.

Figure 11. Evaluation Result (LED Lifting)

※n=24pcs/each condition

Max.

Figure 12. How to Measure the Amount of LED Tilt

Min.

0

20

40

60

80

100

120

140

Amount of Floating [μm]

100μm 120μm 150μm

Stencil Thickness

Aperture Rate:

30%

Aperture Rate:

50%

Aperture Rate:

70%

Average

①x:+0.2mm

y:+0.2mm ② θ:+10°

Table 7. Evaluate Conditions

+Pad pattern Position

+Mounted Position

7. Evaluation of Self-

Alignment Performance

Self-alignment was evaluated under the condition

shown in table 7 with the solder conditions shown

in section 6.

Amount of self-alignment was confirmed from

center of the land pattern.

Amount of LED Tilt (mm) = max. –min.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

11/12 SP-QR-C2-210575-1

Jul. 9, 2021

Assembly Precautions for the Nichia 144 Series LEDs

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

-0.3 -0.2 -0.1 0 0.1 0.2 0.3

⊿y [mm]

⊿x [mm]

Stencil Thickness:100μm

Aperture Rate:30%

Aperture Rate:50%

Aperture Rate:70%

Mount Position

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

-0.3 -0.2 -0.1 0 0.1 0.2 0.3

⊿y [mm]

⊿x [mm]

Stencil Thickness:120μm

Aperture Rate:30%

Aperture Rate:50%

Aperture Rate:70%

Mount Position

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

-0.3 -0.2 -0.1 0 0.1 0.2 0.3

⊿y [mm]

⊿x [mm]

Stencil Thickness:150μm

Aperture Rate:30%

Aperture Rate:50%

Aperture Rate:70%

Mount Position

•Aperture ratio: 50%, stencil thickness: 120μm

(Recommended conditions)

•No abnormality in the self-alignment

•Self-alignment could be acceptable if the mounting

accuracy are x,y <200μm and θ<10o.

•Aperture ratio: 30%, stencil thickness: 100μm

•Some LEDs have issue for the self-alignment.

•If the solder volume is poor, LED may not be mounted

to the proper position that causes misalignment of

LED.

Figure 13. Evaluation Result (①x:+0.2mm,y:+0.2mm)

※n=24pcs/condition

Figure 14. Evaluation Result (② θ:+10°)

※n=24pcs/each condition

-0.8

-0.4

0.0

0.4

0.8

1.2

1.6

2.0

Angle[°]

100μm 120μm 150μm

Stencil Thickness

Mount Angle:10°

Aperture Rate:30%

Aperture Rate:50%

Aperture Rate:70%

Average

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

12/12 SP-QR-C2-210575-1

Jul. 9, 2021

Disclaimer

This application note is a controlled document of Nichia Corporation (Nichia) published to provide technical information/data for

reference purposes only. By using this application note, the user agrees to the following:

•This application note has been prepared solely for reference on the subject matters incorporated within it and Nichia makes no

guarantee that customers will see the same results for their chosen application.

•The information/data contained herein are only typical examples of performances and/or applications for the product. Nichia

does not provide any guarantees or grant any license under or immunity from any intellectual property rights or other rights

held by Nichia or third parties.

•Nichia makes no representation or warranty, express or implied, as to the accuracy, completeness or usefulness of any

information contained herein. In addition, Nichia shall not be liable for any damages or losses arising out of exploiting, using,

or downloading or otherwise this document, or any other acts associated with this document.

•The content of this application note may be changed without any prior or subsequent notice.

•Copyrights and all other rights regarding the content of this document are reserved by Nichia or the right holders who have

permitted Nichia to use the content. Without prior written consent of Nichia, republication, reproduction, and/or redistribution

of the content of this document in any form or by any means, whether in whole or in part, including modifications or derivative

works hereof, is strictly prohibited.

NICHIA CORPORATION

491 Oka, Kaminaka-Cho, Anan-Shi,

TOKUSHIMA 774-8601, JAPAN

Phone: +81-884-22-2311 Fax: +81-884-21-0148

http://www.nichia.co.jp

Assembly Precautions for the Nichia 144 Series LEDs

This manual suits for next models

4

Table of contents

Popular Outdoor Light manuals by other brands

pdlux

pdlux PD-PIR69 instructions

Maximus

Maximus Smart Security Light instruction manual

Cree

Cree NTW Series installation instructions

CristalRecord

CristalRecord NASSIRA 60W quick start guide

Tamlite

Tamlite CITY RL Installation & operating instructions

Clarke

Clarke SAL100B Assembly & operating instructions