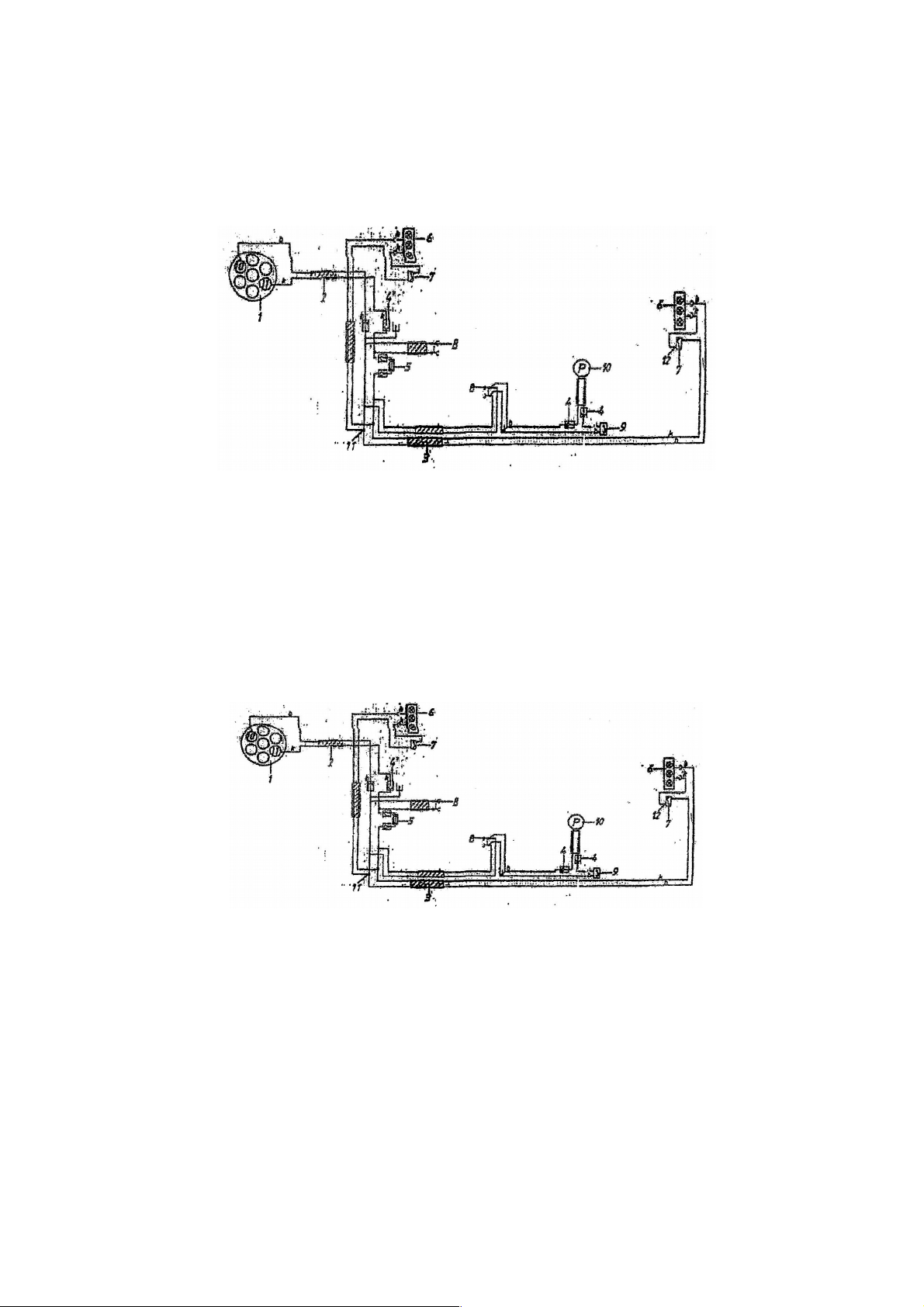

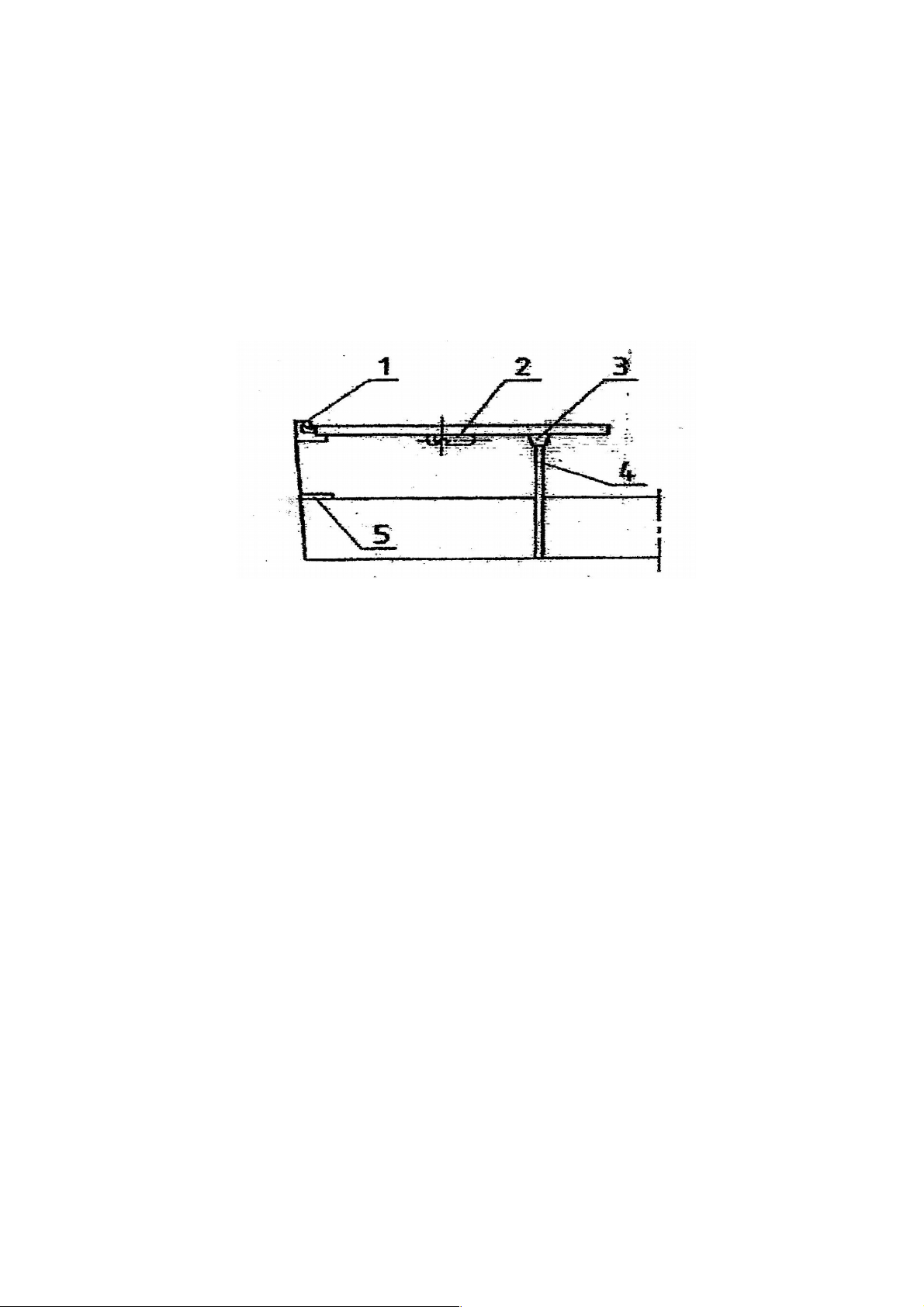

Figure 7 : Diagram of the wiring system 220 V AC.

3.6. Gas s stem

Built-in coo er plate is designed for gas propane or butane under pressure range of 3000-4000 N/m².

Depending on a gassytem, the coo er plate can be equipped with distribution valve for a cooling box

connection. The distribution valve, if exists, is located inside the itchen cupboard. The caravan

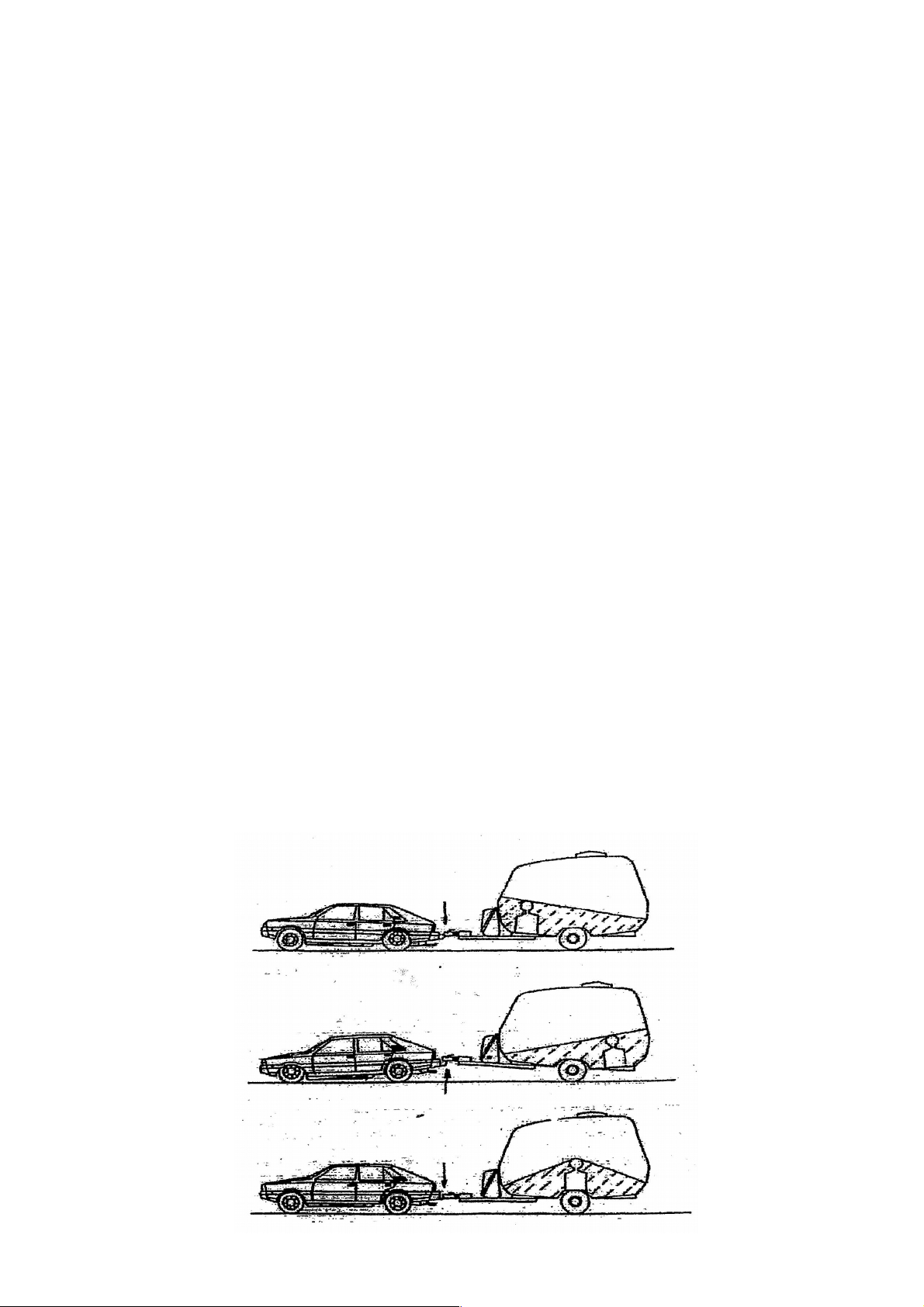

should be equipped with a gas bottle and its pressure reducing valve, suitable to gas pressure of used

coo er. The gas bottle compartment is suitable for two bottles each with a capacity of 2 or 5 ilograms

of gas.

In order to properly using the gas system, carry out following activities :

– screw on the pressure reducing valve on the gas bottle, until the fassteningnut reaches its properly

tightness

– put on the bottle into its compartment

– safe the bottle against suddenly and unnecessary movements in the compartment, using clamps and

flexible fastenings-belts

– put on the flexible hose on the nipple of the reducing valve and fit it with a clamping-ring

– open the valve of the bottle, the distribution valve, if any, choose the gas stream towards the coo er

– ignite the burner, it should be burn with a blue-violet coloured flame and a distinct core

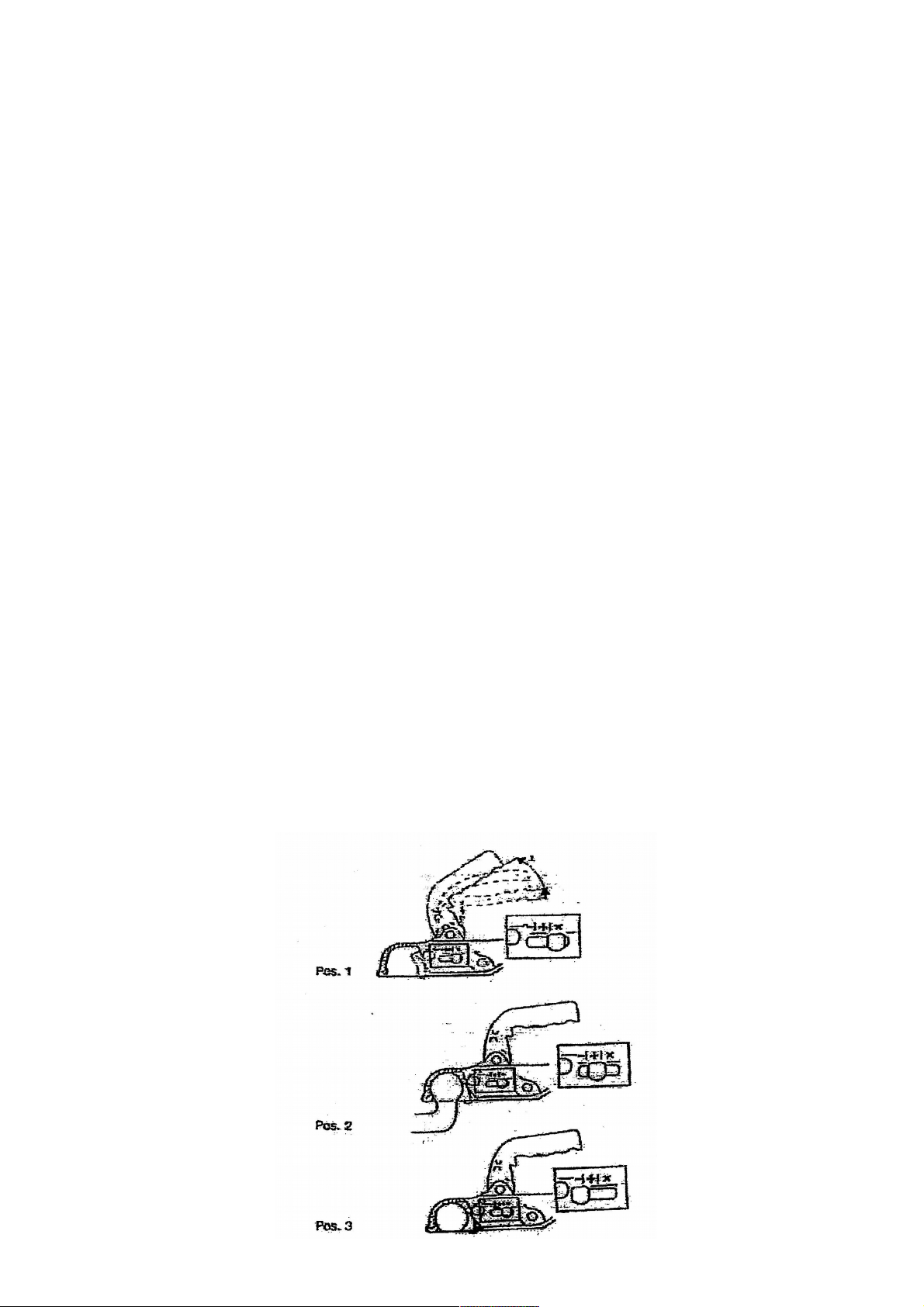

If coo er is equipped with a flame safety device, carry out following activities :

– press the setting hand-wheel and turn it on the maximal flame position

– ignite the burner until to the maximal flame

– hold the hand-wheel pressed for 15 seconds

– set require flame intensity

– try again, when flame has extinguished.

Chec condition of the rubber hose regular and change it if the hose is damaged.

Notice that properly use of the coo er as well as reliable and properly condition of entire gas system

is effecting directly in safety use of the entire caravan.

Thus, on this reason, following is forbidden strictly :

– connecting any gas fed equipment without the gas pressure reducing valve to the bottle directly

– to use any lea y gas fed equipment for lea y gas distribution system

– opening the feeding valve of the cooling box when the box is lea y or opened

– mending or lingering on the gas distribution system or on the gas fed equipment to repair it yourself

– heating with the coo er flame the caravan living space

– to use the coo er by closed vent holes or bloc ed vent system of the caravan living space

– exchange burner nozzles yourself

– to use movable heaters fed on gas

In case of fire : – evacuate all persons out of the caravan

– close the main valve of the bottle and remove it out of the caravan

– fight the fire using the board extinguisher (available as a car obligatory equipment)

– call the fire brigade

Suitable for this caravan purpose is the universal powder extinguisher.