Nikota 01244 User manual

Item No.01244

Owner's Manual

Rotary

Tool W!Flex.

Shaft

Dutil

Rotatif

W/

Arbre

Flexible

Herramienta

Rotatoria

W/Eje Flexible

Points for Safe Attention

Caution: When the machine

is

operated, the following basic safety measures should

be observed to prevent from electric shock, damage and fire.

Children beyond Multifunctional Tool

Do not let the persons, especially for children, reach the tool or electric wire and far

away from the operation site.

Protection from

Electric

Shock

Avoid contacting with grounding parts, such as pipe, electric warmer, electric stove,

refrigerator.

Attention to

Environment

Do not let the tool

be

rained.

Don't

use the tool under the condition

of

humidity.

It

is necessary for operation site to have the adequate light.

Don't

operate the tool

near the place storing the flammable liquid and combustible gas, or the place

storing the explosive materials, for example, near the garage.

PUtting

on

Jumper

Do not carry far clothes or decoration. They can be tangled

by

mobile parts. If

working in the open air, the rubber gloves and skid-proof footwear are

recommendable. Bind your plait shed together or carry a hair net.

Putting

on Glass

and

Face Shield

It is necessary for you to put on the glass and the face shield

in

the dust

environment.

Putting

on

Ear

Shield

If

you work in the heavy noise, it is necessary to put on the ear shield to protect

your

ear.

Keeping Your Body in Stability

Stand on steadily and keep your body

in

balance in any time. Don't climb the

ladder not fastened against the wall. Don't work standing on the chair or similar

matter.

Keeping Site Clean

The disordering working site has the potential

of

hidden danger.

Marking

Location

of

Hidden

Pipe

and

Wire

The electric wire, water pipeline and gas pipe are mounted inside

of

wall. At first,

the location

of

them should be marked.

Using

Correct

Tools

Do not use the improper tools for operation.

Avoid Unintentional

Starting

the Machine

Do not carry tools with the finger at the switch, attached

to

electricity mains. Make

sure that the switch

is

switched

off

to electricity mains with the connection.

Pull the

Power

Supply Plug from the Plug Socket

Pull the power supply plug with non-usage, before the cleaning or maintenance and

before a tool change,

for

example, replacing driller or sharpening grounding rod.

Preventing

Power

Wire

from Damage

When you carry the machine, do not pull the connecting cable and

do

not pull out

the plug from socket. Prevent the power from heating, oiling or contacting with

sharp edges.

Extension

Cable

Line

The extension cable line with the qualified and undamaged indication can

be

used

When you purchase the extension cable line, it

is

necessary to consult with the

related attentions.

You

Are Always Attentive

Observe its work. Advance rationally.

Do

not use the tool ifyou are unknown

for

the work.

Do not let other persons operate the machine or connect line, hold it

of

the field

of

work away.

Ensure

Workpiece in Stability

Use chip devices or a screw cane in order

to

hold the workpiece

Little

Pressure

You

do

not use

in

the use

of

the multifunctional tools to high pressure; bit

it

and

disks ability broken. Use only clean and sharp accessories parts.

No

Overload for Tool

They work better and more certainly

in

the indicated achievement area.

Maintain its Tools with

Care

Hold its tools sharply and cleanly

in

order to work well and certainly. Follow the

maintenance directions and the references for tool change.

Store its Tool Certainly

Store unused tools in a dry room. They must be inaccessible for children.

Control its Device on Damages

Control your the device before each utilize on damages. Device or connection

line damages should show, the device may

be

used no longer until these were

removed regular. All parts correctly must be mounted in order to guarantee the

flawless business

of

the device.

III

Repairs

Only for

an

Electric Specialist

Do not take apart the device. Through improper repairs, considerable dangers can

emerge for the user. Repair work and restoration work may be carried out only

by

authorized specialist staff.

We

recommend you

to

address ourselves as required

to

l.

our service center.

~

t1

Caution!

The use

of

other as the accessories part recommended

in

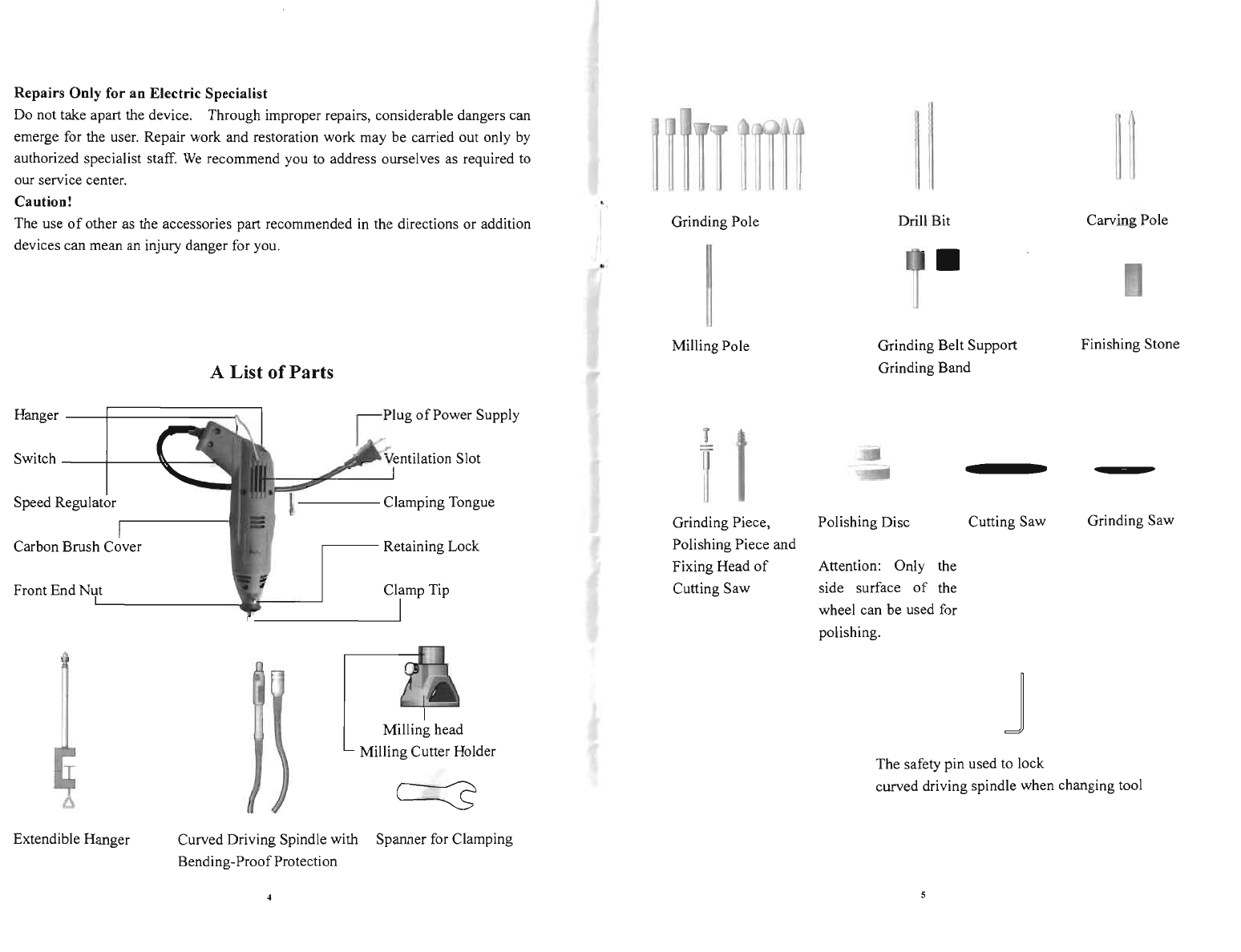

the directions or addition Grinding Pole Drill Bit Carving Pole

devices can mean an injury danger for you. •

Milling Pole Grinding Belt Support Finishing Stone

Grinding Band

A List of

Parts

Hanger

I\.

1

...

. : lug

of

Power Supply i

v

Switch

'k

Speed Regulator

-----

Clamping Tongue Grinding Piece, Polishing Disc Cutting Saw Grinding Saw

Carbon Brush Cover

r----

Retaining Lock Polishing Piece and

Fixing Head

of

Attention: Only the

Front End N Clamp Tip Cutting Saw side surface

of

the

I wheel can be used for

polishing. J

Milling head

Milling Cutter Holder The safety pin used to lock

curved driving spindle when changing tool

c==::s

Extendible Hanger Curved Driving Spindle with Spanner for Clamping

Bending-ProofProtection

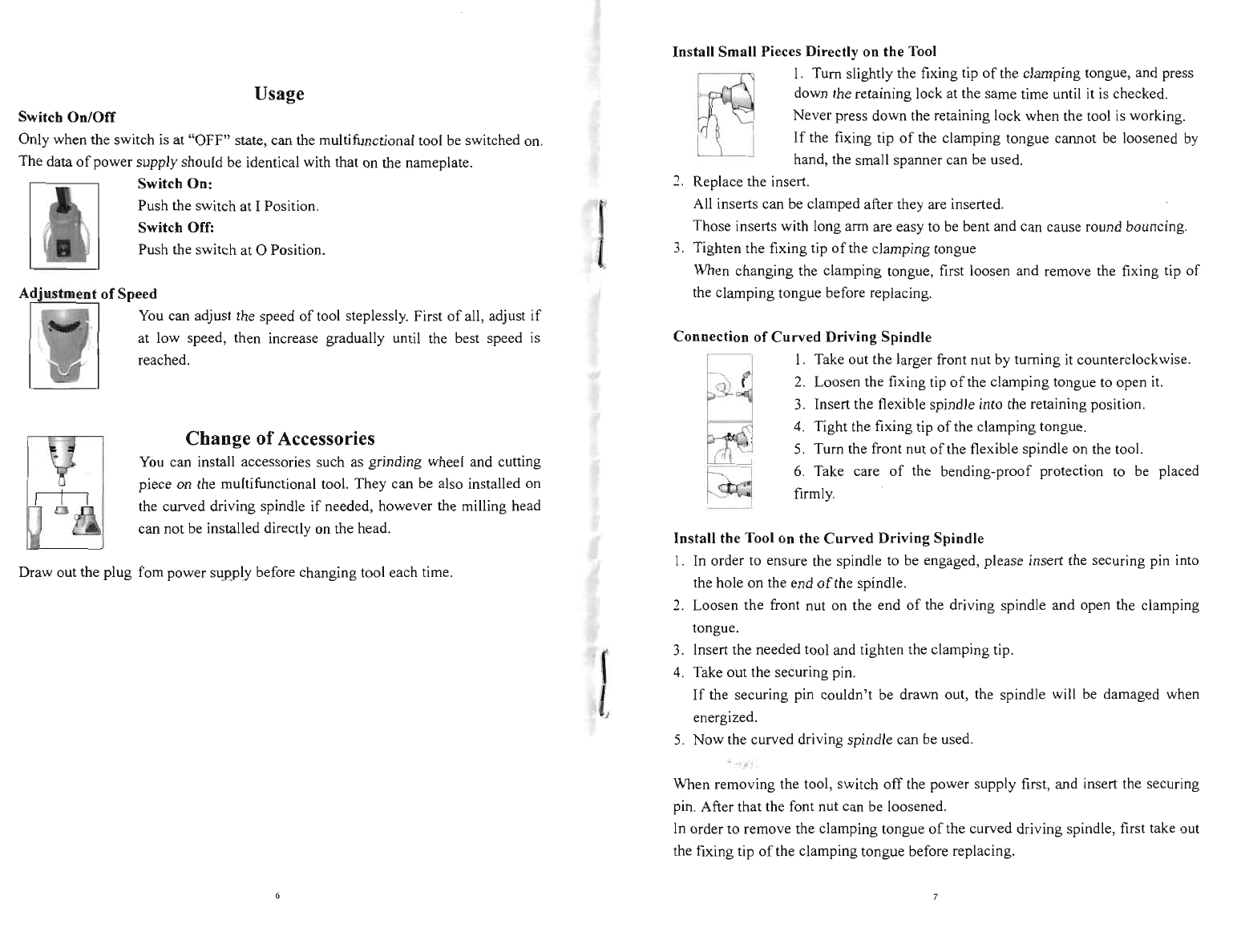

Usage

Switch

On/Off

Only when the switch is at "OFF" state, can the multifunctional tool be switched on.

The data

of

power supply should be identical with that on the nameplate.

i Switch

On:

Push the switch at I Position.

Switch Off:

Push the switch at 0 Position.

Adjustment

of

Speed

0.

You

can adjust the speed

of

tool steplessly. First

of

all, adjust

if

} at low speed, then increase gradually until the best speed

is

, I

~

reached.

Change

of

Accessories

You

can install accessories such as grinding wheel and cutting

piece on the multifunctional tool. They can be also installed on

the curved driving spindle

if

needed, however the milling head

can not

be

installed directly on the head.

Draw out the plug fom power supply before changing tool each time.

Install Small Pieces Directly on the Tool

I. Turn slightly the fixing tip

of

the clamping tongue, and press

down the retaining lock at the same time until

it

is

checked.

Never press down the retaining lock when the tool is working.

If

the fixing tip

of

the clamping tongue calIDot be loosened

by

hand, the small spanner can be used.

..,

Replace the insert.

All inserts can be clamped after they are

in

serted.

Those inserts with long arm are easy to

be

bent and can cause round bouncing.

3.

Tighten the fixing tip

of

the clamping tongue

When changing the clamping tongue, first loosen and remove the fixing tip

of

the clamping tongue before replacing.

Connection

of

Curved

Driving Spindle

I. Take out the larger front nut by turning

it

counterclockwise.

2.

Loosen the fixing tip

of

the clamping tongue to open

it.

3.

Insert the flexible spindle into the retaining position.

4.

Tight the fixing tip

of

the clamping tongue.

5. Turn the front nut

of

the flexible spindle on the tool.

6.

Take care

of

the bending-proof protection to be placed

~

firmly.

Install the Tool on the

Curved

Driving Spindle

1. In order

to

ensure the spindle to be engaged, please insert the securing pin into

the hole on the end

of

the spindle.

2. Loosen the front nut on the end

of

the driving spindle and open the clamping

tongue.

3.

Insert the needed tool and tighten the clamping tip.

I

4.

Take out the securing pin.

If

the securing pin couldn't be drawn out, the spindle will be damaged when

energized.

5.

Now

the curved driving spindle can be used.

When removing the tool, switch

off

the power supply first, and insert the securing

pin. After that the font nut can be loosened.

In

order to remove the clamping tongue

of

the curved driving spindle, first take out

the fixing tip

of

the clamping tongue before replacing.

Connection

of

the Milling

Cutter

Holder

I. Tum the front nut counterclockwise and take it out.

2.

Loosen the fixing tip

of

the clamping tongue to open

it.

3.

Replace with needed tool and all tools should

be

clamped.

4.

Tighten the fixing tip

of

the clamping tongue.

5.

Insert the milling cutter into the fixing holder and tighten

it.

6.

Tighten screws at both sides on the tool.

Operation

Points for Attention in

Operation

Do not process working pieces with asbestos to avoid harm upon bodies.

Always take care

of

good ventilation and the density

of

dust

in

air, interrupt process

if

needed.

Please wear goggles, dust mask and body cover.

If

there are electrical wires and pipes

of

water and gas

in

wall, first find them by

pipe/wire finder and mark the positions

of

wires and pipes.

Please check plugs and connecting wires regularly,

if

damage

is

found, please make

renewal via our after-sale service center.

Please check extended cables (socket panel), and make replacement

if

damaged.

Your

hand holding the tool should

be

dry without oil and grease.

Curved

Driving Spindle

The curved driving spindle

is

specially suitable for the part

of

working piece where

is

hardly accessible, and the precision operation for sensitive materials.

If

possible, hang the curved driving spindle on the extendible fixing hanger.

Attention: In order to avoid damage

of

the spindle,

do

not over

.

..

..

i

10

I bend the driving spindle.

/

·n·

"---/

Extendible Fixed

Hanger

If

connecting the multifunctional tool with the curved driving

spindle, you can hang the tool on the extendible fixed hanger,

thus the working range can

be

freer and vibration could not

be

transmitted from the tool to the working table.

• The multifunctional tool can

be

fixed and hanged.

The adjustable height from 200

mm

to 500 mm.

• The maximum thickness

of

the fixed working table 60 mm.

•

• The hanger can rotate

in

3600

By fixing screws at downside, you can

fix

the extendible fixed hanger on the edge

of

the working table. In order to ensure firm connection between the tool and the

hanger, take care

of

its fixation.

Tum the extendible pole clockwise you can lock the height. Tum

it

counterclockwise, the extendible pole can

be

loosened.

Points for Attention in Processing

•

If

working speed

is

higher and the pressure exerted on the accessories

of

the tool

is

larger, the accessories will

be

broken.

So

exert less pressure when processing

to

save your mighty and to protect the tool and the accessories.

• Please adopt good and clean accessory.

• Following points should

be

taken care when working:

The speed used to process metal should

be

lower than that used for hard timber.

The low speed should

be

adopted to process plastics to avoid damage upon

it.

Rise up the speed

if

vibration occurs.

• The low speed should be adopted when the polishing accessory and the grinding

wheel are used.

• The high speed should

be

adopted when the wire or bristle brush

is

used.

• Hold the tool firmly

by

both hands as can as possible.

•

If

speed lowers much when processing, it means the pressure you exert

is

too

larger.

• Dirt or blunt accessories can reduce efficiency.

If

you feel you larger pressure

should be exerted,

it

means the accessories should be cleaned or replaced.

Milling Device

Adopting the milling device, you can process holes on ceramics, porcelain tile or

porcelain wares easily.

\

...

I I The depth

of

milling can

be

adjusted

by

loosening screws first

and tightening them at the required depth. Here the graduation

is

only used for positioning.

Of

course you can install other tool such

as

the drill bit on the

milling device to drill the hole with certain depth.

Grinding

Pole The field to

be

used: sharpening, deburring, rust-removing and

shaping.

Points for attention: clean and finish the shape

of

the grinding

Hnmn

pole

by

finishing stone.

Carving

Pole

The field to

be

used: make fine carving on different materials.

Points for attention:

o The speed used to process metal should be lower than that

[[J used for hard timber.

o The lowest speed should

be

adopted to process plastics to

avoid damage upon

it.

o Adopt higher speed can avoid vibration.

OJ

Milling

Cutter

The field to be used: open groove or hole on smooth surface.

-I

Cutting

Round

Saw

The field to be used: open groove or cut on pin, screw, lamina

or sheet

of

timber or plastics.

The diameter

of

the saw

is

less than 50

mm.

Grinding

Band

/

Grinding

Saw

I

~

Th'

fi'ld to

b,

""d,

odnd'no, ,mooth'no

",d

,hap'no

of

timber and glass fiber.

Points

for

attention: adopt grinding band/grinding saw with

rougher sizes at the beginning and that with finest sizes at the

end.

Finishing Stone

rn

The field to

be

used: cleaning and shaping

of

grinding

saw.

Polishing Disc The field to be used: polishing

of

metal and plastics.

Points for attention: when polishing, only the side surface

of

the disc can

be

used, otherwise the working piece could be

Ir

;!.

1

10

damaged

by

screws.

Maintenance

Please keep smooth and clean

of

the ventilation slot

of

the tool. When cleaning, use

soft brush and wet cloth, and corrosive liquid could not

be

used.

Never immerse the tool into water and liquid.

Replacement

of

Carbon

Brush

The tool has installed two carbon brushes.

If

the creep occurs

on

the motor or the motor does not turn,

it

means the carbon

brushes are ineffective. Please replace both two carbon brushes.

Open the round cover by a small screwdriver.

Replace the old carbon brushes with new ones.

Retighten the cover.

You

can obtain new carbon brushes from

NIKOT

A

service center and you can find its address and telephone

number

in

my

warranty card.

Technical

Data

Voltage: 120V

-60Hz

Power Consumption: I30W

Speed Range: 8,000/min -30,000/min

Average Noise: LP =82.8 db(A)

Noise Intensity:

LW

= 95.8 db(A)

Vibration Speed: 2.1m/s2 under the load

of

6.9 m/s2•

We

reserve right

to

make technical alteration during the period

of

improvement

of

product.

1/

Any

implied

warranty,

including

the

implied

warranties

of

"merchantability"

and

"fitness

for

a specific

purpose"

,will last only

one

year

from

the

date

of

purchase.

Under

no

circumstances

shall

Nikota

Tools

be

liable

for

any

indirect,

incidental

or

consequential

damages

from

the

sale

or

use

of

the

product.

Some states do not allow the exclusion

or limilation

of

incidental

or

consequential damages, so the above limitation

or

exclusion may not

apply to you. Some states do not allow limitation on how long an implied warranty lasts, so the above

limitation may not apply

to

you.

This warranty gives you specific legal rights and you may also have other rights which

van

from

slate

10

state.

Electric

Tool

90-Day

limited warranty for

commercial

and renlal purpose.

For more information,please call toll free number: 1·87(-4-NIKOTA.

IMPORTANT:please

request

RGA

number

before

you return the defective. Au

non-NIKOTA

products are

nOI

warranted.

PLACE

STAMP

HERE

NIKOTA

TOOLS

Product

Registration Dept.

P.O.Box 7340

~

Alhambra,

CA 91802-7340 \'Sf

U.S.A

No.

Important! please fill out

and

return within the

next7

days to

facilitate warranty claims.

0 _________________________________

NAME

:

LAST

FIRST

MIDDLE

ADDRESS

•

COUNTRY

MODEL

NO.

SERIAL

NO.

DAY

OF

PURCHASE: MID/Y

NAME

OF

RETAILER

ADDRESS

OF

RETAILER

.Which

factor(s) most inOuenced your decision to purchase

this Nikota Tool? (check up to 3)

I.

0 Nikota reputation

8.

0 Appearance/Design

2.

0 Unique features

9·0

Price

3. 0

friend's

recommendation

10.

0 Received as a

gUt

4.

0 Warranty

II.

0 Salesperson's recommendation

5.0

Quality

12.0

Previous usage

6.

0 Durability

7.0

Other

e Where will this Nikota tools be primarily used?

o

At

home

by

a hobbist

o

At

home

by

a do-it-yourselfer

o Professional

.Which

of

the following A)

Nikota

brand tools

do

you

own,

H)

other

brand

tools

do

you

own,

and

C)

tools

do

you

plan

to

buy

in the

next

12

Months?

(check

all that

apply)

A)Nikota

B)ather

brand C)plan

to

Purchase

I.

Circular

saw

I.

0

I.

0

I.

0

2.

Corded

drill

2.0 2.0

2.0

3.

Cordless

drill

3.0

3. 0

3·0

4.

Cordless

Circular

saw

4·0

4·0

4·0

5.

Rotary

tool

5.0

5·0

5·0

6.

Rotary

hammer

6.0 6.0

6·0

7.

Heat

gun

7·0 7.0 7.0

8.

Polisher

8·0

8·0

8.0

9.

Angle

grinder

9·0

9.0

9.0

10.

Jig

saw

10.0

10. 0

10.0

I I.

Orbital

sander

11. 0 11. 0

II.

0

12.

Hammer

drill

12·0

12·0 12·0

13.

Reciprocating

saw

13.0

13. 0 13. 0

14.

Other

14·0 14.0 14.0

15.

None

of

the

above

15

. 0

15.0 15·0

Thank

you

for

taking

the

time

to

fill

out

this

warranty

card.

Please

affix

sufficient

postage

and

return this

card

10 us.

NIKOTA

TOOLS

LIMITED

ONE

YEAR

WARRANTY

Nikota Tools warrants its Power Tools to

be

free

of

defects from workmanship

and materials for a period of one year from the date

of

original purchase.

We

will repair or replace at ouroption, any product covered under this warranly

which, after inspection, shows to be defective

in

workmanship or ma,pr:al

during the

~

warranty period. For repair or replacement. rCI"rn the

complete tool with warranty card

or

purchase receipt. freight prepaid, 10

Nikota Tools. This warranty does not apply where:

• the tool has been misused,abused or improperly maintained

• repairs are required due to normal wear and tear

• repairs have been attempted

or

made by

others

• alterations have been made 10 the 1001

• commerical and rental application

to be continued

~

Table of contents

Other Nikota Power Tools manuals