primatech P260 User manual

Revision 12/10 Printed inCanada

PNEUMATICFLOORINGSTAPLER

P260

OPERATINGINSTRUCTIONS

WARNING

Read theseinstructionsthoroughlybeforeusingthistooland keep it

handyforreference.

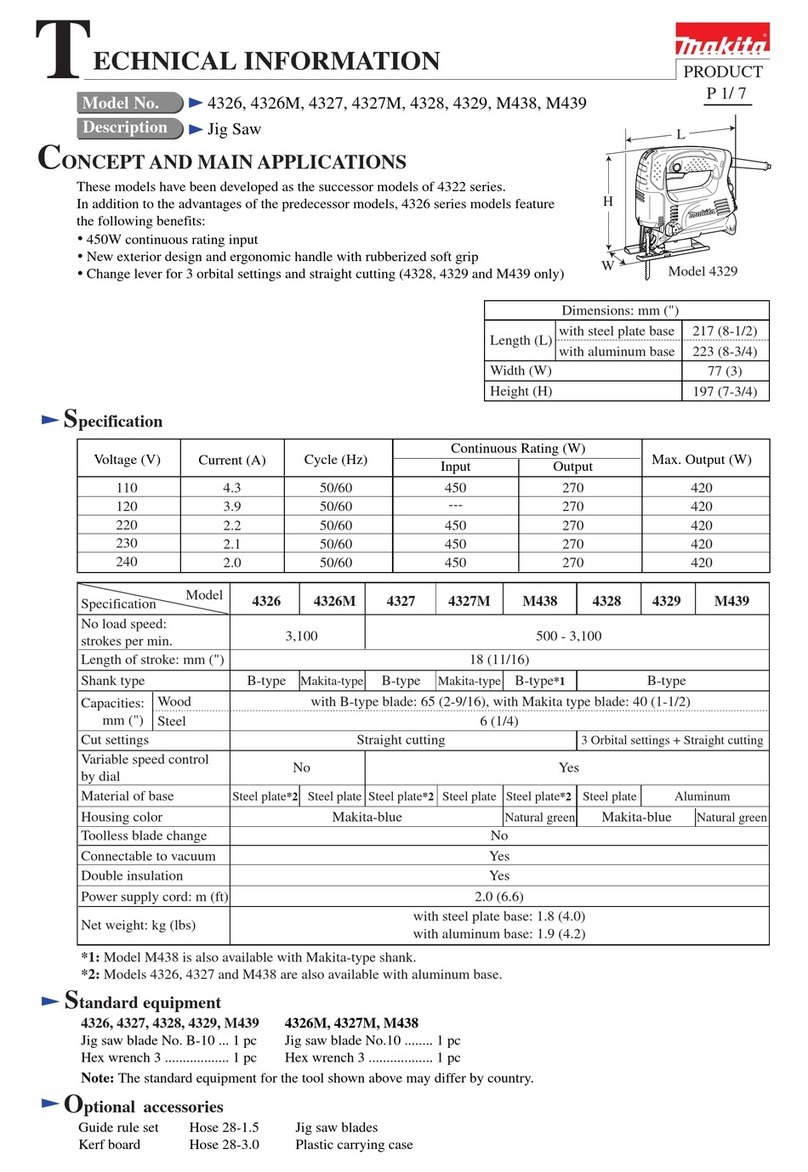

PNEUMATICSTAPLERP260

isaheavydutyprecision toolspeciallydeveloped forthe

installation ofhardwood flooring. Weighting only11

pounds(5kg),thisergonomicallydesigned toolmakes

the installation ofhardwood floorveryeasy,allowing the

operatorto set and nail the boardsinthe standing

position. It usesstandard½"crownflooring staples

availableinlengthsof 1½"(38mm),1¾"(44mm)or2"

(50mm).Forbestresult, onlyPrimatechstaplesshould

be used. Formaximumperformance, the manufacturer

guidelinesshouldbe followed. Read carefullythese

instructionsbeforeoperating thistool.It isimportant to

understand warnings/cautionsand the safetymeasures

to ensure safe use ofthistool.

Additionalinformation isavailabledirectlyfromthe

manufacturer:

1135 Jeremy-Fortin, Québec, QC

Canada, G1J1R8

Phone:1 (800)363-1962, 1 (418)522-7744

Fax:1 (418)522-7466

email: support@primatech.ca

web: www.primatech.ca/support

SAFETYMEASURES

Theseimportant guidelinesshouldalwaysbe followed

to worksafelywith the PRIMATECH pneumaticstapler

modelP260:

1.Read theseinstructionsthoroughlybeforeusing this

tooland keep it handyforreference ifnecessary.

2.Alwayskeep hands,feet orotherbodypartsaway

fromthe staple ejection area.

3.Neveraimthe toolinanydirection otherthan the

working area.

4.Alwayscarryormanipulate the toolbyitshandle

while the airsupplyhose isconnected.

5.Neverhitthe head cap ofthe actuatorifthe plastic

baseisnot sitting perfectlyon the working surface.

6.Neverleavethe toollayingdownon itsside while

the airsupplyhoseisconnected; the toolshould

alwaysbe lefton the floor,standing on itsplastic

base.

7.Do not alterorremove safety.

8.Alwaysdisconnectthe airsupplyhosewhen the tool

isnot in use orwhen move to anotherworkarea.

9.Neverserviceorrepairthe tool,clearobstructions

ormakeadjustmentswhilethe airsupplyhoseis

connected.

10.Onlycompressed airshould be used to powerthis

tool(100 psi, 6.9 barmaximum).

11.Neveruseoxygen oranyothercompressed gasas

a powersource forthistool.

12.AlwayswearOSHA-required Z-87 safetyglasses

with side shields.

13.Alwayswearproperearand feet protection while

the airsupplyhose isconnected.

14.Alwaysremovecleatsfromthe feederchannel

before servicing the tool.

DO NOT REMOVE ORALTERSAFETY.

NEVERDEPRESS THESAFETYCONTACT

WITHYOUR HANDSWHENTOOL IS

CONNECTEDTO AIRSUPPLY.EXTREME

CAUTIONISADVISEDWHENUSING THIS

TOOL.

CONNECTION&AIRSUPPLYSYSTEM

Toensuremaximumperformanceand efficiency,and

alsoaminimumofcare, the PRIMATECH pneumatic

staplerrequiresclean, dryair.It isnecessaryto usea

filterand a pressure regulator.

Thistoolneedsadetachablemalecouplerwith 3/8"

NPTmaletreads.Usea3/8"(1cm)minimumdiameter

airsupplyhose. Asmallerhoseorahoselongerthan

50' (15 m)couldcauseapressuredrop when the toolis

activated repeatedly.

ALWAYSUSE AFREE-FLOWCONNECTION

FORTHECOMPRESSEDAIRSUPPLYTO

PREVENT THAT THETOOL STAYSCHARGED

AFTERDISCONNECTING THEAIRSUPPLY

HOSE.

UNLOADTOOL BEFORECONNECTING AIR

TO PREVENT ACCIDENTAL DISCHARGE.

AFTERMOVING TOOL TO ADIFFERENT

WORK AREA,ORAFTERANYMAINTENANCE

TO THETOOL,ALWAYSENSUREPROPER

OPERATIONBYACTUATING TOOL SEVERAL

TIMES WITHOUT STAPLES OVERTHE

SUBFLOORING .

Dirt, dust, and otherparticlesinthe airsupplycan cause

sluggishoperation orprematurewearofmany

componentsofthe tool.Drainwaterfromthe

compressortankregularly.The compressorstart-stop

limitsshouldbe set to deliveran airpressureofat least

100 psi (7bar) at all time. Consultthe compressor

manualordealerforinstructionson howto makethis

adjustment.

At80 psi(5.5 bar) and100 hitsperminute, the tool

consumesapproximately4.5cu.ft(125 )ofairper

minute at 70°F(21°C).Higherairpressurewill increase

the consumption ofcompressed air.

The toolisdesigned to be operated with acompressed

airpressureof80 psi(5.5 bar).Occasionally,ahigher

pressurecouldbe necessary,forexampleto usethe

toolwith different speciesofharderwood. In thesemore

difficultcases,the compressed airpressurecan be

increased up to 100 psi(6.9 bar).It isveryimportant not

to exceed thismaximumpressureto prevent leaksand

riskofdamage to the tool.

The toolmaybe fitted with the optionalP-055 pressure

releasevalve. thisvalvewill producealoud noiseifthe

maximumairpressure isexceeded.

Checkthe compressed airsupplyhosebefore

connecting to ensurethat theyarefree fromdirtor

particlesthat can alterthe performanceofthe tool.Pay

specialattention to anyairleaks.Afterassembly,check

all the connectionsto prevent the leaksand to have

maximumefficiency.

DO NOT USE ACOMPRESSEDAIR

PRESSUREHIGHERTHAN 100 PSI

(6.9 BAR). HIGHERPRESSURECANCAUSE

PREMATUREWEARORDAMAGETO

CERTAINCOMPONENTS.

TO PREVENT ACCIDENTAL DAMAGETO THE

FINISHEDSURFACEOF THEINSTALLED

FLOOR,REST THETOOL ONTO THE

SUBFLOORING WHENCONNECTING AIR,

LOADING TOOL ORPERFORMING ANY

MAINTENANCETO THETOOL.

LOADING THE TOOL

Pull backthe pushercompletelyinthe rearposition and

applydownwardpressureto engage itinto the locking

position. Drop stripsofstaplesthrough the slot intop of

magazine. Whilepulling backand applying upward

pressure, releasethe pusherfrom itslocking position.

Then, gentlyallowitto moveforwardto engage the

staplesinto the magazine. The slide must be released

slowlyto prevent damage. Formaximumperformance,

alwaysuse Primatech staples.

USE ONLY 15½GA 1/2"-CROWN

FLOORING STAPLES.THEUSE OF ANY

OTHERTYPE OF FASTENERSWILL DAMAGE

THETOOL.FORMAXIMUMPERFORMANCE,

ALWAYSUSE PRIMATECH STAPLES.

Alwaysoperate the toolwith staplesinfeederchannel.

Damage mayoccurifthe toolis operated without

staples.

OPERATION

Placethe toolonto the subflooring, unload tooland

connectthe hose. Afterloading the toolwith PRIMATECH

staples,thePNEUMATICSTAPLER modelP260 isreadyfor

use.

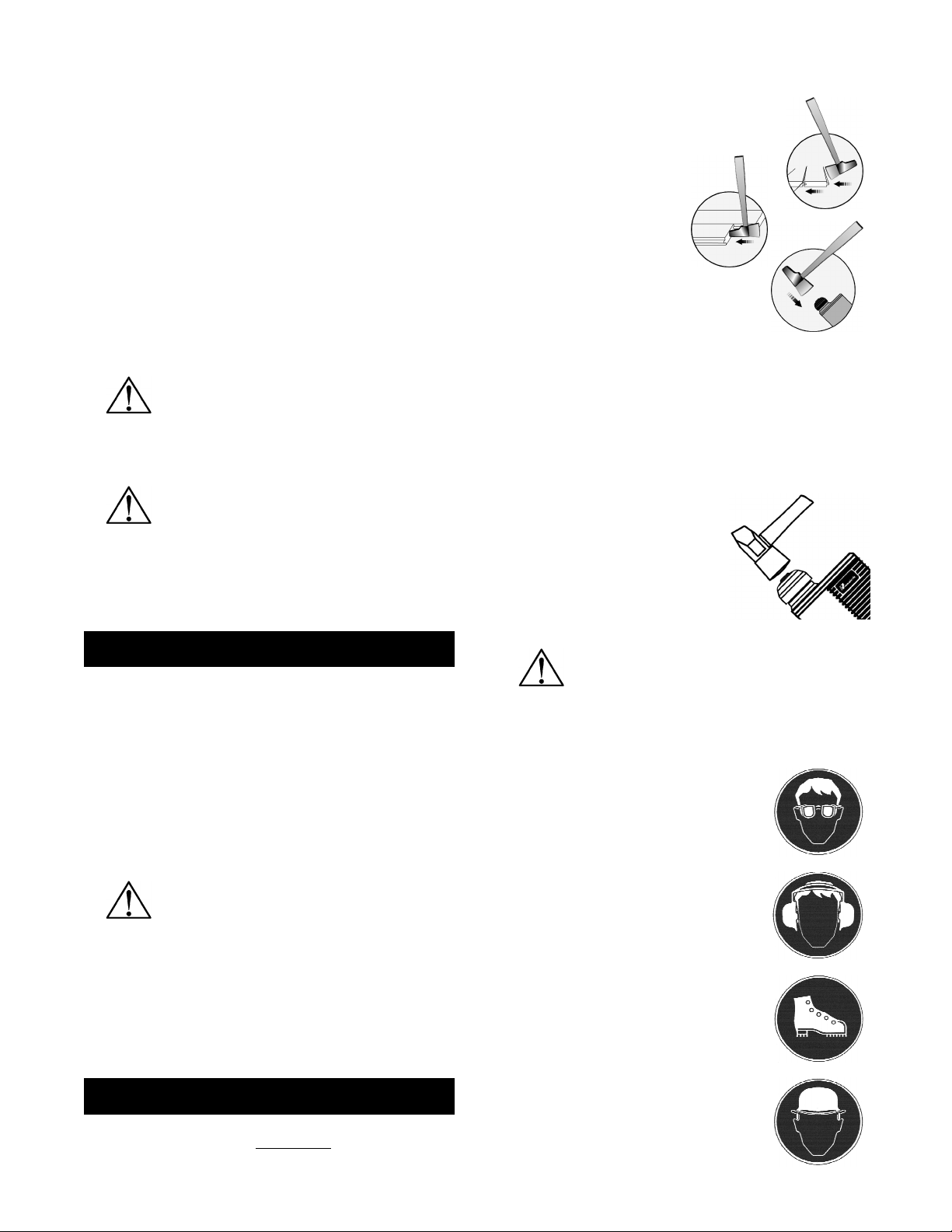

A2.5 lbs(1.1 kg)hammerissupplied with

the tool.Usethe rubberfaceto help

position the boards.Usethe

steelwith caution to prevent

damage to the boards.

Press the flooring firmlyin

place. The lipofthe plastic

baseP-433 shouldrest

snuglyagainstthe tongue of

the flooring. Downwardpressureshould

be applied to ensureproperseating of

the staple. Toactivate the tool,strike

lightlythe head cap P-601 with the RUBBERFACE ofthe

2.5 lbs(1.1 kg)hammersupplied with the tool. Never

strike thetoolwith the metal end of the hammer. If

wood isslightlytwisted, hitting the toolwith more force

will assistinpulling the boardup snugly. NEVER strike

the head cap when the toolisnot sitting on the working

surface.

USE ONLYTHE RUBBER FACE OF

THEHAMMER.USINGTHESTEELEND

WILL DAMAGETHETOOL AND VOID

THEWARRANTY.

AVOIDOPERATING THETOOL WHENTHE

SAFETYCONTACT ISNOT FULLY

DEPRESSED.THISWILL CAUSE

PREMATUREWEARORDAMAGETO THE

DRIVING BLADE,PISTONAND CYLINDER.

Eyeprotection isrecommended and

shouldbe wornbythe operatorand

otherinworking area. Accidental

ejection ofstaplesorwood debris

could cause severe eye injury.

In some environments, earprotec-

tion might be required, asworking

condition mayinclude exposure to

high noise levelswhich lead to

hearing damage.

Wearing safetybootsand safetyhat

isalso highlyrecommended.

NOTE:All the personalprotection

equipmentsmustmeet national

standards.

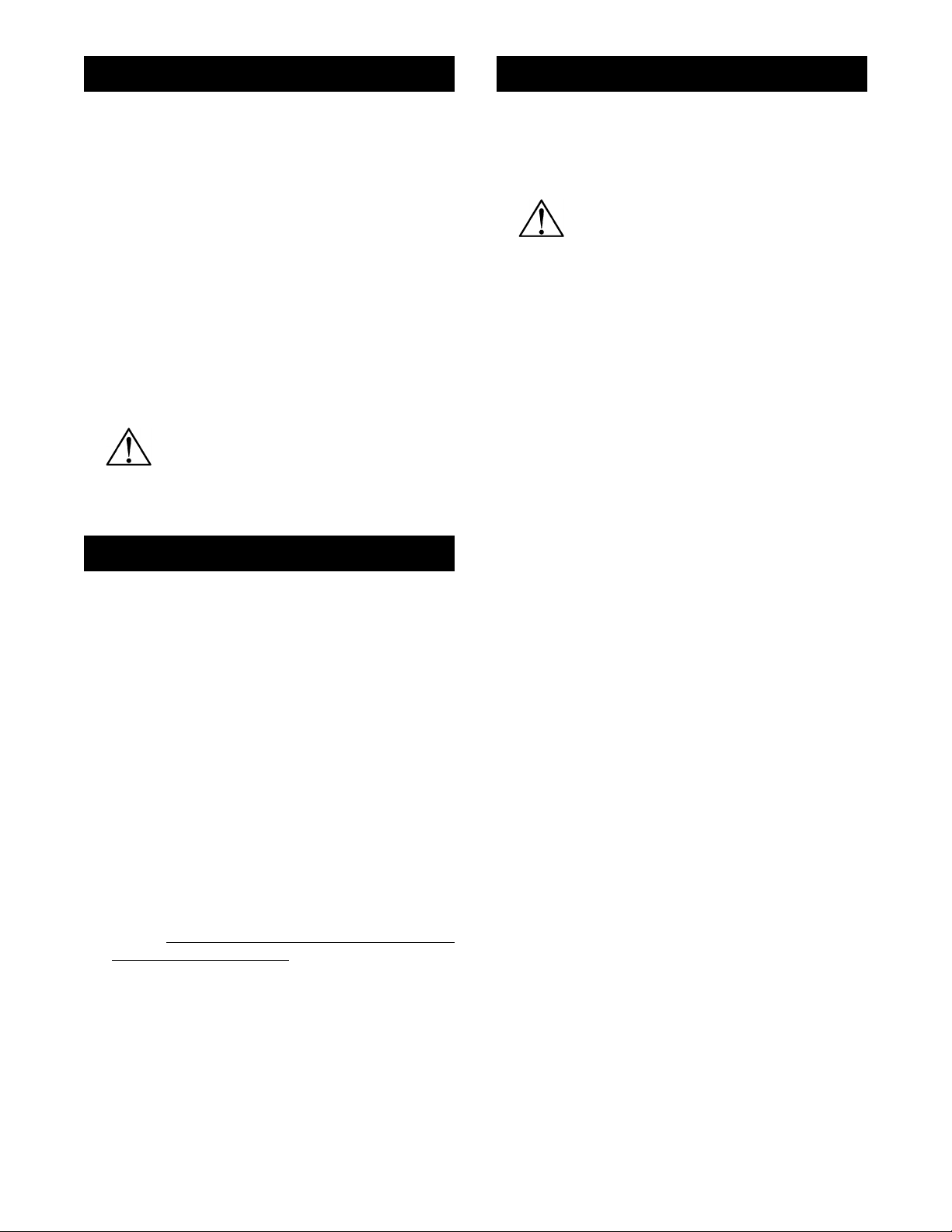

ADJUSTING FORHARDWOOD

THICKNESS

Tofasten 3/4"or25/32"

flooring, no adjustment

to the toolisrequired.

Usethe standardP-433

plasticbasesupplied

with the tool.

Tofasten 1/2"flooring,

install optionaladapter

kitP-188. Ifnecessary,

useone ortwoshims

(supplied)to insurethat

thegate/foot do not sit

onthe tongue. Insert

shimsbetween main

bodyand plasticbaseas

shown.

Tofasten 33/32"flooring,

removeplasticbaseas

shown. Youmayapply

the optionalself-

adhesivebaseP-986 to

protectthe finished

surface ofthe flooring.

BEFORESTARTING ANINSTALLATION,

STAPLEDOWNASAMPLEOF FLOORING TO

ASCERTAINTHAT YOUAREUSING THE

RIGHT TOOL AND FASTENER.

PREVENTIVE MAINTENANCE

Thistoolrequiresminimallubrication. Use

onlydetergent-free oilsuchasPrimatech

P-090. Othertypesoflubricant may

degrade the seals.Twodropsofoil weekly,

directlyin the airinlet, issufficient.

Checkperiodicallyto makesurethat allscrewsare

tight. Payparticularattention to the twoscrewsholding

the feederchannelaswell asthe screwsand nutson

the feederchannelassemblywho might loosen up over

time. Becarefulnot to stripthe threadswhen tightening.

The useofan mediumstrength adhesivesealant such

asthe Loctite 242 isrecommended forthosescrews

and nuts.

MAINTENANCE &REPAIR

Disassemblyofthe toolmustbe done inaclean

environment. Somepartscan be easilydamaged if

disassembled with impropertoolsorbyinadequate

methods.Maintenanceshouldonlybe performed by

trained personnel.Useonlygenuine PRIMATECH

replacement parts.

TO PREVENT INJURY,ALWAYS DISCON-

NECT THEAIRSUPPLYHOSE WHENSER-

VICING ORDISASSEMBLING THETOOL.

When assembling thetool,makesurethat all hexcap

screwsP-005 holding the casing on the basearetight.

Inspectthesescrewsregularly.Do not useany

substitute to gasket P-107.

When servicing the tool,do not twistorforceanyparts.

Damagemayresultfromsuchabuse. Ifpartsdo not

comelooseeasily,contactyourPRIMATECH distributor

formore information.

When opening the toolformaintenance, alwaysclean

all componentsofdirt, grit, orparticles.Inspectthe tool

carefullyforbroken partsorexcessivewear,and

replaceifnecessary.When ordering parts,be sureto

specifythe right partnumber,and alsothe toolserial

number.

AFTERANYMAINTENANCETO THETOOL,

REMOVE ALL STAPLES BEFORE

CONNECTING AIRAND ACTUATETHETOOL

REPEATEDLYOVERAPIECEOF WOODOR

SUBFLOORING TO INSUREPROPER

OPERATION.

CLEANING THE VALVE

Dirt, dustorotherparticles,oreven waterinthe tool

mayimpede the cycling ofthe valveassembly.Toclean

the head and valveassembly,removethe six(6)screws

P-015 and takethe head assemblyoff the tool.Pull out

the main valve assemblyP-543.

Totakethe actuatorP-642 and itscap P-644 apart, rest

the assemblyonto aflat surface, insertthe long armof

an Allen wrenchthrough the top holeofthe actuatorand

gentlytap on it to unclickboth parts.

It isgenerallynot necessaryto removethe head cap

P-601. Checkall sealsand replaceifnecessary.Clean

the interiorand lightlylubricate with non-detergent oil

P-090. Othertypesoflubricant maydegrade the seals.

Ifcareistaken,the gasket P-107 shouldrequireonly

infrequent replacement.

ASSEMBLING THE VALVE

Thistoolfeaturesaredesigned valveassembly.All its

componentscan be assembled togetherwithout the

need ofascreworanytool;simplywith asnap-in

action. The wholeassemblycan nowbe simply

pulled-out ofthe head, making maintenance easier.

1.0First, makesurethat all componentshaveall their

sealsinstalled.

2.Insertthe actuatorP-642 iinto the mainvalveP-543

and snap the actuatorcap P-644 into the actuator.

The actuatorassemblyshould slide smoothly.

3. Make surethe head P-506 isclean and lightlylubricated

and insert the valve assemblyintoit.

4.Ensurethat the diskP-601Aiscompletelysnapped

into the head cap P-601. Snap head cap onto the

head P-506. It isusuallynot necessaryto remove

head cap formaintenance.

AFTERREASSEMBLY,ALWAYSACTUATE

THETOOL AFEWTIMES WITHOUT

STAPLES AGAINST APIECEOF WOODTO

INSUREPROPEROPERATION.

REPLACING THE DRIVING BLADE

1.Checkto partlistto orderthe right replacement

driving blade.

2.Removethe sixP-015 screwsand takeoff the head

assemblyP-506. It isusuallyeasierto replacethe

driving blade byopening the toolfromthe top;

although insomecasesitmaybe necessaryto

access the componentsbyremoving the base

assemblyP-235.

3.Ifthe piston hasfewthreadson itstop face, use

one ofthe P-015 screwsto pull itout thepiston.

You mayalso insert the replacement driving blade

into the gate/foot guide at the bottomof the toolto

push the piston out.

4.Removeanydebrisand disposeofthe broken

driving blade and screw.Atthistimeassess

condition ofcylinderP-518. Ifscratched, usearat-

tail fileto smooth out walls.The piston mustbe

allowed to move without restriction.

5.Lockthe piston inavise, using arag to prevent

scoring. Followthe instructionssupplied with the

replacement driving blade.

6.Reverse the orderofinstructionsto reassemble.

TROUBLESHOOTING

Thissection will helpto diagnoseproblemsthat might

alterthe qualityofwork done bythe operator,orthe

tool,and will givesuggestionson howto solvethem.

Followthe orderofthese instructions.

TO PREVENT INJURY,ALWAYS

DISCONNECT THE AIR SUPPLY

HOSE WHENADJUSTING,SERVICING OR

DISASSEMBLING THETOOL.

FIRST:CHECKTHE COMPRESSEDAIRSUPPLY

Manyofproblemscomefromafaultyorinadequate

compressed airsupplysystem.Beforeattempting

to repairthe tool,thefollowing pointsshouldbe

checked:

a)checkthe pressureat the output ofthe

compressor;adjustto 80-100 psi(5.5-6.9 bar) as

required

b)checkthe tankpressureofthe compressor&

adjust the start/stop limits

c)checkthe airdeliverysystem,useahoseofat

least 3/8"

d)usefewertoolssimultaneously;do not exceed

the capacityofthe compressororofthe delivery

system

e)drain waterfromthe compressor

SECOND:CHECKFORAIRLEAKS

Atrest, thistoolshouldnot haveanyairleak.

Beforeattempting to repairthe tooland replace

parts, checkthe following:

a)Tighten screwsP-015 orreplace gasket P-107

b)CheckrectangularringsP-009 &P-543A;

replace ifnecessary

c)Checkall sealson valveP-543 replaceif

necessary

d)Checkthe top edge ofmaincylinderP-518; it

should be free ofdents.

e)ChecksealP-516B

f)Clean &lubricate the head assembly;

re-assemble the head assemblycarefully

g)Checkinteriorofhead P-506 forscratches

h)Checktop ring P-014; replace ifnecessary

TOOLDOES NOT DRIVE STAPLES

a)Checkthat therearestaplesinthe feeder

channel

b)Makesurethe feederclipisengaged behind the

staples

c)Checkthe front end ofthe feederchannelfor

burrs ordamages

d)Checkthe safetyelement

e)Checkifthe driverisstuckindownposition (see

6 below)

f)Checkforobstruction inthe stapleejection area

STAPLES ARENOT SET COMPLETELY

a)First, verifyairsupply(see 1 above)

b)Clean tooland lubricate tool;particularlythe

head assembly

c)Increaseairpressurewhen working with harder

woods; neverexceed 100 psi(6.9 bar)

d)Checkthe driving blade forbroken end

e)Ensurethe tooliswell seated on the floorwhile

ejecting

TOOLDOES NOT ACTIVATE

a)Checkthe airsupply

b)Inspectthe head assemblyand checkall seals;

reassemble carefully

DRIVING BLADEDOES NOT RETURN

a)Checkforjammed staple orobstruction

b)Checkgate/foot and end offeederchannelfor

damagesorburrs.

c)Checkforbroken orbent driving blade

d)Checkthe band P-518B

e)Inspect the head assemblyand checkall seals;

clean &lubricate

f)Checkfordamaged ormissing bottomO-ring

P-014

g)Tighten reinforcement plate

h)Checkthat the bumperisin place

BROKENORWORN DRIVING BLADE

Replacethe driving blade.Failureto followthe

instructionscarefullywill resultinrepeated

breakage ofthe driving blade.

POORFEEDORTOOLJAMMING

a)Makesurethe feederclipengagesbehind the

staples

b)Checkthe gate and foot fordebris,damagesor

wear

c)Checkthe front end ofthe feederchannelfor

burrs ordamages

OTHERPROBLEMS

Contact Primatech:

byphone1 (800)363-1962

1 (418)522-7744

byemail support@primatech.ca

consult ouron-line TechnicalSupport site at

http://www.primatech.ca/support

TOOLS WARRANTY&LIMITATIONS

Primatechwarrantsthat newlypurchased fastening

tools,partsand accessorieswill be free fromdefectsin

materialand workmanship(excluding wearparts) for

the period shownbelow,afterthe date ofpurchaseby

the originaluserasevidenced byavaluablepurchase

invoice.

ONE-YEARLIMITEDWARRANTYwill applyto all

parts, except those subjected to normalwear

SEVEN-YEAREXTENDEDLIMITEDWARRANTY

covers toolcasing.

WARRANTYSTATEMENT

Primatech‘ssoleliabilityhereunderwill be to replace

anypartoraccessorywhichprovesto be defective

withinthe specifictimeperiod. Anyreplacement partor

accessoriesprovided inaccordancewith thiswarranty

will carryawarrantyforthe balanceofthe period of

warrantyapplicableto the partitreplaces.When repair

orreplacement ofpartortoolisrequired, the complete

toolorpart(s) mustbe returned to Primatechorat such

authorized warrantyservicepoint ofPrimatech,

transportation prepaid, with acopyofproofofpurchase

evidencing that the partortooliswithinthe warranty

period.

Thiswarrantyisvoidasto anytoolwhichhasbeen

subjected to misuse, abuse, accidentalorintentional

damage, used with fasteners not meeting Primatech

specifications,sizeorquality,improperlymaintained,

repaired with otherthan genuine Primatechreplacement

parts,damaged intransitorhandling, orwhich, in

Primatech‘ssoleopinion, hasbeen altered, modified or

repaired inawaythat affectsordetractsfromthe

performance ofthe tool.

PRIMATECH MAKES NOWARRANTY,EXPRESSED

ORIMPLIED,RELATINGTOMERCHANTABILITY,

FITNESS,OROTHERWISE,EXCEPTAS STATED

ABOVE,and Primatech‘sliabilityAS STATED ABOVE

AND AS ASSUMEDABOVE isinlieu ofall other

warrantiesarising out of,orinconnection with, the use

and performanceofthe tool,except to the extent

otherwise provided forbyapplicable law.

PRIMATECH SHALL IN NOEVENTBE LIABLEFOR

ANYDIRECT,INDIRECT,ORCONSEQUENTIAL

DAMAGES WHICH MAY ARISE FROMLOSS OF

ANTICIPATEDPROFITSORPRODUCTION,

SPOILAGEOF MATERIALS,INCREASEDCOSTOF

OPERATION, OROTHERWISE.Anyliability,ifany,

connected with the useofthe toolshall terminate upon

the expiration ofthe warrantyperiod specified above.

Table of contents

Other primatech Power Tools manuals