Nikro PS600 User manual

MINI

POLY AIR SCRUBBER

MODEL #PS600

INSTRUCTION MANUAL

2

RISK OF FIRE, ELECTRIC SHOCK, OR PERSONAL INJURY

Unit must be electrically grounded.

Do not use an adapter.

Plug into matching three-pronged GFCI receptacle only.

Do not operate in standing water.

If electrical components become wet, allow to dry completely before using.

Unplug unit before performing any maintenance, filter changes or cleaning.

Inspect cord and plug for damage before use.

Do not touch cord with wet hands or while standing on wet surface.

Do not operate in flammable or explosive areas.

Do not clean unit while plugged in.’

This unit has been designed for indoor use only.

Do not use to exhaust hazardous or explosive materials or vapors

IMPORTANT SAFETY INSTRUCTIONS

a. “Do not operate any unit with a damaged cord or plug. Discard unit or return it to an authorized service

facility for examination and/or repair.”

b. “Do not run cord under carpeting. Do not cover cord with throw rugs, runners, or similar coverings.

c. Arrange cord away from traffic area and where it will not be tripped over.”

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

“READ AND SAVE THESE INSTRUCTIONS”

RISK OF ELECTRIC SHOCK CAN CAUSE

INJURY OR DEATH.

UNPLUG UNIT BEFORE SERVICING.

TO REDUCE THE RISK OF ELECTRIC SHOCK:

CONNECT TO A GFCI OUTLET, DO NOT USE

AN EXTENSION CORD.

3

All Nikro Industries Inc. products that have rated efficiencies of 99.97% @ 0.3 microns

and/or 99.99% @ 0.3 microns, have H.E.P.A. filters that have been individually tested to

meet these minimum efficiencies.

Although all the filters have been pre-tested, the possibility of leaks or filter failure due to

handling, transportation, punctures, loaded filters, moisture, wear and tear, etc., does

exist.

Therefore, when using this equipment in highly sensitive areas or where any release of

particles above and beyond the minimum efficiencies would be detrimental and harmful

to humans, plants or property; it is strongly recommended that the units be individually

tested prior to their use.

This is to assure that they are maintaining the efficiency levels, which they were

designed to filter out.

FAILURE TO DO SO COULD RESULT IN SERIOUS HARM TO HUMAN LIFE, PLANT

LIFE AND/OR PROPERTY.

BACKDRAFTING AND CARBON MONOXIDE FUMES

To prevent the backdrafting of deadly carbon monoxide, when using your portable air

scrubber to create a negative pressure in a containment area, turn off all open

combustion devices such as but not limited to fireplaces, hot water heaters, furnaces,

boilers etc.

1115 N. Ellsworth Ave., Villa Park, IL 60181

Telephone: 630-530-0558 FAX: 630-530-0740 Toll Free: 800-875-6457

4

Your #PS600 Poly Air Scrubbing System has been thoroughly tested and inspected at the factory and is fully assembled

and ready for use. However, prior to plugging the unit in, inspect it for any damage that may have occurred during

shipping. Inspect and tighten the HEPA filter hold down nuts, which may have loosened during transportation.

ELECTRICAL RATING:

115V 3 Amps 60 HZ

FILTER SET-UP PROCEDURES

The Model #PS600 Air Cleaning unit is equipped with three stages of filtration as follows:

#860958 1" Polyester Filter Pad (1ST Stage)

#860959 2" Pleated Filter (2nd Stage)

#862074 H.E.P.A. Filter (99.97% efficient @ 0.3 microns) (Final Stage)

The H.E.P.A. Filter is held in place by 4 nuts and 2 – hold down brackets.

Slide the brackets over the threaded mounting studs located on the inside

of the housing. Thread the nuts over the brackets and tighten securely with

a 1/2” wrench. Be sure these nuts & brackets are always tightened

securely on the frame of the HEPA filter to guarantee a tight seal with the

H.E.P.A. Filter and the filter frame of the unit. The air flow arrows on this

filter should always be directed towards the motor and blower assembly.

Always turn off and unplug unit when removing or replacing the H.E.P.A.

filter. (See Photo 1)

The 2" Pleated Filter should be set in front of the H.E.P.A. Filter. The air

flow arrows on this filter should always be directed towards the H.E.P.A.

Filter. (See Photo 2)

The 1" Polyester Filter Pad should be placed in the door frame of the unit.

Close the hinged door of the unit and snap the latches into the locked

position...Unit is ready for use. (See Photo 3 & 4)

An optional Carbon Filter can be used to help control odors.

Simply replace the #860959 – 2” Pleated Filter with #860960 – 2” Carbon

Filter (sold separately).

FILTER MAINTENANCE

When performing filter maintenance always wear proper personal protective equipment and clothing. Always follow safe

working practices including proper disposal and handling of used filters in accordance with all federal, state and local

regulations.

The model #PS600 Air Cleaning unit is equipped with a Filter-Monitor gauge. This gauge is located on the control panel of

the unit. When gauge reads 2" or higher (in highest speed position), filter maintenance is required and the following steps

should be taken:

1. Change the 1" Polyester Filter pad (this filter cannot be cleaned or reused. Dispose of Properly)

2. Close cabinet door and turn unit on.. If gauge continues to read 2" (in highest speed position) or higher go to step #3

3. Change the 2" Pleated Filter (this filter cannot be cleaned or reused. Dispose of Properly)

4. Close cabinet door with all filters in proper position. Turn unit on. If gauge continues to read 2” or higher (in highest

speed position), the H.E.P.A. Filter must be replaced. (This filter cannot be cleaned or reused. Dispose of Properly)

NOTE: FILTERS SHOULD BE REPLACED IMMEDIATELY IF TORN OR DAMAGED.

USE OF ANY OTHER FILTERS THAN ORIGINAL NIKRO REPLACEMENT PARTS VOIDS THE PRODUCT

WARRANTY AND PERFORMANCE CLAIMS

TO AVOID CROSS CONTAMINATION CHANGE ALL FILTERS AFTER EVERY REMEDIATION JOB AND CLEAN

ENTIRE UNIT THOROUGHLY BEFORE REMOVING IT FROM THE CONTAINMENT AREA.

5

BEFORE OPERATING THE UNIT

1. Inspect cord and plug for damage.

2. Visually inspect the HEPA Filter for damage, punctures or tears. If you are operating in or exhausting into a highly

sensitive area it is strongly recommended that this unit is independently tested to assure proper filtration

efficiencies.

3. Inspect and tighten the HEPA filter hold down nuts, which may have loosened during transportation of the unit.

TRANSPORTING AND STORING UNIT

1. Always handle this unit with care. Rough handling such as dropping, or tipping over the unit, bouncing around in a

vehicle, and impact from rolling over or off of curbs, stairs and other platforms, could cause serious damage to

this unit.

2. Always clean and decontaminate unit before storing it. Store this unit indoors in a dry location.

TROUBLE SHOOTING

PROBLEM

Machine will not start

Machine will not run

Continuously

No power to GFCI outlet control panel

POSSBILE CAUSE

Power cord unplugged

Blown or tripped circuit breaker

Tripped thermal protector on

motor

Tripped ground fault

Motor speed control set to low

Not enough amperage

Extension cord too long or

inappropriate gauge.

Tripped GFCI on control panel

REMEDY

Plug cord into outlet

Replace/reset building fuse or

breaker

Turn off unit and let cool for

Approximately 20 minutes, then

turn back on.

Push reset button on the GFCI located

on the control panel

Start motor in highest speed position

then lower speed after start-up

Use a larger circuit or remove

other appliances from circuit

Use a 12 gauge extension cord

Maximum length 50’

Reset the breaker on the GFCI

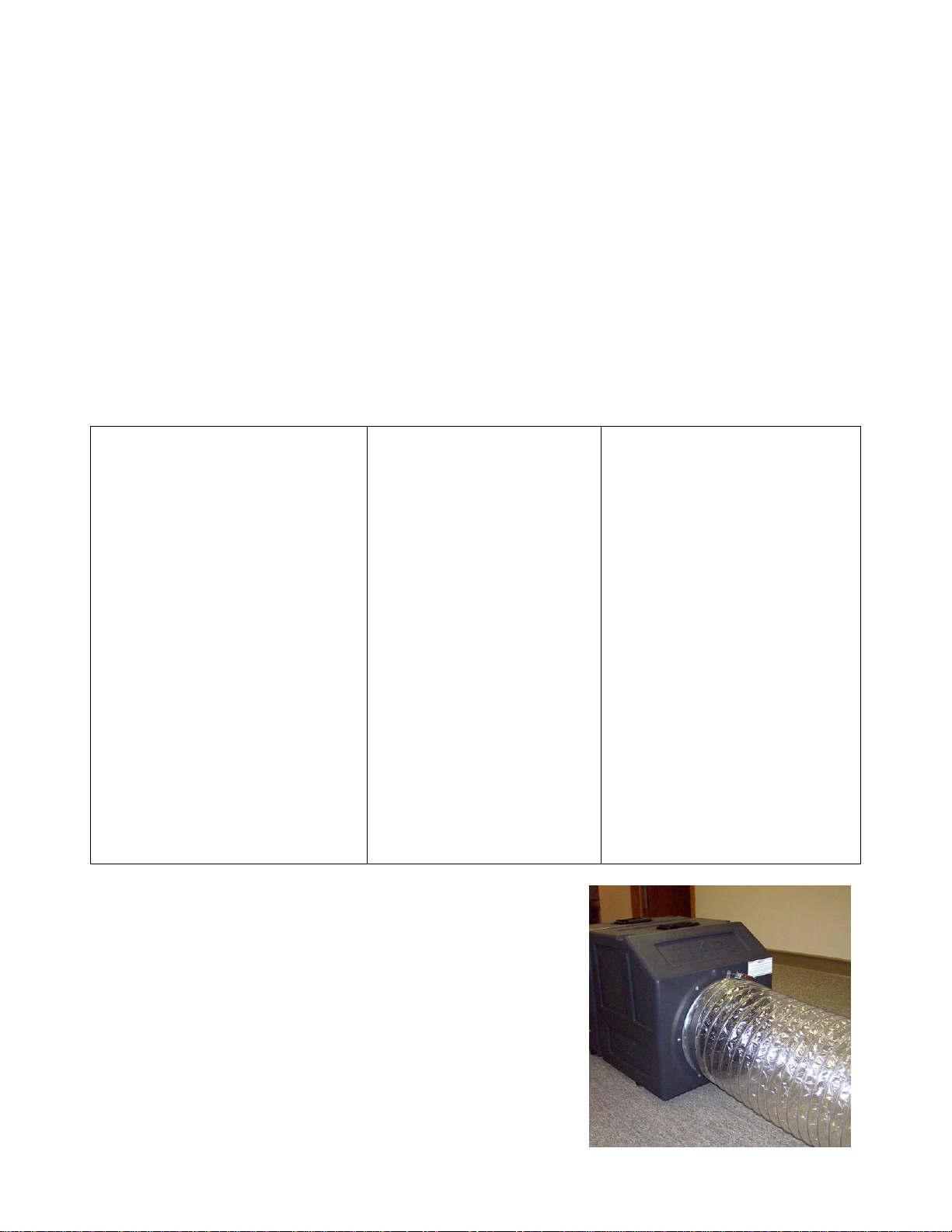

CLEAN AIR EXHAUST DISCHARGE

This portable air scrubber allows the operator to connect a 12”

exhaust hose to the unit allowing for remote or controlled exhausting

and/or to create a controlled negative pressure in a contained area.

Simply connect a 12” hose (#860243) to the 12” exhaust flange

located on the back/exhaust end of unit and extend the hose to the

desired area you wish to exhaust to.

AIR INTAKE FLANGE

This scrubber also has an air intake flange, which allows the operator

to connect a 12” hose and place the open end of the hose in a

contaminated area and the air scrubber in another remote area.

6

#PS600 ASSEMBLY

#861852 BLOWER ASSEMBLY

PC NO PART NO PART NAME QTY

1 860973 HANDLE 2

2 862111 CABINET 1

3 860941 CORD STRIAN RELIEF 1

4 862098 ELECTRICAL CORD 1

5 860699 FILTER MONITOR

GAUGE 1

6 862109 RUBBER FOOT 4

7 860725 LATCH 2

8 862094 EXHAUST PANEL 1

9 861852 BLOWER ASSEMBLY 1

10 860726 STRIKE 2

11 862107 DOOR 1

12 860729 DOOR GASKET 1

13 860958 1” FILTER PAD 1

14 860959 2” PLEATED FILTER 1

15 862074 HEPA FILTER 1

NOT

SHOWN 862106 HEPA BRACKET 2

PC NO PART NO PART NAME QTY

1 862076 MOTOR BRACKET ARM 3

2 862075 MOTOR BRACKET 1

3 861850 MOTOR 1

4 861851 BLOWER 1

5 861924 CAPACITOR BRACKET 1

6 861204 CAPACITOR 1

7 862102 LEFT SMALL BLOWER LEG 1

8 862103 RIGHT SMALL BLOWER LEG 1

861852 BLOWER ASSEMBLY COMPLETE

7

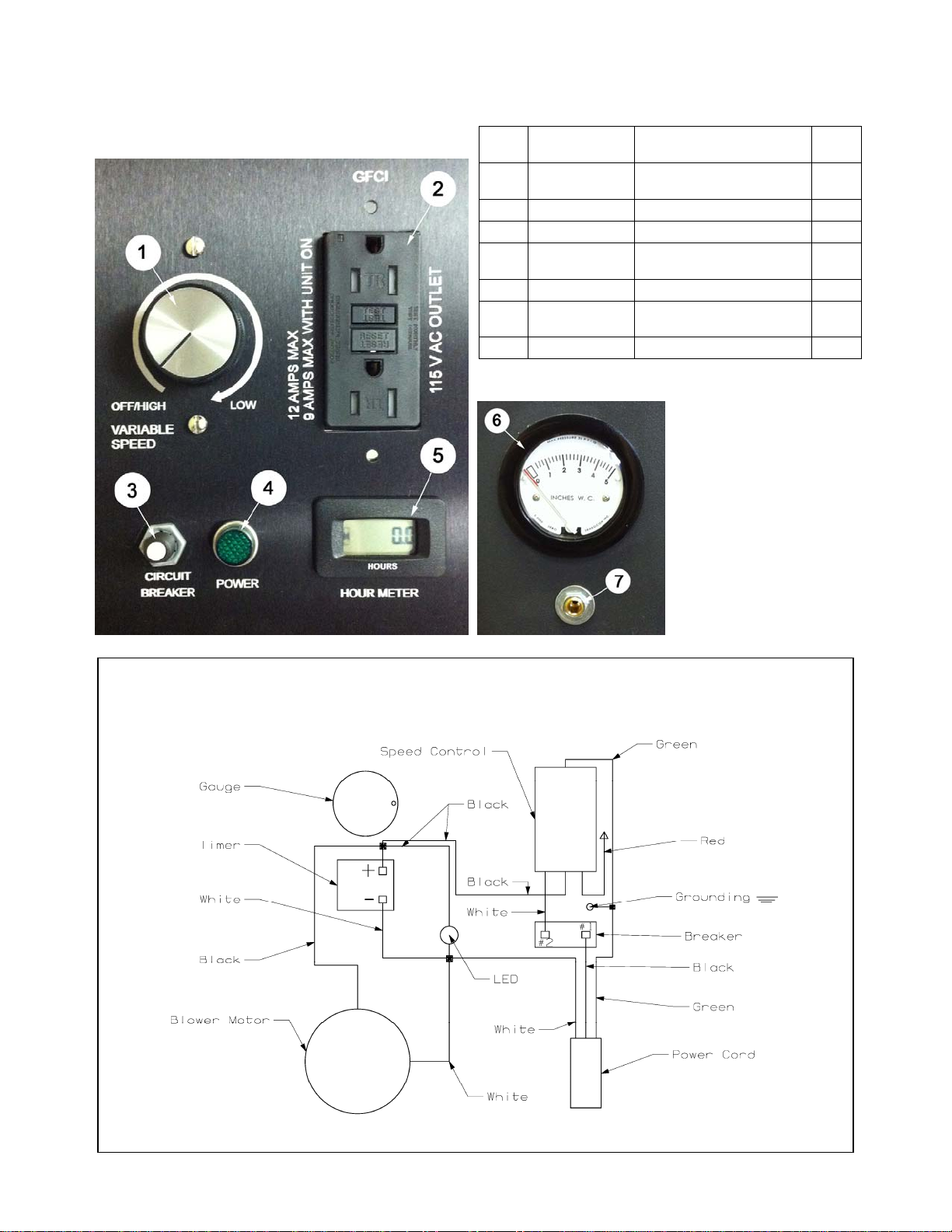

CONTROL PANEL

#NC600 WIRING DIAGRAM

PC

NO PART NO PART NAME QTY

1 861026 VARIABLE SPEED

CONTROL 1

2 862110 GFCI OUTLET 1

3 860976 CIRCUIT BREAKER 1

4 861067 POWER INDICATOR

LIGHT 1

5 860954 HOUR METER 1

6 860699 FILTER MONITORING

GAUGE 1

7 860721 GAUGE RELIEF BARB 1

8

WARRANTY

Nikro Air Scrubbers are warranted for 1 year from the date delivered to the original end

user and may not be assigned or transferred.

Parts, which become defective due to faulty workmanship or materials during normal

use in this period will be repaired or exchanged at no charge if returned and approved

by an authorized Nikro service center. All replaced or repaired parts shall only be

warranted for the remainder of the original one year warranty period.

After the expiration of the one year warranty, all warranties on this unit including fitness

for a proposed usage or purpose will become void.

The end user shall be responsible for freight charges incurred to deliver warranted

product to an approved Nikro service center. Nikro shall be responsible for freight

charges incurred in returning unit to customer, but not to exceed the original freight

charges to customer.

It shall be wholly Nikro’s decision to repair, replace or refund the purchase price of any

such defective goods.

This warranty does not apply to normal wear and tear, neglect, misuse, abuse or

incorrect installation. If any other replacement parts, filters or attachments are used

other than original Nikro parts, this warranty will become void.

Nikro disclaims responsibility for loss of production, profits, goodwill or any other costs

that may indirectly occur due to the failure of this product.

H.E.P.A. FILTER STANDARDS AND CERTIFICATION

All Nikro H.E.P.A. filters are manufactured and individually tested using the MIL-STD

282 D.O.P. test, or the IEST-RP-CC-001.3 test method.

Each filter is tested and certified to have a minimum efficiency of 99.97% @ 0.3 micron

particles. All filters are then individually labeled and registered by the manufacturer.

All H.E.P.A. filters used in Nikro equipment meet, and in most cases, exceed the

minimum standard of 99.97% efficiency @ 0.3 micron particles, and comply with OSHA

and EPA standards for cleaning the air of toxic and nuisance dust such as mold, lead

and asbestos.

ELECTRICAL CERTIFICATION

ETL LISTED

CONFORMS TO UL STD 507

CERTIFIED TO CAN/CSA STD C22.2 NO. 113

Table of contents

Other Nikro Scrubber manuals

Popular Scrubber manuals by other brands

Crescent

Crescent SC351 User and maintenance guide

Tennant

Tennant M17 Series Operator's manual

Numatic

Numatic TGB 516 36V Original instructions

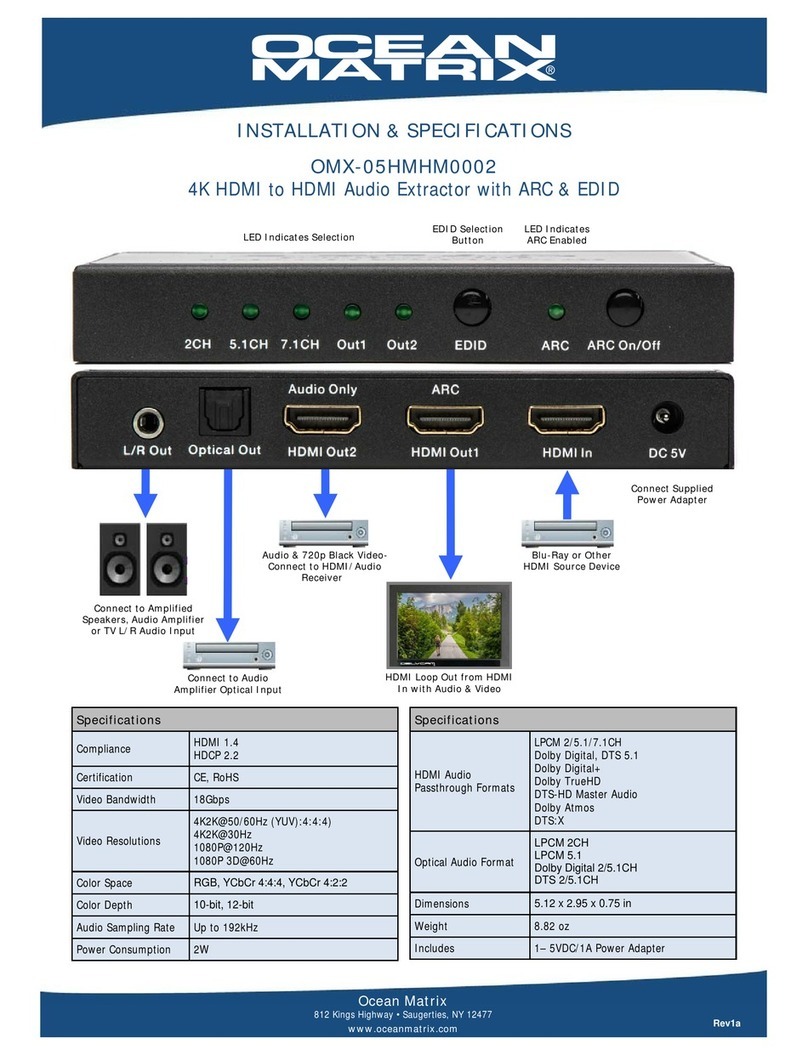

Ocean Matrix

Ocean Matrix OMX-05HMHM0002 INSTALLATION & SPECIFICATIONS

Nilfisk-Advance

Nilfisk-Advance MX 307 H Information & operating instructions

Fimap

Fimap GMG PRO Operator Interface Guide

Nautilus

Nautilus HYDRO-FORCE MX200M operating manual

Kärcher

Kärcher B 40 C Bp manual

Kärcher

Kärcher B 150 R instructions

U.S. Products

U.S. Products ADVANTAGE 1200 Information & operating instructions

CorroVenta

CorroVenta RS 100 Operation and maintenance instructions

Minuteman

Minuteman E Ride ER28C user manual