8/31/07 Pub. 410 www.nilcor.com

Installation

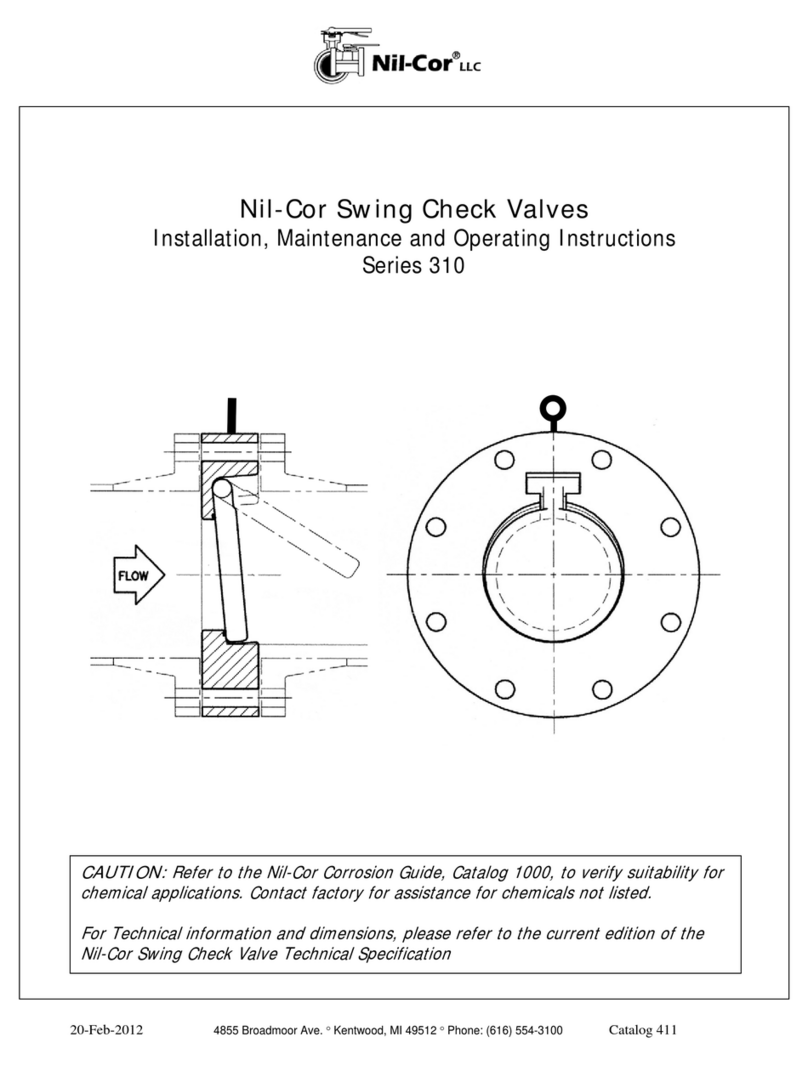

1) Because Nil-Cor Check Valves are unidirectional, it is important to ensure that the arrow on valve points in the direction of free flow.

2) Pipe must be properly aligned and provisions made to minimize stress from thermal expansion. Always review pipe

manufacturer’s recommendations.

3) TFE envelope or 50 Durometer Rubber gaskets are recommended.

4) Flange bolts should be evenly torqued, using a torque wrench, in cross rotation to prevent flange damage. We recommend

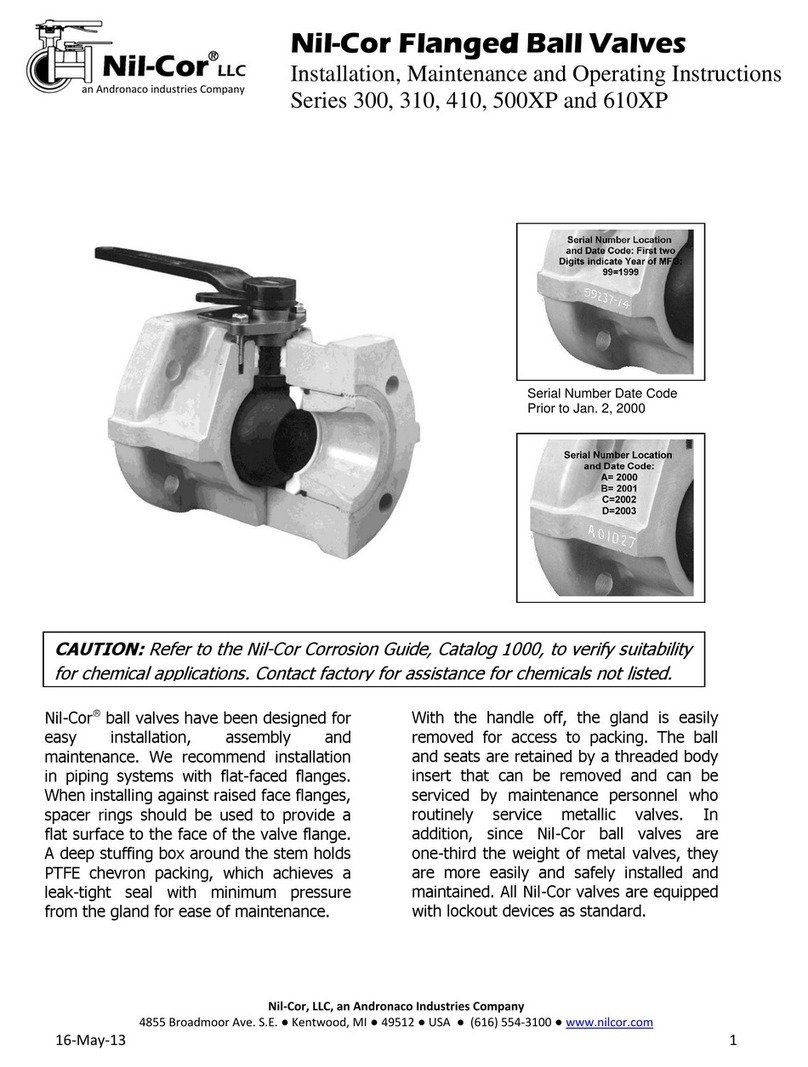

installation in piping systems with flat face flanges. When installing against raised face flanges, spacer rings should be

used to provide a flat surface to the face of the valve flange. Bolts should be lubricated for ease of installation.

Removal/Disassembly

For your safety, it is important that these precautions be taken before removal of the valve from the line or before disassembly:

1) Wear protective clothing or equipment appropriate for the particular fluid.

2) Observe the precautions and follow the procedures in Disassembly Item 1.

Disassembly

1) Isolate and depressurize the valve.

a. Take precaution to properly support pipeline.

b. Temporarily cap off exposed pipeline to prevent infiltration of debris.

2) Remove valve from line.

3) Use insert removal tool to remove threaded insert. Remove ball.

Assembly

1) Inspect and clean all parts to make sure they are free of dust, grit or other material. New O-ring and ball seat

should be used after the valve has been in service. Inspect seat and body retainer rings for damage. If damaged, a complete

seat kit should be used.

2) A good lubricant compatible with fluid service should be applied lightly to seat, seal and body insert threads.

3) Replace ball.

4) Screw body insert into the valve body (flange serrations between body and insert are flush when properly installed). Tighten to torque

values in table below.

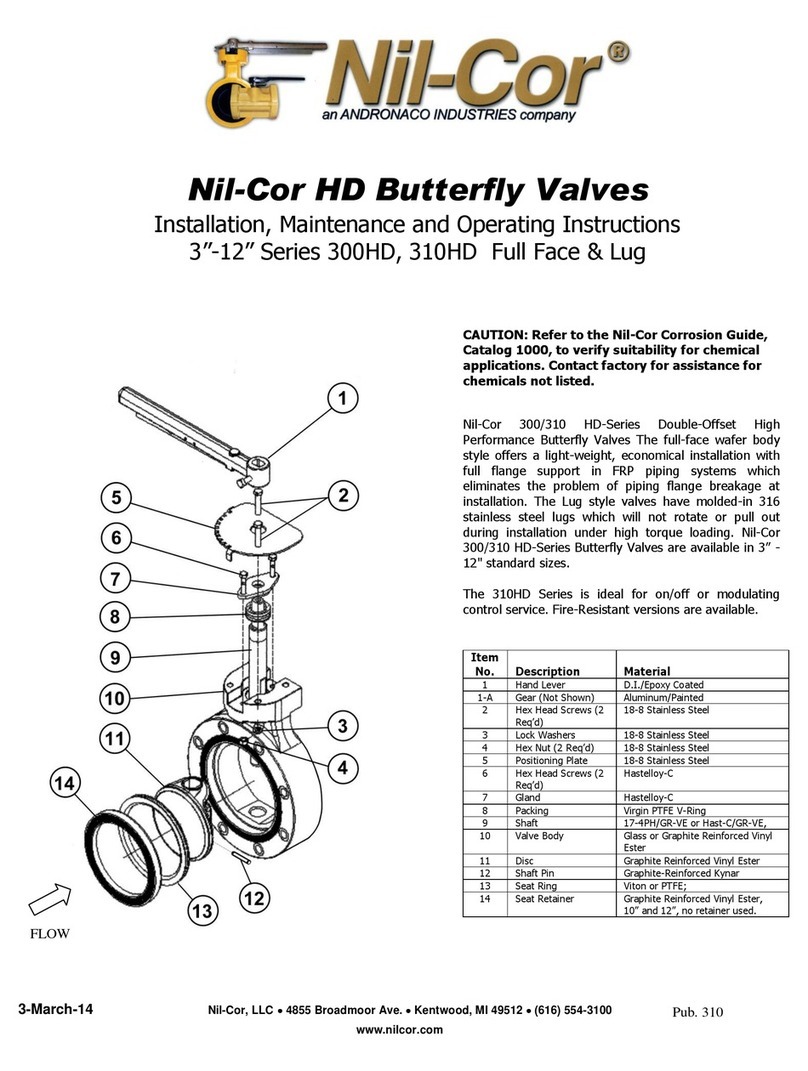

Item Description Material

1Body Vinyl ester w/Glass Fiber or Graphite Fiber/Polysulfone w/Glass

Fiber

2Ball Solid Virgin PTFE

3Seat O-Ring PTFE Coated Viton

4Body O-Ring PTFE Coated Viton

5Body Insert Vinyl ester w/Glass Fiber or Graphite Fiber/Polysulfone w/Glass

Fiber

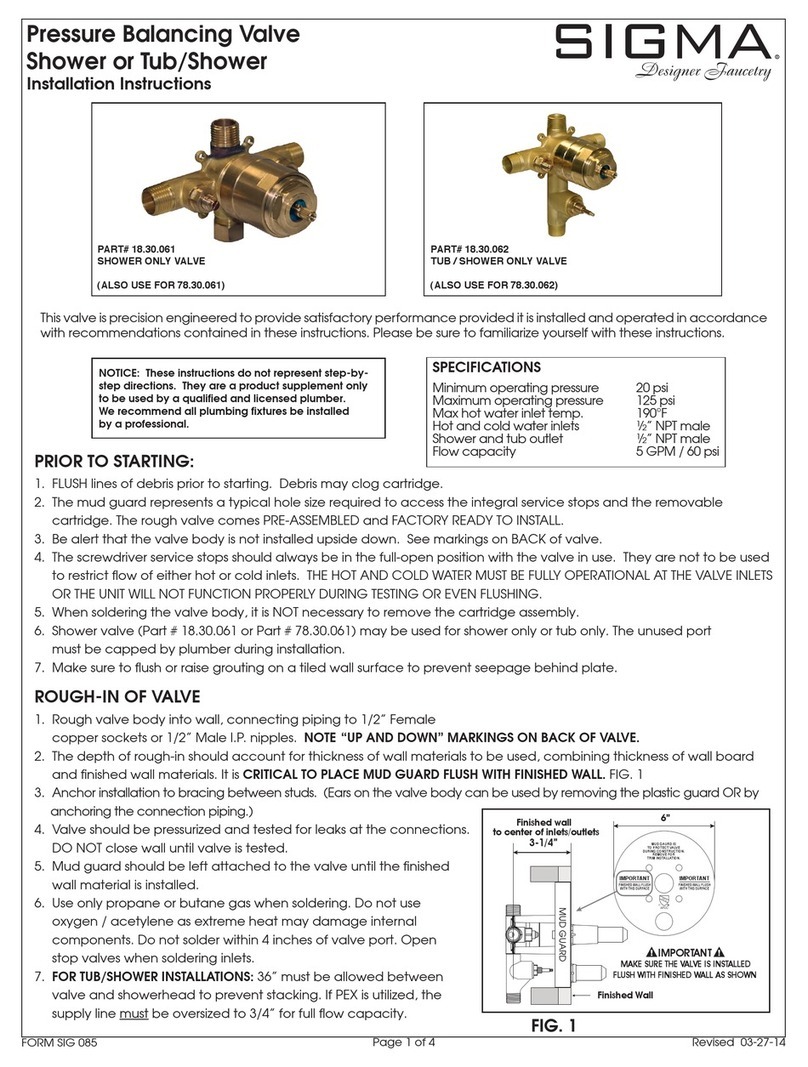

Valve Size Flange Bolt Torque Range

(ft. lbs.) Insert Tightening

Torque (ft. lbs.)

1” 20-30 4

1.5” 20-30 6

2” 20-45 8

3” 25-50 14

4” 25-50 20

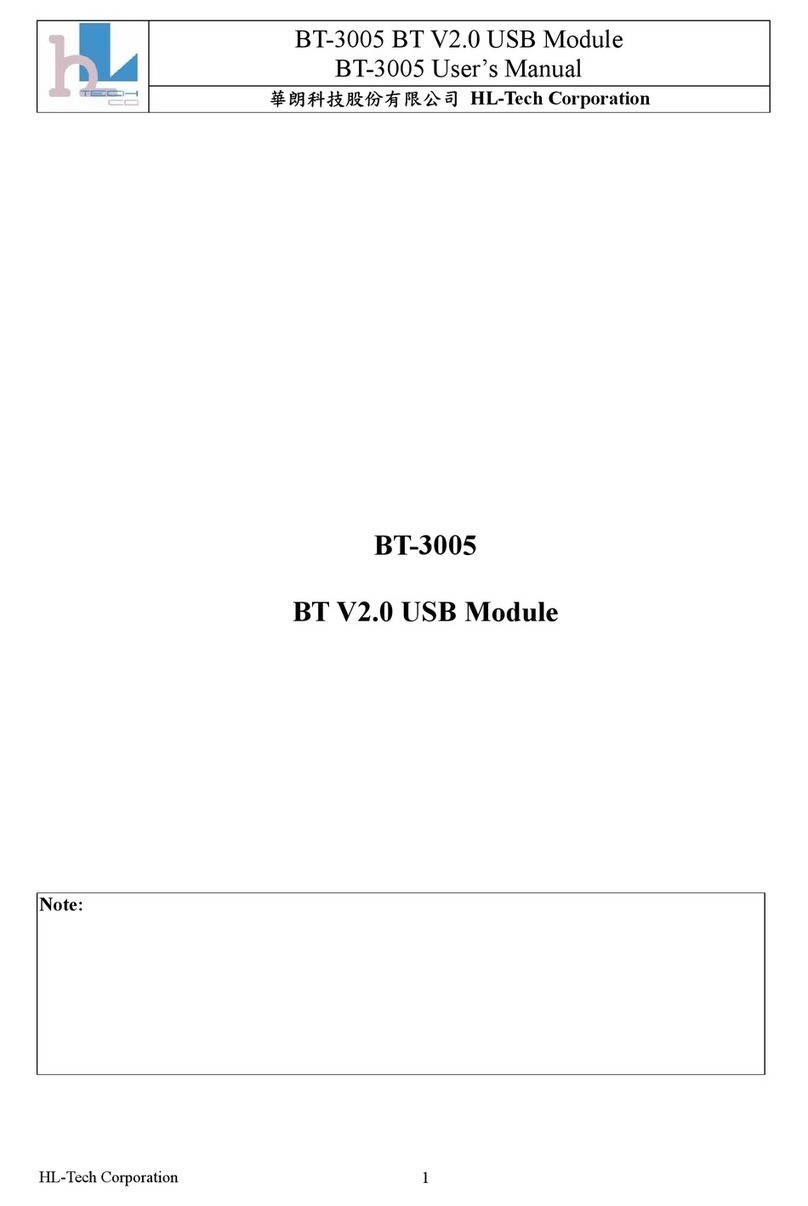

Pressure-Temperature Rating

0

50

100

150

200

250

300

-50 0 50 100 150 200 250 300 350

Temperature (oF)

Pressure (psig)

1"- 4"