Nil-Cor 300 Series Operating and maintenance manual

Nil-Cor, LLC, an Andronaco Industries Company

4855 Broadmoor Ave. S.E. ●Kentwood, MI ● 49512 ●USA ●(616) 554-3100 ●www.nilcor.com

16-May-13 1

Nil-Cor ball valves have been designed for

easy installation, assembly and

maintenance. We recommend installation

in piping systems with flat-faced flanges.

When installing against raised face flanges,

spacer rings should be used to provide a

flat surface to the face of the valve flange.

A deep stuffing box around the stem holds

PTFE chevron packing, which achieves a

leak-tight seal with minimum pressure

from the gland for ease of maintenance.

With the handle off, the gland is easily

removed for access to packing. The ball

and seats are retained by a threaded body

insert that can be removed and can be

serviced by maintenance personnel who

routinely service metallic valves. In

addition, since Nil-Cor ball valves are

one-third the weight of metal valves, they

are more easily and safely installed and

maintained. All Nil-Cor valves are equipped

with lockout devices as standard.

an Andronaco industries Company

Nil-Cor Flanged Ball Valves

Installation, Maintenance and Operating Instructions

Series 300, 310, 410, 500XP and 610XP

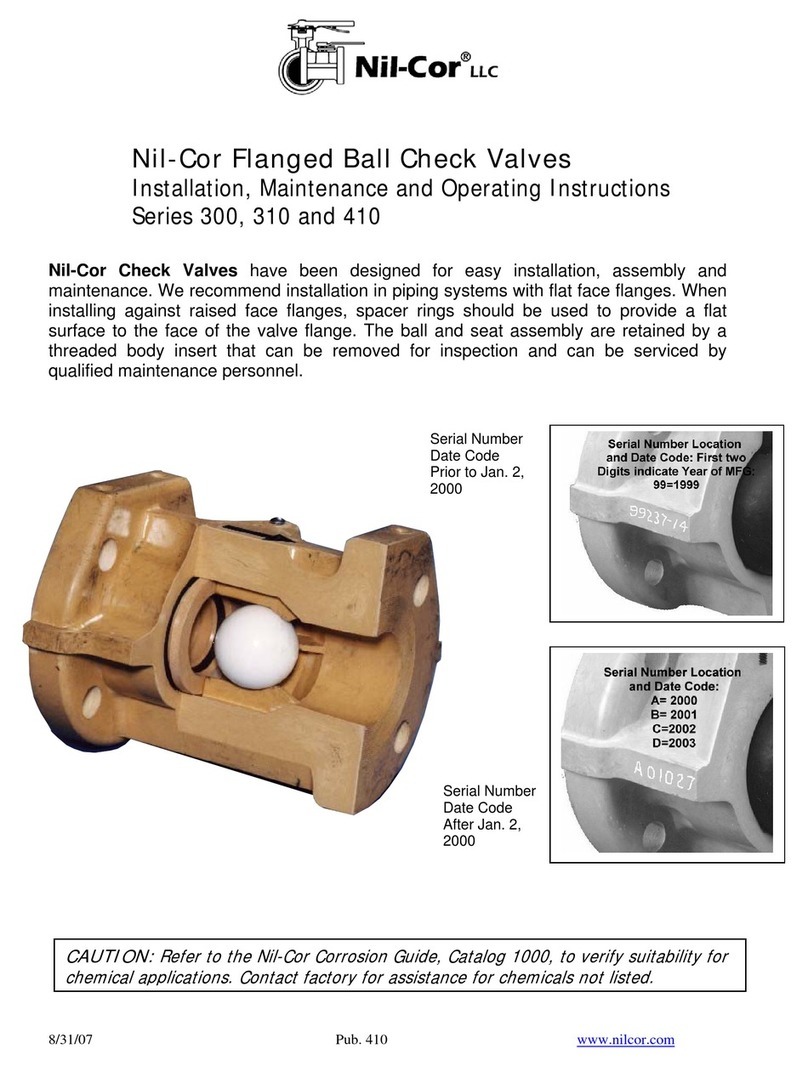

Serial Number Date Code

Prior to Jan. 2, 2000

CAUTION: Refer to the Nil-Cor Corrosion Guide, Catalog 1000, to verify suitability

for chemical applications. Contact factory for assistance for chemicals not listed.

Location of Serial Number

and Date Code

Nil-Cor, LLC, an Andronaco Industries Company

4855 Broadmoor Ave. S.E. ●Kentwood, MI ● 49512 ●USA ●(616) 554-3100 ●www.nilcor.com

16-May-13 2

Site Storage Precautions

1. For outside site storage ensure valves or containers are

wrapped in plastic or otherwise protected from ingress of

dust or blowing sand. Do not remove flange covers.

2. Actuated or gear operated valves should be kept dry.

3. Inside warehouse storage requires no special

protections.

Installation

1. Fluid flow may be in either direction and the valve may

be mounted in any position. When the valve terminates

a line, the insert end should be positioned toward the

flow direction (upstream side).

2. Pipe must be properly aligned and provisions made to

minimize stress from thermal expansion. Always

review pipe manufacturer's recommendations.

3. Expanded PTFE or 50 Durometer Rubber Full-Face

gaskets are recommended.

4. Flange Bolts should be evenly tightened, using a

torque wrench, in cross rotation to prevent flange

damage. Refer to the table below for proper flange

bolt torque. We recommend installation in piping

systems with flat-faced flanges.

5. When installing against raised face flanges, spacer

rings should be used to provide a flat surface to the

face of the valve flange.

6. When washers are used under the nuts on flange

studs, AN960 Aeronautics Specification washers

should be used. Optional stainless steel washer kits

meeting this specification are available from Nil-Cor.

7. After valve installation, the packing bolt torque should

be checked to ensure the stem seal. Refer to the table

below for the Packing Bolt Torque.

Valve Size

Flange Torque,

Min-Max (ft-lbs)

Packing Torque,

Min-Max (in-lbs)

Packing

Rings (in addition

to top and bottom

adapter rings)

1 "

20-25

20-40

2

1.5"

20-25

30-60

2

2"

20-35

35-70

2

2.5"

20-35

35-70

3

3"

25-35

50-100

3

4"

25-45

65-130

3

5"

25-40

65-130

3

6"

30-45

65-130

3

8"

40-50

65-130

3

10"

50-60

65-130

3

Safety Precautions

For your safety, it is important that these

precautions be taken before removal of the valve

from the line or before disassembly:

Wear protective clothing or equipment

appropriate for the particular fluid.

Observe the precautions and follow the

procedures in Disassembly Item 1.

Disassembly

1. Depressurize the line and valve as follows:

2. Open valve and drain the line.

3. Before removal from the line, cycle (open and close)

the valve to relieve residual pressure in the body

cavity.

4. After removal and before disassembly, cycle (open

and close) the valve several times to clear it of fluid;

then flush with water.

5. Open valve completely and remove handle.

6. Secure body in a clamping device, being careful not to

damage or crush it.

7. Remove gland bolts from the valve body.

8. Use the Insert Removal Tool, sold separately, to

unscrew body insert and remove ball, body insert

gasket, (o-ring) and the two ball seats. Take care not

to damage sealing surfaces in body or gland.

9. Carefully push valve stem down into the valve body

and withdraw it through the open end. Remove the

thrust washer from stem.

Assembly

1. Inspect and clean all parts to make sure they are free

of dust, grit or other material. New O-ring and ball

seats should be used after the valve has been used in

service and is reassembled.

2. A good lubricant compatible with the fluid service,

such as silicone grease, should be applied lightly to

seats, seal, ball, stem, and body insert threads.

3. Assemble thrust washer on stem. Carefully insert

upper end of stem into body of valve and maneuver

into opening in top of valve. Push stem upward until

thrust washer is seated.

4. While holding stem in position with one hand, slip

gland packing into cavity around upper end of stem.

See table at left for correct number of compression

rings and adapter rings. Use the gland to press

packing into place and slightly draw up the packing by

tightening the gland bolts. Assemble valve handle to

stem, insert cap screw and tighten hex nut.

5. Press one ball seat firmly into the valve body seat

cavity. When using self-relieving seats, make sure the

spherical surface of the seat faces the center of the

valve. When using seats with an o-ring backup care

should be taken to be sure that the o-ring does not fall

out or become misaligned inside the valve.

6. Rotate stem so that stem bottom is aligned axially

with the valve and ball can be fully inserted.

7. Place ball in body against seat, with ball in the closed

position. Rotate stem and ball to the open position so

that ball can not fall out.

8. Place second ball seat into the body against the ball,

and the insert O-ring in the body against the back of

the seat.

9. Screw body insert into the valve body until flange

serrations between body and insert are flush with

each other.

Nil-Cor, LLC, an Andronaco Industries Company

4855 Broadmoor Ave. S.E. ●Kentwood, MI ● 49512 ●USA ●(616) 554-3100 ●www.nilcor.com

16-May-13 3

10. Attach handle, being sure to line up stop on the gland

with the raised stop on the handle. Carefully tighten

handle setscrew to 48 in-lbs (4 ft-lbs.) max.

11. Cycle valve open and closed to turn ball slowly with a

gentle back and forth motion, building gradually to a full

quarter turn. By rotating slowly, the seat lips will assume

a permanent seal shape against the ball and prevent

damage to the seals.

12. If maximum torque levels are exceeded, the body insert

should be installed in 2 or 3 steps as follows: Tighten the

insert until about ¼ inch still protrudes beyond the valve

face, then operate the valve on and off several times as

in step 10. Tighten the insert to about 1/32-inch from

flush and operate valve several times. Tighten insert until

flush with flange. Seat leak tests at 20 and 80 psi are

recommended.

13. Gland bolts should be tightened as indicated in the table

on page 2. If leakage should occur in service, adjustment

is made by alternately turning each packing bolt ¼ turn

until the leak stops or the maximum packing torque is

reached. (See Torque Table on preceding page.)

14. If the valve is gear-operated or automated, assemble the

mounting bracket to the actuator, but do not fully tighten

the cap screws.

15. Install the coupler into the gear or actuator drive. Be

certain that the valve and actuator are in the

corresponding position, i.e., for DA actuators, the drive

should be in the full-clockwise position with the valve

closed. For SR actuators, be certain the ball is the

position corresponding to the desired actuator air-fail

position. The axis of the actuator cylinder should align

with the axis of the valve bore.

16. Bring the actuator, bracket and coupler down onto the

valve, being certain that the coupler properly engages the

stem. Visually align coupler and stem.

17. Install and tighten the flange mounting cap screws.

Tighten the actuator mounting screws.

18. Apply air and test operation.

Maintenance

Periodic observation is recommended to ensure that the valve

is functioning well. The frequency of observation depends on

the application. Adjustment to stem gland packing should be

made periodically to compensate for wear and packing

consolidation.

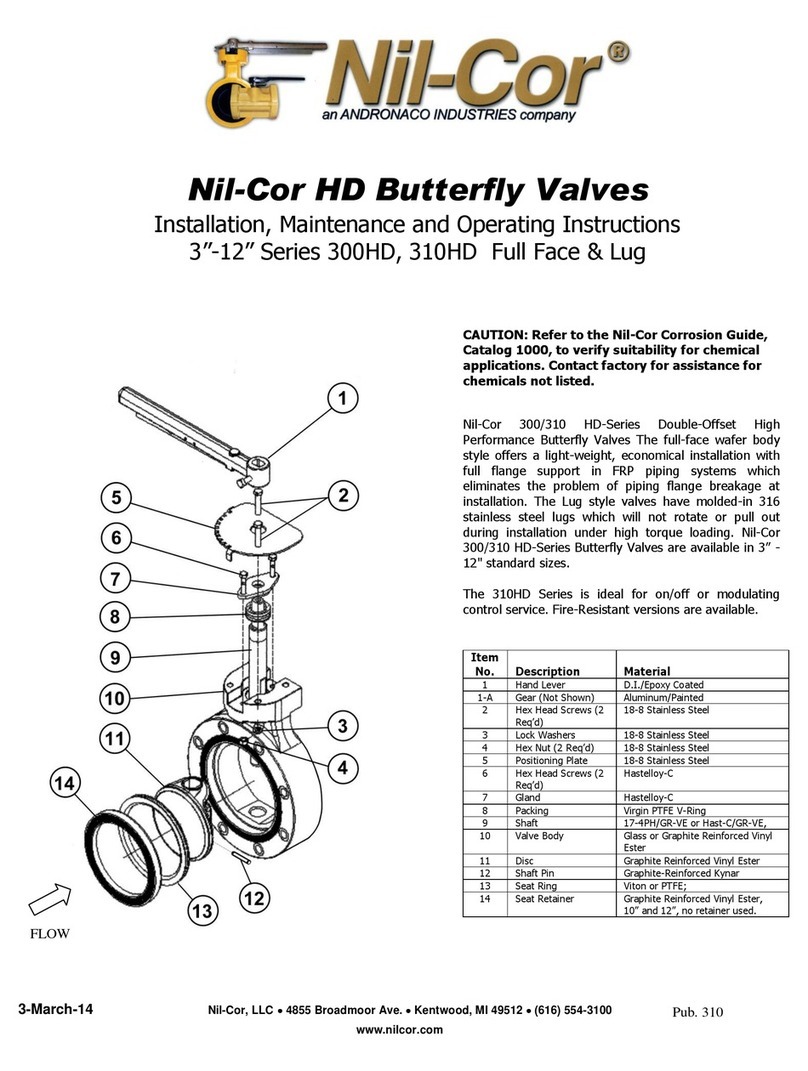

1. Setscrew: Stainless Steel.

2. Handle: VE FRP (1”-4”). All handles have locking

provision.

3. Gland Bolts: Hastelloy-C.

4. Gland: Hastelloy-C with integral locking plate.

5. Stem Packing: Chevron style PTFE.

6. Body: Solid construction of fiberglass or graphite

reinforcement and resin matrix.

7. Thrust Washer: Glass and carbon-filled PTFE.

8. Stem: Hastelloy-C metal insert with molded

composite on all wetted surfaces.

9. Seats: Virgin PTFE. Glass-filled and cavity-filler

seats available.

10. Ball: Solid construction of fiberglass or graphite

reinforcement and same resin as body.

11. Seals: PTFE-coated Viton O-ring.

12. Insert: Solid composite, same as body material.

13. Insert Removal Tool

B

A

C

D

Line Flange

Gasket

Nil-Cor Valve Flange

E

For Metal Flanges For FRP Flanges

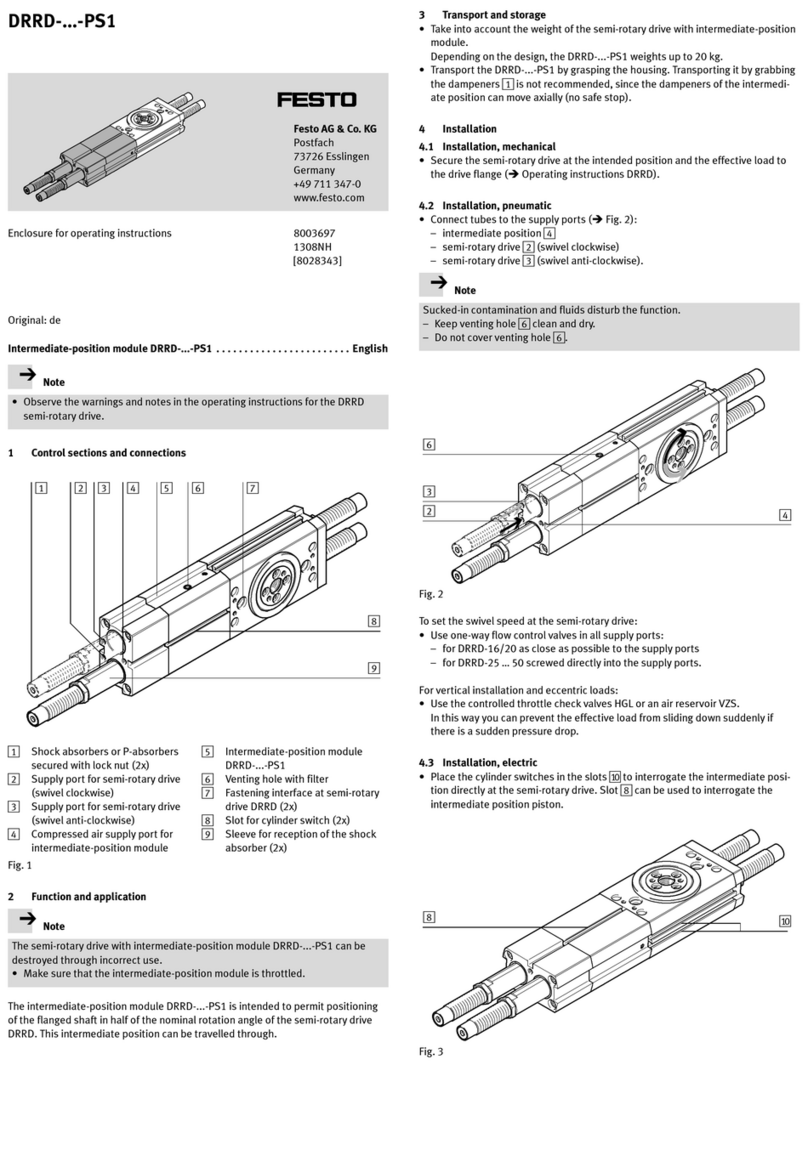

SIZE A (FRP) B C D E No. Size and Length Size and Length

1" 0.875 0.13 0.88 0.5 0.2 4 1/2-13 UNC x 2.25" 1/2-13 UNC x 3.25"

1.5" 1.188 0.13 1.00 0.5 0.2 4 1/2-13 UNC x 2.5" 1/2-13 UNC x 3.5"

2" 1.188 0.13 1.00 0.63 0.2 4 5/8-11 UNC x 2.75" 5/8-11 UNC x 3.5"

2.5" 1.188 0.13 1.19 0.63 0.2 4 5/8-11 UNC x 3.0" 5/8-11 UNC x 3.5"

3" 1.188 0.13 1.36 0.63 0.2 4 5/8-11 UNC x 3.5" 5/8-11 UNC x 4.0"

4" 1.5 0.13 1.50 0.63 0.2 8 5/8-11 UNC x 3.75" 5/8-11 UNC x 4.25"

5" 1.6 0.13 1.50 0.76 0.2 8 5/8-11 UNC x 3.75" 5/8-11 UNC x 4.5"

6" 1.6 0.13 1.63 0.76 0.2 8 3/4-10 UNC x 4.0" 3/4-10 UNC x 4.75"

8" 2.06 0.13 1.75 0.76 0.2 8 3/4-10 UNC x 4.5" 3/4-10 UNC x 5.0"

10" 3.06 0.13 2.00 0.89 0.2 12 7/8-10 UNC x 4.75" 7/8-10 UNC x 6.5"

Nil-Cor Ball Valve Flange Bolt Lengths

Materials of

Construction

13

Nil-Cor, LLC, an Andronaco Industries Company

4855 Broadmoor Ave. S.E. ●Kentwood, MI ● 49512 ●USA ●(616) 554-3100 ●www.nilcor.com

16-May-13 4

Valve

Size

A

B

C

D

E

F

G

H

J-

Lever

J -

Gear

HW

Dia

HW

Hgt

K

K

(QTY)

L

M

W

1”

5.00

.88

1.00

2.25

3.13

4.25

.88

2.50

3.08

5.60

8

8.00

.62

4

2.77

6.25

6.32

1-1/2”

6.50

1.25

1.50

3.00

3.88

5.00

1.00

3.25

3.73

6.53

8

8.92

.62

4

3.55

6.25

6.32

2”

7.00

1.50

2.00

3.66

4.75

6.00

1.00

3.50

4.18

6.71

8

9.11

.75

4

3.96

9.00

6.32

2-1/2”

7.50

1.88

2.50

4.25

5.50

7.00

1.19

3.75

5.44

8.52

8

10.92

.75

4

5.17

9.00

6.32

3”

8.00

2.31

3.00

5.00

6.00

7.50

1.36

4.00

5.58

8.52

8

10.92

.75

4

5.42

9.00

6.32

4”

9.00

3.00

4.00

6.19

7.50

9.00

1.50

4.50

7.05

9.56

8

11.96

.75

8

6.50

11.44

6.32

5”

10

3.75

5.00

7.50

8.50

10.00

1.50

5.00

7.75

11.08

12

14.46

.88

8

7.21

Note 4

7.39

6”

10.50

4.50

6.00

8.50

9.50

11.00

1.63

5.25

10.51

11.58

12

14.96

.88

8

7.91

Note 4

7.39

8”

11.50

6.00

8.00

11.25

11.75

13.50

1.75

5.75

11.77

13.00

12

17.11

.88

8

9.21

Note 4

8.77

10”

13.00

7.50

10.00

14.00

14.25

16.00

2.00

6.50

NA

13.64

18

17.50

1.00

12

11.10

NA

8.77

Actuation Mounting Dimensions

Actuation Torque (in-lbs.)

Weight (lbs.)

Valve

Size

N

P

R x (deep1)

S

T

+.000-

.010

U

+.000-

.010

V

Valve

Running

Torque

(2)

Breakaway

Torque (3)

0-100 psi

Breakaway

Torque (3)

>100 psi

Flow

Coeff.

Max

Cv

w/o

Gear

(lbs.)

With

Gear

(lbs.)

1”

4.18

1.75

5/16 - 18 x 1/2

0.64

0.50

0.375

0.500

90

140

160

75

3

9

1-1/2”

5.62

1.75

5/16 - 18 x 1/2

1.05

0.70

0.375

0.500

125

190

230

115

6

12

2”

6.18

2.25

5/16 - 18 x 5/8

0.96

0.75

0.375

0.625

150

230

270

135

8

15

2-1/2”

6.62

2.63

3/8 - 16 x 3/4

1.67

0.75

0.50

0.88

260

400

475

250

13

20

3”

7.12

3.50

3/8 - 16 x 3/4

1.67

0.75

0.500

0.875

370

570

680

350

14

21

4”

8.00

4.00

7/16 - 14 x 7/8

2.00

1.13

0.750

1.000

680

1040

1250

540

23

30

5”

9.00

4.75

7/16 - 14 x 7/8

2.21

1.13

0.75

1.00

1000

1570

1825

1000

33

46

6”

9.00

5.25

7/16 - 14 x 1-1/8

2.41

1.13

0.750

1.000

1400

2100

2400

1240

40

53

8”

9.75

6.00

7/16 - 14 x 1-1/8

2.46

1.13

1.094

1.250

2800

4200

4800

1700

65

90

10”

11.25

7.75

½ - 13 –X 1-1/8

3.10

1.13

1.258

1.438

4100

6300

7200

2600

100

125

Pressure/Temperature Rating

0

50

100

150

200

250

300

-50 050 100 150 200 250 300

Temperature (0F)

Pressure (psig)

4” - 10”

2”, 3”

1”, 1-1//2”

J-For 6”, 8”

Handle

Adapter only

1. Minimum thread engagement required to develop design joint strength on the actuator mounting pad (composite valve body).

2. Flowing fluid, ball in motion between 0 and 90 deg.

3. Maximum breakaway torque for clean liquid service.

4. For manual 5”-8” size, use handle adapter or gear operator. Gear only on 10”

Flanged Ball Valve Dimensions

This manual suits for next models

4

Other Nil-Cor Control Unit manuals