Table 1: System 450 terminal wiring information

Label Terminal function Wire sizes

LNC1, LNC2 1Connects equipment control circuit to the normally closed contact on the SPDT1 relay.

LNO1, LNO2 Connects equipment control circuit to the normally open contact on the SPDT1 relay.

LC1, LC2 Connects line (power) to common on the SPDT1 relay.

0.08 mm2 to 2.5 mm2

28 AWG to 14 AWG

1 See Internal SPDT Relay insert in Figure 2 for more System 450 relay contact and terminal information. See System 450 Series Reset

Control Modules with Real-Time Clock and Relay Output technical specifications for SPDT relay electrical ratings.

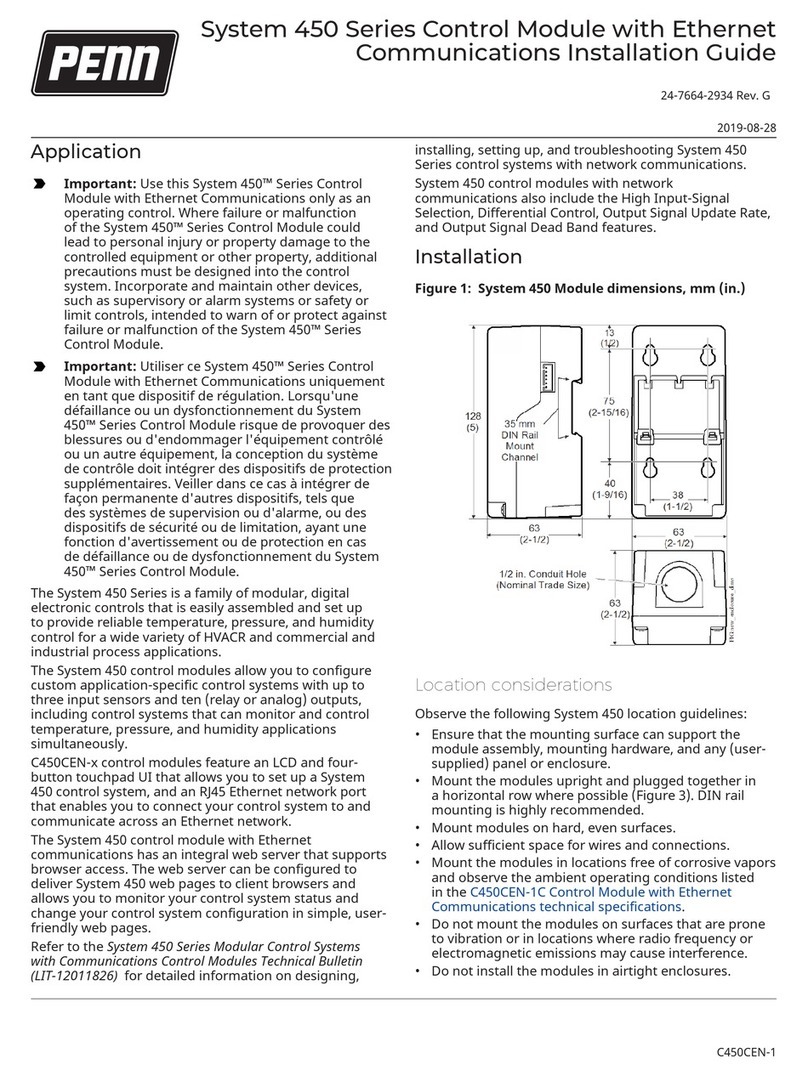

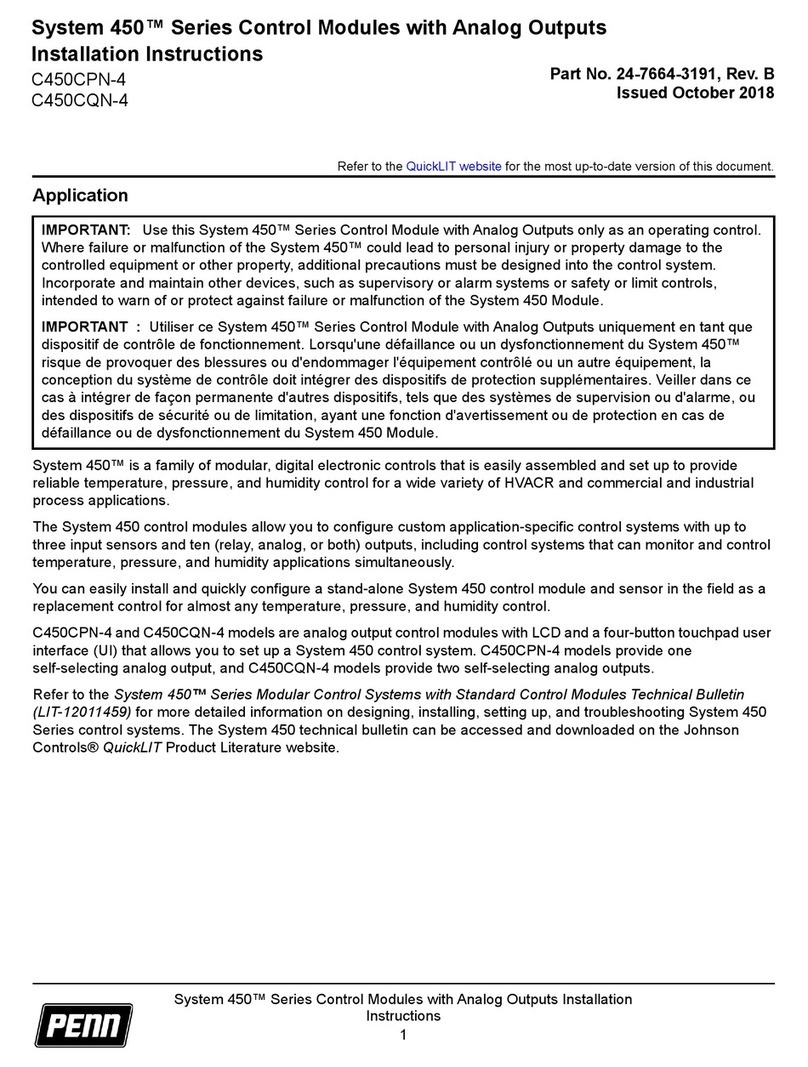

Figure 4: System 450 Reset Control Module output

relay LEDs, LCD, and four-button touch pad UI

Table 2: System 450 Control Module Output Analog

LEDs, LCD, four-button touchpad UI

Callout Feature Description

1 Status or setup

value

Displays the current input status, output status, or

setup parameter value for the displayed input sensor

or output. Press Down or Up to select a different

parameter value when the value is flashing. Here,

100 = 100%.

2 LED Green LEDs on Control Modules and Expansion

Modules with relays (only) indicate if the associated

Relay Output is On or Off.

3 Output (or

Sensor) number

Displays a numerical value that identifies the output

or sensor associated with the status or setup

value shown on the screen. Output numbers are

automatically determined by the outputs' physical

positions (left to right) in the module assembly. Here,

4 = Output 4.

4 Control ramp

icon

Displays whether an analog output increases

or decreases as the sensor input increases, and

whether the output signal strength is at minimum or

maximum when the sensed property is at Setpoint.

The control ramp icon displayed is determined by the

output's SP, EP, Pb, OSET, OSP, and OEP setup values.

5 Next button In the Main screens, press Next to scroll through the

system status screens. In a setup screen, press Next

to save the flashing setup value and go to the next

setup screen.

6 Up and Down

buttons

Press Up or Down to select a different value for any

flashing value in the setup value field. In the Main

sensor status screens, press and hold both Up and

Down for 5 seconds to access the Setup Start screens.

7 Menu button Press M to move through the sensor and output

setup start screens. When moving through the status

or setup screens, press M to return to the status start

screen or setup start screen.

Table 2: System 450 Control Module Output Analog

LEDs, LCD, four-button touchpad UI

Callout Feature Description

8 Status or setup

identifier

Displays the unit of measurement, output, sensor

number, or setup parameter for the displayed

status or setup value. Here, the setup identifier OSP

represents % output signal strength at setpoint.

9 LCD Backlit LCD screen. The LCD brightness is adjustable.

During normal operation, the LCD displays the Main

screens.

Setup and adjustments

A System 450 reset control system consists of one reset

control module, one to three input sensors, and one to

ten outputs that provide any combination of (On/Off)

relay control or (0–10 VDC or 4–20 mA) analog control.

Figure 3 shows a reset control system for two boilers, a

boiler water circulation pump, and an outside air damper.

Setting up a module assembly

1. Determine the controlled conditions, sensor types,

and value ranges required for your control system,

and select the appropriate System 450 sensors.

2. Determine the number and type (relay or analog)

of outputs required to control your application, and

select the appropriate System 450 control module

and expansion modules.

3. Assemble the control and expansion modules,

starting with the control module on the left.

Note: If you use a C450YNN-1 power module, it

must be plugged into the control module. Plug

in any expansion modules (for your control

system) to the right of the power module.

4. Apply supply power to the module assembly.

You can now set up your control system in the System 450

reset control module UI.

Note: After you power on your module assembly,

you can set up your control system in the control

module UI before wiring the sensors or outputs to

your assembly.

Setting active/passive sensor jumpers

Before putting your System 450 reset control system into

operation, you must set up each sensor in your system

as either passive or active by positioning the jumper on

the terminal pins on the terminal block located below the

sensor terminal block. See Figure 3.

System 450 Series Reset Control Modules with Real-Time Clock and Relay Output Installation Guide 5