Nilar ReOx 1 User manual

Document ID: 73-H001. Copyright © Nilar AB. All rights reserved.

Page 0 (39)

INSTRUCTION MANUAL

Thank you for purchasing a Nilar product.

It is required to read and understand these instructions carefully for a safer installation and operation, as well as

optimum performance and longer service life.

Keep this manual in a safe place for future reference.

This manual may be modified and updated without prior notice. Contact Nilar for validation.

Colours used in illustrations, e.g., for cables, are only illustrative and might deviate from the actual colour.

Without written permission from Nilar, this manual is not to be copied or transferred for other purposes, neither in its

entirety nor parts of it.

The product described in this manual is manufactured in compliance with the Low Voltage Directive (LVD) 2014/35/EU,

the Electromagnetic Compatibility Directive (EMCD) 2014/30/EU, and Restrictions of Hazardous Substances (RoHS)

Directive 2011/65/EU.

The product contains metal hydride battery packs that follow the EU-directive 2006/66/EC (‘Battery Directive’). The

battery packs do not contain the heavy metals lead, mercury, or cadmium.

The product adheres to the Waste Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU. This means that

the manufacturer/importer is responsible for the manufactured products being collected, taken care of, and recycled

after they have reached the end of their lifespan.

Nilar products are in compliance with EU regulation (EC) No. 1907/2006 concerning the Registration, Evaluation,

Authorization, and restriction of Chemicals (REACH). We check that our suppliers comply with REACH requirements for

all the materials and components they deliver to us.

©Nilar AB. All rights reserved.

Document identification: 73-H028

Version

Status

Date

1.0

Released for ReOx 1

2022-12-07

INSTRUCTION MANUAL

This manual will give you, as a reader, all the necessary instructions for more professional and safer handling of the

product. Read the manual carefully to avoid mistakes and risks. The manual is divided into the following chapters:

Chapter

Content

1. Safety Information

General safety information

2. Technical Support and Warranty

References

3. Environment

Content, recycling

4. Function description

General description of the product

5. Transportation, lifting, and storage

Instructions, conditions

6. Installation

Instructions for installation

7. Operation

Operational conditions

8. Maintenance

Advises, schedules

9. Decommissioning

Instructions, references

10. Troubleshooting

Self-help

INSTRUCTION MANUAL

Table of contents

1. Safety Information...........................................................................................................................1

1.1 Safety markings in this instruction.................................................................................................................. 1

1.2 General warnings and cautions ...................................................................................................................... 1

2. Technical support and warranty......................................................................................................3

3. Environment ....................................................................................................................................4

3.1 Compliance..................................................................................................................................................... 4

4. Function description........................................................................................................................5

4.1 Datasheet ....................................................................................................................................................... 5

4.2 Battery pack specification and build-up.......................................................................................................... 6

4.3 Front of the battery pack................................................................................................................................ 7

4.4 Connections IMU............................................................................................................................................ 9

4.5 Signals IMU................................................................................................................................................... 10

4.6 Reoxygenating (ReOx)........................................................................................................................................ 11

5. Transportation, lifting, and storage ...............................................................................................12

5.1 Transportation.............................................................................................................................................. 13

5.2 Moving and lifting......................................................................................................................................... 14

5.3 Storage ......................................................................................................................................................... 14

6. Installation .....................................................................................................................................15

6.1 General conditions on-site............................................................................................................................ 16

6.2 Preparation of connections before installation ............................................................................................ 17

6.3 Orientation and placement of battery pack.................................................................................................. 17

6.4 Installation of a single battery pack .............................................................................................................. 18

6.5 Series connection of battery packs to form a battery string......................................................................... 20

7. Operation.......................................................................................................................................23

7.1 Charging........................................................................................................................................................ 23

7.2 Discharging ................................................................................................................................................... 24

7.3 Resistance..................................................................................................................................................... 24

7.4 Self-discharge ............................................................................................................................................... 24

7.5 Cycle life ....................................................................................................................................................... 24

INSTRUCTION MANUAL

8. Maintenance..................................................................................................................................25

8.1 Protective measures during maintenance .................................................................................................... 25

9. Decommissioning...........................................................................................................................26

9.1 Temporarily decommissioning...................................................................................................................... 26

9.2 Permanent decommissioning ....................................................................................................................... 26

9.3 Damage......................................................................................................................................................... 26

10. Troubleshooting............................................................................................................................27

11. Appendix 1: Information bulletin, IT-grounding ..........................................................................28

INSTRUCTION MANUAL

Figures

Figure 1: Indication of the serial number on the battery pack ...................................................................................................3

Figure 2: Overview of 144 V and 120 V battery packs incl. IMU (from left to right) .................................................................5

Figure 3: Build-up of a 144 V battery pack with IMU ..................................................................................................................5

Figure 4: Measurement illustration of 144 V battery pack with length incl. IMU .....................................................................6

Figure 5: Parts of 144 V Battery pack excl. IMU...........................................................................................................................6

Figure 6: 144 V Battery pack .........................................................................................................................................................7

Figure 7: Design, positive (+) chassis connector, type Phoenix 1805180...................................................................................8

Figure 8: Design, negative (-) chassis connector, type Phoenix 1805177 ..................................................................................8

Figure 9: Design, positive (+) cable connector, type Phoenix 1774674 .....................................................................................8

Figure 10: Design, negative (-) cable connector, type Phoenix 1774687...................................................................................8

Figure 11: Disconnection of cable connectors.............................................................................................................................8

Figure 12: Overview of IMU with the cover lid removed ............................................................................................................9

Figure 13: CAN connector, Shielded RJ45 ..................................................................................................................................10

Figure 14: 144 V Battery pack with IMU on front and location of ReOx connector ................................................................11

Figure 15: Orientation of battery pack.......................................................................................................................................12

Figure 16: Battery pack incl. lifting straps ..................................................................................................................................14

Figure 17: Orientation of battery pack.......................................................................................................................................17

Figure 18: Before and after placement of battery pack on insulation tray..............................................................................18

Figure 19: Before and after cover lid removal ...........................................................................................................................18

Figure 20: Installation of CAN connection into CAN port on IMU ............................................................................................19

Figure 21: Installation of negative (-) cable before connection (IMU connections not displayed).........................................19

Figure 22: Installation of negative (-) cable after connection (IMU connections not displayed)............................................19

Figure 23: Installation of positive (+) cable before connection (IMU connections not displayed) .........................................20

Figure 24: Installation of positive (+) cable after connection (IMU connections not displayed) ............................................20

Figure 25: Finished installation of interpack cable between the ‘first’ and ‘secondary’ battery pack (IMU connections are

not displayed) ..............................................................................................................................................................................22

Figure 26: Finished installation of interpack cable between the ‘first’, ‘second’, third, and ‘fourth’ battery packs (IMU

connections are not displayed)...................................................................................................................................................22

Figure 27: Finished installation of interpack cable between the ‘first’, ‘second’, third, and ‘fourth’ battery packs and

cables from the BMS (IMU connections are not displayed)......................................................................................................22

Figure 28: WEEE symbol for separate disposal..........................................................................................................................26

INSTRUCTION MANUAL

Tables

Table 1: Technical specification of ReOx 1 battery pack in various sizes @ +20oC....................................................................5

Table 2: Description of visual signals............................................................................................................................................9

1. SAFETY INFORMATION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 1 (39)

1. Safety Information

This chapter contains safety information that applies to

the Nilar battery pack.

To avoid personal injury, do not perform any service

unless you are qualified. Refer to all safety summaries

before installing, operating, maintaining, and

decommissioning. For a more detailed specification

regarding safety, contact Nilar.

1.1 Safety markings in this instruction

1.2 General warnings and cautions

WARNING! Wear electrically insulated gloves when

handling a battery pack. Battery pack surfaces may carry

hazardous voltage due to lowered insulation resistance.

Do not place battery packs on conductive surfaces.

WARNING! Risk for electric shock and arcing if the

product is misused or electrically installed incorrectly.

WARNING! The battery packs cannot be switched off.

Please note:

•Work only with one battery pack terminal at a

time.

•The printed circuit board (PCB); Integrated

Monitoring Unit (IMU) at the front of the battery

pack may have hazardous voltage.

•The rupture disc may release electrolyte during

abnormal use. We, therefore, recommend

wearing safety glasses.

WARNING! Risk for electrical hazards if the product is

exposed to rain or moisture.

WARNING! Never install a damaged battery pack or a

damaged insulation tray.

WARNING! If a battery fire occurs, it can be extinguished

by using CO2. Ensure that fire extinguishers are

available.

WARNING! Do not operate the product with suspected

failures. If you suspect the product is damaged, have it

inspected by qualified service personnel.

WARNING! Do not block or cover the rupture disc outlet

at the back of the battery pack.

CAUTION! To avoid potential hazards, use this product

only as specified.

CAUTION! Do not install other battery chemistry types or

batteries together with Nilar’s battery packs.

CAUTION! If the battery pack(s) is damaged

mechanically, the following may occur:

•High heat generation on battery pack surface.

•Electrolyte may escape.

•The smoke from burning battery packs can irritate the

skin, eyes and respiratory system.

Therefore, follow these guidelines:

•Do not open the battery pack.

•Do not modify or mechanically damage the battery

pack or its cables

•Operate the battery pack only within the allowed

operating range.

•Do not short-circuit the battery pack(s).

•Do not continue to use the battery pack after

identified as faulty.

CAUTION! Do not install or place the products in direct

sunlight for a longer time to avoid potential damage to

plastics on the battery pack and insulation tray.

CAUTION! Do not expose the battery pack or insulation

tray to heat or fire.

The exclamation mark within an

equilateral triangle is intended to

alert the user that negligence of

this information can be life

threatening.

WARNING!

The exclamation mark within a

circle is intended to alert the user

that negligence of this information

can be associated with bodily

injury and/or damage to the

product.

CAUTION!

1. SAFETY INFORMATION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 2 (39)

CAUTION! Do not operate the product with the covers

removed. If covers are removed during, e.g., repair, do

not touch any exposed connections.

CAUTION! The product shall not be exposed to liquids

(not even dripping or splashing), and objects filled with

liquids shall not be placed on or close to the product.

CAUTION! The product shall be installed inside an

enclosure with panels and doors that only a key or

screws can open.

CAUTION! Remove personal metal items from hands,

wrists and neck, such as rings, bracelets, necklaces, and

watches, when physically handling the product since it

can result in a short-circuit current, causing a severe

burn. Please note:

•We recommend using tools rated to 1000 VAC

according to EN 60900.

•We recommend using flame-resistant protective

clothing according to EN 61482-1-1 and rated as

minimum class 1 according to EN 61482-1-2.

CAUTION! Keep product surfaces clean and dry.

2. TECHNICAL SUPPORT AND WARRANTY

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 3 (39)

2. Technical support and warranty

The battery pack’s serial number can be found on the

side of the battery pack at the top ①.

①

Figure 1: Indication of the serial number on the battery pack

Please see the separate document for the detailed

warranty and conditions.

Please make sure to always have

your serial number of your

product(s) available for warranty

and technical support matters.

CAUTION!

3. ENVIRONMENT

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 4 (39)

3. Environment

This chapter will inform about how the Nilar battery

pack is recycled.

When the Nilar battery pack has reached its end of life

(EOL), Nilar takes full responsibility for the recycling

process by accepting the complete battery packs back.

Contact your local Nilar representative for more

information. The recycling process ensures that most

materials are reused or recycled appropriately.

3.1 Compliance

Nilar products are compliant with the following

environmental directives and regulations:

•EU-Directive 2006/66/EC (‘Battery Directive’).

The battery pack(s) do not contain the heavy

metals lead, mercury or cadmium.

•Waste Electrical and Electronic Equipment

(WEEE) Directive 2012/19/EU.

•Restrictions of Hazardous Substances according

to RoHS Directive 2011/65/EU.

•Nilar products comply with EU regulation (EC)

No. 1907/2006 concerning the Registration,

Evaluation, Authorisation and Restriction of

Chemicals (REACH).

4. FUNCTION DESCRIPTION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 5 (39)

4. Function description

This chapter will describe the functions of the various

parts of the battery pack.

Figure 2: Overview of 144 V and 120 V battery packs incl. IMU (from left to right)

Figure 3: Build-up of a 144 V battery pack with IMU

1

For more information, see section 6.1.2 Humidity and ventilation

4.1 Datasheet

Table 1: Technical specification of ReOx 1 battery pack in various sizes @ +20oC

Properties

96V

108V

120V

144V

Unit

Rated energy

0.96

1.08

1.20

1.44

kWh

Nominal

voltage

96

108

120

144

VDC

Max.

continuous

charging power

0.96

1.08

1.20

1.44

kW

Max.

continuous

discharging

power

0.96

1.08

1.20

1.44

kW

Dimensions

(LxHxW)

246 x

306 x

127

269 x

306 x

127

291 x

306 x

127

335 x

306 x

127

mm

Weight

24

26

29

34

kg

Ingress

protection

(Battery pack)

20

20

20

20

IP

Battery pack

voltage range

80-132

90-144

100-160

120-192

V

Min - Max.

allowed

ambient

humidity

(without

condensation)1

5 –55

5 –55

5 –55

5 –55

% RH

Ambient

operating

temperature

0 to +30

0 to +30

0 to +30

0 to +30

oC

Battery pack

operating

temperature

0 to +55

0 to +55

0 to +55

0 to +55

oC

Allowed

ambient

temperature

for handling

-20 to

+40

-20 to

+40

-20 to

+40

-20 to

+40

oC

Overvoltage

category

III

III

III

III

Category

EMC

EN 61000-6-2:2005 (Immunity)

EN 61000-6-3:2007 (Emission)

IEC

Maximum

installation

altitude

2000

2000

2000

2000

m (a.s.l.)

4. FUNCTION DESCRIPTION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 6 (39)

4.2 Battery pack specification and build-up

A battery pack can contain between 8 and 12 modules

(12 VDC per module), and each module always contains

10 battery cells.

Battery packs are designed to be used in systems with a

maximum system voltage of up to 800 VDC. The

maximum voltage is obtained during charging, namely

when fully charged.

Note! The following measurements do not include the

additional space that is required for an insulation tray, which is

mandatory for all installations (see section 6.3 Orientation

and placement of battery pack).

Figure 4: Measurement illustration of 144 V battery pack with length incl. IMU

①

②

③

④

⑤

Figure 5: Parts of 144 V Battery pack excl. IMU

4.2.1 Rupture disc (① not displayed)

The Nilar battery pack is fitted with a ‘rupture disc’that

is activated when the pressure is too high. The rupture

disc is located on the rear side of the battery pack. The

rupture disc is only activated under abusive conditions.

4.2.2 Module voltage terminals (②)

Each module provides the IMU (see section 4.5.1

Module voltages) with voltage through the

module voltage terminals. From each module’s pole

terminal (first to last), there is a cable to the IMU.

306 mm

335 mm

127 mm

4. FUNCTION DESCRIPTION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 7 (39)

4.2.3 End pieces (③, blue ●)

There is one end piece on each side of the battery pack

to ensure the required compression.

4.2.4 Steel strapping bands (④, black ●)

The battery pack is bound together by three (3) isolated

steel strapping bands, and their function is both to hold

the modules together and to ensure the correct

compression for the battery pack.

4.2.5 Module (⑤, black and white cream ●●)

The 12 V module is the building block for all Nilar

battery packs. Ten (10) cells are connected in series to

create modules with a rated capacity of 10 Ah and

nominal voltages of 12 VDC.

4.3 Front of the battery pack

The Integrated Monitoring Unit (IMU) is attached to the

front of the battery pack behind the cover lid, with one

IMU per battery pack.

Positive terminal (+)

Negative terminal (-)

Cover lid for connections of IMU

Figure 6: 144 V Battery pack

4. FUNCTION DESCRIPTION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 8 (39)

4.3.1 Negative (-) and positive (+) terminals

The terminal posts are located on the upper side of the

IMU. The connections are ‘Phoenix Sunclix PV, chassis

connector’type. The cables to connect the battery

packs need to have the connection type ‘Phoenix

Sunclix PV, cable connector’. A flat screwdriver is

required to detach the assembled male and female

connection. The chassis-mounted terminals come as

standard equipment with the battery pack.

Figure 7: Design, positive (+) chassis connector, type Phoenix 1805180

Figure 8: Design, negative (-) chassis connector, type Phoenix 1805177

Figure 9: Design, positive (+) cable connector, type Phoenix 1774674

Figure 10: Design, negative (-) cable connector, type Phoenix 1774687

In order to detach the assembled male and female

connection, a flat screwdriver is needed.

Figure 11: Disconnection of cable connectors

Never detach the assembled male

and female connection during load.

This is related to electrical arcs or

sparks hazards.

WARNING!

4. FUNCTION DESCRIPTION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 9 (39)

4.4 Connections IMU

All connections for the IMU are to be found under the

cover lid.

①

②

③

④

⑤

Figure 12: Overview of IMU with the cover lid removed

4.4.1 Reset button (①)

By pushing the Reset button, the IMU will be manually

restarted.

4.4.2 Operation LED (②)

The operation LED indicates the status of the IMU, as

displayed in the following table.

Table 2: Description of visual signals

Visual signal

State

●Green

Normal mode (system measuring is

active)

●Red

Active alarm

●Yellow

Start-up sequence (IMU requests

settings input from superior control

system)

●White

Automatic addressing on IMU

An IMU that is running in normal mode will flash:

Green →off →Green →off etc.

An IMU that does not have the correct safety pulse IN

will have static light:

Yellow

An IMU that is in addressing mode will flash:

White →off →White →off etc.

An IMU that is in addressing mode with no safety pulse

IN will have a static light:

White

An IMU with an active safety alarm will replace the

green signal and hence flash:

Red →off →Red →off etc.

4. FUNCTION DESCRIPTION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 10 (39)

4.4.3 Communication connections, (③)

Connections that are available on the IMU are as

follows:

④ CAN + safety IN (From SCU or IMU)

⑤CAN + safety OUT (to SCU or IMU)

The CAN connections (type: RJ45/8P8C shielded) are

used as input and output per battery pack in order to

series connect the battery string for communicating

with the IMU as described in section 4.5 Signals

IMU.

Figure 13: CAN connector, Shielded RJ45

4.5 Signals IMU

The IMU monitors the following signals and

communicates them to the Battery Management

System (BMS), which is briefly explained in subsequent

sections.

For more detailed descriptions, please see the

Integrations Manual for BMS 3.0, 73-H027.

4.5.1 Module voltages

The voltage monitors measure the voltage of each

module. An alarm will be triggered if the actual voltage

is out of the defined range.

In addition to the module voltages, the combined

voltage of the battery pack is also measured and

presented as a total battery pack voltage value.

4.5.2 Pressure sensor

An internal battery pressure sensor measures the

relative pressure in each battery pack. Due to the

common gas channel in the Nilar bipolar pack design, all

the cells in the battery pack have the same pressure. If

the pressure is out of the defined range, an alarm will

be triggered and communicated to the BMS to prevent

damage due to high pressure.

4.5.3 Battery temperature

There is a temperature sensor in each battery pack that

measures the temperature. If the temperature exceeds

the defined range, an alarm will be triggered and

communicated to the BMS to prevent the battery from

overheating.

4.5.4 Safety

A safety circuit is built into the IMU and monitors the

battery packs’pressure and temperature.

4. FUNCTION DESCRIPTION

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 11 (39)

4.6 Reoxygenating (ReOx)

Nilar’s battery pack is fitted with a connector for the

Reoxygenating service. The connector is only for the

Reoxygenating service and should not be used in normal

operation.

Nilar performs the Reoxygenating service of the battery

pack(s). Please contact Nilar for more information about

when your battery pack(s) needs a reoxygenating

service.

ReOx connector

Figure 14: 144 V Battery pack with IMU on front and location of ReOx connector

Do not modify or mechanically

damage the pneumatic ReOx

connection. Hydrogen and oxygen

might escape from the inside of the

battery pack.

WARNING!

Do not connect anything to the

pneumatic ReOx connection

without permission and instructions

from Nilar. Hydrogen and oxygen

might escape from the inside of the

battery pack.

WARNING!

5. TRANSPORTATION, LIFTING, AND STORAGE

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 12 (39)

5. Transportation, lifting, and storage

This chapter deals with Nilar products’ required

conditions when transported, moved, lifted, and stored.

The battery packs must always be placed in an upright

position (with the terminals in the upper position)

during transportation and storage:

Figure 15: Orientation of battery pack

Battery pack surfaces may carry

hazardous voltage due to lowered

insulation resistance. Always

transport and/or store the battery

packs on insulating (non-

conductive) surfaces.

WARNING!

Please make sure that the battery

packs are positioned in the correct

way during transportation and

storage. If the battery pack tips over

turn it up as soon as possible.

CAUTION!

Always wear Personal Protective

Equipment (PPE) when handling

battery packs. At minimum this

includes:

Safety glasses, safety shoes with

steel toe and electrically insulated

gloves.

CAUTION!

5. TRANSPORTATION, LIFTING, AND STORAGE

Document ID: 73-H028. Copyright © Nilar AB. All rights reserved. Page 13 (39)

5.1 Transportation

When transporting Nilar products, some preparations

and precautions must be taken, which will be described

in this part of the chapter.

5.1.1 Packaging, duration and outside conditions

Nilar battery packs are delivered well-protected in their

original packaging. Nevertheless, transport damages can

occur. If any transport damage is discovered:

•Document the damage

•Report the damage to the responsible logistics

company

•Contact your local Nilar representative

If undamaged, we advise keeping the original packaging

for future transportation. If this is not possible, please

get in touch with your local Nilar representative.

Transport duration, incl. storage, shall be made at an

ambient temperature of −20°C to +40°C.

5.1.2 Transportation regulations of Battery packs

Nilar battery packs do not require UN-approved

packaging or marking when transported by sea, road,

rail, or air.

No dangerous goods documentation is required when

transporting Nilar battery packs by road or rail.

A dangerous goods declaration is required if battery

packs are transported by sea in quantities of over 100

kg in one transport unit. Nilar battery packs are then

defined as dangerous goods, class 9. UN number and

Proper Shipping Name (PSN) are UN 3496, and

Batteries, Nickel Metal Hydride, respectively.

An Air Waybill or similar is required if battery packs are

transported by air. Nilar battery packs are not classified

as dangerous goods and belong to the entry Batteries,

dry in the list of dangerous goods in IATA (no UN

number). If an Air Waybill is used, the words ‘Not

Restricted’ and the Special Provision number (A123)

must be included in the description of the substance on

the Air Waybill, according to IATA-DGR.

The battery packs must be separated from each other

to prevent short circuits and be securely packed to

prevent movement that could lead to short circuits;

Nilar’s original packaging ensures that this cannot occur.

Please observe that special regulations apply for

defective or damaged battery packs that can potentially

lead to a hazardous event during transportation. Please

contact your local Nilar representative for advice

regarding transporting damaged or defective battery

packs.

When performing the visual

inspection, it is important not to

remove the battery packs from their

original Nilar sealed plastic

packaging.

CAUTION!

It is important to always pack the

battery packs in their original Nilar

sealed plastic packaging with

moisture-absorbent bags if being

transported.

CAUTION!

The Nilar product package shall

under no circumstances be exposed

to rain.

CAUTION!

Table of contents

Other Nilar Batteries Pack manuals

Popular Batteries Pack manuals by other brands

SolaX Power

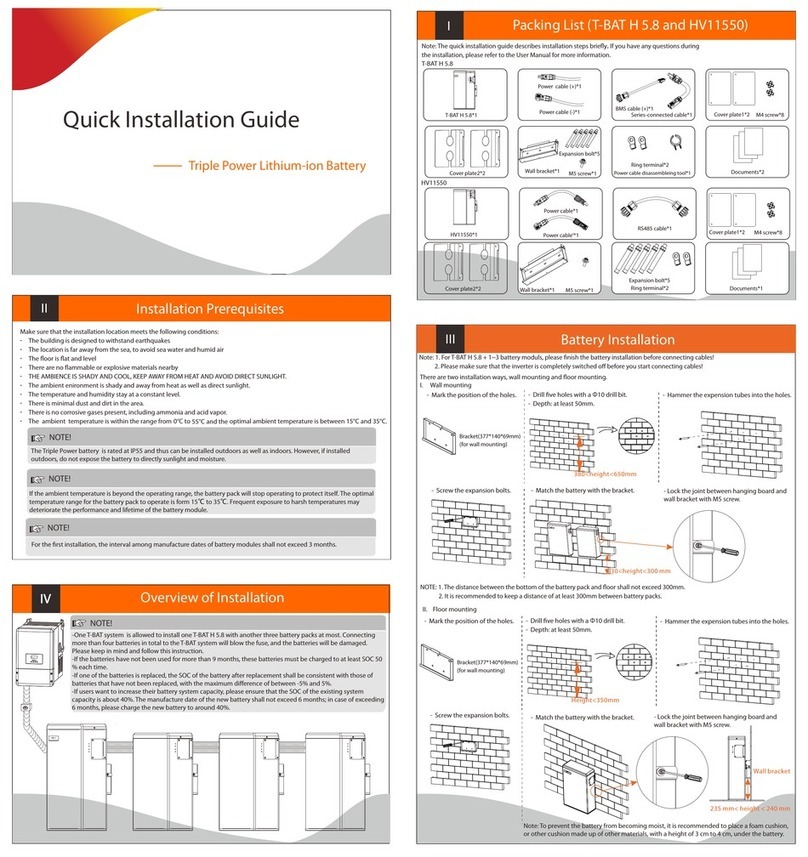

SolaX Power T-BAT H 5.8 Quick installation guide

Ronde & Schwarz

Ronde & Schwarz R&S TSMA6B-BP Getting started

XTT

XTT XLT Series user manual

UPOWER Ecoline

UPOWER Ecoline NauticBattery NA-12Li200BL quick start guide

Hennlich

Hennlich HMS Series Instruction and maintenance manual

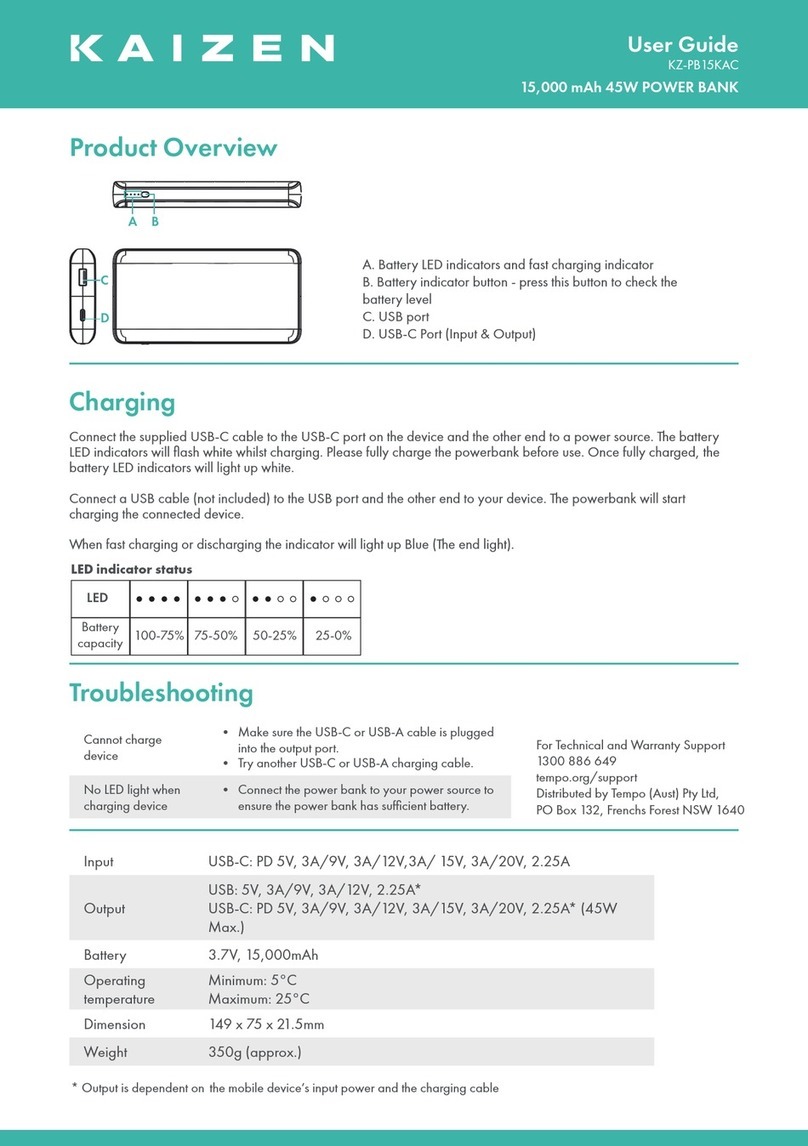

Kaizen

Kaizen KZ-PB15KAC user guide