Impact Instrumentation 306 Series User manual

INSTRUCTION

MANUAL

OPERATION

&

SERVICE

306

SERIES

PROGRAMMABLE

INTERMITTENT

SUCTION

-

ASPIRATOR

SYSTEM

NSN

6515-01-267-2726

NSN

6515-01-267-2727

IMPACT

INSTRUMENTATION,

INC.

NON°S

9212-01-20/-2/20,

6515-01-267-272/

TABLE

OF

CONTENTS

SUBJECT

PAGE

LIST

OF

ILLUSTRATIONS

iii

SHIPPING

CONTENTS

v

ACCESSORIES

LIST

vi

LIMITED

COPYRIGHT

RELEASE

vii

CALIBRATION

NOTICE

vii

UNPACKING

vii

LOCATION

OF

USE

vii

WARNINGS

REGARDING

USE

vii

ASSEMBLY,

INTERCONNECTIONS

AND

INITIAL

ADJUSTMENTS

viii

Cart

Assembly

Interconnections

-

Rear

Panel,

Overflow

Shutoff

Valve,

Hydrophobic

Filter,

Collection

Jar

System

SECTION

I.

OPERATION

INTRODUCTION

1-1

Electronic

Vacuum

Regulator

Electronic

Intermittent

Suction

Circuits

Emergency

Battery

OPERATION

1-1

Description

of

Controls

and

Indicators

Operating

Power

Selection

&

Stopping

Continuous

Suction

Operation

Intermittent

Suction

Operation

Electronic

Vacuum

Regulator

Collection

Jar

System

Operator

Performance

Checks

BATTERY

CARE

2=1

Recharging

Batteries

ROUTING

CARE

AND

MAINTENANCE

3-1

Cleaning

Maintenance

Rev.

E

(10/87)

eSATA

BR

S

RENE

NI:

LAGOS

AE

EST

TABLE

OF

CONTENTS

(cont'd)

20666

PAGE

a

IN

CASE

OF

DIFFICULTY

4-1

Operator

Correctible

Problems

Operator

Problems

Requiring

Service

STORAGE

INFORMATION

5-1

WARRANTY

5-1

SPECIFICATIONS

6-1

SECTION

II.

SERVICE

INTRODUCTION

7-1

CAUTIONARY

NOTES

7-4

External

12VDC

Operation

Internal

Rechargeable

Battery

HELPFUL

HINTS

У

DISASSEMBLY

/REASSEMBLY

8-1

CALIBRATION

PROCEDURE

9-1

de

CIRCUIT

DESCRIPTIONS

10-1

PREVENTATIVE

MAINTENANCE

INSPECTIONS

diet.

TROUBLESHOOTING

GUIDE

1231

TECHNICAL

DOCUMENTATION

1351

Bills

of

Material

Schematics

and

Wiring

Diagrams

»

IMPACT

INSTRUMENTATION,

INC.,

27

Fairfield

Place,

West

Caldwell,

NJ

07006

ii

Rev.

E

(10/87)

NON'S

D212-U1-20/-2/206,

6515-01-267-2727

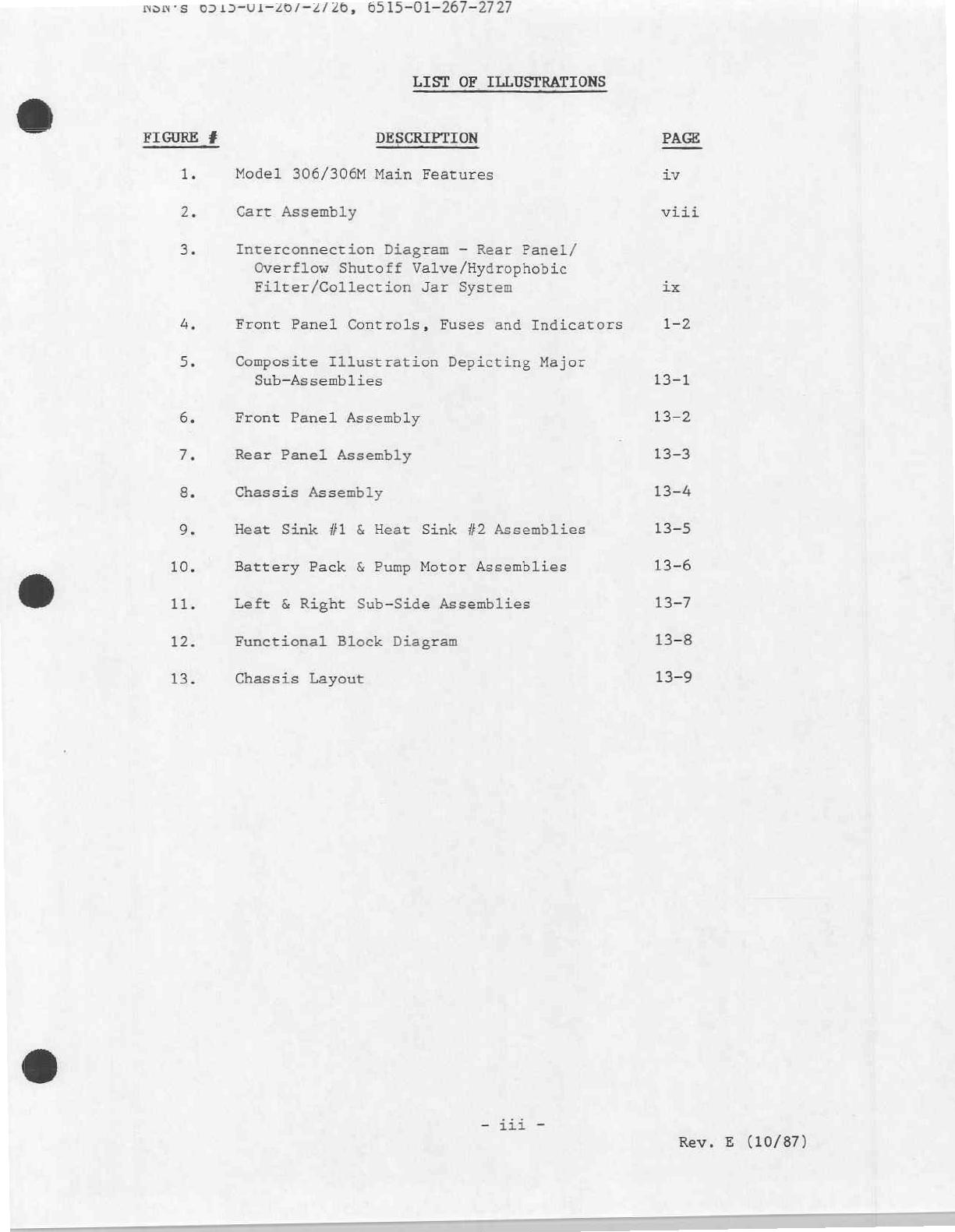

LIST

OF

ILLUSTRATIONS

FIGURE

#

DESCRIPTION

1.

Model

306/306M

Main

Features

2.

Cart

Assembly

9,

Interconnection

Diagram

-

Rear

Panel/

Overflow

Shutoff

Valve/Hydrophobic

Filter/Collection

Jar

System

4.

Front

Panel

Controls,

Fuses

and

Indicators

5.

Composite

Iilustration

Depicting

Major

Sub-Assemblies

6.

Front

Panei

Assembly

7.

Rear

Panel

Assembly

8.

Chassis

Assembly

9

Heat Sink

#1

&

Heat Sink

#2

Assemblies

10.

Battery

Pack

&

Pump

Motor

Assemblies

11.

Left

&

Right

Sub-Side

Assemblies

12

Functional

Block

Diagram

13%

Chassis

Layout

ЗЕ

=

РАСЕ

iv

viii

Rev.

E

(10/87)

2

——

NE

EOE

EL

ED

92152—91-20/-2/27/

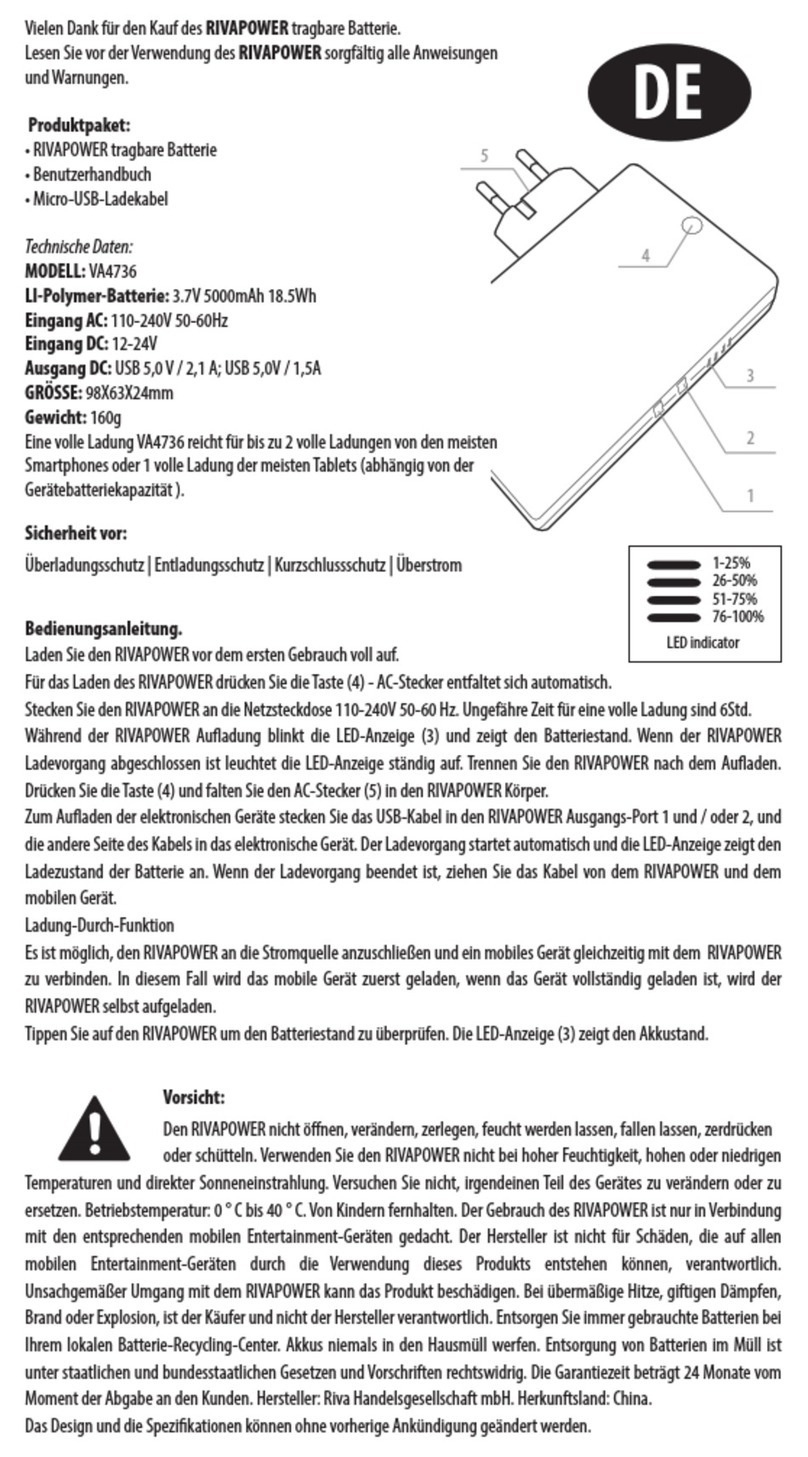

Master

Power

Switch

Power

Mode,

Suction

Mode

and

Suction

Level

Switches

Electronic

Vacuum

Regulator

Overflow

Shutoff

Valve

Dual-Seale

Vacuum

Gauge

"Grab"

Side

Panels

Programmable

Intermittent

Suction

Dual

Collection

Jars

(Types

1

&

3)

Removable

Collection

Jar

Baskets

(Types

1

&

3)

Disposable

Filter

Tip-Resistant

Cart

(Types

2

&

3)

Diagonally

Locking

Casters

(Types

2

&

3)

Hospital-Grade

Plug

with

SJT

Cable

Figure

1.

Model

306/306M

Main

Features

-

iv

—

Rev.

E

(10/87)

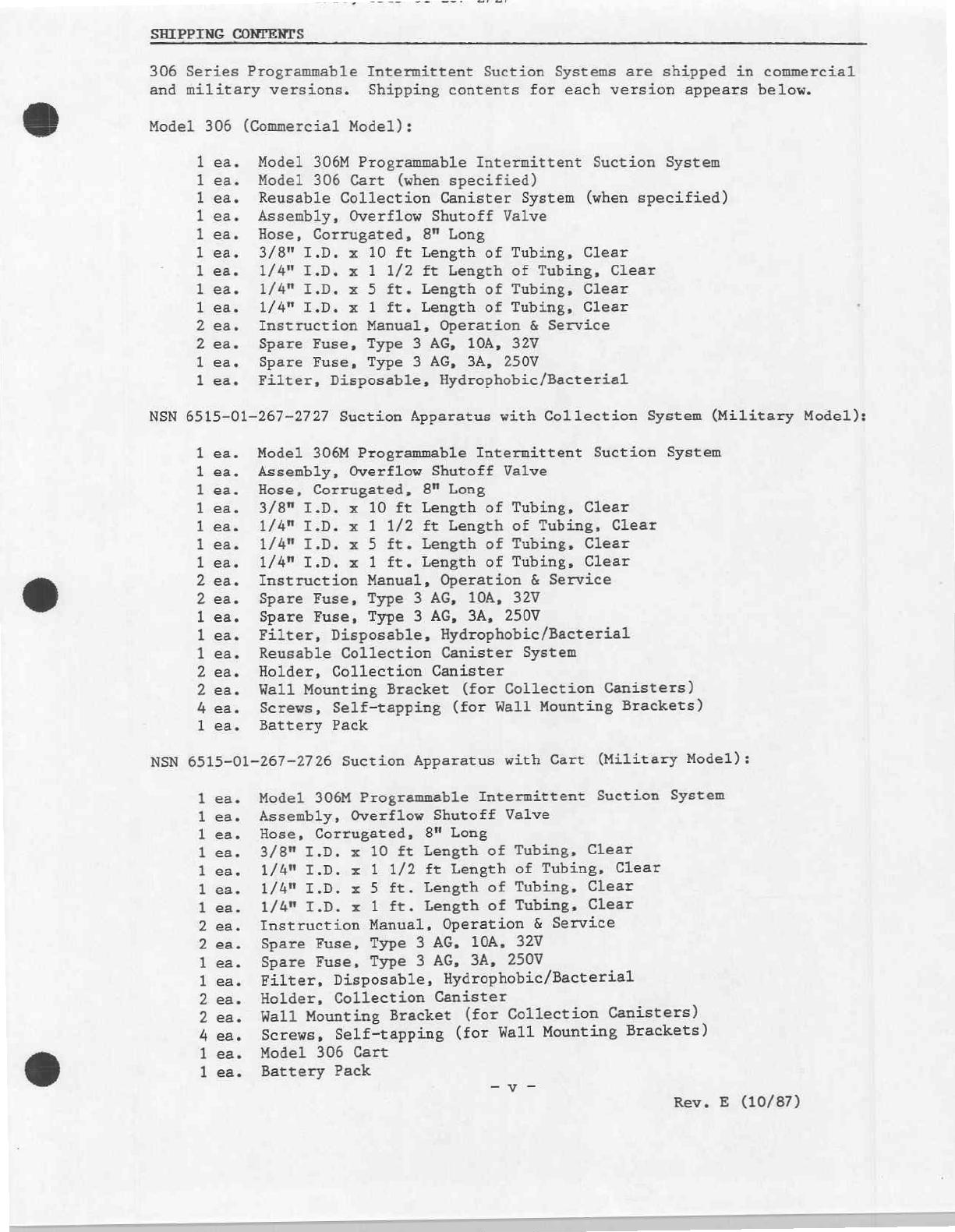

SHIPPING

CONTENTS

306

Series

Programmable

Intermittent

Suction Systems

are

shipped

in

commercial

and

military

versions.

Shipping

contents

for

each

version

appears

below.

Model

306

(Commercial

Model):

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ビビ

ウゥ

らら

ビビ

ビビ

ビビ

ロロ

ビビ

ロビ

Model

306M

Programmable

Intermittent

Suction

System

Model

306

Cart

(when

specified)

Reusable

Collection

Canister

System

(when

specified)

Assembly,

Overflow

Shutoff

Valve

Hose,

Corrugated,

8"

Long

3/8"

I.D.

x

10

ft

Length

of

Tubing,

Clear

1/4"

1.D.

x

1

1/2

ft

Length

of

Tubing,

Clear

1/4"

Т.О.

х

5

ft.

Length

of

Tubing,

Clear

1/4"

I.D.

x

1

ft.

Length

of

Tubing,

Clear

Instruction

Manual,

Operation

&

Service

Spare

Fuse,

Type

3

AG,

10A,

32V

Spare

Fuse,

Type

3

AG,

3A,

250V

Filter,

Disposable,

Hydrophobic/Bacterial

NSN

6515-01-267-2727

Suction

Apparatus

with

Collection

System

(Military

Model):

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

O

Model

306M

Programmable

Intermittent

Suction

System

Assembly,

Overflow

Shutoff

Valve

Hose,

Corrugated,

8"

Long

3/8"

I.D.

x

10

ft

Length

of

Tubing,

Clear

1/4" I.D.

x

1

1/2

ft

Length

of

Tubing,

Clear

1/4" I.D.

x

5

ft.

Length

of

Tubing,

Clear

1/4"

I.D.

x

1

ft.

Length

of

Tubing,

Clear

Instruction

Manual,

Operation

&

Service

Spare

Fuse,

Type

3

AG,

10A,

32V

Spare

Fuse,

Type

3

AG,

3A,

250V

Filter,

Disposable,

Hydrophobic/Bacterial

Reusable

Collection

Canister

System

Holder,

Collection

Canister

Wall

Mounting

Bracket

(for

Collection

Canisters)

Screws,

Self-tapping

(for

Wall

Mounting

Brackets)

Battery

Pack

NSN

6515-01-267-2726

Suction

Apparatus

with

Cart

(Military

Model):

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ea.

ロビ

よら

らい

ビ

ビ

い

らら

ロビ

ロビ

ビビ

ロビ

Model

306M

Programmable

Intermittent

Suction

System

Assembly,

Overflow

Shutoff

Valve

Hose,

Corrugated,

8"

Long

3/8"

I.D.

x

10

ft

Length

of

Tubing,

Clear

1/4"

I.D.

x

1

1/2

ft

Length

of

Tubing,

Clear

1/4"

I.D.

x

5

ft.

Length

of

Tubing,

Clear

1/4"

I.D.

x

1

ft.

Length

of

Tubing,

Clear

Instruction

Manual,

Operation

&

Service

Spare

Fuse,

Type

3

AG,

10A,

32V

Spare

Fuse,

Type

3

AG,

3A,

250V

Filter,

Disposable,

Hydrophobic/Bacterial

Holder,

Collection

Canister

Wall

Mounting

Bracket

(for

Collection

Canisters)

Screws,

Self-tapping

(for

Wall

Mounting

Brackets)

Model

306

Cart

Battery

Pack

Rev.

E

(10/87)

ας,

προς

ROE

ITE"

SI

ROS

SA

PN

ST

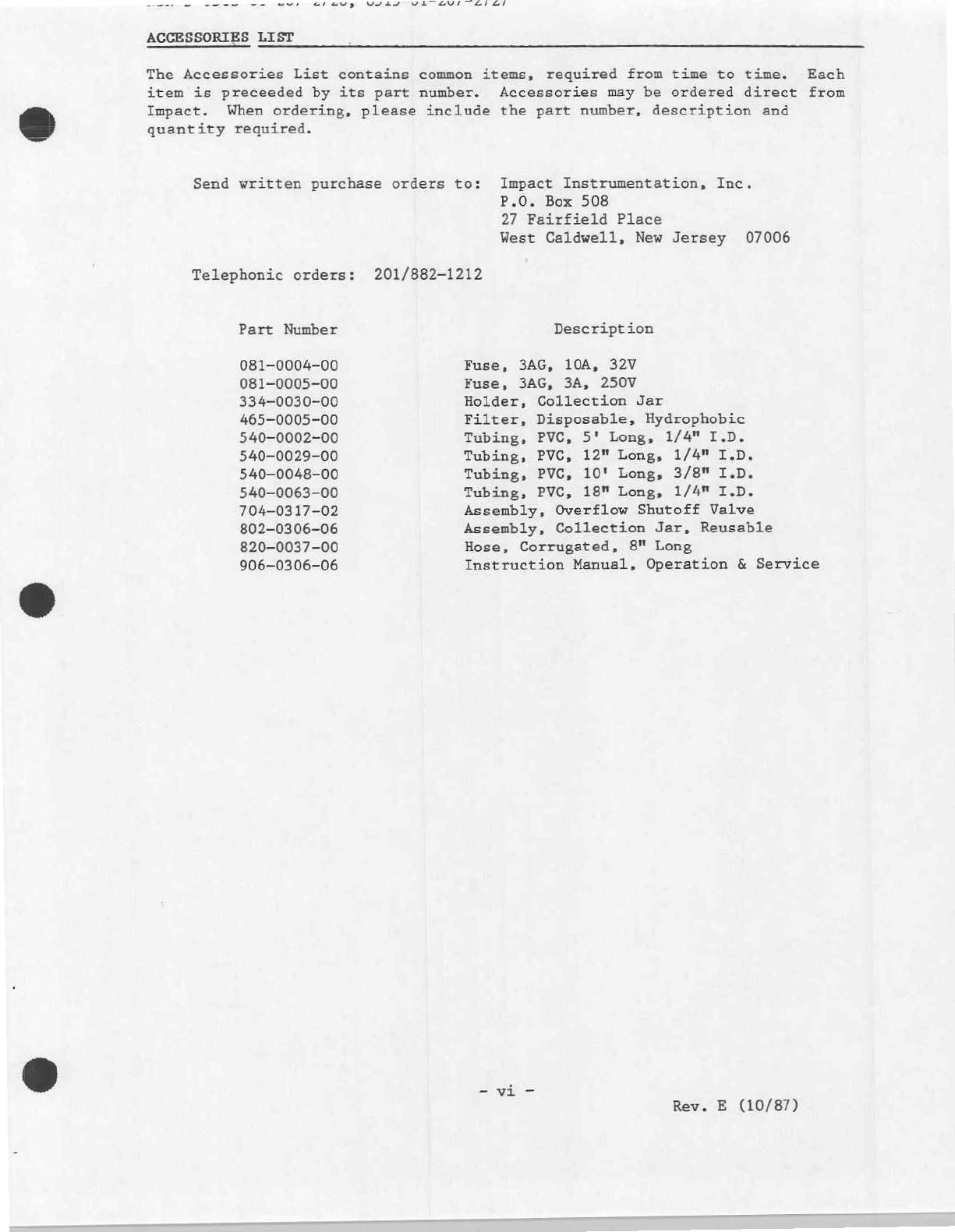

ACCESSORIES

LIST

The

Accessories

List

contains

common

items,

required

from time

to

time.

Each

item

is

preceeded

by

its

part

number.

Accessories

may

be

ordered

direct

from

Impact.

When

ordering,

please

include

the

part

number,

description

and

quantity

required.

Send

written

purchase

orders

to:

Impact

Instrumentation,

Inc.

P.O.

Box 508

27

Fairfield

Place

West

Caldwell,

New

Jersey

07006

Telephonic

orders:

201/882-1212

Part

Number

Description

081-0004-00

Fuse,

3AG,

10A,

32V

081-0005-00

Fuse,

3AG,

3A,

250V

334-0030-00

Holder,

Collection

Jar

465-0005-00

Filter,

Disposable,

Hydrophobic

540-0002-00

Tubing,

PVC,

5'

Long,

1/4"

I.D.

540-0029-00

Tubing,

PVC,

12"

Long,

1/4"

I.D.

540-0048-00

Tubing,

PVC,

10'

Long,

3/8"

I.D.

540-0063-00

Tubing,

PVC,

18"

Long,

1/4"

I.D.

704-0317-02

Assembly,

Overflow

Shutoff

Valve

802-0306-06

Assembly,

Collection

Jar,

Reusable

820-0037-00

Hose,

Corrugated,

8"

Long

906-0306-06

Instruction

Manual,

Operation

&

Service

-vi

-

Rev.

E

(10/87)

E

AN

A

ARE,

LIMITED

COPYRIGHT

RELEASE

Permission

is

hereby

granted

to

the

Department

of

Defense

to

reproduce

all

material

furnished

under

this

contract

for

use

in

a

military

service

training

program

and

other

technical

training

programs.

CALIBRATION

NOTICE

>

This

device

should

be

incorporated

into

a

regular

preventative

maintenance

program

to

insure

compliance

with

operating

specifications.

Calibration

measurements

should

be

made

on

a

biannual

basis

unless

significant

usage

warrants

a

shorter

period

between

preventative

maintenance

inspections.

A

calibration

check

should

be

made

following

each

cumulative

period

of

300

hours

of

operation.

Recommended

maintenance

checks

can

be

found

in

the

SERVICE

section

of

this

Manual.

UNPACKING

Check

the

contents

of

the

shipping

case(s)

against

the

enclosed

packing

list.

Examine

the

instrument

for

any

obvious

signs

of

shipping

damage.

If

there

is

no

apparent

sign

of

mechanical

damage,

read

the

instructions

contained

within

this

manual

before

attempting

to

operate

the

instrument.

LOCATION

OF

USE

2

The

Model

306/306M

is

a

portable

device,

therefore,

its

physical

area

of

use

will

vary.

When

operated

in

a

wet

environment,

user's

should

take

precautions

and

protect

this

device

by

covering

it

with

a

protective

barrier

(small

tarp,

plastic

sheet,

etc.).

WARNINGS

REGARDING

USE

This

equipment

is

intended

for

use

by

qualified

medical

personnel

only.

Danger

-

Possible

explosion

hazard

if

used

in

the

presence

of

flammable

anesthetics.

Caution

-

Electric

shock

hazard,

do

not

remove

instrument

covers.

Refer

servicing

to

qualified

service

personnel

only.

Do

not

operate

this

instrument

prior

to

reading

the

instructions

contained

within

this

manual.

Always

use

overflow

shutoff

valve

to

protect

pump

mechanism.

External

12VDC

Operation

—

Operate

only

from

diode

protected

external

12VDC

sources

when

simultaneous

AC

power

is

applied

(see

SERVICE

section

EXTERNAL

12VDC

OPERATION).

MILITARY

VERSIONS

-

DO

NOT

operate suction

apparatus

until

the

battery

pack

(shipped

separately)

is

installed.

Rev.

E

(10/87)

NSN's

6515-01-267-2726,

6515-01-267-2727

ASSEMBLY,

INTERGONNECTIONS

AND

INITIAL

ADJUSTMENTS

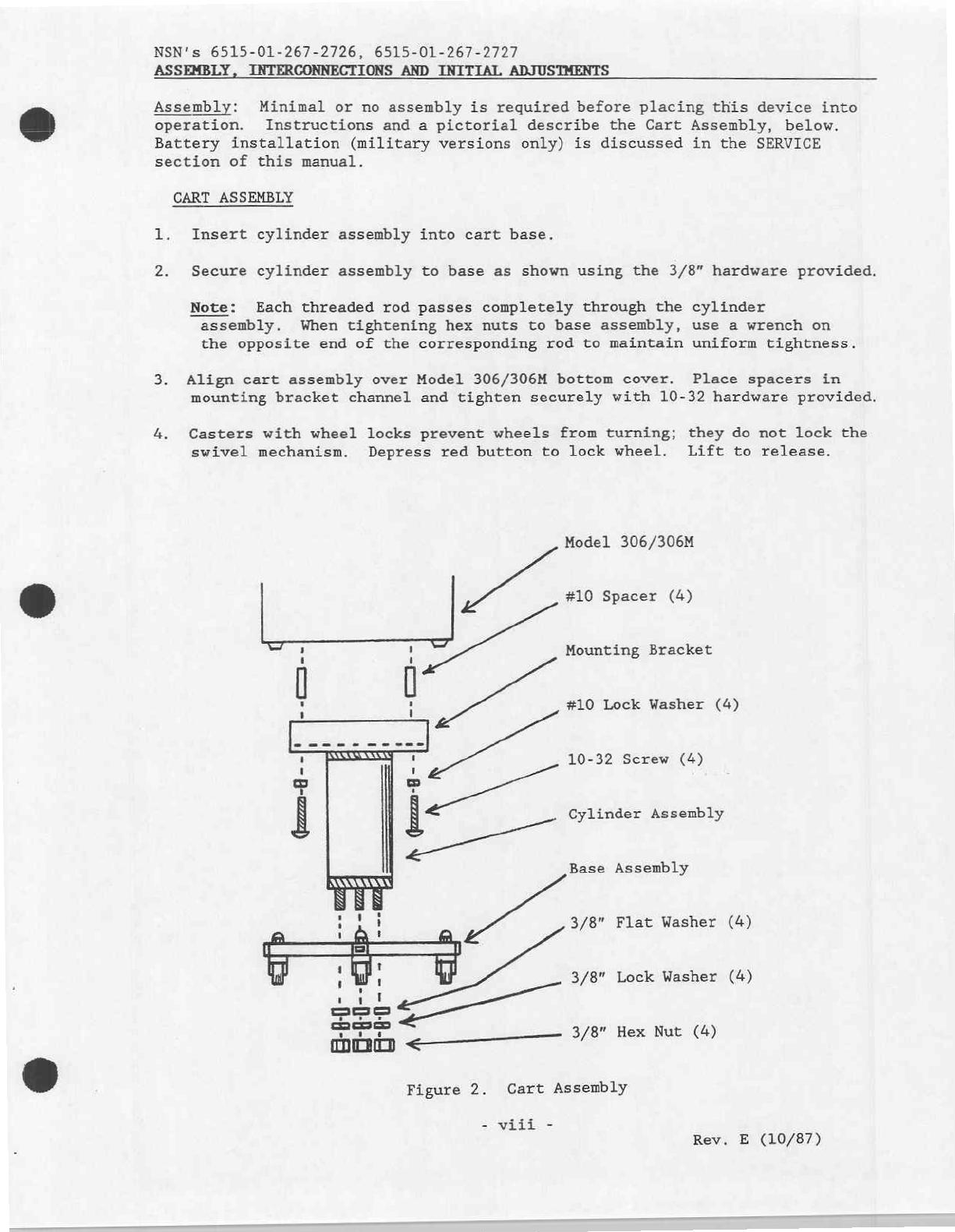

Assembly:

Minimal

or

no

assembly

is

reguired

before

placing

this

device

into

operation.

Instructions

and

a

pictorial

describe

the

Cart

Assembly,

below.

Battery

installation

(military

versions

only)

is

discussed

in

the

SERVICE

section

of

this

manual.

CART

ASSEMBLY

1.

Insert

cylinder

assembly

into

cart

base.

2.

Secure

cylinder

assembly

to

base

as

shown

using

the

3/8”

hardware

provided.

Note:

Each

threaded

rod

passes

completely

through

the

cylinder

assembly.

When

tightening

hex

nuts

to

base

assembly,

use

a

wrench

on

the

opposite

end

of

the

corresponding

rod

to

maintain

uniform

tightness.

3.

Align

cart

assembly

over

Model

306/306M

bottom

cover.

Place

spacers

in

mounting

bracket

channel

and

tighten

securely

with

10-32

hardware

provided.

4.

Casters

with

wheel

locks

prevent

wheels

from

turning;

they

do

not

lock

the

swivel

mechanism.

Depress

red

button

to

lock

wheel.

Lift

to

release.

Model

306/306M

#10

Spacer

(4)

Mounting

Bracket

AI

a

o

#10

Lock

Washer

(4)

ビー

ニー

で

ここ

oe

10-32

Screw

(4)

Cylinder

Assembly

(24

--

Base

Assembly

3/8"

Flat

Washer

(4)

de

3/8"

Lock

Washer

(4)

“na

ce

3/8"

Hex

Nut

(4)

Figure

2.

Cart

Assembly

-

viii

-

Rev.

E

(10/87)

NSN's

6515-01-267-2726,

6515-01-267-2727

ASSEMBLY,

INTERCONNECTIONS

AND

INITIAL

ADJUSTMENTS

(cont'd)

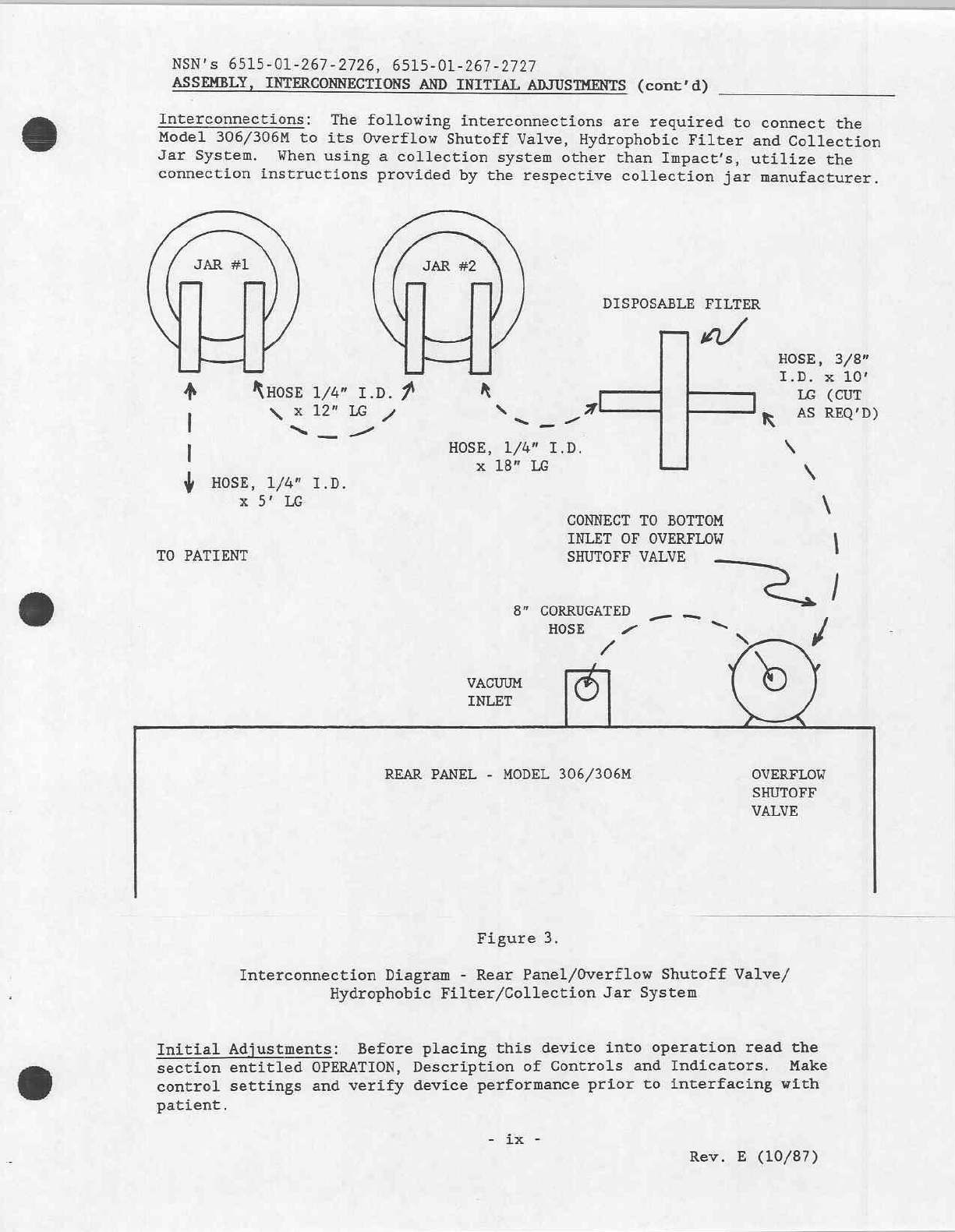

Interconnections:

The

following

interconnections

are

required

to

connect

the

Model

306/306M

to

its

Overflow

Shutoff

Valve,

Hydrophobic

Filter

and

Collection

Jar

System.

When

using

a

collection

system

other

than

Impact's,

utilize

the

connection

instructions

provided

by

the

respective

collection

jar

manufacturer.

DISPOSABLE

FILTER

asi

ca

HOSE,

3/8”

I.D.

x

10!

4

KHOSE

1/4"

I.D.

À

R

可

=

LG

(CUT

x

12"

LG

N

,

|

NE

Ea

aio

R

45

REQ'D)

|

E

HOSE,

1/4"

I.D.

x

x

18"

LG

X

Ý

HOSE,

1/4"

I.D.

x

9°

LG

N

CONNECT

TO

BOTTOM

INLET

OF

OVERFLOW

|

TO

PATIENT

SHUTOFF

VALVE

νι

η

8”

CORRUGATED

__

_

HOSE

à

=

и

и

N

/

VACUUM

INLET

©

REAR

PANEL

-

MODEL

306/306M

OVERFLOW

SHUTOFF

VALVE

Figure

3.

Interconnection

Diagram

-

Rear

Panel/Overflow

Shutoff

Valve/

Hydrophobic

Filter/Collection

Jar

System

Initial

Adjustments:

Before

placing

this

device

into

operation

read

the

section

entitled

OPERATION,

Description

of

Controls

and

Indicators.

Make

control

settings

and

verify

device

performance

prior

to

interfacing

with

patient.

-

ix

-

Rev.

E

(10/87)

ーー

-~

veste

va

GUI

TAI

LUS,

OD13-U1-20/—2/2/

SECTION

I.

OPERATION

INTRODUCTION

The

Model

306M

Programmable

Intermittent

Suction

System

represents

the

state

of

the

art

in

portable

suction

apparatus.

This

device

will

provide

years

of

reliable

service

when used

in

accordance

with

the

instructions

contained

within

this

manual.

The

following

text

highlights

several

of

its

key

features.

Electronic

Vacuum

Regulator

-

This

circuit

differs

from

conventional

mechanical

regulators

in

several

ways.

First,

the

regulator

is

eliminated

from

the

vacuum

path

and,

therefore,

cannot

leak,

clog,

jam

or

stick.

Second,

the

regulator

is

energy

efficient;

it

only

draws

current

proportional

to

the

amount

of

vacuum

you

require.

Third,

the

regulator

can

precisely

select

vacuum

levels

with

micrometer

precision

for

your

most

critical

suction

needs.

Electronic

Intermittent

Suction

Circuits

-

These

circuits

determine

ON

and OFF

times,

selectable

in

144

different

combinations.

The OFF

circuit

shuts

dow

virtually

the

entire

unit

during

its

time

period

thereby

maximizing

energy

efficiency.

The

ON

circuit

immediately

energizes

the

system

for

prompt

response.

Emergency

Battery

-

A

sealed

lead-acid

(GEL

Cell)

battery

is

provided

for

emergency

and

transitory

use.

Its

operating

time

varies

depending

upon

the

vacuum

levels

drawn.

With

this

in

mind,

a

high

capacity

battery

was

chosen

which

can

provide

over

one

hour

of

continuous

use

at

maximum

vacuum

(550

mm/hg).

At

200

mm/hg

cycled

intermittently

at

5

seconds

ON

and

5

seconds

OFF,

the

battery

will

provide

more

than

twelve

hours

continuous

use.

Because

this

battery

is

not

considered

the

primary

power

source,

its

use

should

be

restricted

to

emergencies

and

transport

to

insure

available

power.

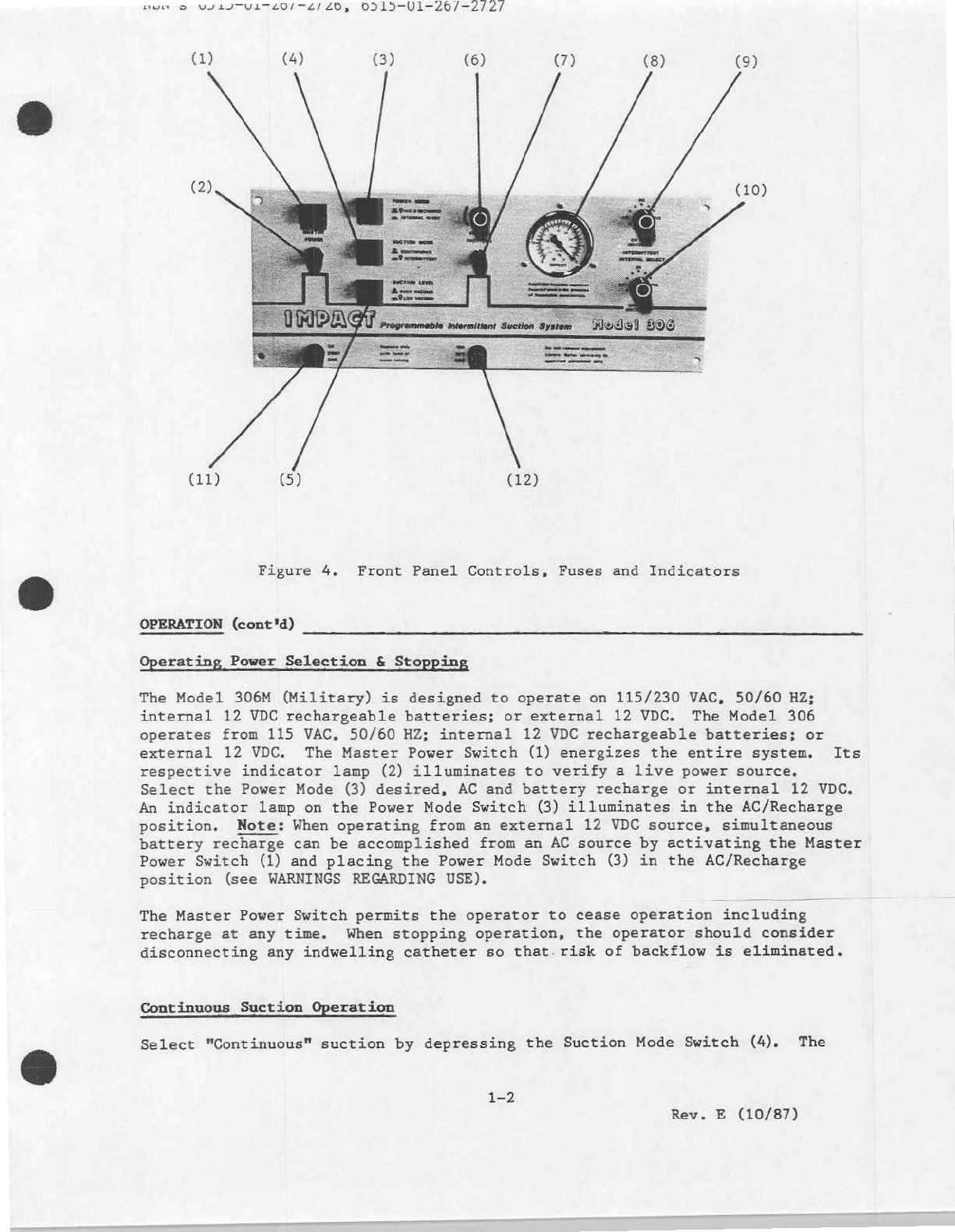

OPERATION

Description

of

Controls

and

Indicators

Refer

to

the

reference

pictorial

on

the

following

page.

Numbers

contained

within

this text

(in

parentheses)

correspond

to

the

numbers

indicated

in

the

pictorial.

(1)

Master

Power

Switch

(7)

Vacuum

Regulator

Power

Lamp

(2)

Master

Power

Indicator

Lamp

(8)

Vacuum

Gauge

(3)

Power

Mode

Switch

(9)

On

Time

Selector

Switch

(4)

Suction

Mode

Switch

(10)

Off

Time

Selector

Switch

(5)

Suction

Level

Switch

(11)

Fuse,

3A,

250V,

3AG

(6)

Vacuum

ON/OFF/ADJ

Switch

(12)

Fuse,

10A,

32V,

3AG

aaah

Rev.

E

(10/87)

мым

©

VY4JTVLTE0/74/

20,

BDL5-UV1—26/—2/2/

(1)

(4)

G)

(6)

(7)

(8) (9)

(11)

(5)

(12)

Figure

4.

Front

Panel

Controls,

Fuses

and

Indicators

OPERATION

(cont'd)

Operating

Power

Selection

&

Stopping

The

Model

306M

(Military)

is

designed

to

operate

on

115/230

VAC,

50/60

HZ;

internal

12

VDC

rechargeable

batteries;

or

external

12

VDC.

The

Model

306

operates

from

115

VAC,

50/60

HZ;

internal

12

VDC

rechargeable

batteries;

or

external

12

VDC.

The

Master

Power

Switch

(1)

energizes

the

entire

system.

Its

respective

indicator

lamp

(2)

illuminates

to

verify

a

live power

source.

Select

the

Power

Mode

(3)

desired,

AC

and

battery

recharge

or

internal

12

VDC.

An

indicator

lamp

on

the

Power Mode

Switch

(3)

illuminates

in

the

AC/Recharge

position.

Note:

When

operating

from

an

external

12

VDC

source,

simultaneous

battery

recharge

can

be

accomplished

from

an

AC

source

by

activating

the

Master

Power

Switch

(1)

and

placing

the

Power Mode Switch

(3)

in

the

AC/Recharge

position

(see

WARNINGS

REGARDING

USE).

The

Master

Power Switch

permits

the

operator

to

cease

operation

including

recharge

at

any

time.

When

stopping

operation,

the

operator

should

consider

disconnecting

any

indwelling

catheter

so

that.

risk

of

backflow

is

eliminated.

Continuous

Suction

Operation

Select

"Continuous"

suction

by

depressing

the

Suction

Mode

Switch

(4).

The

1-2

Rev.

E

(10/87)

NSN's

0515-01-207-2726,

6515

OPERATION

(cont'd)

indicator

lamp

for

this

switch

will

not

illuminate

in

this

mode.

.

The

Suction

Level

Switch

(5)

selects

two

operating

limits

for

vacuum;

0-200

mm/hg

(Low

Vacuum),

or

0-550

mm/hg

(High

Vacuum).

An

indicator

lamp

illuminates

when

Low

Vacuum

is

selected.

To

operate

the

Electronic

Vacuum

Regulator

(EVR),

turn

the

control

(6)

clockwise

to

its

"ON"

position

and

continue

rotating

it

to

the

desired

vacuum

level.

Preselecting

the

desired

vacuum

limit

can

be

accomplished

by

blocking

the

free

flow

of

air

through

the

system.

Allow

air

to

evacuate

from

any

collection

jar

system

when

preselecting

the

vacuum

limit,

Remember

that

the

maximum

vacuum

limit

is

regulated

by

the

Suction

Level

Switch

(5).

The

EVR

indicator

lamp

(7)

will

remain

on

until

the

EVR

Control

Switch

(6)

is

"clicked

off"

by

turning

fully

counterclockwise.

Vacuum

readings

may

be

read

directly

from

the

front

panel

Vacuum

Gauge

(8).

Intermittent

Suction

Operation

The

Suction

Mode

and

Suction

Level

Switches

(4,

5)

must

be

depressed

and

illuminated

for

intermittent

operation.

To

prevent

dangerous

high

vacuum

levels

from

appearing

at

the

pump

output

during

intermittent

suctioning,

a

safety

lockout

allows

this

mode

to

operate

in

the

Low

Vacuum

Level

range

only.

After

preselecting

the

desired

vacuum

level

as

described

in

the

previous

section,

the

ON

(9)

and

OFF

(10)

time

suction

circuits

may

be

set

to

the

desired

range.

Each

circuit

is

programmable

in 12

increments

of

5

seconds

each.

A

total

of

144

programmable

combinations

are

available

to

"custom

tailor"

the

Model

306M

to

your

patient's

needs.

Electronic

Vacuum

Regulator

The

EVR

(6)

works

in

conjunction

with

the

Suction

Level

Switch

(5).

Precise

vacuum

levels

may

be

selected

with

extreme

accuracy

for

most

procedures.

Variability

from

0-200

mm/hg

and

0-550

mm/hg

adds

additional

versatility

and

power

when

needed

for

emergencies

or

surgical

applications.

The

EVR

is an

energy

efficient

circuit,

drawing

only

an

amount

of

current

proportional

to

the

level

of

vacuum

desired.

Unlike

conventional

regulators

which

"bleed"

an

efficient

system

running

at

full

power,

the

EVR

runs

at

lower

speeds

unless

full

power

is

required.

Collection

Jar

System

ALWAYS

use the

Overflow

Shutoff

Valve

provided

with

this unit

to

protect

the

suction

mechanism

from

overflows

which

may

permanently

damage

the

vacuum

pump.

Vacuum

tubing

is

provided

for

interconnection

of

Collection

Jars,

Hydrophobic

Filter,

Overflow

Shutoff

Valve

and

rear

panel

barbed

hose

inlet

(see

Figure

3).

A

disposable

filter

which

is

both

hydrophobic

and

bacterial

is

provided.

This

filter

connects

between

the

Overflow

Shutoff

Valve

and

final

collection

jar.

This

filter

should

be

replaced

when

discoloration

of

its

membrane

occurs,

the

membrane

contacts

aspirate,

or

following

150

cumulative

hours

of

use.

This

filter

is

designed

to

retain

bacteria

which

would

otherwise

be

exhausted

into

the

immediate vicinity.

DO

NOT

bypass

this

filter.

1-3

Rev.

E

(10/87)

NSN's

6515-01-20

OPERATION

(cont

'd)

Operator Performance

Checks

Before

placing

this

device

into

operation,

the

operator

can

perform

various

operational

checks

to

insure

proper

performance.

1.

Verify

operating

power

selections

at

115

or

230

VAC,

internal

rechargeable

batteries

and

external

12

VDC.

2.

Verify

continuous

operation

at

both

high

and

low

ranges,

in

each

of

the

operating

power

modes.

3.

Verify

that

intermittent

suction

operates

only

in

the

low

vacuum

range

in

each

of

the

operating

power

modes.

4.

Test

the

Electronic

Vacuum

Regulator

by

adjusting

vacuum

in

the

high

and

low

ranges,

in

each

of

the

operating

power

modes.

1-4

Rev.

E

(10/87)

WOINTS

ODLITYUINL0/—

2/20,

OD19-01-20/—4/427

BATTERY

CARE

The

Model

306/306M

utilizes

sealed

GEL

Cell

batteries

which offer

excellent

charge

retention

characteristics,

particularly

during

long

periods

of

storage.

This

ensures

an

ample

amount

of

power

during

emergencies

and

transitory

procedures.

The

battery

pack

in

this

device

is

not

intended

for

routine,

day-

to-day

use,

therefore,

it

should

be

used with

discretion

and

its

design

understood.

To

provide

long

life

and

maximum

performance

capabilities,

the

Model

306M

requires

sixteen

hours

to

fully

recharge

its

fully

discharged

batteries.

Of

course,

the

batteries

are

rarely

discharged

this

much

so

the

subsequent

recharge

time

is

usually

less.

GEL

Cell

batteries

require

little

user

care

to

provide

optimum

performance

and

life

expectancy.

Because

their

self-discharge

rate

is

extremely

low

(approximately

1-1/2%

per

month),

lengthy

periods

of

disuse

without

replenishment

charging

is

possible.

The

life

of

these

batteries

depends

to

a

great

extent

upon

the

care

they

receive.

Following

these

simple

guidelines

will

prevent

premature

charge

depletion

and

reduction

of

battery

life.

1.

DO

NOT

operate

this unit

where

the

temperature

range

exceeds

-60°C

to

60°C

(-76°F

to

140°F).

2.

DO

NOT

charge

this unit

where

the

temperature

range

exceeds

-20°C

to

50°C

(-4°F

to

122°F).

3.

DO

NOT

store

this

unit

with

the

batteries

discharged.

Always

store

in

a

charged

condition.

4.

For

long-term

storage,

the

optimum

temperature

range

is

10°C

to

30°C (50°F

to

80°F).

Recharging

Batteries

Ensure

that

the

AC

line

cord

is

connected

to

a

3-wire,

grounded

outlet.

Turn

the

Master

Power

Switch

(1)

ON

and

verify

that

the

Master

Power

Indicator

Lamp

(2)

illuminates.

Depress

the

Power

Mode

Switch

(3)

to

the

"AC

and

Recharge"

position.

Its

built-in

lamp

will

illuminate.

Verify

that

the

Vacuum

ON/OFF/ADJ

Switch

(6)

is

"clicked"

off and

its

respective

indicator

(7)

is

unlit.

The

unit

is

now

in

a

recharge

state.

During

normal

AC

operation,

a

charging

current

automatically

flows

into

the

batteries

keeping

them

replenished

while

normal

operating

power

requirements

are

met.

Rev.

E

(10/87)

やら

>

VJYLJTV1T60/T4/

40,

0515-01-26/-2

ROUTINE

CARE

AND

MAINTENANCE

Cleaning

Periodically

or

when

applicable,

clean

the

exterior

case

using

mild,

non-

abrasive

cleansers.

DO

NOT

allow

liquids

to

enter

the

control

system;

a

damp

cloth

will,

in

most

cases,

suffice.

Disinfectant

spraying

is

recommended

at

regular

intervals.

Collection

jar

systems

should

be

cleaned

or

disposed

of

in

accordance

with

their

respective

instructions.

Impact's

reusable

collection

jar,

its

cover

and

hose

connectors

may

be

autoclaved.

Maintenance

Routine

maintenance

should

be

performed

on

this

apparatus

at

regular

intervals

and

prior

to

being

placed

into

service.

Routine

maintenance

should

consist

of

the

following:

1.

Cleaning

checks

-

as

described

above.

2.

Filter

checks

-

replace

when

discolored,

contact

with

aspirate

occurs,

airflow

performance

diminishes

considerably

or

following

150

hours

of

cumulative

use.

3.

Overflow

shutoff

valve

-

clean

in

warm,

soapy

water

or

with

a

mild

disinfectant

solution

when

contacted

with

aspirate

or

following

150

hours

of

cumulative

use.

Dry

thoroughly

before

reassembling.

4.

Operational

checks

-

as

described

in

Operator

Performance

Checks.

5.

Tubing

checks

-

replace

crimped,

cracked

or

worn

tubing

as

required.

6.

Cart

checks

-

verify

smooth

turning

of

casters

and

operation

of

locks.

Replace

worn

casters.

Rev.

E

(10/87)

NSN's

6515-01-267-2720,

0515-01-267-2727

IN

CASE

OF

DIFFICULTY

Authorization

to

service

this

instrument

by

other

than

factory-trained

and

certified

personnel

will

not

be

given,

nor

does

Impact

Instrumentation,

Inc.

assume

any

responsibility

and/or

liability resulting

from

such

unauthorized

servicing.

Impact

will,

upon

request,

provide

competent

biomedical

engineering

departments

with

service

data

and

schematics.

Such

departments

are

encouraged

to

contact

the

factory

for

assistance

when

needed

and

it

is

recommended

that

staff

members

attend

a

factory

training

course.

Details

may

be

obtained

by

contacting

the

Impact

Customer

Service

Department.

Operator

Correctible

Problems

Common

problems

may

be

quickly

rectified

by

users.

Should

the

Model

306/306M

fail

to

operate

properly,

verify

the

integrity

of

all

tube

connections,

tubing,

fittings,

and

control

settings.

One

can

quickly

isolate

problems

to

an

accessory

item

or

the

control

unit

by

testing

for

vacuum

at

various

locations.

To

isolate

a

problem,

check

for

vacuum

at

the

inlet

of

each

item,

tracing

backwards

through

the

system,

i.e.:

vacuum

from

jar

#1

to

jar

#2,

vacuum

from

the

filter

to

jar

#1,

vacuum

from

the

Overflow

Shutoff

Valve

to

the

filter,

vacuum

from

the

rear

panel

vacuum

port

to

the

Overflow

Shutoff

Valve.

Operator

Problems

Requiring

Service

If

the

tests

described

above

do

not

resolve

an

operating

problem,

service

is

required.

Should

servicing

be

necessary,

contact

your

nearest

Impact

representative

or

the

Impact

Customer

Service

Department

(201)

882-1212.

Please

have

the

Model

and

Serial

Numbers

ready

and

any

other

pertinent

data

you

wish

to

include

in

your

service

request.

The

Model

306/306M

Serial

Number

is

located

on

the

Rear

Panel

identification

label.

Rev.

E

(10/87)

wen's

09212-01-20/-2/26,

6515-01-20

STORAGE

INFORMATION

For

prolonged

storage

periods,

the

Model

306/306M

should

be

stored

indoors.

The

environment

should

be

clean,

and

out

of

direct

sunlight.

Storage

temperature

range

should

be

within

5°

to

104°F

(-15°

to

40°C),

humidity

should

be

low.

When

batteries

are

in

extended

storage,

it

is

recommended

that

they

receive

a

refresh

charge

at

recommended

intervals:

Storage Ambient

Recharge

Interval

below

68°F

(20°C)

18

months

68°

to

86°F

(20°

to

30°C)

12

months

86°

to

104°F

(30°

to

40°C)

6

months

LIMITED

WARRANTY

Impact

Instrumentation,

Inc.

warrants

this

instrument

to be

free from

all

defects

in

materials

and

workmanship

for

a

period

of

one

(1)

year.

Batteries,

which

by

their

nature

are

consumable

and

subjected

to

environmental

extremes,

will

be

warranted

only

for

defects

of

manufacturing

origin

for

a

period

of

ninety

(90)

days.

This

warranty

is

neither

assignable

nor

transferable,

nor

does

it

apply

if

this

instrument

is

tampered

with,

misused

or

serviced

by

unauthorized

personnel.

Rev.

E

(10/87)

em:

UDIITUI=40/=2/70,

6515-01-207-2727

SPECIFICATIONS

Vacuum

Range:

Continuous:

Low:

High:

Intermittent:

Free

Airflow

Range:

Temperature

Operating

Range:

Power:

External:

Internal:

Operating

Time:

Recharge

Time:

Controls:

Master

Power:

Power

Mode:

Suction

Mode:

Suction

Level:

Suction:

On

Interval

Select:

Off

Interval

Select:

Indicators:

Case:

Size:

Weight:

Cart:

Size:

Weight:

O

-

200

mm/Hg,

+/-

25

mmHg

(0

-

8"

Hg,

+/-

1"

Hg)

0

-

550

mm/Hg,

+/-

50

mmHg

(0

-

22"

Hg,

+/-

2"

Hg)

O -

200

mm/Hg,

+/-

25

mmig

(0

—

8"

Hg,

+/-

1"

Hg)

24

-

35

Liters

Per

Minute

(LPM)

-60°C

to

60°C

(-76°F

to

140°F)

115/230

VAC,

50/60

HZ;

12

VDC

12

VDC

(Rechargeable

Batteries)

1

Hour

at

maximum

vacuum

(typical)

16

Hours

(typical)

ON/OFF

AC

&

Recharge/Internal

12

VDC

Continuous/Intermittent

High

Vacuum/Low

Vacuum

ON/OFF

/ADJUST

5

-

60

seconds

in

5

second

increments

5

-

60

seconds

in

5

second

increments

Master

Power

Lamp

AC

&

Recharge

Lamp

Intermittent

Suction

Mode

Lamp

Low

Vacuum

Level

Lamp

Suction

"ON"

Lamp

Vacuum

Gauge

-

Dual

Scale,

Metric/English

Aluminum,

Epoxy

Paint

Combination

46cm

W

x

18cm

H x

25cm

D

(18"

W

x

7"

H x

10"

D)

11

KG

(25

lbs.)

46cm

W x

46cm

D x

75cm

H

(18"

W x

18"

D

x

30"

H)

11

Кб

(25

lbs.)

Specifications

contained

herein

represent

typical

device

performance.

Impact

Instrumentation,

Inc.

reserves

the

right

to

change

these

specifications

without

prior

notification.

Rev.

E

(10/87)

NSN's

0515-Ui-20/-2/20,

SECTION

II.

SERVICE

INTRODUCTION

The

information

contained

herein

is

intended

only

for use

by

factory-trained,

and

certified personnel

or

military

personnel

trained

in

the

care

and

servicing

of

this

product.

The

manufacturer

does

not

authorize

or

assume

any

obligations

resulting

from

unauthorized

servicing

nor

will

it

be

held

liable

for

any

injuries

or

damages

incurred

therefrom.

Impact

Instrumentation

will

provide

service

training

at

the

manufacturing

site

at

no

schooling

charge

to

users;

however,

travel

and

meal

costs

resulting

therefrom

shall

be

borne

by

the

user.

Training

at

the

user's

site

will

result

in

travel,

meal

and

time

costs

charged

to

the

user

at

prevailing

rates.

The

Impact

service

facility

encourages

dialogue

from

user

service

personnel

towards

rectifying

any

service

related

matter.

All

service

requests

may

be

addressed

to

the

Service

Manager,

Impact

Instrumentation,

Inc.,

27

Fairfield

Place,

West

Caldwell,

New

Jersey

07006,

201/882-1212.

CAUTIONARY

NOTES

External,

12VDC

Operation

Warning:

If

simultaneous

AC

recharging

and

external

12VDC

operation

is

employed,

insure

that

the

external

12VDC

source

is

diode

protected

against

potentially

high

currents.

This

warning

does

not

apply

for

independent

operation

from

an

external

12VDC

source.

Internal

Rechargeable

Battery

Military

versions

of

this

product

are

shipped

with

batteries

in

separate

cartons.

Prior

to

placing

this

device

into

operation,

the

battery

pack must

be

installed.

Do

not

operate

this

unit

until

battery

pack

is

installed.

HELPFUL

HINTS

Before

attempting

to

repair/calibrate

this

instrument,

please

take

a

few

moments

to

insure

that

the

problem

is

not

accessory

related.

Check

the

integrity

of

all

vacuum

hoses

and

tubing.

Verify

that

the

tubing

has

no

crimps

or

cuts

in

it.

Insure

that

all

collection

jars

seal

properly.

Insure

that

overflow

shut-off

valves

do

not

stick.

Refer

to

the

enclosed

schematics

and

assembly

drawings

when

electrically

troubleshooting.

Isolate

the

problem

to

a

functional

segment

of

the

circuitry.

Always

insure

the

integrity

of

circuit

ground

and

the

correct

power

supply

voltages.

Always

safeguard

your

personal

well

being

when

troubleshooting

electronic

circuitry.

Keep

jewelry

and

liquids

from

the

vicinity

of

active

circuitry.

JET

Rev.

E

(10/87)

This manual suits for next models

1

Table of contents

Other Impact Instrumentation Batteries Pack manuals