SOLAREVER SE-BAT SYS-HV User manual

SE-BAT Lithium-ion Battery

User Manual

50Ah

Copyright Declaration

UL

The copyright of this manual belongs to Solarever Tecnologia de America S.A.de C.V. Any

corporation or individual should not plagiarize, partially or fully copy it (including software, etc.),

and reproduction or distribution in any form or by any means shall not be allowed. All rights

reserved. Solarever Tecnologia de America S.A.de C.V. reserves the right of nal interpretation. The

information contained herein is subject to change without notice.

www.solarever.com.mx

Solarever Tecnologia de America S.A.de C.V.

Autopista Mexico-Queretaro KM 71.9, S/N Noxtongo Tepeji del

Rio de Ocampo C.P. 42885, Hidalgo Mexico

Tel.: +55 4364 0437

E-mail: contacto@solarever.com.mx 614.00748.00

CONTENTS

1 NOTE ON THIS MANUAL..............................................................................................................................................1

1.1 SCOPE OF VALIDITY............................................................................................................................................1

1.2 TARGET GROUP......................................................................................................................................................1

1.3 SYMBOLS USED.....................................................................................................................................................1

2 SAFETY.......................................................................................................................................................................................2

2.1 SAFETY INSTRUCTIONS..................................................................................................................................2

2.1.1 GENERAL SAFETY PRECAUTIONS..................................................................................................2

2.1.2 EXPLANATION OF SYMBOLS.............................................................................................................3

2.2 RESPONSE TO EMERGENCY SITUATIONS..........................................................................................5

2.2.1 LEAKING BATTERIES..................................................................................................................................5

2.2.2 FIRE........................................................................................................................................................................5

2.2.3 WET BATTERIES AND DAMAGED BATTERIES........................................................................5

2.3 QUALIFIED INSTALLER.....................................................................................................................................6

3 PRODUCT INTRODUCTION......................................................................................................................................7

3.1 PRODUCT OVERVIEW.......................................................................................................................................7

3.1.1 DIMENSION AND WEIGHT..................................................................................................................7

3.1.2 APPEARANCE................................................................................................................................................8

3.2 BASIC FEATURES................................................................................................................................................10

3.2.1 FEATURES......................................................................................................................................................10

3.2.2 CERTIFICATIONS......................................................................................................................................10

3.3 SPECIFICATIONS.................................................................................................................................................11

3.3.1 SE-BAT SYS-HV CONFIGURATION LIST.....................................................................................11

3.3.2 PERFORMANCE.........................................................................................................................................11

4 INSTALLATION..................................................................................................................................................................12

4.1 INSTALLATION PREREQUISITES..............................................................................................................12

4.2 SAFETY GEAR.......................................................................................................................................................12

4.3 TOOLS.......................................................................................................................................................................13

4.4 INSTALLATION.....................................................................................................................................................13

4.4.1 CHECK FOR TRANSPORT DAMAGE..........................................................................................13

4.4.2 UNPACKING.................................................................................................................................................13

4.4.3 ACCESSORIES.............................................................................................................................................14

4.4.4 BATTERY INSTALLATION STEPS....................................................................................................16

1 Note on this Manual

1.1 Scope of Validity

This manual is an integral part of SE-BAT Series. It describes the assembly,

installation, commissioning, maintenance and failure of the product. Please read

it carefully before operating.

SE-BAT SYS-HV

1.2 Target Group

This manual is for qualied ele tricians. The tasks described in this manual may

only be performed by qualied ele tricians.

1.3 Symbols Used

The following types of safety instructions and general information appear in this

document described as below:

DANGER!

“DANGER” indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING!

“WARNING” indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTIOIN!

“CAUTION” indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTE!

“NOTE” provides tips that are valuable for the optimal operation of

your product.

4.5 OVERALL INSTALLATION.....................................................................................................................................18

4.5.1 CABLE CONNECTION...................................................................................................................................20

4.5.2 CONNECTING POWER CABLES............................................................................................................22

4.5.3 CONNECTING POWER LINES.................................................................................................................26

4.5.4 CONNECTING CAN COMMUNICATION CABLE.......................................................................27

4.5.5 CONNECTING RS485 COMMUNICATION CABLE...................................................................28

4.5.6 CONNECTING GROUND WIRE..............................................................................................................29

4.6 OVERVIEW OF INSTALLATION..........................................................................................................................31

5 COMMISSIONING...................................................................................................................................................................32

5.1 CONFIGURING BATTERY SYSTEM....................................................................................................................32

5.2 COMMISSIONING.........................................................................................................................................................33

5.3 STATUS INDICATORS...............................................................................................................................................35

5.3.1 BMS ............................................................................................................................................................................35

5.3.2 BATTERY PACK....................................................................................................................................................36

5.4 SHUTTING DOWN SE-BAT SYSTEM.............................................................................................................36

6 TROUBLESHOOTING............................................................................................................................................................37

6.1 TROUBLE SHOOTING.............................................................................................................................................37

7 DECOMMISSIONING............................................................................................................................................................40

7.1 DISMANTLING THE BATTERY............................................................................................................................40

7.2 PACKAGING....................................................................................................................................................................40

SE-BAT-MA H 5.8

NOTE: There are 4 models for SE-BAT system, which includes BMS and battery

pack(s). Please refer to section 3.3.1 SE-BAT SYS-HV Conguration List on page 11

for detailed models.

SE-BAT PACK-HV

SE-BAT-SL H 5.8

8 MAINTENANCE AND WARRANTY.............................................................................................................................41

23

2 Safety

2.1 Safety Instructions

For safety reasons, installers are responsible for familiarizing themselves with the

contents of this manual and all warnings before performing installation.

2.1.1 General Safety Precautions

Observe the following precautions:

ŸRisks of explosion

–Do not subject the battery pack to strong impacts.

–Do not crush or puncture the battery pack.

–Do not dispose of the battery pack in a re.

ŸRisks of re

–Do not expose the battery pack to temperatures in excess of 13 .1℉/55°C.

–Do not place the battery pack near a heat source, such as a replace.

–Do not expose the battery pack to direct sunlight.

–Do not allow the battery connectors to touch conductive objects such as

wires.

ŸRisks of electric shock

–Do not disassemble the battery pack.

–Do not touch the battery pack with wet hands.

–Do not expose the battery pack to moisture or liquids.

–Keep the battery pack away from children and animals.

ŸRisks of damage to the battery pack

–Do not allow the battery pack to get in contact with liquids.

–Do not subject the battery pack to high pressures.

–Do not place any objects on top of the battery pack.

SE-BAT SYS-HV can be used only in the household energy eld. It is not allowed to

be used in other industries, such as the medical equipment and automotive

application.

WARNING!

Please don't crush or impact the battery, and always dispose it

according to the safety regulation.

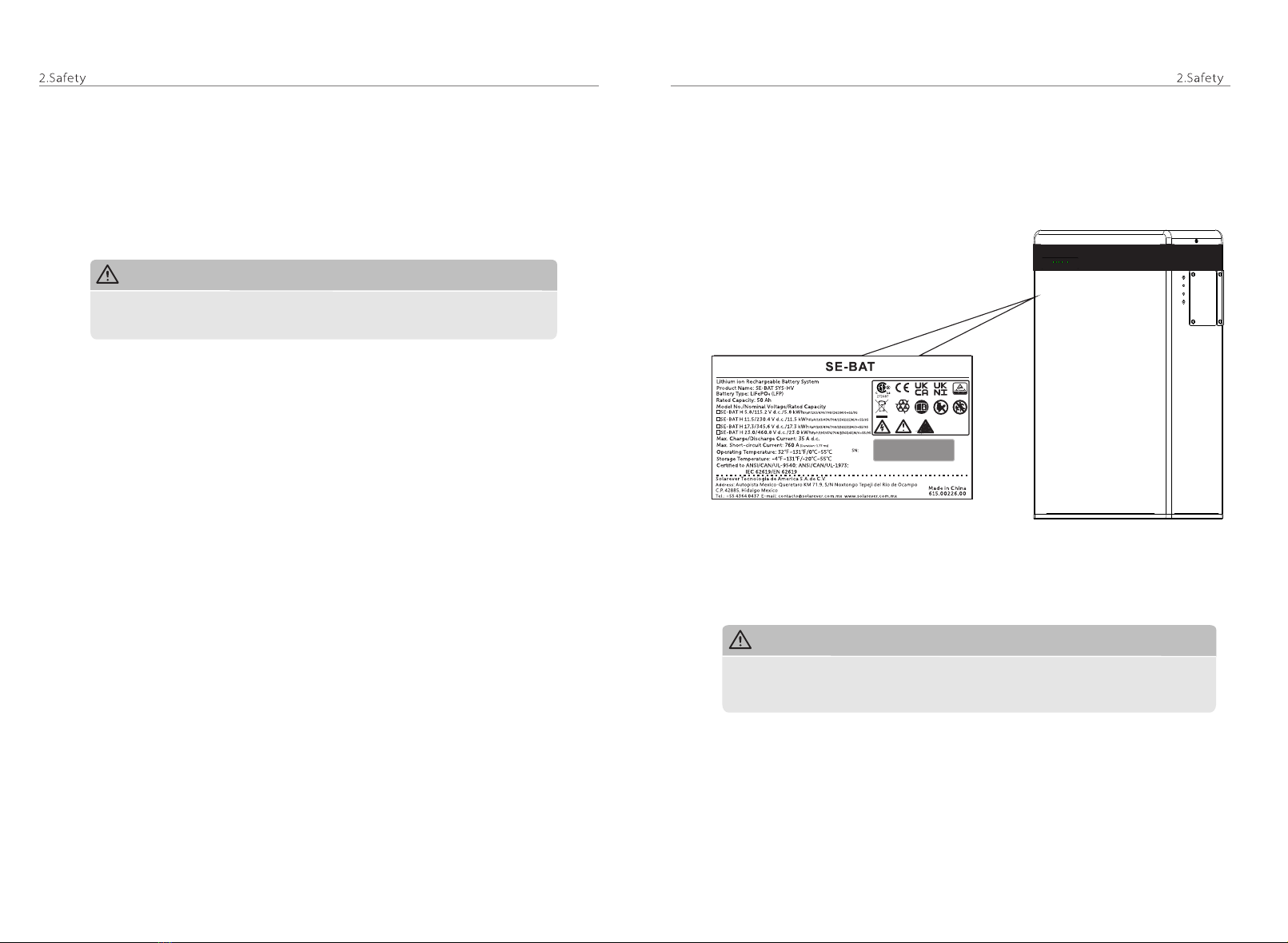

2.1.2 Explanation of Symbols

This section gives an explanation of all the symbols shown on the SE-BAT system

and on the warning label.

CAUTION!

If the battery is not installed within one month after receiving the battery, the

battery must be charged till the SOC is more than 50% for maintenance.

45

Wear protecitve glasses

Observe enclosed documentation.

Keep the battery system away from open ames or i nition

sources.

Keep the battery system away from children.

Danger of high voltages.

Danger to life due to high voltages in the battery system!

Danger.

Risk of electric shock!

The battery pack may explode.

Symbol Explanation

The PV inverter is compliant with TUV

The battery system should be disposed of at a proper facility

for environmentally safe recycling.

The battery system should not be disposed together with the

household waste.

Disposal information can be found in the enclosed documentation.

2.2 Response to Emergency Situations

2.2.1 Leaking Batteries

If the battery leaks electrolyte which is corrosive, avoid contact with the leaking

liquid or gas. Direct contact may lead to skin irritation or chemical burns. If one is

exposed to the leaked substance, do these actions:

Accidental inhalation of harmful substances:Evacuate people from the

contaminated area , and seek medical attention immediately.

Eye contact: Rinse eyes with owing water or 15 minutes, and seek medical

attention immediately.

Dermal contact: Wash the affected area thoroughly with soap and water, and

seek medical attention immediately.

Ingestion: Induce vomiting, and seek medical attention immediately.

2.2.2 Fire

In case of a re, make sure an ABC or carbon dioxide extinguisher is nearby.

WARNING!

The battery pack may catch re when heated above 150°C.302℉/

If a re breaks out where the battery pack is installed, do

these actions:

1. Extinguish the re before the batterry pack catches re;

2. If the battery pack has caught re, do not try to

extinguish the re. Evacuate people immediately.

WARNING!

If the battery pack catches re, it will produce noxious and poisonous gases.

Do not approach.

2.2.3 Wet Batteries and Damaged Batteries

If the battery pack is wet or submerged in water, do not try to access it.

If the battery pack seems to be damaged, they are not t or use and may pose a

danger to people or property.

Please pack the battery in its original container, and then return it to Solarever or

your distributor.

CAUTION!

CSA certied

CE mark.

The inverter complies with the requirements of the applicable

CE guildlines.

272687

Damaged batteries may leak electrolyte or produce ammable gas. If

you suspect such damage, immediately contact Solarever for advice

and information.

2.3 Qualied nstaller

WARNING!

All operations of SE-BAT SYS-HV relating to electrical connection and

installation must be carried out by qualied personne.

A skilled worker is dened as a trained and qualied electrician or installer who

has all of the following skills and experience:

ŸKnowledge of the functional principles and operation of on-grid systems

ŸKnowledge of the dangers and risks associated with installing and using

electrical devices and acceptable mitigation methods

ŸKnowledge of the installation of electrical devices

ŸKnowledge of and adherence to this manual and all safety precautions and

best practices

67

3 Product Introduction

3.1 Product Overview

For safety reasons, installers are responsible for familiarizing themselves with the

contents of this manual and all warnings before performing installation.

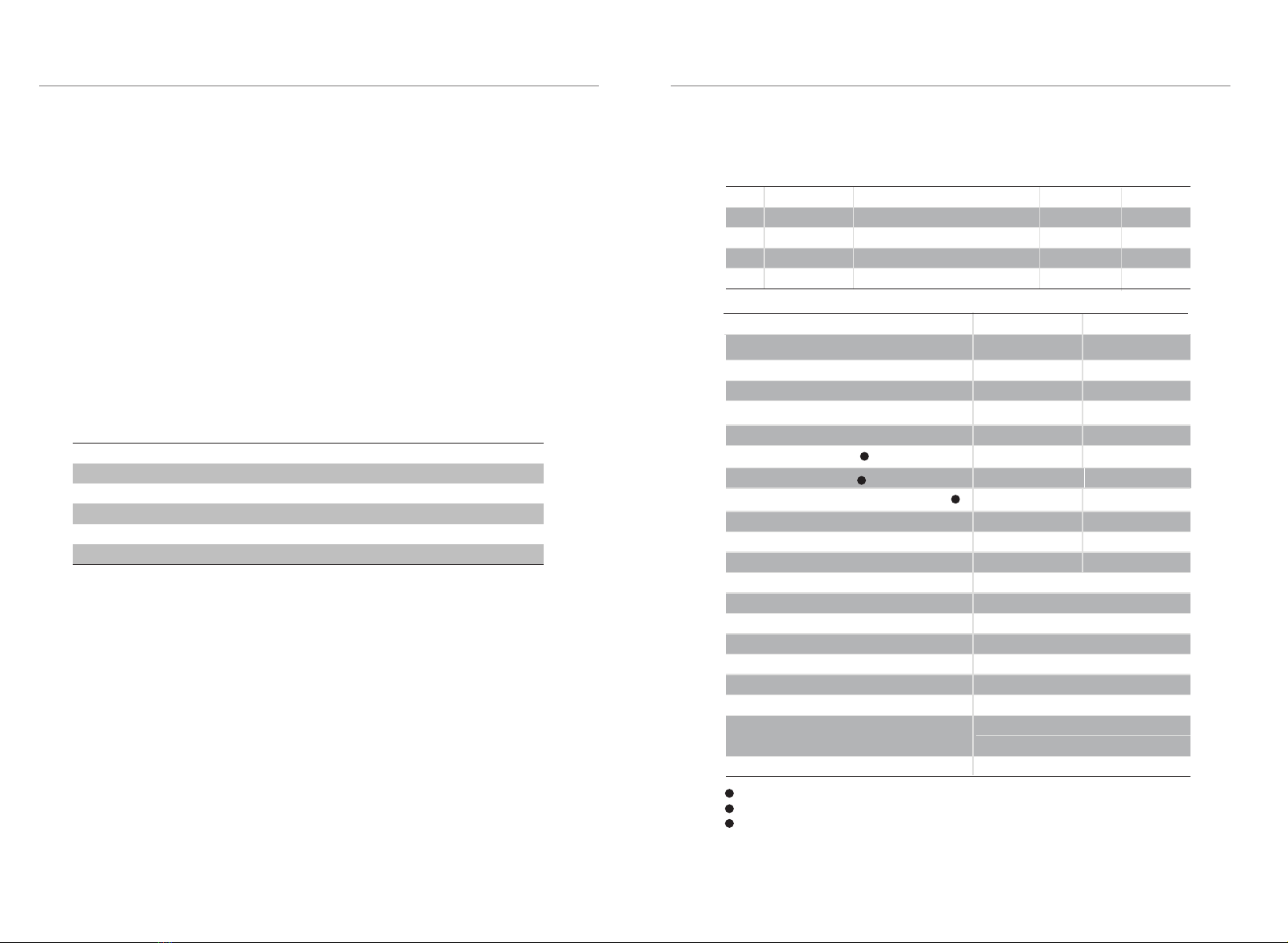

3.1.1 Demension and Weight

A battery management system (BMS) is any electronic system that manages a

rechargeable battery.

Battery pack is a type of electrical battery which can be charged, discharged into

a load.

A battery system includes BMS and battery pack(s).

SE-BAT-SL H 5.8

(Battery Pack)

SE-BAT-MA H 5.8

Length

Width

Height

Weight

SE-BAT-MA H 5.8 SE-BAT-SL H 5.8

3. Product Introduction

18.66 in/474.00 mm

7.60 in/193.00 mm

27.87 in/708.00 mm

159.2 lbs/72.2 kg

25.47 in/647.00 mm

151.0 lbs/68.5 kg

18.66 in/474.00 mm

7.60 in/193.00 mm

27.87 in/708.00 mm

25.47 in/647.00 mm

18.66 in/474.00 mm

7.60 in

193.00 mm

18.66 in/474.00 mm

7.60 in

193.00 mm

ŸSection view of SE-BAT-SL H 5.8

3. Product Introduction 3. Product Introduction

89

3.1.2 Appearance

ŸSection view of SE-BAT-MA H 5.8

Object Mark Description

Ⅰ

Ⅱ

Ⅲ

Ⅳ

BAT+/BAT-

CAN

GND

/

Charge/Discharge Connectors

CAN Connector

GND

Air Valve

Object Mark Description

Ⅰ'

Ⅱ'

Ⅲ'

Ⅳ'

Ⅴ'

XPLUG

+

RS485 I

GND

/

Ⅰ

Ⅱ Ⅲ

Ⅳ

Ⅴ Ⅵ

Ⅶ

ⅧPower Connector’ to YPLUG of upper battery pack

RS485 Connector to RS485 II of upper battery pack

GND

RS485 Connector to RS485 I of next battery pack

Power Connector’ to XPLUG of next battery pack, or

to “-” of the same pack

Air valve

BAT+BAT-

CAN

-YPLUG

RS485 II

Ⅲ

+

XPLUG

RS485 I

-YPLUG

RS485 II

Ⅰ'Ⅱ’'

Ⅲ’'Ⅳ’'

Ⅴ’'

Ⅵ’'Ⅶ'

Ⅷ’'Ⅳ'

Power Connector to “-” of upper battery pack

Power Connector to + of next battery pack, or to YPLUG

of the same pack

RS485 Connector to RS485 I of next battery pack

Power Button

DIP Switch

Circuit Breaker

Ⅴ

Ⅵ

Ⅶ

Ⅷ

Ⅸ

Ⅹ

-

YPLUG

RS485 II

POWER

DIP

ON/OFF

Power Connector’ to XPLUG of next battery pack,

or to “-” of the same pack

Power Connector to + of next battery pack, or to

YPLUG of the same pack

Ⅵ'

Ⅶ'

Ⅷ'

-

YPLUG

RS485 II

X

IX

3.2 Basic Features

3.2.1 Features

The SE-BAT SYS-HV is one of the advanced energy storage systems on the market

today, incorporating state-of-the-art technology, high reliability, and convenient

control features shown as below:

Ÿ90% DOD

Ÿ99% Faradic charge efficiency

Ÿ95% Battery roundtrip efficiency

ŸCycle life > 6000 times

ŸSecondary Protection by hardware

ŸIP55 protection level

ŸSafety & Reliability

ŸSmall footprint

ŸFloor or wall mounting

3.2.2 Certications

3. Product Introduction 3. Product Introduction

10 11

SE-BAT system safety

Battery cell safety

UN number

Hazardous materials classication

UN transportation testing requirements

International protection marking

CE, FCC, RCM, TUV (IEC 62619), UL 1973

UL 1642

UN 3480

Class 9

UN 38.3

IP 55

3.3 Specications

3.3.1 SE-BAT SYS-HV Conguration List

3.3.2 Performance

Model Battery Pack Energy(kWh) Voltage (V)

No.

1

2

3

SE-BAT H 5.8

SE-BAT H 11.5

SE-BAT H 17.3

SE-BAT-MA H 5.8*1

SE-BAT-MA H 5.8*1+SE-BAT-SL H 5.8*1

SE-BAT-MA H 5.8*1+SE-BAT-SL H 5.8*2

5.8

11.5

17.3

100-131

200-262

300-393

SE-BAT-MA H 5.8 SE-BAT-SL H 5.8

Dimension (in/mm)

Weight (kg)

Nominal Voltage (V d.c.)

Operating Voltage (V d.c.):

Nominal Capacity (Ah)

Nominal Energy (kWh) :

Recommend Charge/Discharge Current (A d.c.):

Standard Power (kW)

Maximum Power (kW)

72.2

115.2

100-131

50

5.8

25

2.9

4.0

68.5

115.2

100-131

50

5.8

25

2.9

4.0

Altitude (m)

Faradic Charge Efficiency (25°C/77°F)

Battery Roundtrip Efficiency (C/3,25°C/77°F)

Expected Lifetime (25°C/77°F)

Cycle Life (90% DOD, 25°C/77°F)

Available Operating Temperature

Optimal Operating Temperature

Storage Temperature

Ingress Protection

≤2000

99%

95%

10 years

6000 cycles

IP55

Test conditions: 100% DOD, 0.5C charge & discharge @+25°C

Discharging: 41 /0 ~5 and /45-55 will be rating 32℉~℉°C °C 113℉~131℉°C

90% DOD; System usable energy may vary with inverter different setting

Charging: 32℉~41℉/0°C~5°C and 104℉~122℉/40°C~50°C will be rating

1

2

1

Usable Energy (kWh) :

Max. Сharge/Discharge Current (A d.c.) :

5.2

35

5.2

35

2

3

3

32℉~131℉/0°C~55°C

59 ~95 15 ~35℉ ℉/ °C °C

-4℉~131℉/-20°C~55°C (3 months)

32℉~104℉/0°C~40°C (1 year)

18.66*7.60*27.87

474.00*193.00*708.00

18.66*7.60*25.47

474.00*193.00*647.00

4 Installation

4.1 Installation Prerequisites

Make sure that the installation location meets the following conditions:

ŸThe building is designed to withstand earthquakes

ŸThe location is far away from the sea, to avoid salt water and humidity

ŸThe oor is at and level

ŸThere are no ammable or explosive mateials nearby

ŸThe ambience is shady and cool, keep away from heat and avoid direct

sunlight.

ŸThe temperature and humidity stays at a constant level.

ŸThere is minimal dust and dirt in the area.

ŸThere is no corrosive gases present, including ammonia and acid vapor.

ŸThe ambient temperature is within the range from 32℉113℉45°C, and the /0°C to /

optimal ambient temperature is between ℉ ℉ .9/15°C and 95 /35°C

NOTE!

If the ambient temperature is outside the operating range, the battery pack

stops operating to protect itself. The optimal temperature range for the battery

pack to operate is 15°C to 35°C. Frequent exposure to harsh temperatures may

deteriorate the performance and lifetime of the battery pack.

4.2 Safety Gear

Installation and maintenance personnel must operate according to applicable

federal, state and local regulations as well as the industry standards regarding the

product installation personnel shall wear safety gears, etc. in order to avoid short

circuit and personal injury.

Insulated gloves Safety goggles Safety shoes

4. Installation

12 13

4. Installation

4.3 Tools

These tools are required to install the SE-BAT system.

Torque screw driver Phillips-screw driver Socket nut wrench

Phillips-head screw driver Flat-head screw driver Torque wrench

Tape measure Drill Pencil or Marker

4.4 Installation

4.4.1 Check for Transport Damage

Make sure the battery is intact during transportation. If there are some visible

damages, such as cracks, please contact your dealer immediately.

4.4.2 Unpacking

Unpacking the battery package by cutting the packing tape and make sure the

battery packs and the relevant items are complete. See package items on section

4.4.3, please check the packing list carefully, if there's any item missing, please

contact Solarever or your distributer directly.

CAUTION!

According to regional regulations, several people may be required for

moving equipment.

WARNING!

Please strictly follow the installation steps. Solarever will not answer for

any hurting or loss arising by incorrectly assembling and operation.

NOTE!

The SE-BAT battery pack is rated at IP55 and thus can be installed

outdoors as well as indoors. However, if installed outdoors, do not allow the

battery pack to be exposed to direct sunlight and moisture.

4. Installation 4. Installation

15

14

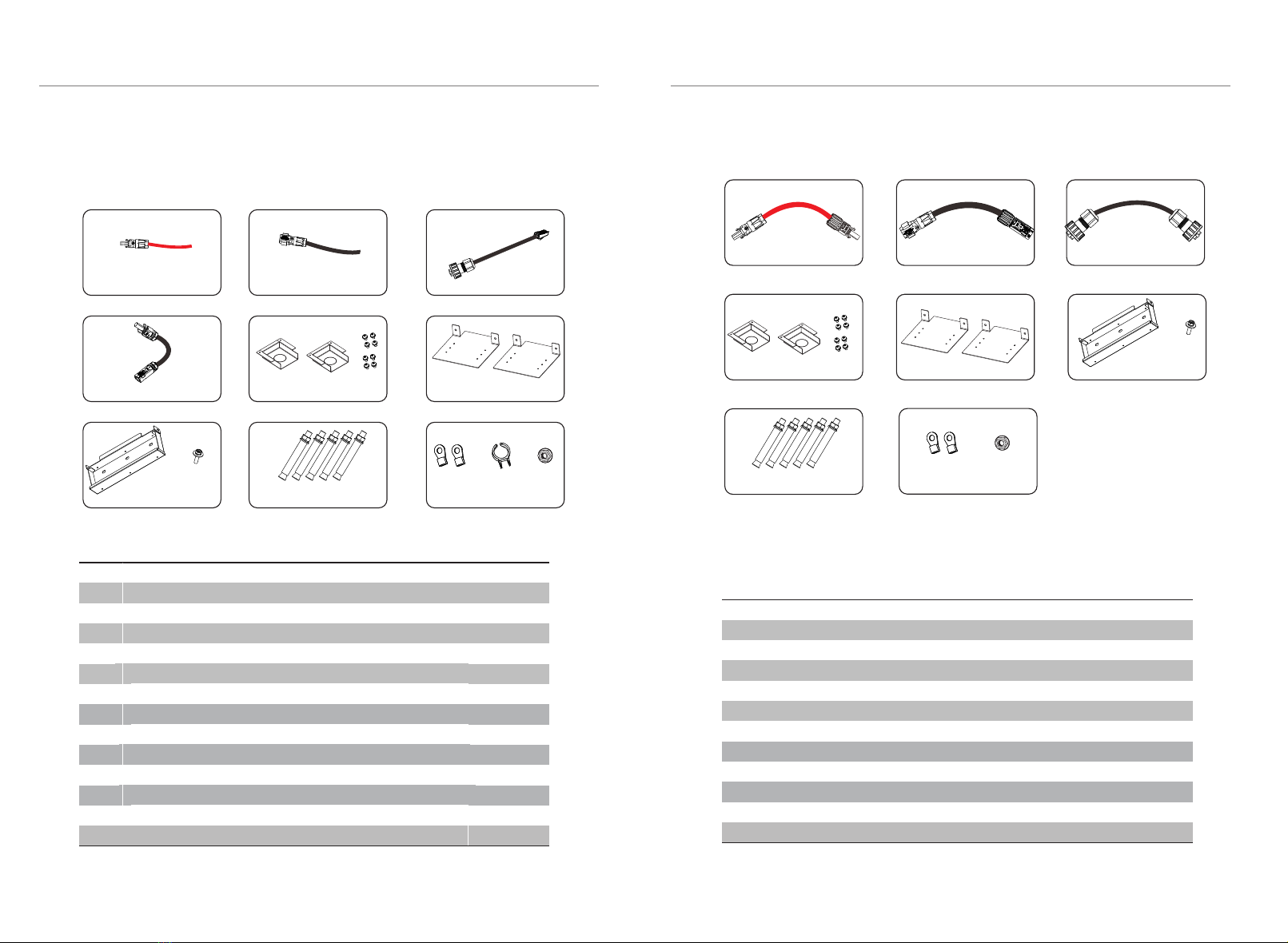

4.4.3 Accessories

E

HJ

The table below lists the number of each component.

SE-BAT-MA H 5.8:

K

Object

A

B

C

D

E

F

G

H

I

J

K

L

M

Description

Power line between Inverter and SE-BAT-MA H 5.8 (+) ( )6.56 ft/2.00 m)

Power line between Inverter and SE-BAT-MA H 5.8 (-) ( )6.56 ft/2.00 m

CAN communication cable ( )6.56 ft/2.00 m

Series-connected plug

Cover plate2

M4 screw

Cover plate2

Wall bracket

M5 screw

Expansion bolt

Ring terminal (for grounding)

Power cable disassembling tool

Grounding nut

Quantity

1

1

1

1

2

8

2

1

1

5

2

1

2

L

SE-BAT-SL H 5.8:

Quantity Object

A1

B1

C1

D1

E1

F1

G1

H1

I1

J1

K1

Description

Power cable between battery packs ( )259.59 in/650.00 mm

Power cable’ between battery packs ( )259.59 in/650.00 mm

Rs485 communication cable ( )259.59 in/650.00 mm

Cover plate2

M4 screw

Cover plate2

Wall bracket

M5 screw

Expansion bolt

Ring terminal (for grounding)

Grounding nut

A(Red cable)B(Black cable) C

D(Black cable)

A1

F

I

B1 C1

G1 H1F1

I1

D1 E1

1

1

1

2

8

2

1

1

5

2

2

The table below lists the number of each component.

G

M

J1 K1

RS485cable*1

4. Installation 4. Installation

16 17

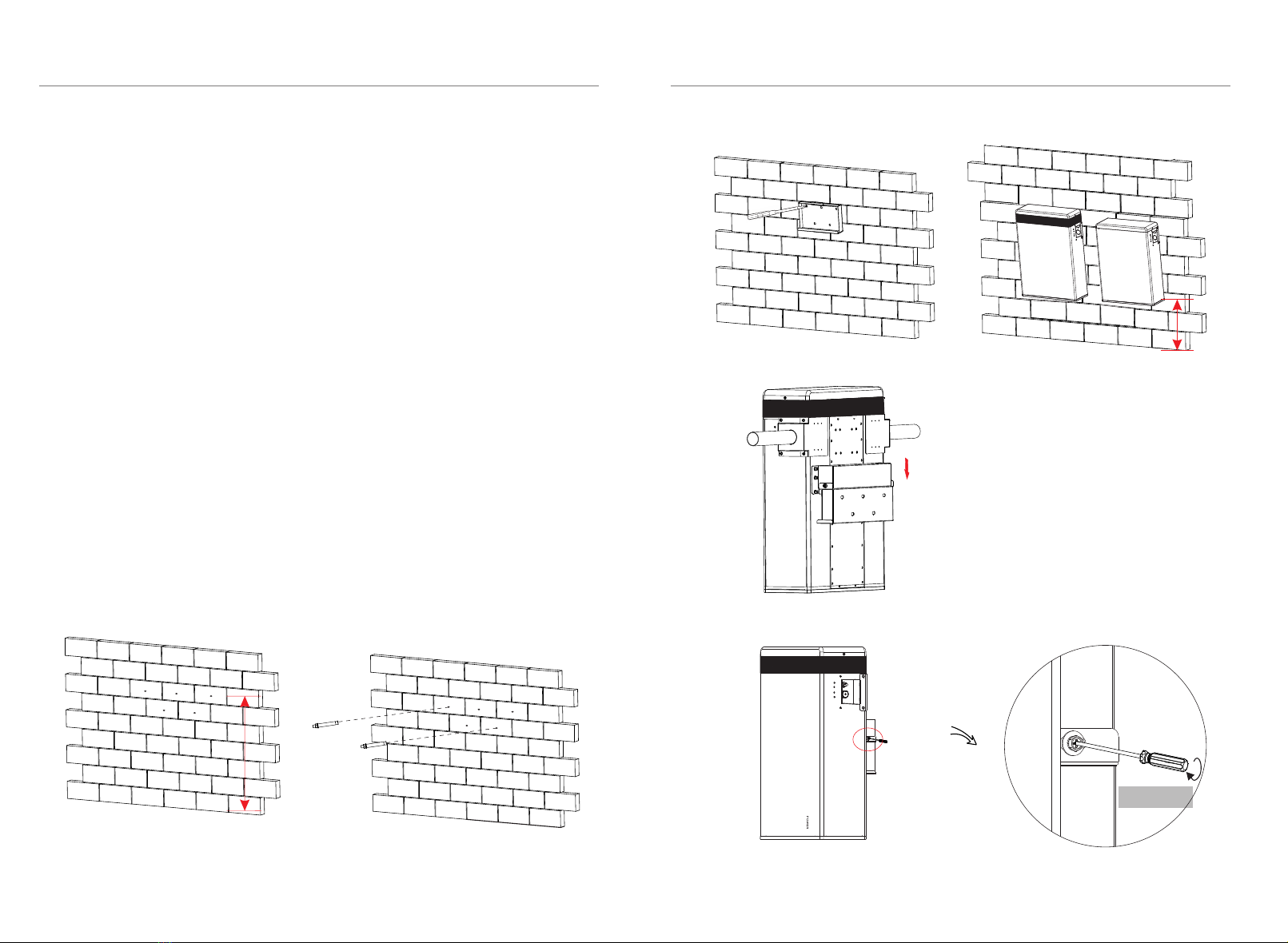

4.4.4 Battery Installation Steps

It is recommended that the space between battery packs is more than

300mm.

Steps (for SE-BAT-MA H 5.8 or SE-BAT-SL H 5.8):

Make sure the wall is strong enough to withstand the weight of battery packs.

Step 1: x the wall brac et (H or G1) on the wall

ŸUse the wall bracket as a template to mark the position of the 5 holes

ŸDrill holes with φ 0.39 in/10 mm drill, make sure the holes are deep enough (at least

80mm) for installing and tightening the expansion bolts (J or I1)

ŸInstall the expansion bolts in the wall, and screw the bracket by using the

wrench.

Step 2: Match the battery with the wall bracket

ŸTransport the battery to the wall bracket

ŸHang the battery over the wall bracket, move the battery close to it, and

match it on the wall bracket

Step3: Lock the joint between hanging board and wall bracket with M5

combinationscrew (I or H1).

Note: 1 Keep the distance from installation point to the oor less than 259.59 in/650.00 mm..

Side view of hanging the battery to

the wall bracket.

Torque: 2 N·m

2. It is recommended to keep a distance of 32.44 in/824.00 mm between the center of

wall bracket and the wall bracket.

3. It is recommended to keep a distance of 13.78 in/350.00 mm between battery packs,

Must be between 12.60~14.96 in/320.00 ~380.00 mm.

1.18 in/30 mm<height<11.81 in/300 mm

14.96 in/380 mm<height<25.59 in/650 mm

Overall Installation

It is recommended to protect the cables by using corrugated pipe.

1. Connect all the cables on the left side of SE-BAT-MA H 5.8.

2. Install cover plates and conduits.Install cover plate and conduit. Pass the

3. Get the cables through theconduit .

right side of SE-BAT-MA H 5.8 to make a complete circuit.

6. Set the cables into the groove of metal plates and screw them back to the

battery pack on both sides.

A1

A2

A3

A4

conduits(A1) and joint(A2) through the round hole of the cover plate(A3) and

tighten it with the Hexagon flange head screw(A4). These conduits must be

standard size and match the holes in the battery cover plate. The catheter fittings

must be waterproof and preferably insulated. (conduit size: 1-1/1 in/12.7-12.7 mm)

4. Finally, screw the front and side cover plates onto the battery.(torque:2N.M)

5 . DO remember to insert the series-connected plug at “-” and “YPLUG” on the

4.5

For SE-BAT-MA H 5.8:

4

For SE-BAT-MA H 5.8 + 1~3 battery packs:

1. Connect the cables at one end of the SE-BAT-MA H 5.8/SE-BAT-SL H 5.8.

2. Get the cables through theconduit. (conduit size: 1-1/2 in/12.7~25.4 mm)

3. Finally, screw the front and side cover plates onto the battery.(torque:2N.M)

4. DO remember to insert the series-connected plug at “-” and “YPLUG” on the

right side of last battery pack to make a complete circuit.

(please refer to section 4.5 For SE-BAT-MA H 5.8 step 2)

18 19

+

-

+

-

+

-

+

-

+

-

Please refer to section 4.5 for the installation of conduit and cover plate, and

then make connection.

On the left side of SE-BAT-MA H 5.8 , after the charging cables (please refer to

section 4.5.2) and CAN communication cable (please refer to section 4.5.4) are

correctly connected, screw the terminal box_small (J) with M4 srews and lock

the terminal box cover (K) also with M4 screws.

On the right side of SE-BAT-MA H 5.8 , after the battery modules (please refer to

section 4.5.1 For 2~3 battery modules) are correctly ,screw the terminal

box_medium_right (I1) with M4 screws and lock the terminal box cover (K1) in

the same way as BMS.

Please see the installation diagram on the right. (screw torque: 2 N·m)

4. Installation 4. Installation

For 2~3 battery modules:

The power cable between battery modules (A1) is different from the one that

between BMS and battery module (C). The other end of the power cable is black,

and this color is connected to YPLG (Ⅴ’), which is on the right side of the battery

module.

1. Connect YPLUG (Ⅴ’)on the right side of battery module to XPLUG (Ⅰ’) on the

left side of the second battery module. The rest battery modules are connected

in the same way. The following gue shows that four battery modules are

connected.

2. Before connecting the cables to XPLUG (Ⅰ’) on the left side of follow-up

battery module, lock the terminal box_medium_right(I1) on the right side of

previous battery module with M4 screws(H1), and get the cables through the

conduits which length is 7.87~9.45 in/200.00~240.00 mm, then lock the terminal

box cover (K1) with M4 screws.

3. Lock the terminal box_medium_left(J1) on the left side of follow-up battery

module, and keep the terminal box cover (K1) unlocked until the cables are

correctly connected to the YPLUG.

GND RS485

Power Cable

GND

RS485

Power Cable

4.5.1 Cable Connection

20 21

+

-

+

-

4. Installation 4. Installation

1. The only step of connecting power cable for SE-BAT-MA H 5.8 is connecting the

series-connected plug to “-” and “YPLUG” on the right side. The series-connected

plug is used to make a complete circuit.

-YPLUG

RS485 II

For SE-BAT-MA H 5.8 + 1~3 battery packs:

1. Connect “-” (Ⅴfor SE-BAT-MA H 5.8 or ’ for SE-BAT-SL H 5.8) on the right side Ⅵ

to “+” ’) on the left side of the next battery pack. (Ⅱ

2. Connect “YPLUG” ( for SE-BAT-MA H 5.8 or ’ for SE-BAT-SL H 5.8) on the right Ⅵ Ⅶ

side to “XPLUG” (Ⅰ’) on the left side of the next battery pack.

3. The rest battery packs are connected in the same way.

4. Insert the series-connected plug at “-” and “YPLUG” on the right side of last

battery pack to make a complete circuit.

-YPLUG

RS485 II

-YPLUG

RS485 II

4.5.2 Connecting Power Cables

For SE-BAT-MA H 5.8:

XPLUG +

RS485

-YPLUG

RS485 II

-YPLUG

RS485 II

-YPLUG

RS485 II

22 23

3. Pass the other end of the charging cable through the inverter's pipe.Insert the

trip head of each wire into the hole.

NOTE!

1. When connecting the cable to SE-BAT-MA H 5.8, t the wo connectors together

until the connection audibly locks into place.

2. Check to make sure the connection is securely locked.

3. Don't shake both ends of the cable at the joint once the connection is locked.

4.5.3 Connecting Power Lines

4. Installation 4. Installation

Connecting Charging Cables between Inverter and SE-BATsystem:

Ø

This step is going to connect power lines between Inverter and SE-BAT system.

The default length of power lines are 2 meters, so customers can6.56 feet/

propriately cut the cable accroding to the actual installation environment. As a

result, eachpower line has one terminal block when leaving the factory, and

customers need to connect the other end of terminal block by themselves.

1. Connect the positive cable (+)(A) and negative cable (-)(B) through the accessory

Cover plate1 to the corresponding port as shown in the following gue.

BAT- BAT+

CAN

-

+

BAT- BAT+

CAN

24 25

-

+

BAT- BAT+

CAN

Disassemble the power line by plugging the slot type screwdriver to the terminal

groove of charging cable. Please see the illustration as shown below:

BAT- BAT+

CAN

BAT- BAT+

CAN

DO NOT disassemble power cables when the SE-BAT system is not

turned off, otherwise there will be an arc discharge that could cause

serious injury!

CAUTION!

Disassembling Power Line (on BAT+, BAT-, “+”, XPLUG port)

Ø

4. Installation 4. Installation

-YPLUG

RS485 II

Disassemble the power line by plugging the Power cable disassembling tool(L)

to the terminal groove of charging cable. Please see the illustration as shown

below:

-YPLUG

RS485 II

-YPLUG

RS485 II

Disassembling Power Cable (on ”-”, YPLUG port)

Ø

26 27

+

-

+

-

4. Installation 4. Installation

4.5.4 Connecting CAN Communication Cable

It is required for the BMS to communicate with the inverter for proper operation.

2. Connect the CAN communication cable to

the CAN connector (II) which is marked in red.

Insert the other end of the CAN communication

cable to the CAN connector. Assemble the cable

gland and screw the cable nut.

1. Insert one end of the CAN communication

cable (C) which has no cable nut directly to the

BMS port of the Inverter.

BAT- BAT+

CAN

The wire order of the communication cable is as follows:

1 2 3456 7 8

1) White with an orange stripe

2) Orange

3) White with a green stripe

4) Blue

5) White with a blue stripe

6) Green

7) White with a brown stripe

8) Brown

Sequence 1 2 3 4 5 6 7 8

CAN /GND /CAN_H CAN_L /A1 B1

4.5.5 Connecting RS485 Communication Cable

For SE-BAT-MA H 5.8:

There's no need to use RS485 communicaton cable.

For SE-BAT-MA H 5.8 + 1~3 battery packs:

Connect RS485 II ( for SE-BAT-MA H 5.8 orⅧ’ for SE-BAT-SL H 5.8) of upper Ⅶ

battery on the right side to RS485 I ( ’) of the follow-up battery pack which is on Ⅲ

the left. Assemble the cable gland and screw the cable nut.

Sequence 1 2 3 4 5 67 8

RS485I

RS485II

VCC_485

VCC_485

GND_485

GND_485

B2

B2

N-

N-

P+

P+

A2

A2

VCC_485_2

VCC_485_2

GND_485

GND_485

The wire order of the communication cable is as follows:

-YPLUG

RS485 II

-YPLUG

RS485 II

-YPLUG

RS485 II

+XPLUG

RS485 I

28 29

4. Installation 4. Installation

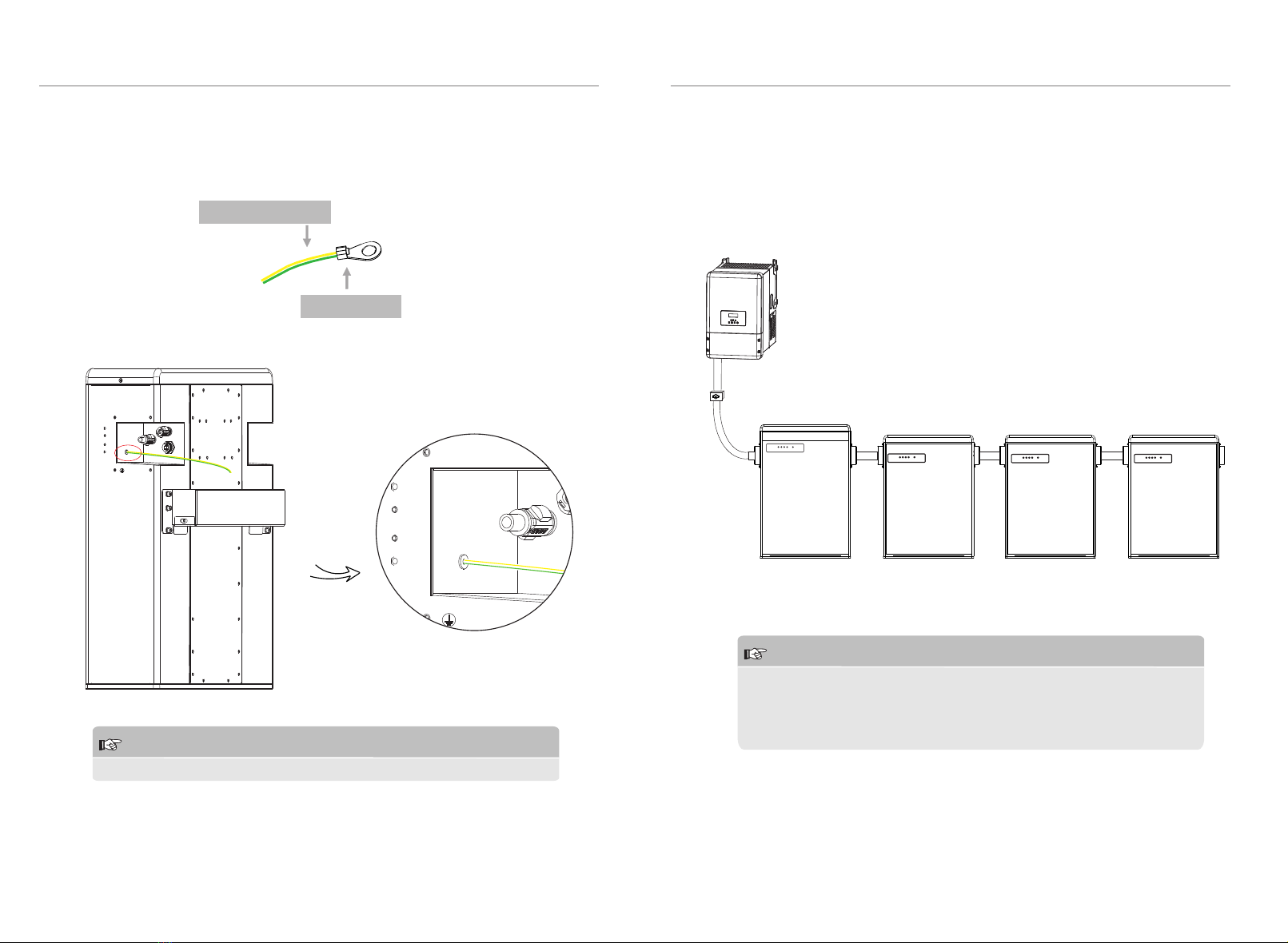

4.5.6 Connecting Ground Wire

CAUTION!

GND is mandatory!

The terminal point for GND connection is on the side of grooves as shown

below (torque: 1.5 N·m):

-YPLUG

RS485 II

Cable size: 10AWG.

ring terminal

-YPLUG

RS485 II

CAUTION!

One SE-BAT system is allowed to install one SE-BAT-MA H 5.8 plus at most

three battery packs. Connecting more than three battery packs will blow

the fuse, and the battery pack will be damaged. Please make sure the

number of battery packs meets the requirement.

4.6 Overview of Installation

The following diagram is a complete SE-BAT system installation with

SE-BAT-MA H 5.8 + three battery packs.

30 31

5 Commissioning

5.1 Conguing Battery System

The DIP switch is used to congue the number of battery packs which are

communicating to Inverter. The detailed conguration inormation is shown as

follows:

0

1

2

3

4

5

6

7

Conguration a tivated by inverters

0-

1-

2-

Matching SE-BAT-MA H 5.8 (default)

Matching SE-BAT-MA H 5.8 + 1*SE-BAT-SL H 5.8

Matching SE-BAT-MA H 5.8 + 2*SE-BAT-SL H 5.8

The black-start function is only used in the off-grid environment and there is no

other power supply.

Note: if the battery is started in black-start mode, although there is no BMS

communication, the port still has high voltage and there is a risk of electric

shock!

After the black-start mode is started, if the BMS communication has still not been

built within 3 minutes , the black start fails.

4-

5-

6-

Matching SE-BAT-MA H 5.8

Matching SE-BAT-MA H 5.8 + 1*SE-BAT-SL H 5.8

Matching SE-BAT-MA H 5.8 + 2*SE-BAT-SL H 5.8

Black-start conguration

Ø

5. Commissioning

5. Commissioning

NOTE!

When powering on the BMS, the system will start self-testing. If the

buzzer bips, it means DIP conguration fault or communication failue

occurs. If the buzzer bips, please check if the number of battery packs is

corresponding to the DIP conguration, and also check if the RS485

communication calbes are correctly connected. After these two

situation checked OK, press the POWER button to power on, and press

the POWER button again 10s later. In addition: The buzzer will only

alarm on the corresponding fault during the power-on self-test. After

the self-test is completed, it won't bip again even if the same fault

occurs.

NOTE!

Frequently pressing the POWER button may cause the system error.

Please make sure at least 10 seconds is needed when you are going to

press the POWER button from the last pressing operation.

5.2 Commissioning

32 33

Commissioning Steps

If all the battery packs are installed, follow these steps to put it in operation.

1. Remove the upper cover board of SE-BAT-MA H 5.8;

2. Remove the small cover plate;

3. Rotate the DIP to corresponding number with small tool accroding to the

number of battery pack(s) that has(have) been installed;

4. Move the circuit breaker to the ON position;

5. Press the POWER button to turn on the SE-BAT system;

6. Put the small cover plate back;

7. Reinstall the upper cover board to SE-BAT-MA H 5.8;

8. Power on the Inverter.

1

small cover plate

2

3

4

5

5. Commissioning

5. Commissioning

34 35

No.

1

2

3

Mode

Power off

Inverter sends Idle command

BMS Protection

Status of BMS

5.3 Status Indicators

The LED indicators on the front panel of the battery pack are showing the

operating status.

5.3.1 BMS

The capacity indicators show the SOC:

ŸWhen the battery pack is neither charging nor discharging, the indicator

lights off.

ŸWhen the battery pack is charging, part of the Blue LED is ashing with the

frequency of light on for 0.5s, light off for 0.5s, and part of the Blue LED keeps

light on. Take SOC 60% for instance, in charging state:

1. The rst wo Blue LED indicators keeps on

2. The third Blue LED indicator ashes once evey 1s

ŸWhen the battery pack is discharging, the Blue LED is ashing with the

frequency of light on for 1s, and light off for 4s. Take SOC 60% for instance, in

discharging state:

1. The rst three blue LED indicators ash once every 5s

The following table shows the status of BMS.

Charging Discharging

25% 50% 75% 100%

SOC Status

The Green LED is light on for 0.3s, and light o fffor 0.3s

The Green LED keeps light on

25% 50% 75% 100%

SOC Status 25% 50% 75% 100%

SOC Status

Light off

The Green LED is light on for 1s, and light o fffor 4s

The Orange LED is light on for 1s, and light o fffor 4s

The Red LED keeps light on for 10min, then

ic ers with light on for 1s, and light o fffor 4s

Upgrade for BMS

Active

Fault

5

6

4

This manual suits for next models

3

Table of contents

Popular Batteries Pack manuals by other brands

PowerWalker

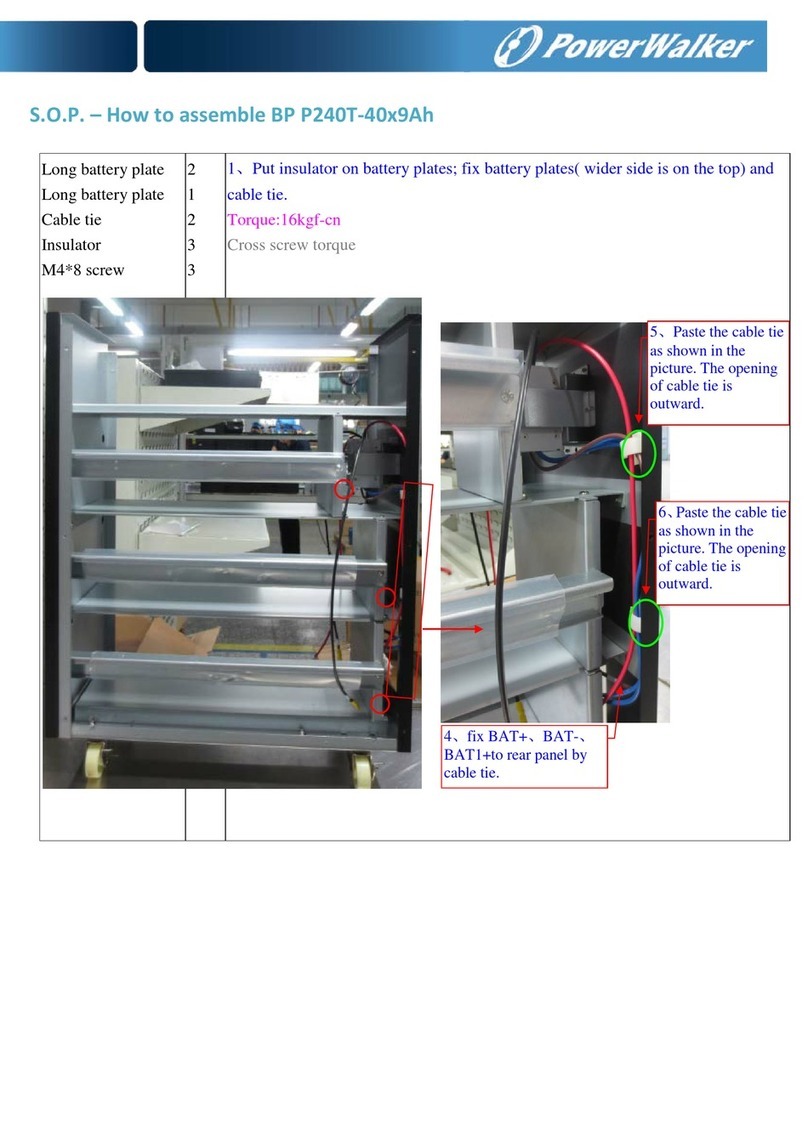

PowerWalker BP P240T-40x9Ah How to assemble

PowerWalker

PowerWalker BPH P48R-8 How to assemble

Tripp Lite

Tripp Lite BP192V557C-1PH Specification sheet

PowerWalker

PowerWalker LiFe Battery System 48-100 manual

Tripp Lite

Tripp Lite BP240V120 Specification sheet

Tripp Lite

Tripp Lite BP192V12-3U Specification sheet