Niles IRP-2+ Troubleshooting guide

Other Niles Extender manuals

Niles

Niles MSU480 User manual

Niles

Niles IRP6+ User manual

Niles

Niles MSU480 Original operating instructions

Niles

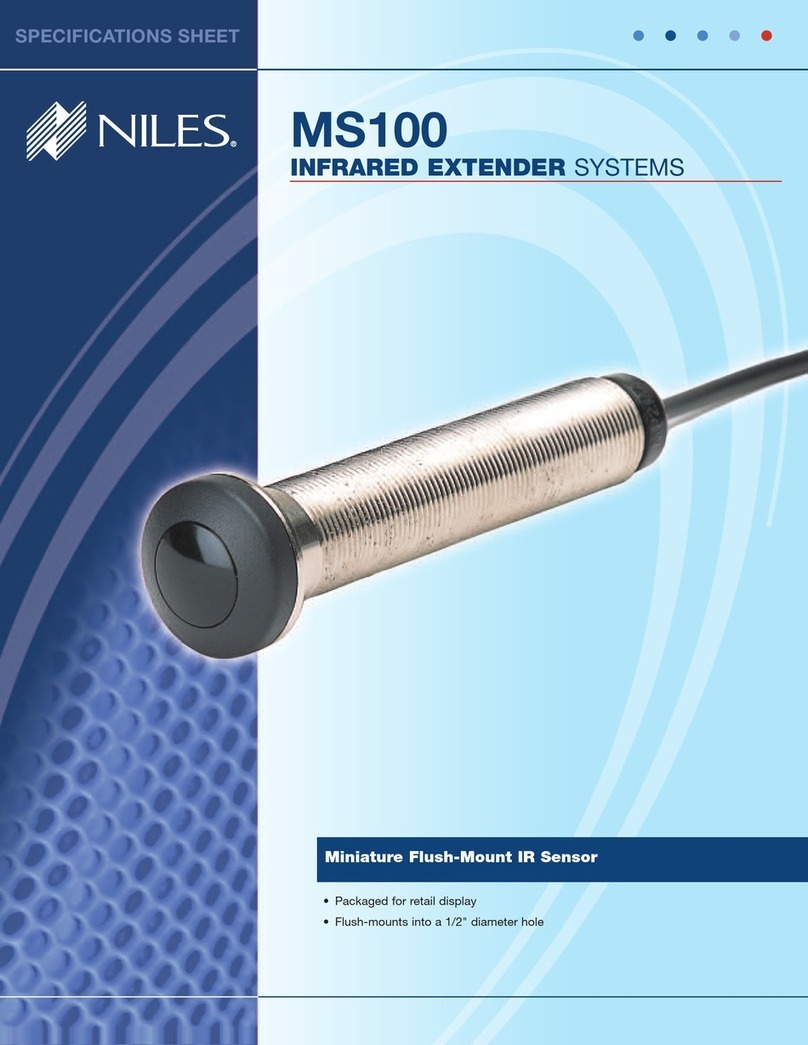

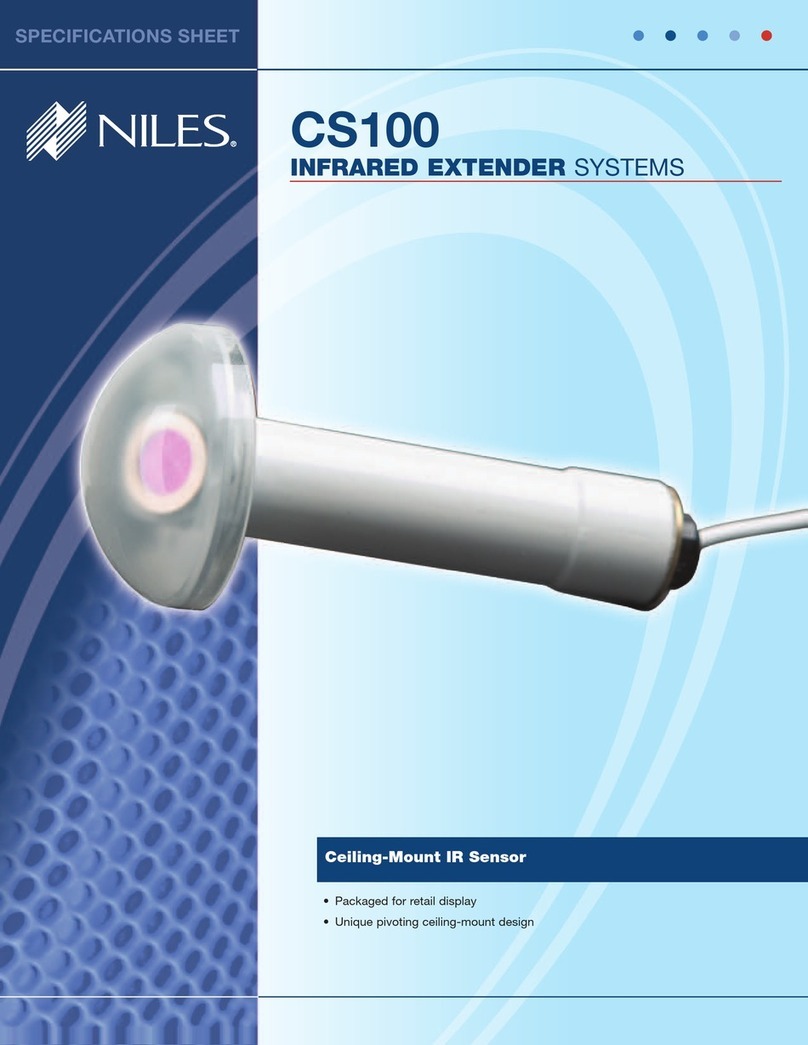

Niles CS100 User manual

Niles

Niles IRB1 User manual

Niles

Niles IRH610 User manual

Niles

Niles ZR-KE User manual

Niles

Niles MSU440Z User manual

Niles

Niles Extender System iWare ES1 User manual

Niles

Niles Wall-Mount IR Sensor WS110R User manual

Niles

Niles MF1VF User manual

Niles

Niles IRZ6+ INTELLIPAD User manual

Niles

Niles ZR-4 SERIES User manual

Niles

Niles PAR4 User manual

Niles

Niles iWare ES1 User manual

Niles

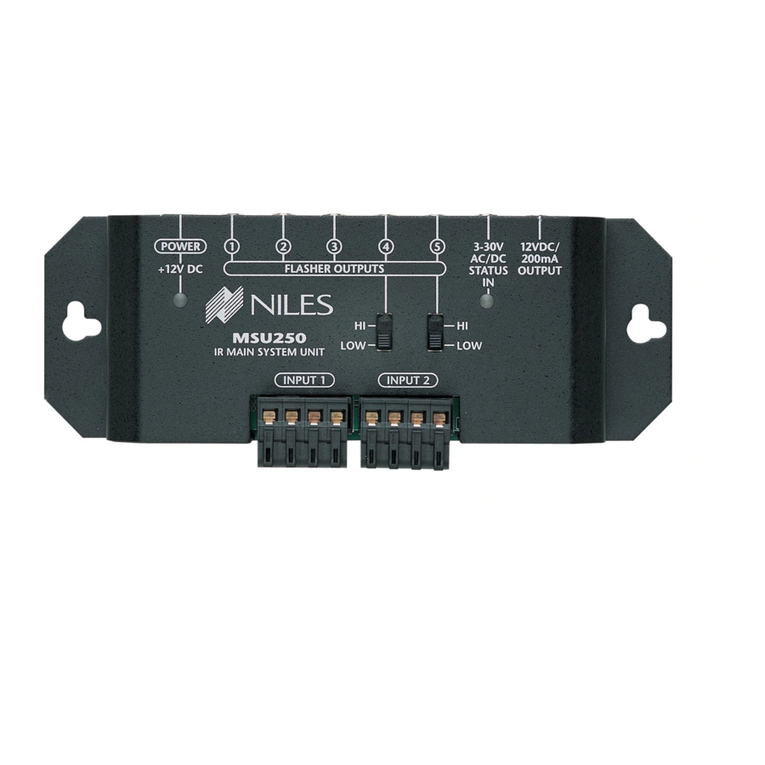

Niles MSU250 User manual

Niles

Niles MF2VF User manual

Niles

Niles RCA2 User manual

Niles

Niles C5-SVA2 User manual

Niles

Niles C5-A2WM User manual

Popular Extender manuals by other brands

foxunhd

foxunhd SX-AEX01 operating instructions

TERK Technologies

TERK Technologies LFIRX2 owner's manual

Devolo

Devolo Audio Extender supplementary guide

Edimax

Edimax EW-7438RPn V2 instructions

Shinybow USA

Shinybow USA SB-6335T5 instruction manual

SECO-LARM

SECO-LARM ENFORCER EVT-PB1-V1TGQ installation manual