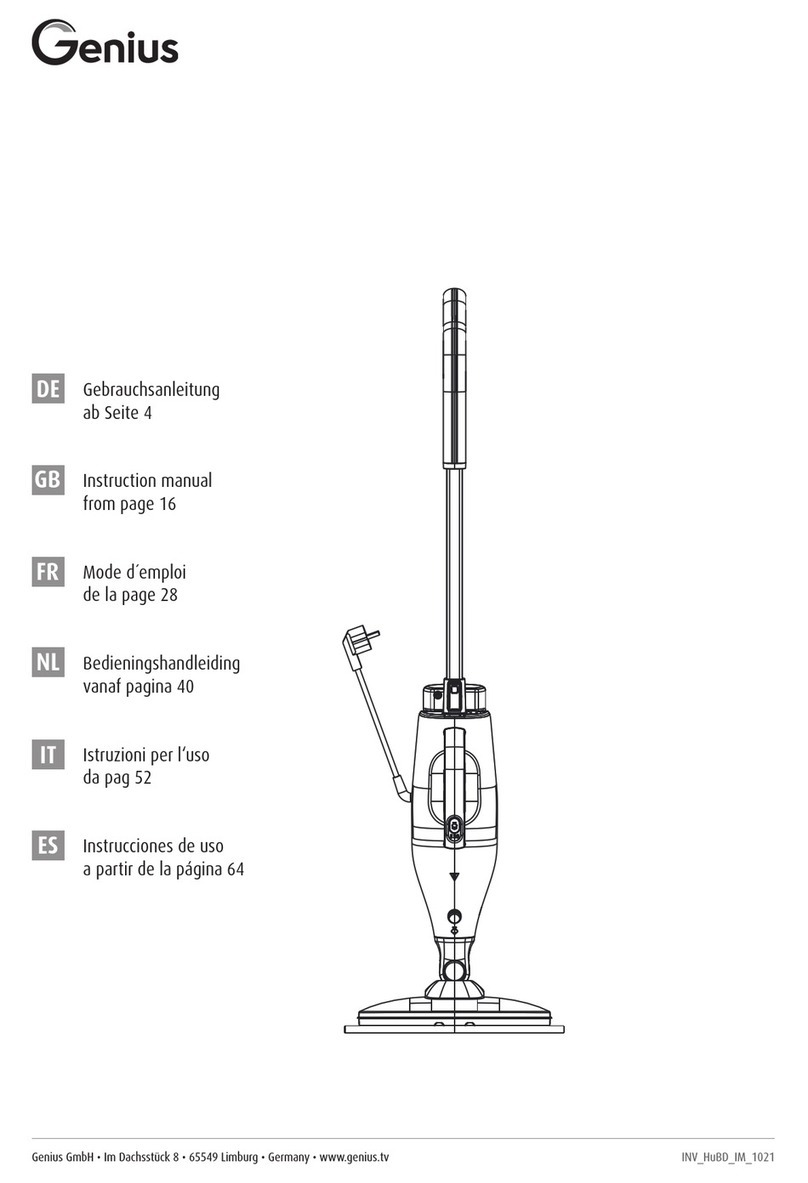

Nilodor S Pile Brush User manual

Maintenance & Care Manual

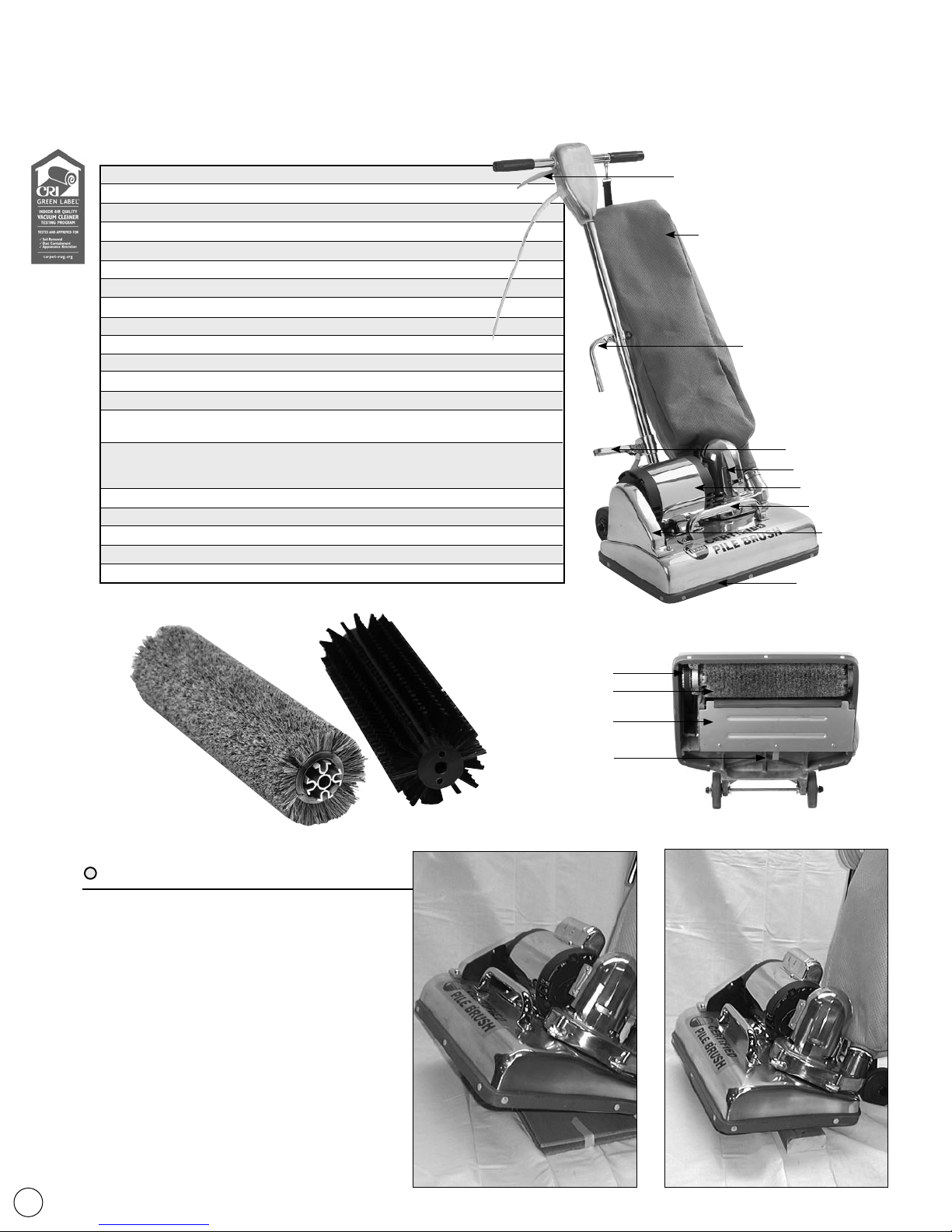

Your Certified Model S Pile Brush:

Serial Number Date Purchased

Maintenance and Specs for your Pile Brush

Timing Belt

Sand Trap

Finger Lift

STORAGE

After using your pile brush always empty the sand

trap and check the refill bag and cord.

Wrap the cord around the cord rest and the

handle.

When not in use, do not leave weight of

machine resting on brush. Place a block or the

corraguted material from shipping, under the

machine away from brush.

(It will flat-spot its fibers, which causes vibration, poor clean-

ing and premature brush replacement.)

Avoid wet carpeted areas. (This is not good for

the natural fiber brush, vacuum bag and motor, or its drive

system.)

Store the pile brush in a dry area.

Brush

Sand Trap

Soild Vegetable

Brush

Power Switch

Heavy C-Tex Outer Bag

Cord Wrap

Clamp Lever

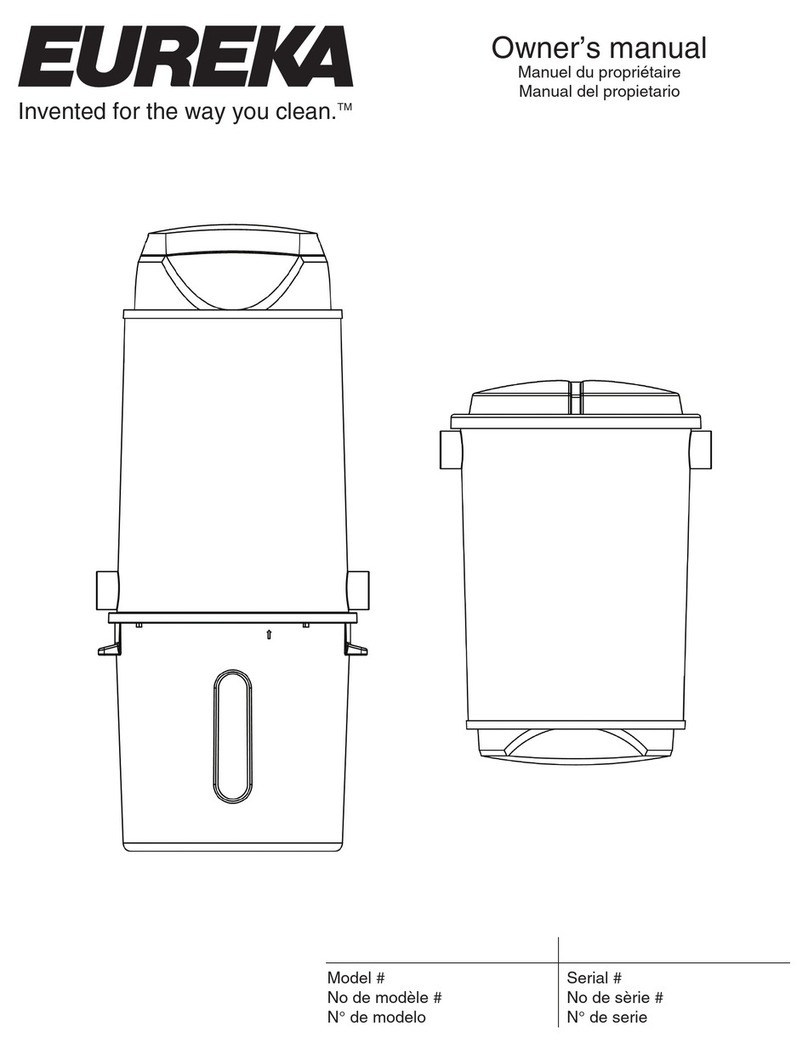

Certified Dry Extraction Pile Lifter Specs:

WEIGHT: 67 lbs.. (30.4 kilo)

OVERALL WIDTH: 19.25” (48.90 cm)

OVERALL DEPTH: 18” (45.72 cm)

OVERALL HEIGHT: 43.25” (109.86 cm)

BRUSH DRIVE MOTOR: 1/2 hp, 60Hz, 115 volt

BRUSH LENGTH: 15” Self-Leveling (38.10 cm)

BRUSH DIAMETER: 4.5” (10.16 cm)

Choice of two brushes: Solid reversible Vegetable fill, Tufted nylon

VACUUM MOTOR: 1/2 hp universal 115 volt

BASE: Polished rugged aluminum casting

CABLE: 50’ x 14.3 U.L. approved

SWITCH: Momentary contact

GEARED DRIVE: No slipping

OUTER BAG: Heavy C-Tex™ material

(Collection efficiency 97.25% @ 0.3 microns)

SAND TRAP: Exclusive hinged sand trap on bottom of base

to collect heavy objects from passing through

vacuum motor.

WHEELS: 4” heavy duty, non-marking

FLOOR ROD: Heavy 1/4” (32 cm) wall tubing fully adjustable

HANDLE: Extra wide 18” (45.72 cm)

SWITCH LEVER: 5” (12.7 cm) plastic coated finger tip control

SHIPPING WEIGHT: 80 lbs.. (36.3 kilo)

Vacuum Motor

Drive Motor

Handle

Rubber Bumper

Tufted Nylon

Brush

Belt Guard

1

Corrugated 2x4 Block

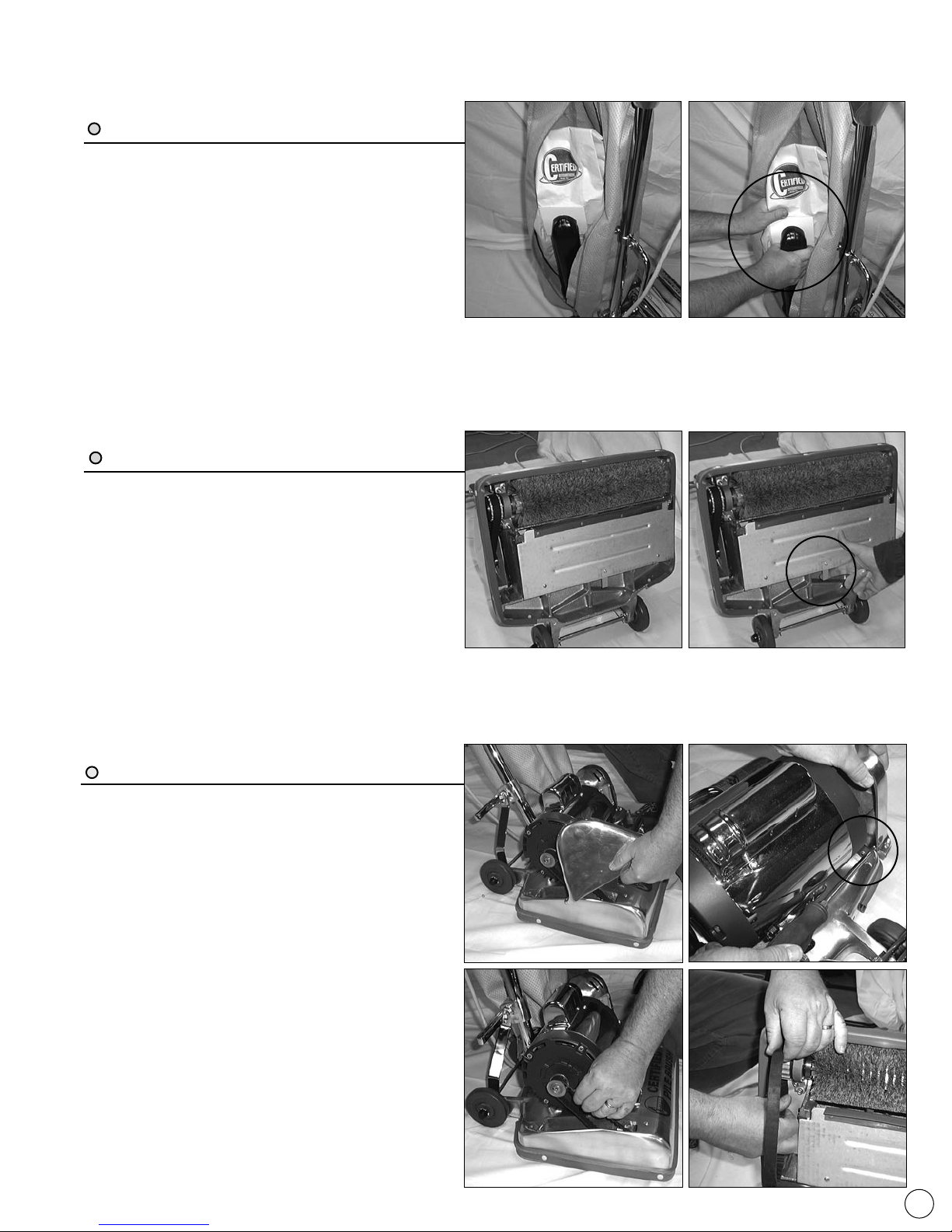

EMPTY THE VACUUM BAG FREQUENTLY

IMPORTANT: Empty insert bag when 3/4 full to maximize

vacuum performance.

Unplug Pile Brush from outlet before bag replacement.

1- Unzip outer bag.

2- Disconnect the paper bag from the bellow

3- Remove old paper bag and dispose in a suitable container.

4- Connect the pile brush bellow to the new bag insert.

Note: Alway make sure the paper bag insert is not folded or restricted.

Items needed: 924-058 High Efficiency bag insert

EMPTY SAND TRAP FREQUENTLY

Unplug Pile Brush from outlet before emptying sand trap.

1- Place the Pile Brush over an old newspaper and turn

back so that it rests on the rear wheels and handle.

2- Grab the finger lift on the center of the sand trap door

and pull open.

3- Remove all debris from inside the sand trap.

Dispose of debris.

4- Close the sand trap door (make sure lid is always

fully sealed.)

Maintenance and Specs for your Pile Brush

TIMING BELT REPLACEMENT Or adjustment

Unplug Pile Brush from outlet before replacing belt.

1- Remove the 2 bolts on the belt guard and the smaller

screw on the inside of the belt guard shield.

2- Loosen the 4 bolts on the Drive motor and slide the motor

forward. This will help loosen tension on the belt for easier

removal.

3- Slide belt over the brush drive assembly and replace

with the new belt.

4- Slide the motor back into place and tighten the 4 motor

mount bolts. Making sure the belt has no slack.

5- Make sure the belt is aligned properly.

6- Attach and reassemble the belt guard.

For belt adjustment -To adjust motor alignment, loosen

motor mount bolts. Push motor forward to loosen tension

on timing belt or back to tighten. Turn motor slightly to

the left or right to get belt running in the center of pul-

leys. Then tighten the motor mount bolts securely. Fine

adjustment can be effected by turning bolts in front and

back slightly.

Items needed: Straight screw driver, 1/2 wrench

Timing belt 941-001

Handle

Belt Guard

2

Maintenance and Specs for your Pile Brush

REVERSE BRUSH Every 100 hours

Unplug Pile Brush from outlet before reversing brush.

1- Remove the 2 bolts on the belt guard and the smaller

screw on the inside of the belt guard shield.

2- Loosen the 4 bolts on the Drive motor and slide the

motor forward. This will help loosen tension on the belt for

easier removal of the brush.

1-Turn the Pile Brush over so that the brush is exposed.

2- Remove the 4 bolts holding the brush drive assembly

and the 2 bolts holding the idler assembly, disconnect

the drive belt from the pulley, lift and pull the brush out.

3- Pull idler assembly and drive assembly off both ends

of the brush (You may have to pry with a screwdriver if

necessary.) The brush may now be turned or replaced

if needed.

4- Attach the idler assembly and drive assembly to the

opposite side of the brush, and tap into place with a

rubber mallet.

5- Place the reversed brush back into pilebrush base

and attach the drive belt.

6- Replace the 4 drive assembly bolts into the base, and

the 2 idler assembly bolts. The shorter bolt will go into

the recessed hole on the drive assembly.

Items needed: Rubber mallet, straight screw driver,

3/16” Allen wrench

TROUBLE SHOOTING

The Pile Brush is not picking up the larger particules. Check the sand trap to make sure it is clean with no obstruction and

properly conected

The Pile Brush is not picking up the dry particules. Check the sand trap to make sure it is clean and properly sealed, check

or replace refill bag if necessary. Make sure bellow is not clogged.

The machine drive motor is making a rough sound. Make sure you are not lifting the wheels up from the carpet surface.

This will add extra drag to the motor.

3

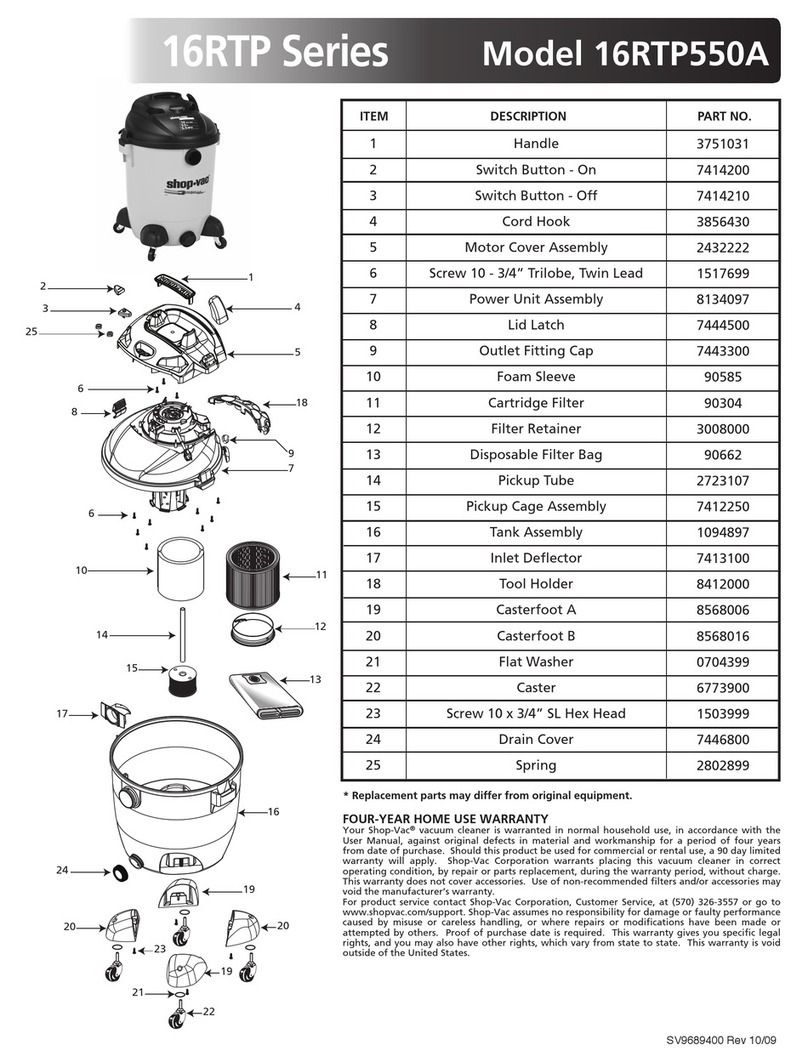

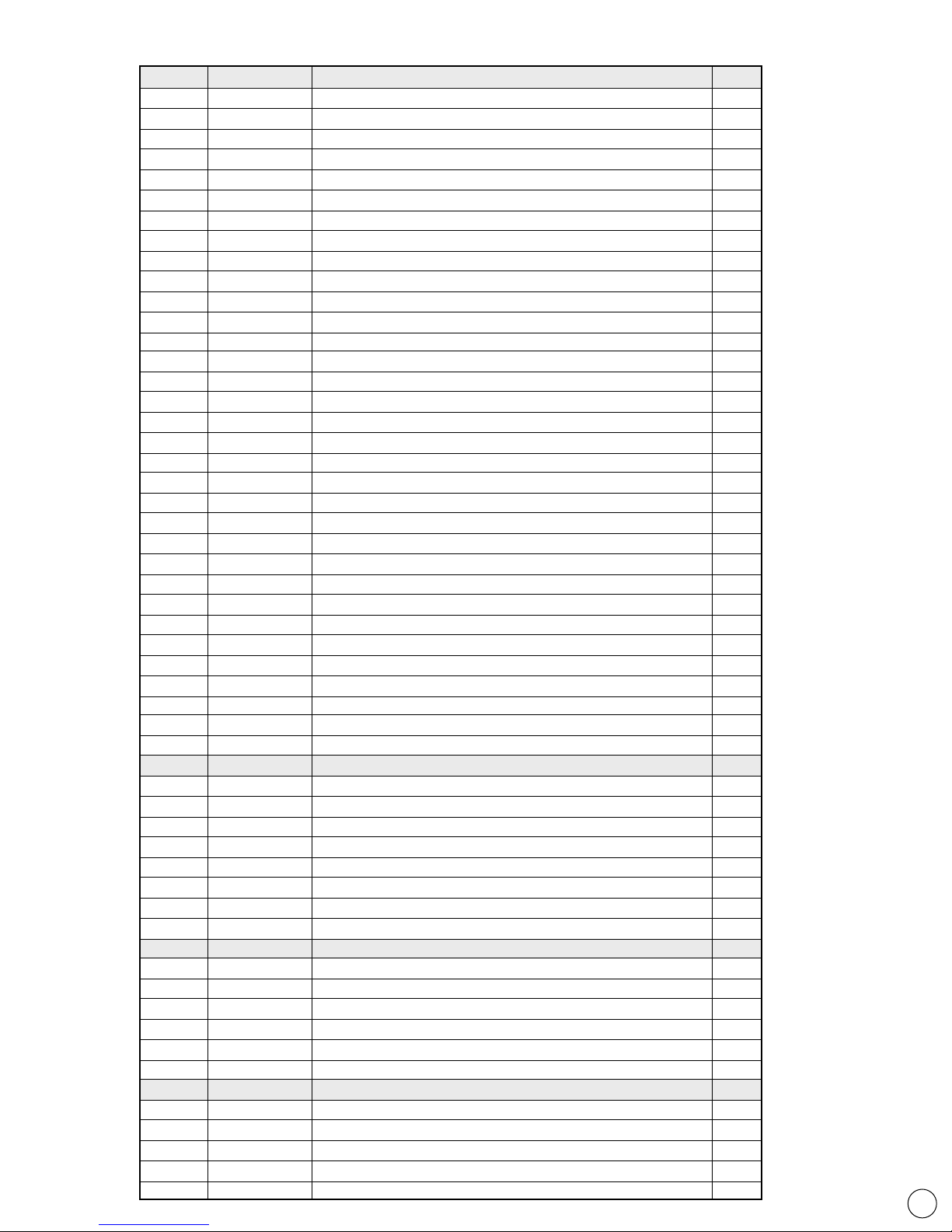

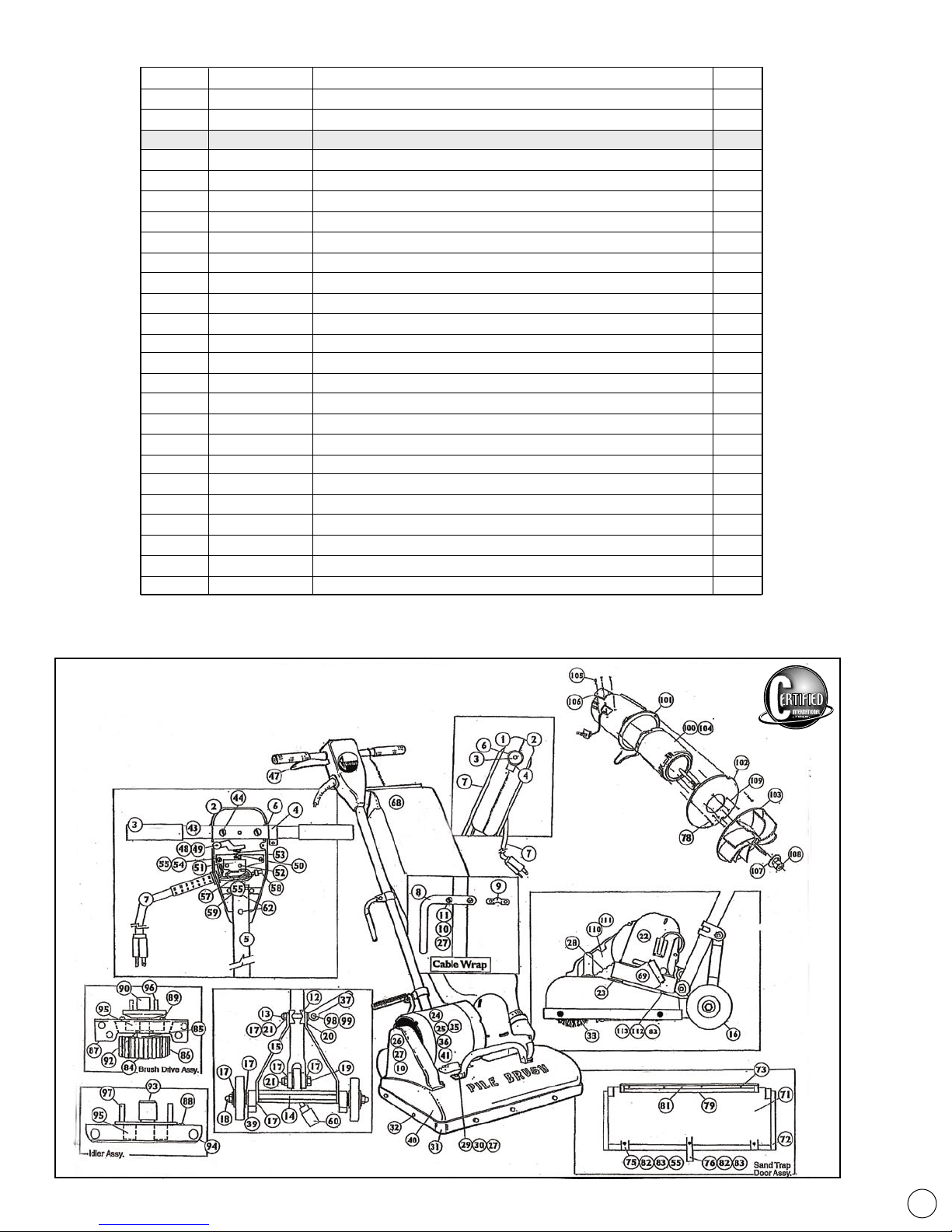

Pile Brush Handle Assembly - Includes

1 900-078 Switch Box Cover Casting 1

2 900-077 Switch Box Back Casting (has 3 thru holes) 1

**905-002 Bottom Switch Box Screw 2

**905-019 Top Switch Box Screw 1

3. 929-006 Plastic Handle Grip 2

4. 946-005 Dust Bag Support Ring 1

5. 957-008 2” Floor Rod & Yoke 1

6. 938-001 Plastic Handle Bushing 2

7. 921-041 Power Cable w/Plug 1

8. 915-051 Cable Wrap 1

9. 915-052 Cable Wrap Clamp 1

10 903-007 1/4-20 x 3/4 Rd. Hd. Screw 2

11 908-004 1/4-20 Hex Nut 2

43 930-008 Handle Bar 1

44 904-034 Handle Bar Screws 1/4-20 x 1-1/2 2

47 900-092 Switch Lever Casting 1

48 901-016 3/16 x 1-1/2 Spiral Pin 2

49 907-023 3/16 id Spiral Pin Washer 1

50 946-010 Motor Drive Switch Auxiliary Spring 1

51 920-008 Motor Drive Switch 1

52 903-015 Motor Drive Switch Screws 2

53 915-036 Motor Drive Mounting Bracket 1

54 903-020 10-32 x 3/8 Rd. Hd. Screw - S 3

55 906-004 #10 Lock Washer 2

57 922-062 #10 Butt Wire Connector 1

58 922-060 Acorn Nut Wire Connector 1

59 913-002 3/8 x 1/2 Strain Relief Tubing 1

60 921-009 Floor Rod Electric Cable w/Plug 1

62 910-002 Allen Head Cap Screw 2

19 910-005 Floor Rod Base Bolt 1

17 907-002 3/8 Wrought Steel Washer - Small 2

21 908-002 3/8-16 Essna Lock Nut 1

27 906-001 1/4” Lock Washer 2

101-014 2” FLOOR ROD CLAMP ASSEMBLY

12 900-147 2” High Floor Rod Clamp Casting (for 1-1/4” dia.) 1

13 902-001 Cam Thrust Bolt 1

20 907-009 3/8 Wrought Steel Washer 1

21 908-002 3/8-16 Essna Lock Nut 1

37 915-003 Clamp Cam Lever 1

98 902-002 5/16-18 x 1 Clamp Cam Lever Bolt 1

99 908-005 5/16-18 Clamp Cam Lever Lock Nut 1

17 907-002 3/8 Wrought Steel Washer - Small 1

101-016 AXLE ASSEMBLY

14 943-001 Axle 1

16 927-0104 Non-Marking Wheels (3/8 i.d.) 2

17 907-002 3/8 Flat Washer 6

18 942-004 Axle Hub Cap 2

**939-024 Large Axle X Ring 2

**939-023 Small Axle X Ring 2

68 924-024 ZIPPER BAG - TOP FILL (HIGH EFFICIENCY)

**924-058 High Efficiency Paper Bag Inserts 3/pkg (fits #924-024 bag only) 1

**924-056 Paper Bag Inserts 3/pkg. (fits bottom fill bag only) 1

**946-011 Paper Bag Support Ring 1

**924-002 Shake Down Dust Bag discontinued

**935-001 Clamp, Chain & Hook Assem. (for original shake down bag)

Drawing Part Number

Number Number Description Required

4

101-004 BASE WITH BUMPER ASSEMBLY

40 900-009 Polished Base Casting w/939-004 helicoils 1

31 928-009 Plastic Bumper 1

32 913-001 Nylon Bumper Rivets 9

101-007 BRUSH DRIVE SHAFT BEARING & HOLDER ASSEMBLY

84 939-002 Drive Shaft Pulley Snap Ring 1

85 939-003 Brush Drive Shaft Pulley Key 1

86 936-003 Brush Drive Pulley 1

87 900-007 Drive Shaft Bearing Holder Casting 1

89 903-001 8-32 x 1/4 Rd. Hd. Screw 2

90 936-002 Brush Drive Shaft 1

96 901-025 1/4 x 3/4 Spiral Pin 2

95 937-001 Drive Bearing 1

92 939-001 Drive Bearing Snap Ring 1

**903-018 1/4-20 x 1-1/2” Rd. Hd. M/S (Holds 900-007) 1

**903-019 1/4-20 x 1-5/8” Rd. Hd. M/S in place) 3

101-009 IDLER SHAFT BEARING & HOLDER ASSEMBLY

93 936-004 Brush Idler Shaft 1

94 900-008 Idler Bearing Holder Casting 1

95 937-001 Idler Bearing 1

97 901-025 1/4 x 3/4 Spiral Pin 2

88 903-004 6-32 x 1-1/4 Rd. Hd. Screw 1

**903-019 1/4-20 x 1-5/8” Rd. Hd. M/S (Holds 900-008 in place) 2

101-013 SAND TRAP DOOR ASSEMBLY

**901-003 7/8 Spiral Pin for Right Side Hinge & Sand Trap Spring 3

71 915-005 Sand Trap Door Stamping 1

72 914-012 Sand Trap Door Foam Tape Gasket, 26” 1

73 913-008 1/8 x 7/16 Semi-Tubular Rivet 4

**901-004 1-1/8 Spiral Pin for Left Side Hinge 1

75 942-002 Spring Clamp 2

76 942-003 Finger Lift 1

79 928-012 Plastic Cigarette Catch 1

81 915-006 S.S. Reinforcing Strip 2

82 903-006 Spring Clamp Screw 2

903-009 Finger Lift Screw 1

83 908-003 Spring Clamp & Finger Lift Nut 3

112 906-004 #10 Lock Washer “S” 3

22 101-102 VACUUM MOTOR ASSEMBLY (115V) 1

100 916-102 Vacuum Motor w/Pig Tail Only (115V) 1

101 1-871001-000 Motor Housing 1

102 932-052 Vac Motor Mount Plate 1

103 1-608005-000 Fan 1

78 911-009 Self Tapping Screw 4

105 903-001 #8-32 x 1/4 Screw 911-009A 3

106 915-224 Cover, Strain Relief 1

107 907-056 Washer Shims a.r.

108 908-026 Nut - Left Hand 5/16-24 1

109 903-080 #10-32 x 1/4 Pan Hd. Screw 4

22 101-112 VACUUM MOTOR ASSEMBLY (220V) 1

104 916-112 Vacuum Motor w/Pig Tail Only (220V) 1

101 1-871001-000 Motor Housing 1

102 932-052 Vac Motor Mount Plate 1

103 1-608005-000 Fan 1

78 911-009 Self Tapping Screw 4

105 903-001 #8-32 x 1/4 Screw 4

106 915-224 Cover, Strain Relief 1

Drawing Part Number

Number Number Description Required

5

®

107 907-056 Washer Shims a.r.

108 908-026 Nut - Left Hand 5/16-24 1

109 903-080 #10-32 x 1/4 Pan Hd. Screw 4

MISCELLANEOUS PARTS

15. 915-004 Angle Support 2

33 945-082 Vegetable Fibre Brush 1

33 945-005 Nylon Tufted Brush 1

23 914-056 Vacuum Motor Gasket 1

24 916-049 Brush Drive Motor (115V, 60Hz) 1

24 916-095 Brush Drive Motor (220V, 50Hz) 1

25 910-046 5/16-18 x 3/4 Motor Mount Bolt 4

26 900-014 Belt Guard Casting 1

27 906-001 1/4 Lock Washer a.r.

10 903-007 1/4-20 x 3/4 Rd. Hd. Screw a.r.

28 941-001 Timing Belt 1

29 923-005 Chromed Handle 1

30 903-027 1/4-20 x 1/2 Rd. Hd. Screw a.r.

35 936-001 Drive Motor Pulley w/912-002 Set Screws 1

36 907-035 5/16 Motor Mount Flat Washer 4

41 906-015 5/16 Lock Washer 4

110 915-215 Shield - Belt Guard 1

111 903-001 #8-32 x 1/4” Hd. Screw 2

69 2-015410-000 Fan Case 1

83 908-003 #10-24 Nut (Fan case to base) 3

55 906-004 #10 Lock Washer (Fan case to base) 3

113 904-049 #10-24 x 5/8 Lg. Flat Hd. Screw (Fan case to base) 3

**INDICATES NOT ILLUSTRATED a.r. - as required

Drawing Part Number

Number Number Description Required

CERTIFIED reserves the right to make changes and improvements in design and construction.

Please furnish the Serial Number of the machine for which parts are required so we may furnish the proper or equivalent

replacements if available.

6

Every Pile Brush is personally hand crafted in the United States.

10966 Industrial Parkway, Bolivar, Ohio 44612

800-443-4321 or fax 330-874-3366 www.nilodor.com

Nilodor/Certified Commercial Limited Warranty

What this limited warranty covers:

Nilodor, Inc. warrants that your Certified Model S Pile Lifter, for a period of one year from your date of purchase, will be

free from defects in material and workmanship for normal use in accordance with the Owner’s Manual. This limited war-

ranty is granted only to the original purchaser. This limited warranty is subject to the following provisions:

What this limited warranty does not cover:

• Expenses related to pick up, delivery or house calls for warranty service.

• Parts of the cleaner that require replacement under normal use, such as disposable refill bags, drive belts brushs.

• Damages or malfunctions caused by accident, acts of God, negligence, abuse or use not in accordance with the

Owner’s Manual.

• Defects or damages caused by improper service or maintenance, the use of parts other than genuine Certified Model

S Pile Lifter parts or modifications made to the Pile Lifter without our prior written approval.

• Damage that occurs during shipment.

• Certified Model S Pile Lifter purchased outside the United States.

• Certified Model S Pile Lifter subjected to rental use.

What Nilodor will do:

Nilodor/Certified will, at its option, repair or replace a defective Pile Lifter or Pile Lifter part that is covered by this limited

warranty. As a matter of warranty policy, Nilodor will not refund the customer’s purchase price.

Warranty Registration:

To register for warranty, please fill out the registration card accompanying your unit. Mail to Nilodor within 30 days of

purchasing.

Obtaining warranty service:

To obtain warranty service, you must return the defective Certified Model S Pile Lifter or Pile Lifter part, with proof of

purchase to Nilodor, Inc. For service information, call 800-443-4321 or email info@nilodor.com.

If you prefer, you can write to: Nilodor, Inc.

10966 Industrial Parkway

Bolivar, OH 44612

If it is necessary to ship the Pile Brush outside your community to obtain warranty repair, you must pay the shipping charg-

es. When returning parts for repair, please include the serial number from the base of the unit, under the vacuum bag.

Further Limitations and Exclusions:

THE WARRANTY PROVIDED ABOVE IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS OR IMPLIED WARRANTIES

INCLUDING, BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICU-

LAR PURPOSE. SOME LAWS DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES. IF THESE LAWS APPLY,

THEN ALL EXPRESS AND IMPLIED WARRANTIES ARE LIMITED TO THE WARRANTY PERIOD IDENTIFIED ABOVE. UN-

LESS STATED HEREIN, ANY STATEMENTS OR REPRESENTATIONS MADE BY ANY OTHER PERSON OR FIRM ARE VOID.

EXCEPT AS PROVIDED IN THIS WRITTEN WARRANTY, NEITHER NILODOR, INC. OR ITS AFFILIATES SHALL BE LIABLE

FOR ANY LOSS, INCONVENIENCE OR DAMAGE INCLUDING DIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, RESULTING FROM THE USE OR INABILITY TO USE THE VACUUM PRODUCT, WHETHER RESULTING FROM

BREACH OF WARRANTY OR ANY OTHER LEGAL THEORY. IN NO EVENT WILL NILODOR’S LIABILITY EXCEED THE

PURCHASE PRICE OF THE CLEANER, LESS DEPRECIATION.

Some jurisdictions do not allow limitations on how long an implied warranty lasts and some jurisdictions do not allow

exclusion or limitation of incidental or consequential damages, so the above limitations and exclusions may not apply

to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from jurisdiction to

jurisdiction.

Table of contents