Ningbo Dino-power Machinery DP-6880 User manual

NINGBO DINO-POWER MACHINERY CO., LTD.

Operating Instruction

Product Model: DP-6880 Airless sprayer for putty plaster

Please read and keep this manual. Read carefully before attempting to assemble, install, operate or

maintain the product described. Protect yourself and others by observing all safety information.

Failure to comply with instructions could result in personal injury and property damage. Retain

instruction for future reference.

NINGBO DINO-POWER MACHINERY CO., LTD.

Contents

Warning and Special Cautions....................................................................1

Introduction of contents and data ...............................................................2

Instruction for DP6880 Invert.....................................................................3

Operation.....................................................................................................4

Preparation before spraying.....................................................................4

Preparation before spraying.....................................................................6

Spraying...................................................................................................7

Procedure of releasing pressure...............................................................9

Daily Maintenance Measures ................................................................10

Spraying Technique..................................................................................10

Cleaning....................................................................................................14

Repairs ......................................................................................................15

Troubleshooting........................................................................................18

Exploded View: ........................................................................................21

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 1

Warning and Special Cautions

1. Special cautions when operating

Never put your fingers, hands or any other parts of the body into

the spray jet.

Never point the spray gun at yourself or any other else.

Never use the spray gun without the spray tip cove.

Close the safety guard at any time, except spraying and cleaning.

Please release the pressure before repair and maintenance.

Don’t clean it with bleached water or solvent containing strong

acid and alkali.

2. Special cautions when spraying

Please operate the machine in a bright place.

Never operate the machine in a place with sparks or combustible

substances.

Never operate the machine beyond 10 seconds without paints.

Paints with glue, pellets, strong corrosive or without solvent are

prohibited.

This machine can be produced with 220V or 380V electricity.

Never pull the electric wire.

Never smoke when operating the machine.

Warning!

Don’t operate the equipment without reading the following special cautions.

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 2

Introduction of contents and data

Model number

DP-6880 piston pump sprayer

Motor power

4HP 3000W

Voltage

380V 3 phase or 220V 1 phase

Max. flow rate

8L/min

Max. pressure

25Mpa / 250bar / 3300psi

Max. tip size

0.041”

Length of standard hose

10mm*10m /1 roll, 8mm*10m/ 1

roll , 8mm*2m / 1 roll

8mm*10m / 1 roll,

8mm*2m / 1roll

Max. length of hose

90m

Wooden case Dimension

56*67*79cm

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 3

Instruction for DP6880 Paint Sprayer

Invert

Step 1: Input the password.

Continuously press MODE key after power on. Press the ENTER

key when U0.00 displays on the screen and press the ENTER key again

when 00 displays. Press the UP key to 00.08 after “00.00” displays and

press ENTER key for confirmation. Input the original password with UP

and DOWN key after “00” appears.

Step 2: Set the operation instruction source.

Input the password and press the UP key to adjust 00 to 02 then

press ENTER key for confirmation. Press the UP key to 02.01 after 02.00

displays and press ENTER key for confirmation. When “0” appears,

adjust 0 to 2 and confirm the adjustment, then normal operation is

available after pressed the power switch.

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 4

Operation

Preparation before spraying

1. Tools:

Tools

Quantity

6 inch, 8inch, 10inch wrench

One each

“ + “ screwdriver

One

Brush

One

Rag

One

Electric meter

One

Electric wire within 30 meters,

25mm2

One roll

Electric pressure stabilizing device

One

2. Preparation procedure

Siphon hose and return tube should be connected correctly and screw

tightly.

Connect 15 meters high pressure hose to the outlet fitting and screw

tightly.

Connect airless spray gun to the other end of hose with two wrenches

and screw tightly.

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 5

Make sure the prime/spray valve is set horizontal state (ON).

Inject 5-6 drops PLS oil at oil cup.

Check the voltage with a electric ammeter and make sure it’s between

220V or 380V which is permitted by machine.

Place the machine in a dry area at least 10 meters away from the

operation area.

3. When it is used for the first time

Because there is protective lubricating oil in new machine, you should

use some soapsuds to wash it when using it for the first time. Please

follow the instructions as below:

Put siphon hose in a clean water bucket added with little soapsuds.

Put return tube in a waste bucket.

Set the pressure control knob middle pressure by which the machine

could work ( don’t whirl too tight).

Set the PRIME/SPRAY VALVE horizontal.

Turn on the electricity.

Operate the machine to circulate the soapsuds until clean water flows

out from the return tube.

Turn off the electricity

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 6

Preparation before spraying

Before spraying, make sure the paints is in harmonious proportion and is

simply filtered, otherwise unpurified paints will cause wear and tear to

the machine and reduce the machine’s lifetime. Besides, circulate the

special thinner and then spray. Please follow the instructions as below:

Put siphon hose in a bucket full of special thinner or clean water.

Put return tube in a waste bucket.

Set PRESSURE CONTROL KNOB middle pressure by which the

machine could work (Don’t whirl too tight).

Set PRIME/SPRAY VALVE horizontal.

Turn on electricity.

Let the machine work for 15-30 seconds until clean thinner flow

out of return tube.

Turn off electricity.

Set PRIME/SPRAY VALVE vertical.

Turn on electricity.

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 7

Open safety guard.

Point the spray gun at the inside of waste bucket, pull the trigger

until clean solvent flows out, so that old solvent in paint tube and

spray gun flows out.

Close safety guard (see upper picture).

Slowly set PRESSURE CONTROL KNOB high pressure (whirl

tight).

Carefully check every component whether it leaks, in that case,

release the pressure according to the “ pressure releasing

procedure” then whirl tight where it leaks.

Spraying

Put siphon hose into painting bucket.

Put return tube into waste bucket.

Set PRESSURE CONTROL KNOB middle pressure by which the

machine could work (don’t whirl too tight).

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 8

Set PRIME/SPRAY VALVE horizontal.

Turn on electricity.

Make the machine work until the paints flow out of return tube.

Turn off electricity.

Remove return tube into painting bucket.

Set PRIME/SPRAY VALVE vertical.

Turn on electricity.

Open safety guard.

Point spray gun at the inside of waste bucket, pull the trigger until

paints spray out so that remnants solvent flows out.

Close safety guard.

Turn off electricity.

Load spray tip cover and spray tip, whirl tight.

Turn on electricity.

Slowly set Pressure Control Knob middle pressure or high

pressure, try it somewhere else, and slowly increase paints

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 9

pressure until paints are totally atomized, and then it can be

operated.

Procedure of releasing pressure

Close safety guard.

Turn on electricity.

Set PRESSURE CONTROL KNOB low pressure.

Open safety guard, ,reverse the spray tip nozzle by 180。

Point spray jet at the inside of paint bucket, pull the trigger release

the pressure inside the machine and the tube.

Close safety guard.

Set PRIME / SPRAY VALVE horizontal, let out all the remnants

pressure.

Warning!

Release pressure according to pressure releasing procedure, in the

course of cleaning, maintenance, repair or interruption.

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 10

Daily Maintenance Measures

Before every operation, check whether electricity complies with

requirements.

Before every operation, inject 5-6 drops PLS oil at oil cup.

After spraying, clean thoroughly machine and component.

After cleaning, roll the soft pipe avoiding tying a knot.

In case of long-term setting aside, protective solution should be

used to circulate inside the machine, in order to prevent

component from being corroded. Finally le the machine siphon a

little lubricating oil, and inject PSL oil or #45 sewing machine oil.

Spraying Technique

The following techniques, if followed, will assure professional painting

results. Hold the gun perpendicular to the surface and always at equal

distance from the surface. Depending on the type of material, surface or

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 11

desired spray pattern, the gun should be held at a distance of 30 to 35cm.

Move the gun either across or up and down the surface at a steady rate.

Move the gun at a consistent speed conserves material and provides even

coverage. The correct spraying speed allows full, wet coat of paint to be

applied without runs or sags. Holding the gun closer to the surface

deposits more paint on the surface and produces a narrower spray pattern.

Holding the gun farther from the surface produces a thinner coat and

wider spray pattern. If runs, sags or excessive paint occur, change to a

spray tip with a smaller orifice. If there is an insufficient amount of paint

on the surface or you desire to spray faster, a large orifice tip should be

selected.

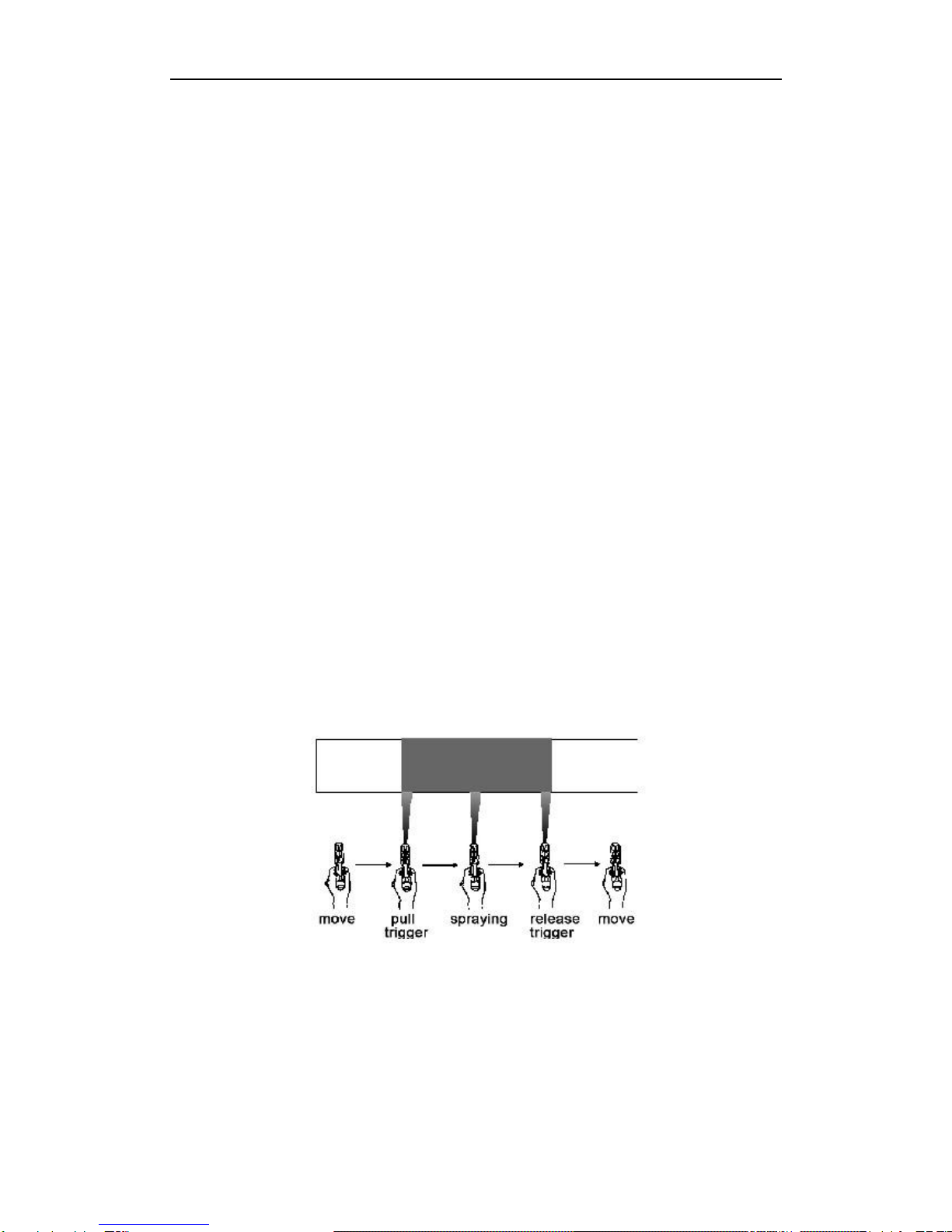

Maintain uniform spray stroke action. Spray alternately from left to right

and right to left. Begin movement of the gun before the trigger is pulled.

Avoid arcing or holding the gun at an angle. This will result in an uneven

finish.

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 12

Proper lapping (overlap of spray pattern) is essential to an even finish.

Lap each stroke. If you are spraying horizontally, aim at the bottom edge

of the preceding stroke, so as to lap the previous pattern by 50%.

For corner and edge, split the center of the spray pattern on the corner or

edge and spray vertically so that both adjoining sections receive

approximately even amounts of paint.

When spraying with a shield, hold it firmly against the surface. Angle the

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 13

spray gun slightly away from the shield and toward the surface. This will

prevent paint from being forced underneath.

Shrubs next to houses should be tied back and covered with a canvas

cloth. The cloth should be removed as soon as possible. Our gun

extensions are extremely helpful in these situations. Nearby objects such

as automobiles, outdoor furniture, etc. should be moved or covered

whenever in the vicinity of a spray job. Be careful of any other

surrounding objects that could be damaged by overspray.

Practice

Be sure that the paint house is free of links and clear of objects

with sharp cutting edges.

Turn the pressure control knob counterclockwise to its to its

lowest setting.

Turn the PRIME/SPRAY valve up to its SPRAY position

Turn the pressure control knob clockwise to its highest setting.

The paint hose should stiffen as paint begins to flow through it.

Unlock the gun trigger-lock

Trigger the spray gun to bleed air out of the hose.

When paint reaches the spray tip, spray a test area to check the

spray pattern

Use the lowest pressure setting necessary to get a good spray

pattern. If the pressure is too high, the spray pattern will be too

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 14

light. If the pressure too low, tailing will appear or the paint will

spatter out in gods rather than in a fine spray

Cleaning

Exhaust the pressure and the paints inside the machine according to

the “Pressure Releasing Procedure”.

Unload the spray tip and safety guard.

Put Siphon Hose into special thinner or clean water bucket.

Put Return Tube into waste bucket.

Set PRIME/SPRAY Valve horizontal.

Set Pressure Control Knob high pressure.

Turn ON electricity.

Circulate the solvent inside of the machine and let out the remnants

paints until clean solvent or clean water flows out of Return Tube.

Turn OFF electricity

Set PRIME/SPRAYValve vertical and open safety guard.

Turn on electricity.

Pull the trigger and make solvent or clean water wash paints pipe and

remnants paints inside the spray gun until clean solvent or clean water

sprays out.

Close safety guard.

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 15

Load spray tip cover and open safety guard.

Reverse the spray nozzle by 180º,keep pulling the trigger for 1-2

seconds(in order to clean spray tip),then unload the spray tip and its

cover and then wash them with a brush (Take care that the spray tip

contains a white seat and spray tip holder, please keep them in good

preservation.

Wipe the overall of the machine, Paints pipe and the spray gun with a

nag containing solvent or clean water until the overall is totally clean

without any paints.

Inject 5-6 drops PLS oil at oil cup

Put the machine in a dry,sanitary and ventilatory palce.

Repairs

Before repairing, Please make sure where the fault is, otherwise,

unnecessary disassembly will severely affect the machine´s function and

greatly reduce the machine´s life. Besides, in the course of repair, Please

wear standard uniform and protective tools. Repair it in a bright and

ventilatory place, and prepare a bucket of clean solvent. Clean the

components at all times.

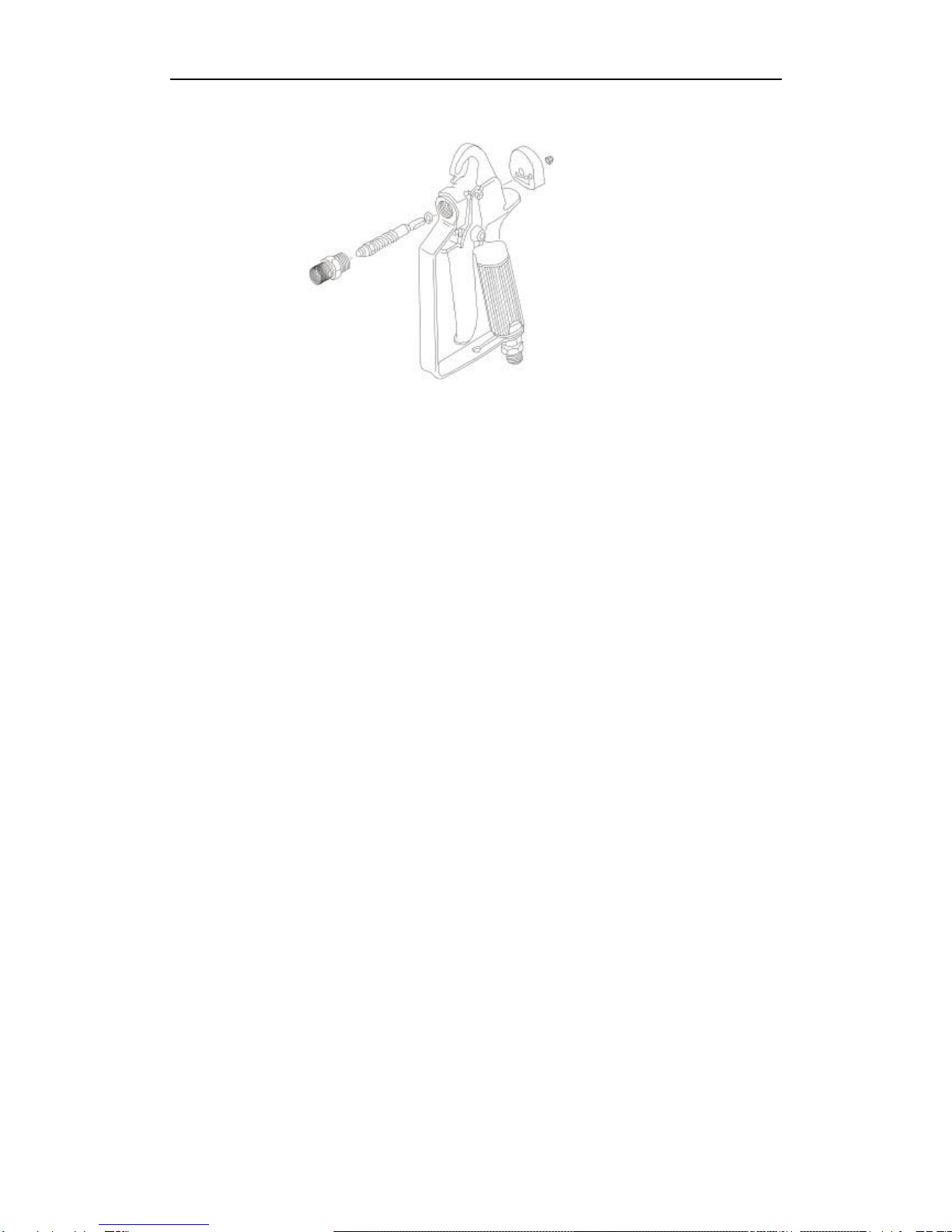

Introduction of components of airless spray gun:

Procedure of repairing siphon components

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 16

Before the maintenance or repair, siphon hose and return tube should be

unloaded, and then they can be repaired or maintained. Follow the

instructions as below:

Whirl loose and unload six screws on the upper front cover with

“╋”Screwdriver.

Whirl loose and unload Return Tube with wrench.

Remove the Siphon Hose Clip, and take Siphon Hose out of the Foot

Valve Housing.

To facilitate the operation, incline the machine a little backward when

taking siphon hose out.

▲Procedure of repairing Ball Valve: Among all the components, Ball

Valve is mostly likely to get blocked up for incomplete cleaning, which

could cause abnormal operation. Therefore, it´s very important to clean

and maintain the Ball Valve. The following is the procedure of

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 17

disassembling the Ball Valve.

Remove the whole pump with the wrench as well as Foot Ball Valve.

Carefully check and clean every part. In case of damage, it should be

replaced.

Whirl loose the Upper Ball Valve and remove it from the Piston Rod

with the wrench, check whether it is blocked up or it has any wear

and tear. Clean or replace it when necessary.

Check whether Foot Ball Valve is blocked up or has any wear and tear.

Clean or replace it when necessary.

After the cleansing of the Ball Valve, assemble it into Siphon

Components to the same sequence.

Note: When Foot Ball Valve gets blocked up, it usually couldn´t siphon.

If Foot Ball Valve works normally, please disassemble Upper Ball Valve.

Use clean soft cotton nag to clean Ball Valve. Hard Substances are

prohibited.

NINGBO DINO-POWER MACHINERY CO., LTD.

www.dpairless.com 18

Troubleshooting

General Problems and Troubleshooting

Problem

Cause

Solution

The unit will

not run.

1.The unit is not plugged in.

1. Plug the unit in.

2. Tripped breaker.

2. Reset the breaker.

3.The pressure is set too low (pressure

control knob set at minimum setting

dose not supply power to unit)

3. Turn the pressure control

knob clockwise to supply

power to the unit and increase

the pressure setting.

4.Faulty or loose wiring.

4. Inspect or take to a

authorized service center.

5.Excessive motor temperature.

5. Allow motor to cool.

The unit will

not prime.

1.The PRIME/SPRAY valve is in the

SPRAY position.

1.Rotate the PRIME/SPRAY

valve colockwise to the PIME

position.

2.Air leak in the siphon tube/suction

set.

2.Check the siphon

tube/suction set connection

and tighten or re-tape the

connection with Teflon tape.

3.The pump filter and/or inlet screen is

clogged.

3.Remove the pump filter

element and clean. Remove

the inlet screen and clean.

4.The siphon tube/suction set is

clogged.

4.Remove the siphon

tube/suction set and clean.

The unit will

not build or

maintain

pressure.

1.The spray tip is worn.

1.Replace the spray tip

following the instructions that

came with the spray gun.

2.The spray tip is too large.

2.Replace the spray tip with a

tip that has a smaller orifice

following the instructions that

came with the spray gun.

3.The pressure control knob is not set

properly.

3.Turn the pressure control

knob clockwise to increase the

pressure settings.

4.The pump filter, gun filter, or inlet

screen is clogged.

4.Remove the pump filter

element and clean. Remove

the gun filter and clean.

Remove the inlet screen and

clean.

5.Material flows from the return hose

5.Clean or replace the

Table of contents

Other Ningbo Dino-power Machinery Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Central Pneumatic

Central Pneumatic 93506 Assembly and operating instructions

Tack life

Tack life SGP17AC user manual

Black Ridge

Black Ridge S-770S instruction manual

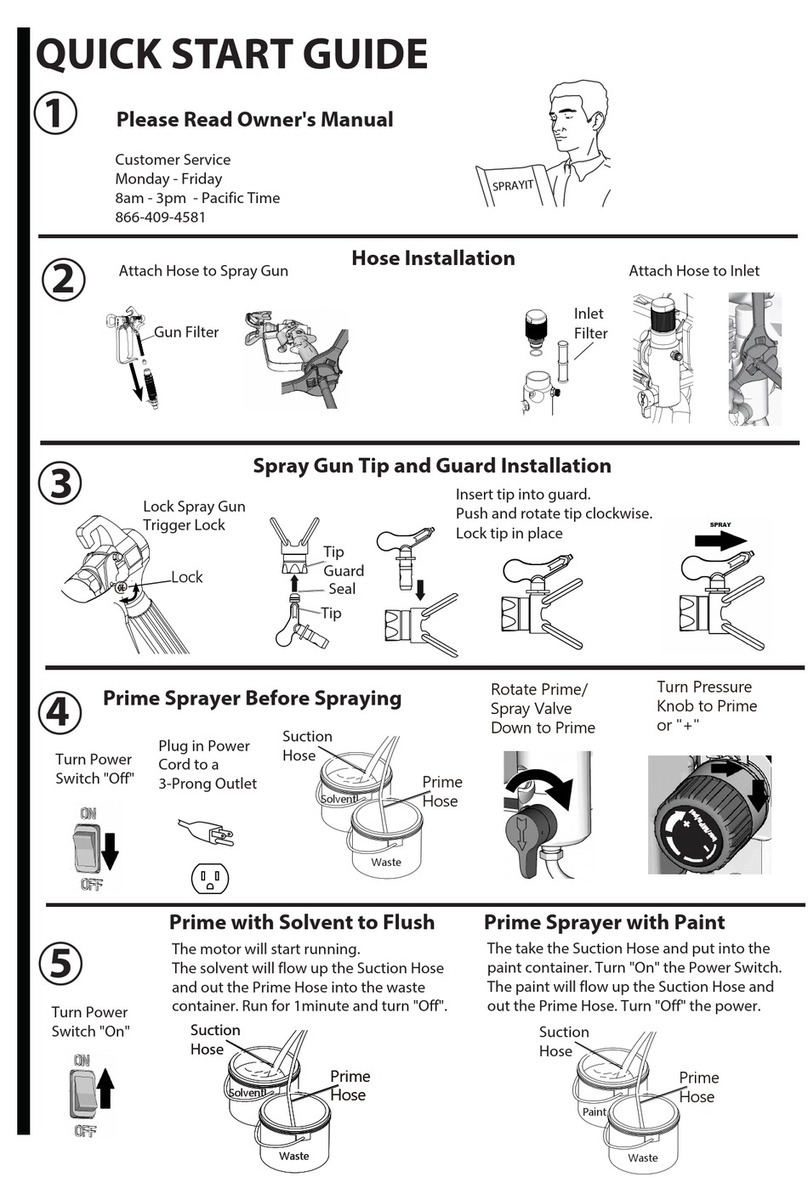

Sprayit

Sprayit PRO 21 quick start guide

BLACK DECKER

BLACK DECKER SmartSelect BDPH1200 instruction manual

EUROPRO

EUROPRO Compact-Pro Joint 20 user manual

Central Pneumatic

Central Pneumatic 97855 Set up and operating instructions

Garten Meister

Garten Meister 88 21 61 Original instructions

In-Ex

In-Ex SPRAYER 50 manual

Greenleaf

Greenleaf Workhorse PSE ATV 1502 Assembly / operation instructions / parts

Gloria

Gloria FoamMaster FM10 flex user manual

SIKA

SIKA Aliva 257 Top user manual