In-Ex Sprayer 200 User manual

OWNER’S MANUAL

FOR THE

Sprayer 200/400 range

In-Ex™

P O Box 1010, 145 Harts Road

Palmerston North

Ph: 06 354 6060

Fax: 06 355 3199

E-Mail: sales@c-dax.co.nz

www.c-dax.co.nz

2

SAFETY PRECAUTIONS

Warnings are mandatory instructions to prevent serious injury or permanent damage.

Cautions are advisory instructions to ensure reliable operation of the equipment.

Notes are for convenient operation.

WARNING

Making pesticides is a most dangerous time as it involves handling the concentrated material. For toxic compounds,

use protective clothing such as overalls, hat, gloves, boots and respirator.

When using concentrated sprays, full protection is necessary.

When using diluted sprays, wear at least a hat, long-sleeved cotton overalls and boots. If you use pesticides

regularly it is a good idea to always wear a respirator to avoid cumulative effect … other protection may be required

–check the label. It may have specific directions for that particular chemical.

Protective clothing should always be properly cared for. Rinse heavily contaminated clothes in the open before

washing in the laundry.

Wash and dry these clothes every day –but keep them separate from other washing.

Respirators need special care … clean respirator after spraying. Use soapy water then rinse and allow to dry

completely before storing in a clean plastic bag. Replace canisters in respirator after every 8 hours use.

In-Ex Sprayer 200/400 range

OWNER’S MANUAL

(Pt.No.2400-5200 Issue 16, April 2018)

TABLE OF CONTENTS

2 Safety Precautions

Table of Contents

3 Description

Specifications

Order Information

4 Warranty

Liability

4 Operating Hints

Suction Filter

Chemical Application

Chemical Advice

6Maintenance

Cleaning

Filters

Pressure Switch Adjustment

7 Troubleshooting

8 Parts Diagrams

CAUTION

The Sprayer 200/400T utilizes floatation tyres to dampen bumps. It is essential that these

tyres are not over-inflated otherwise the unit will be exposed to excessive shock. The

recommended tyre pressure is 5-7 psi.

3

DESCRIPTION

The In-Ex Sprayer 200 & 400 litre amenity/boom sprayers are a series of high strength spray tanks manufactured of

non-corrosive polyethylene that either come complete as a trailed unit or as a stand alone tank and frame assembly

for deck mounting.

SPECIFICATIONS

(Specifications subject to change without notice)

Capacity 200L or 400L

Power Consumption 12 VDC 12A (Max)

Pump 12 VDC Flojet

Tank Non-corrosive, medium density, UV stabilised polyethylene

Filtration Inline suction filter

spray gun/boom filter(s)

Frame Zinc plated mild steel

Tyre Pressure 7 Psi

ORDER INFORMATION

200L

Deck Mounted with Hand lance

In-Ex Sprayer 200 Pt.No. 1028

Deck Mounted with Hand lance and 4.5m spray boom

In-Ex Sprayer 200+4.5m Boom Pt.No. 1090

Trailed with Hand lance

In-Ex Sprayer 200 Trailed Pt.No. 1026

Trailed with Hand lance and 4.5m spray boom

In-Ex Sprayer 200Trailed+4.5mBoom Pt.No. 1089

400L

Deck Mounted with Hand lance

In-Ex Sprayer 400 Pt.No. 1096

Deck Mounted with Hand lance and 4.5m spray boom

In-Ex Sprayer 400+4.5m Boom Pt.No. 1098

Trailed with Hand lance

In-Ex Sprayer 400 Trailed Pt.No. 1095

Trailed with Hand lance and 4.5m spray boom

In-Ex Sprayer 400Trailed+4.5mBoom Pt.No. 1097

4

WARRANTY

1WARRANTY AND LIABILITY

Use of the equipment

1.1 You must satisfy yourself as to the suitability of the equipment for your intended use(s) of the

equipment.

Your relationship with the retailer

1.2 Where you consider you have a warranty claim (or any other claim) in relation to the equipment,

you must contact the retailer who sold you the equipment, not C-Dax directly. The retailer is

responsible for liaising with C-Dax in respect of your claim.

Warranty

1.3 C-Dax warrants to the original purchaser that the equipment is sold free from defects in materials

and workmanship for a period of 12 months from date of first retail sale (6 months from date of

first retail sale if the equipment is sold in the U.K.) subject to the terms set out below.

1.4 C-Dax will at its option repair or replace the defective equipment (or part of the equipment) or

notify the retailer of the equipment to refund the purchase price for such defective equipment to

you in the event of a breach of this warranty, subject to the terms set out below.

Liability

1.5 Except for the warranty set out in clause 1.2 above, all warranties and representations (including

those expressed or implied by law) in respect of the equipment or advice relating to the equipment

provided to you by C-Dax are excluded to the extent permitted by law.

1.6 Notwithstanding anything else in this manual, C-Dax’s maximum liability to you (in the event that

such liability exists) in respect of any breach of warranty, any matter set out in this manual, or for

defective equipment or advice relating to the equipment provided is limited at C-Dax’s option to:

(a) repairing or replacing the equipment (or part of the equipment); or

(b) notifying the retailer of the equipment to refund the price for the equipment paid by you.

1.7 Notwithstanding anything else in this manual, in no event will C-Dax be liable, whether in contract,

tort (including negligence) or otherwise:

(a) where you have altered or modified the equipment, misused or misapplied the equipment, or

the equipment has been subjected to any unusual, excessive or non-recommended use,

service or handling (including as set out in this manual);

(b) where the equipment is not transported, stored, handled or used in accordance with any

directions given by C-Dax (or the retailer) to you (including as set out in this manual);

(c) where the equipment:

(i) has been subject to neglect, accident or hireage, or the damage arises from fair wear

and tear, battery damage or chemical attack;

(ii) has been built to a customer’s specifications; or

(iii) has been dismantled, repaired or serviced other than by an authorised service agent of

C-Dax;

(d) for loss or damage caused by any factors beyond C-Dax’s control; or

5

(e) for any loss of profit or revenue, or for any special, indirect, incidental or consequential

damage, loss or injury of any kind suffered by you.

1.8 Where C-Dax elects to repair or replace the equipment it will use reasonable endeavours to do so

as soon as practicable but will not be liable for any delay in doing so.

1.9 You agree that the transactions entered into between you and the retailer (and C-Dax) are for the

purposes of trade and that, having regard to all relevant circumstances of the transactions, it is fair

and reasonable that the provisions of the Consumer Guarantees Act 1993 (NZ) do not apply to

those transactions to the fullest extent permitted by law.

.

6

OPERATING HINTS

Suction Filter

When mounted on a horizontal plane the U-filter is factory fitted (200 litre only) with what is called a “snorkel”

device. This ensures that incoming fluid must rise to nearly the top of the filter body (expelling all air) before exiting

the filter and continuing to the pump. Rapid priming is therefore expelled. On the 400 litre an inline filter is attached

to the pump via a ‘Quadport’ fitting.

WARNING

DO NOT MOUNT THESE SPRAYERS ON TO AN ATV CARRIER FRAME!

CHEMICAL APPLICATION

As no control can be exercised over the use of the equipment or over weather, plant or soil conditions, or over the

storage, handling, mixing, use or application of sprays or chemicals, In-Ex will not accept any liability for loss or

damage (consequential or otherwise) arising directly or indirectly from the use of this equipment.

Chemical Advice

In-Ex or their agents cannot make recommendations or give advice as to the use of chemicals and cannot accept

responsibility for any damage, injury or other consequence for disregarding this warning notice. Contact your

chemical supplier for advice.

MAINTENANCE

Cleaning

Clean the sprayer regularly! After each use flush the unit out three times with fresh water. Use a neutralising agent

for the second rinse.

CAUTION

To prevent damage to the sprayer and spray gun, drain the water from the sprayer and spray gun when there is a

risk of frost.

Filters

Clean all filter screens regularly.

WARNING

If the pump has been mounted without the pump cover, all warranty is void.

NOTE

If the pump is observed to be leaking from between the motor and black pump body or from the motor itself, cease

operation and have the pump serviced immediately. In-Ex and their distributors have a comprehensive parts

inventory and capable staff. Because of the complications of the pump it may be best to get your In-Ex agent to post

it back to the authorised service centre.

Pressure Switch Adjustment

CAUTION

Operating the pump with a higher than normal shut off pressure will shorten pump life.

The shut off pressure of the Flojet pump is adjustable by rotating a 2mm allen head on the top of the pressure

switch assembly. To increase shut off pressure rotate adjustment screw clockwise, to decrease shut off pressure

rotate adjustment screw anti clockwise.

Increasing the shut-off pressure will not increase the flow or the spraying pressure.

7

TROUBLESHOOTING

In-Ex and their distributors have a comprehensive parts inventory and capable service staff. Repairs should only be

undertaken by In-Ex, or an authorised In-Ex service centre.

Switch on but pump does not

operate

1. Blown fuse

Check wiring and replace

15A fuse

2. Pressure switch operated

Operate spray gun trigger

3. Pressure switch failed

Replace pressure switch

4. On/Off switch failed

Replace switch

Pump runs but does not stop.

1. Spray gun trigger open

Close trigger

2. Air lock in pump

Operate spray gun trigger

until all air is expelled from

the pump and hose.

3. Suction hose loose

Check and tighten all

suction hose connections

between pump inlet and

tank.

4. Dirt or spray residue in

pump valves

Replace valves.

5. Blocked suction filter mesh

Clean filter mesh.

Pump runs but pulses while

pumping

1. Spraying pressure higher

than the pump shut off

pressure

Reduce spraying pressure

by opening the adjustable

spray tip.

2. Pump shut off pressure too

low

Increase pump shut off

pressure. Refer

maintenance.

Fluid leaks from drain holes in

pump

1. Internal leak within pump

head

Remove pump for

servicing.

8

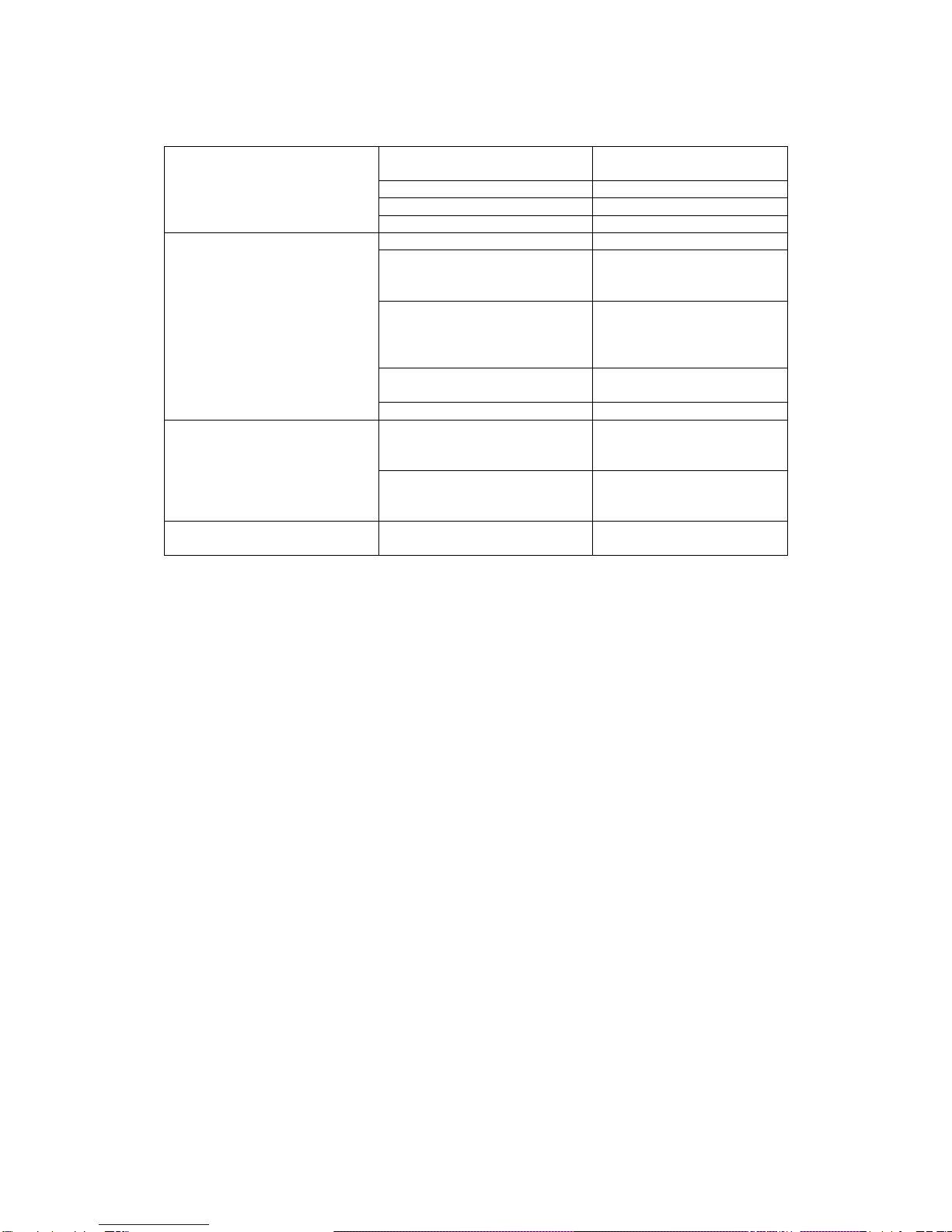

PARTS DIAGRAM (200 litre flat deck)

9

PARTS LIST (200 litre flat deck)

Item

No.

QTY.

Part No.

Description

1

1

1500-3000

Cable-Electrical-Loom-1 Switch Box-3.0M

2

1

1500-7300

Cable-Electrical-Single Core-1mm2-1000VDC-Red

3

1

1500-7310

Cable-Electrical-Single Core-1mm2-1000VDC-Black

4

1

2000-0017

Clamp-Hose-Herbi-G-Ratchet-16.9<>19.1mm-Black-Nylon

5

2

2000-2014

Clamp-Hose-Oetiker-Single Ear Stepless-14.5<>7.0mm-S/S

6

2

2000-2017

Clamp-Hose-Oetiker-Single Ear Stepless-16.6<>19.8mm-S/S

7

2

2000-2019

Clamp-Hose-Oetiker-Single Ear Stepless-19.4<>22.6mm-S/S

8

1

2250-8200

Cover-Switch-Water Proof Boot-Toggle Lever-Rubber-Black

9

2

3110-0512

Fastener-Machine-Screw-Pan-M5x12-Pozi-ZP

10

2

3110-0516

Fastener-Machine-Screw-Pan-M5x16-Pozi-ZP

11

4

3110-0520

Fastener-Machine-Screw-Pan-M5x20-Pozi-ZP

12

2

3170-0008

Fastener-Nut-Nyloc-M8-ZP

13

2

3170-0010

Fastener-Nut-Nyloc-M10-ZP

14

6

3270-8012

Fastener-Self Tap-Screw-CSK-8Gx1/2"-Pozi-Stainless

15

2

3290-1025

Fastener-Set Screw-Hex-8.8 Grade-M10x25-ZP

16

8

3310-6005

Fastener-Washer-Flat-M5-ZP

17

2

3310-6008

Fastener-Washer-Flat-M8-ZP

18

1

3400-1110

Filter-Basket-D150-Mesh

19

1

3500-6900

Frame-Trailed/FlatDeck-In-Ex 200-GL

20

1

4000-6020

Hand Gun-Teejet-Trigger Jet X18-Shank 10mm

21

2

4085-1010

Hook-Bolt-Threaded-M8-Slimline-ZPG

22

1

4085-4050

Hook-Hose-In-Ex 200/400-ZP

23

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow (10m)

24

1

4100-3013

Hose-Suction-Wire Reinforced-13mm ID-Clear Plastic(0.2m)

25

1

4100-0013

Hose-Spray-Delivery-40 Bar-13mm ID-Yellow(0.31m)

26

1

5450-2220

O'Ring-Imperial-1/8"x5/8"-N70

27

1

6200-2980

Pipe-Fitting-Flojet-Elbow-10 ShankxQuad Port Pump-Nylon

28

1

6200-3020

Pipe-Fitting-Flojet-Straight-10-13mm ShankxQuad Port Pump-Plastic

29

1

6200-6260

Pipe-Fitting-Plug-Thumb Screw-3/8BSPM-Black-Plastic

30

1

6200-7350

Pipe-Fitting-Reducer-1/2NPTMx3/8NPTF-Straight-Plastic

31

1

6200-9470

Pipe-Fitting-Thru Tank-Straight-13x13 Shankx1/2&1/4BSPM-Plastic

32

1

6250-3001

Plug-Electrical-2 Pin-Male-20 Amp-With Cover

33*

1

6800-5500

Pump-Flojet-High Flow-10.9LPM-Quad Ports

34

1

7500-4200

Rota-Tank & Pump Cover-200L-Spray-Natural/Red-MDPE-In-Ex

35

1

8410-9106

Strap-Web Sling-1320 Long-38mm-900KG-Reduced and Reversed-KS1 Material-

Black

36

1

8427-3500

Sub-Filter Assembly-C-Dax U Filter

37

1

8427-6000

Sub-Lid & Ring Assembly-D150-In-Ex Vented-Nylon-Black

38

1

8450-2410

Switch-Electrical-Toggle-SPST-250V-16Amp

39

1

8790-4400

Terminal-Joiner-Crimp-Insulated Blue

40

2

8790-8020

Terminal-Spade-Female-6.3mm-Blue

41

1

8840-8413

Tube-Transluscent-13MM-100PSI(0.26m)

42

1

8900-4600

Valve-Lid Vent-D150

Item 33*: Units manufactured prior to Jan 2015 fitted with pump 6800-5000,

Pump-Flojet-Triplex-12 Volt-7.6LPM-Quad Ports.

10

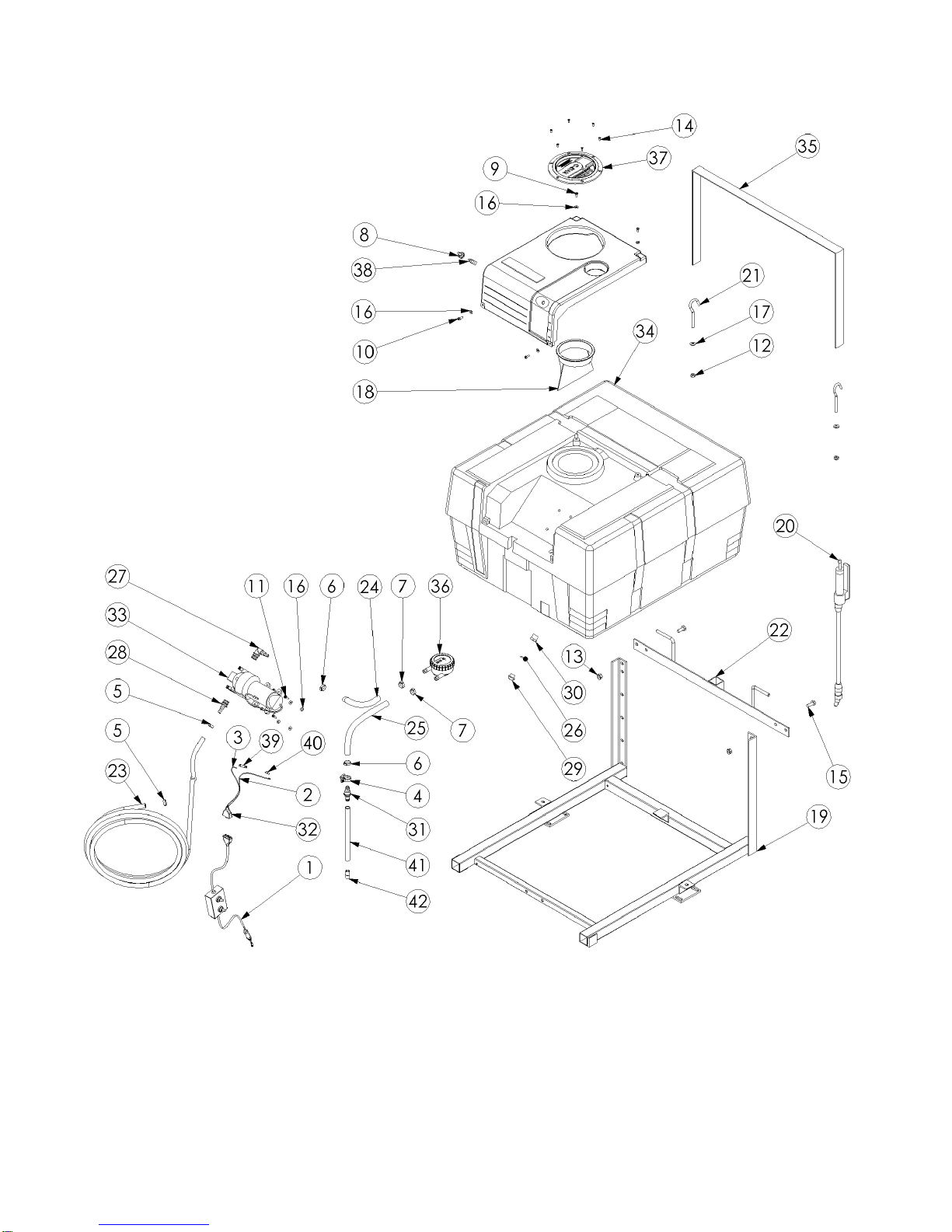

PARTS DIAGRAM (200 litre trailed)

11

PARTS LIST (200 litre Trailed)

Item

No.

QTY.

Part No.

Description

1

1

1082-4380

Axle-In-Ex 200T-GL

2

1

1500-3000

Cable-Electrical-Loom-1 Switch Box-3.0M

3

1

1500-7400

Cable-Electrical-Twin Core-Double Insulated-15 Amp-26x.3mm-Black

4

1

2000-0017

Clamp-Hose-Herbi-G-Ratchet-16.9<>19.1mm-Black-Nylon

5

4

2000-2014

Clamp-Hose-Oetiker-Single Ear Stepless-14.5<>7.0mm-S/S

6

2

2000-2017

Clamp-Hose-Oetiker-Single Ear Stepless-16.6<>19.8mm-S/S

7

2

2000-2019

Clamp-Hose-Oetiker-Single Ear Stepless-19.4<>22.6mm-S/S

8

1

2250-8200

Cover-Switch-Water Proof Boot-Toggle Lever-Rubber-Black

9

1

2550-4200

Drawbar-In-Ex 200T-GL

10

2

2840-1065

Fastener-Bolt-Hex-8.8 Grade-M10x65-ZP

11

2

3110-0512

Fastener-Machine-Screw-Pan-M5x12-Pozi-ZP

12

2

3110-0516

Fastener-Machine-Screw-Pan-M5x16-Pozi-ZP

13

4

3110-0520

Fastener-Machine-Screw-Pan-M5x20-Pozi-ZP

14

2

3170-0008

Fastener-Nut-Nyloc-M8-ZP

15

10

3170-0010

Fastener-Nut-Nyloc-M10-ZP

16

6

3270-8012

Fastener-Self Tap-Screw-CSK-8Gx1/2"-Pozi-Stainless

17

6

3290-1025

Fastener-Set Screw-Hex-8.8 Grade-M10x25-ZP

18

2

3290-1050

Fastener-Set Screw-Hex-8.8 Grade-M10x50-ZP

19

8

3310-6005

Fastener-Washer-Flat-M5-ZP

20

2

3310-6008

Fastener-Washer-Flat-M8-ZP

21

1

3400-1110

Filter-Basket-D150-Mesh

22

1

3500-6900

Frame-Trailed/FlatDeck-In-Ex 200-GL

23

1

4000-6020

Hand Gun-Teejet-Trigger Jet X18-Shank 10mm

24

2

4085-1010

Hook-Bolt-Threaded-M8-Slimline-ZPG

25

1

4085-4050

Hook-Hose-In-Ex 200/400-ZP

26

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow (10m)

27

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow

28

1

4100-0013

Hose-Spray-Delivery-40 Bar-13mm ID-Yellow (0.31m)

29

1

4100-3013

Hose-Suction-Wire Reinforced-13mm ID-Clear Plastic

30

1

5450-2220

O'Ring-Imperial-1/8"x5/8"-N70

31

1

6200-2980

Pipe-Fitting-Flojet-Elbow-10 ShankxQuad Port Pump-Nylon

32

1

6200-3020

Pipe-Fitting-Flojet-Straight-10-13mm ShankxQuad Port Pump-Plastic

33

1

6200-6260

Pipe-Fitting-Plug-Thumb Screw-3/8BSPM-Black-Plastic

34

1

6200-7210

Pipe-Fitting-Quick Release-Male Connectorx8.5 Shank-Brass

35

1

6200-7250

Pipe-Fitting-Quick Release-Valve-Stopx8.5 Shank-Brass

36

1

6200-7350

Pipe-Fitting-Reducer-1/2NPTMx3/8NPTF-Straight-Plastic

37

1

6200-9470

Pipe-Fitting-Thru Tank-Straight-13x13 Shankx1/2&1/4BSPM-Plastic

38

1

6250-3001

Plug-Electrical-2 Pin-Male-20 Amp-With Cover

39

1

6800-5000

Pump-Flojet-Triplex-12 Volt-7.6LPM-Quad Ports

40

1

7500-4200

Rota-Tank & Pump Cover-200L-Spray-Natural/Red-MDPE-In-Ex

41

1

8410-9106

Strap-Web Sling-1320 Long-38mm-900KG-Reduced and Reversed-

KS1 Material-Black

42

1

8427-3500

Sub-Filter Assembly-C-Dax U Filter

43

1

8427-6000

Sub-Lid & Ring Assembly-D150-In-Ex Vented-Nylon-Black

44

1

8450-2410

Switch-Electrical-Toggle-SPST-250V-16Amp

45

1

8800-3800

Tow-Coupling-Handle-Double Ended-1 78 x 50mm-ZP

46

1

8840-8413

Tube-Transluscent-13MM-100PSI(0.26m)

47

1

8900-4600

Valve-Lid Vent-D150

48

2

9200-4556

Wheel-Knobbly -Bearing-22x11-8

Item 39*: Units manufactured prior to Jan 2015 fitted with pump 6800-5000,

Pump-Flojet-Triplex-12 Volt-7.6LPM-Quad Ports.

12

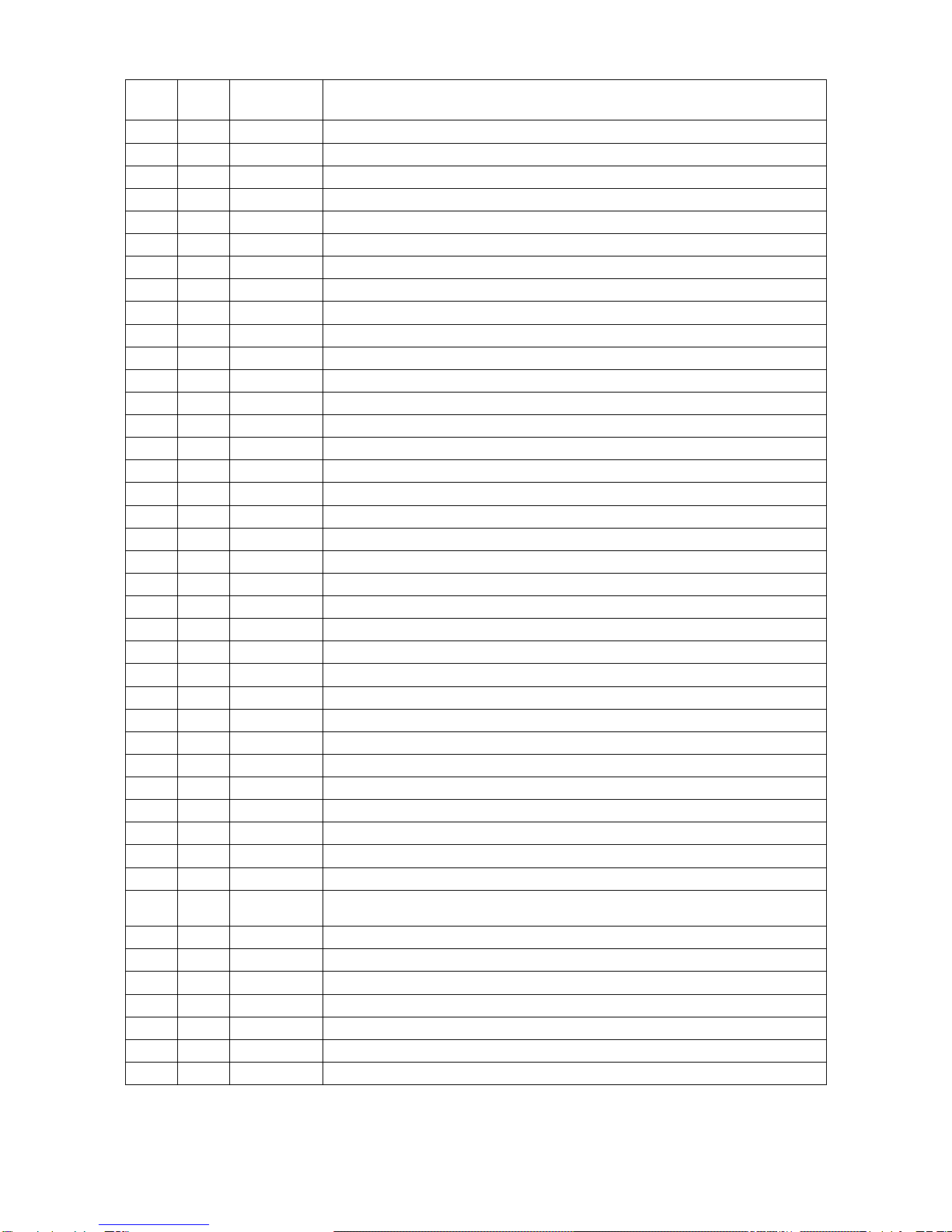

PARTS DIAGRAM (400 litre trailed)

13

PARTS LIST (400 litre Trailed)

Item

No.

QTY.

e9 part no

e9 description

1

1

1082-4384

Axle-In-Ex 400T-GL

2

4

2000-2014

Clamp-Hose-Oetiker-Single Ear Stepless-14.5<>7.0mm-S/S

3

4

2000-2017

Clamp-Hose-Oetiker-Single Ear Stepless-16.6<>19.8mm-S/S

4

8

3070-0300

Fastener-Machine-Screw-CSK-8Gx3/4-Pozi-Stainless

5

4

3110-0520

Fastener-Machine-Screw-Pan-M5x20-Pozi-ZP

6

4

3170-0005

Fastener-Nut-Nyloc-M5-ZP

7

4

3170-0008

Fastener-Nut-Nyloc-M8-ZP

8

10

3170-0010

Fastener-Nut-Nyloc-M10-ZP

9

10

3290-1030

Fastener-Set Screw-Hex-8.8 Grade-M10x30-ZP

10

4

3310-6005

Fastener-Washer-Flat-M5-ZP

11

4

3310-6008

Fastener-Washer-Flat-M8-ZP

12

1

3400-1120

Filter-Basket-D255-204x185x240mm

13

1

3500-6600

Frame-Trailed-F6-400L-GL

14

1

4000-6020

Hand Gun-Teejet-Trigger Jet X18-Shank 10mm

15

4

4085-1000

Hook-Bolt-Threaded-M8-Boxmate-ZPG

16

1

4085-4050

Hook-Hose-In-Ex 200/400-GL

17

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow (10m)

18

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow

19

1

4100-1013

Hose-Spray-Delivery-7 Bar-13mm ID-PVC

20

1

4100-1013

Hose-Spray-Delivery-7 Bar-13mm ID-PVC

21

1

5000-1600

Lid-Tank-D255 Bare-Vented-Black-Nylon

22

1

5000-1650

Lid-Tank-D255-Ring Only-Incl Gasket

23

2

6200-2980

Pipe-Fitting-Flojet-Elbow-10 ShankxQuad Port Pump-Nylon

24

1

6200-5400

Pipe-Fitting-Nut-Back-1/2BSP-Plastic

25

1

6200-7210

Pipe-Fitting-Quick Release-Male Connectorx8.5 Shank-Brass

26

1

6200-7250

Pipe-Fitting-Quick Release-Valve-Stopx8.5 Shank-Brass

27

1

6200-8310

Pipe-Fitting-Straight-13 Shankx1/2BSPM-Plastic

28

2

6250-8620

Plug-Tube End-Square-1 1/2"x1 1/2"-Black-Plastic

29*

1

6800-5500

Pump-Flojet-High Flow-10.9LPM-Quad Ports

30

1

6800-5150

Pump-Flojet-Triplex-Filter-In Line-Quad Ports

31

1

7500-4352

Rota-Tank-400L-Spray-Natural-MDPE-Horizontal

32

2

8410-9104

Strap-Web Sling-1200 Long-38mm-900KG-Reduced and Reversed-KS1

Material-Black

33

1

8800-3800

Tow-Coupling-Handle-Double Ended-1 78 x 50mm-ZP

34

1

8900-8410

Valve-Tap-Inline-13 Shankx13 Shank-Black-Nylon

35

2

9200-4556

Wheel-Knobbly Turf-Bearing-22x12x8-4 Ply-CLAW

Item 29*: Units manufactured prior to Jan 2015 fitted with pump 6800-5000,

Pump-Flojet-Triplex-12 Volt-7.6LPM-Quad Ports.

14

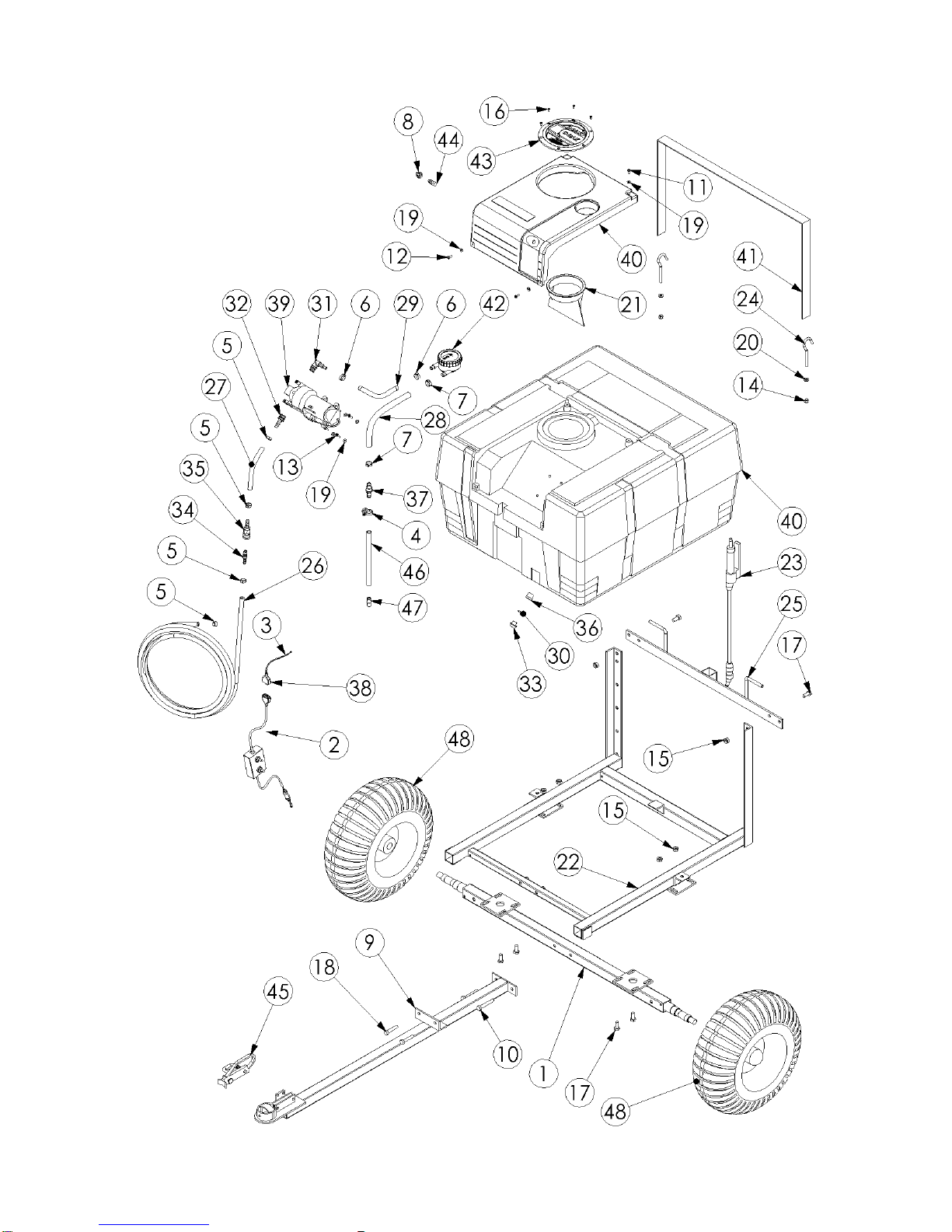

PARTS DIAGRAM (400 litre Flat Deck)

15

PARTS LIST (400 litre Flat Deck)

Item

No.

QTY.

e9 part no

e9 description

1

1

3500-3700

Frame-Flat Deck-F5-400L-GL

2

1

6800-5500

Pump-Flojet-High Flow-10.9LPM-Quad Ports

3

1

1500-3000

Cable-Electrical-Loom-1 Switch Box-3.0M

4

1

7500-4352

Rota-Tank-400L-Spray-Natural-MDPE-Horizontal

5

1

5000-1650

Lid-Tank-D255-Ring Only-Incl Gasket

6

1

3400-1120

Filter-Basket-D255-204x185x240mm

7

1

5000-1600

Lid-Tank-D255 Bare-Vented-Black-Nylon

8

8

3070-0300

Fastener-Machine-Screw-CSK-8Gx3/4-Pozi-Stainless

9

4

4085-1010

Hook-Bolt-Threaded-M8-Slimline-ZPG

10

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow (10m)

11

2

6200-2980

Pipe-Fitting-Flojet-Elbow-10 ShankxQuad Port Pump-Nylon

12

1

4100-1013

Hose-Spray-Delivery-7 Bar-13mm ID-PVC

13

1

8900-8410

Valve-Tap-Inline-13 Shankx13 Shank-Black-Nylon

14

4

2000-2017

Clamp-Hose-Oetiker-Single Ear Stepless-16.6<>19.8mm-S/S

15

1

4100-1013

Hose-Spray-Delivery-7 Bar-13mm ID-PVC

16

1

6200-8310

Pipe-Fitting-Straight-13 Shankx1/2BSPM-Plastic

17

4

3110-0525

Fastener-Machine-Screw-Pan-M5x25-Pozi-ZP

18

4

3310-6005

Fastener-Washer-Flat-M5-ZP

19

4

3170-0005

Fastener-Nut-Nyloc-M5-ZP

20

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow

21

4

2000-2014

Clamp-Hose-Oetiker-Single Ear Stepless-14.5<>7.0mm-S/S

22

1

6200-7250

Pipe-Fitting-Quick Release-Valve-Stopx8.5 Shank-Brass

23

4

3170-0008

Fastener-Nut-Nyloc-M8-ZP

24

2

8410-9105

Strap-Web Sling-1440 Long-38mm-900KG--Reduced and Reversed-KS1

Material-Black

25

1

6200-7210

Pipe-Fitting-Quick Release-Male Connectorx8.5 Shank-Brass

26

1

6200-5400

Pipe-Fitting-Nut-Back-1/2BSP-Plastic

27

1

6250-3001

Plug-Electrical-2 Pin-Male-20 Amp-With Cover

28

2

6250-8620

Plug-Tube End-Square-1 1/2"x1 1/2"-Black-Plastic

29

1

6200-1300

Pipe-Fitting-Cap-3/4BSPF-Plastic

30

1

4085-4050

Hook-Hose-In-Ex 200/400-ZP

31

1

4000-6020

Hand Gun-Teejet-Trigger Jet X18-Shank 10mm

32

2

3290-1030

Fastener-Set Screw-Hex-8.8 Grade-M10x30-ZP

33

2

3170-0010

Fastener-Nut-Nyloc-M10-ZP

34

1

6800-5150

Pump-Flojet-Triplex-Filter-In Line-Quad Ports

Item 29*: Units manufactured prior to Jan 2015 fitted with pump 6800-5000,

Pump-Flojet-Triplex-12 Volt-7.6LPM-Quad Ports.

16

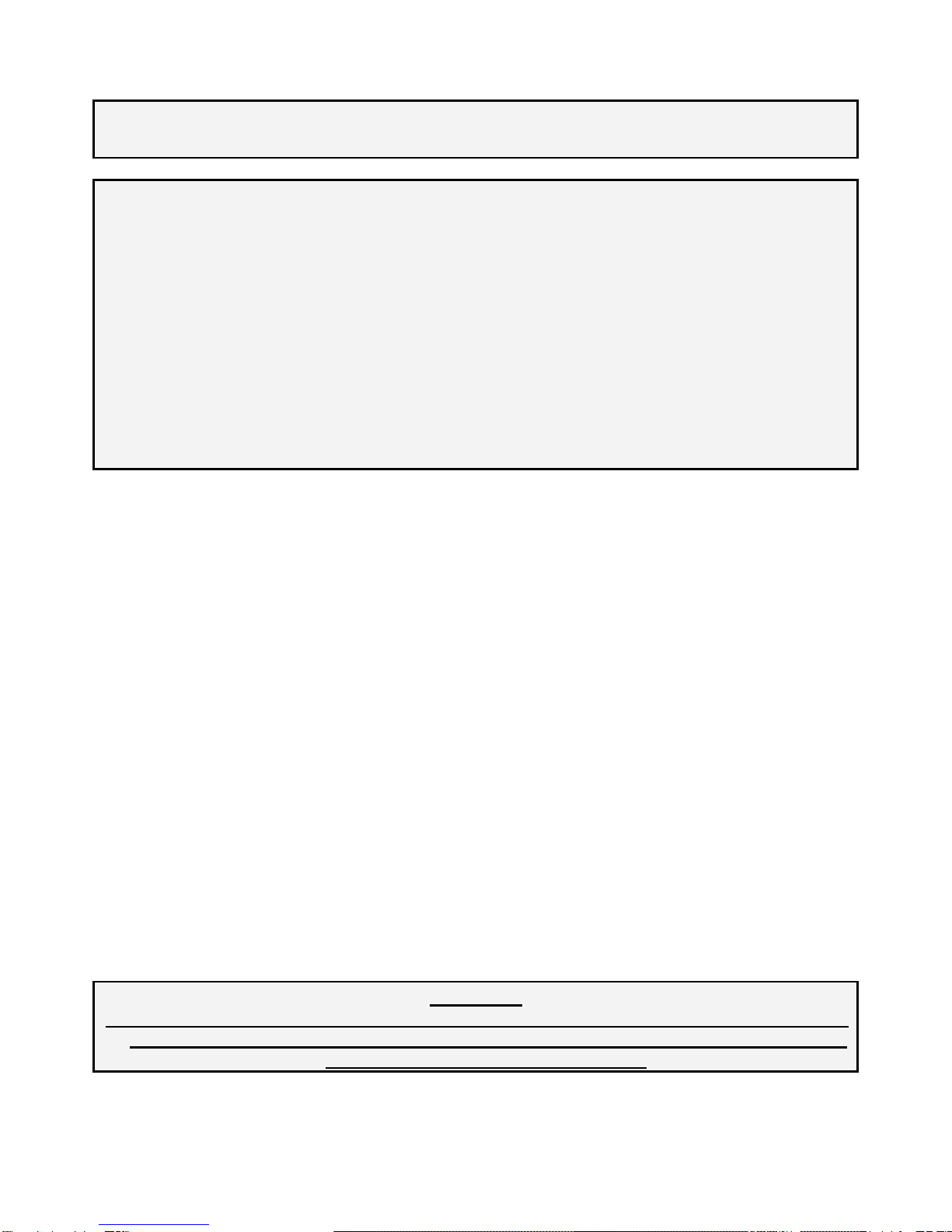

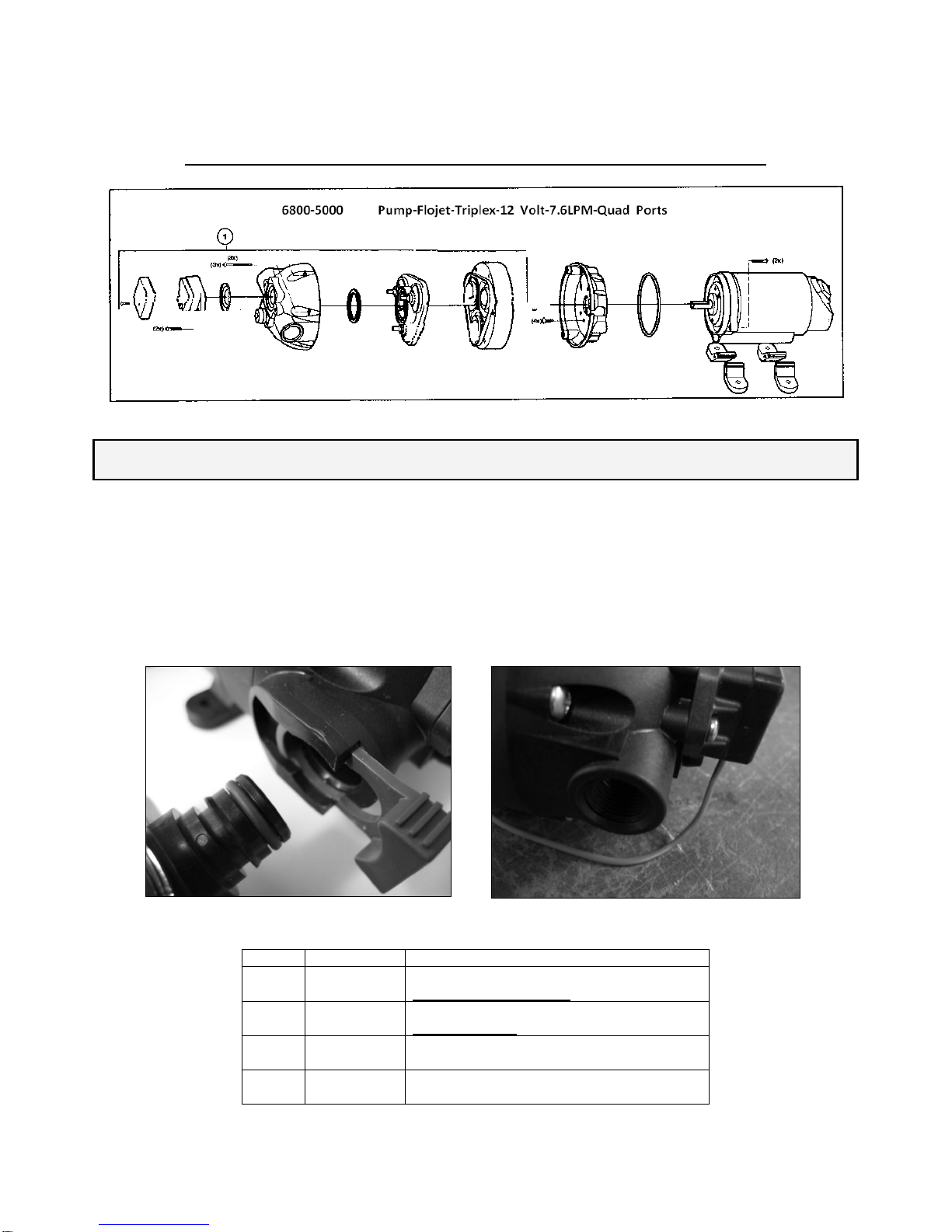

FLOJET SPRAY PUMP RELACEMENT PARTS

The following replacement parts for the 12V Flojet 7.6 L/Min pump are available from any C-Dax dealer:

This diagram is for 7.6L/min pump only, units manufactured prior to Jan 2015.

PLEASE NOTE THAT NO REPLACEMENT PARTS ARE AVAILABLE FOR 10.9L PUMP

NOTE

Please select the correct hose connection type for your pump

The below pictures show the quadport type (Left hand photo) and threaded type (Right hand

photo). The threaded type is no longer available for ordering and should be replaced with a

quadport type. When replacing a threaded pump head with a quadport type you will require

replacement quadport hose fittings in addition to the pump head.

Quadport Type:

Screw Type:

ITEM

PART NO.

DESCRIPTION

1

6800-5160

Pumphead Kit (includes pressure switch)

To Suit Quadport Type

6800-5000

Replacement Pump

Quadport Type

6200-2980

Pipe-Fitting-Flojet-Elbow-10-13mm

ShankxQuad Port Pump-Nylon

6200-3020

Pipe-Fitting-Flojet-Straight-10-13mm

ShankxQuad Port Pump-Plastic

This manual suits for next models

1

Table of contents

Other In-Ex Paint Sprayer manuals