In-Ex SPRAYER 50 User manual

1

Sprayer 50 Pt.No 1025 / 1080

(Leaflet 2400-1400 Issue 6, May 2018)

DESCRIPTION

The In-Ex SPRAYER 50 is an entry-level spot sprayer which can be used in a variety

of applications. It is especially suitable for use with small vehicles or anywhere where

there is a flat surface to attach it to and a source of 12VDC power. The Sprayer 50 is

supplied ready to use and includes a sturdy tie down strap and 1.5 metre power

cable.

1025 (pump size 3.8Lpm)

1080 (pump size 7.6Lpm)

WARRANTY

1WARRANTY AND LIABILITY

Use of the equipment

1.1 You must satisfy yourself as to the suitability of the equipment for your intended use(s)

of the equipment.

Your relationship with the retailer

1.2 Where you consider you have a warranty claim (or any other claim) in relation to the

equipment, you must contact the retailer who sold you the equipment, not C-Dax

directly. The retailer is responsible for liaising with C-Dax in respect of your claim.

Warranty

1.3 C-Dax warrants to the original purchaser that the equipment is sold free from defects in

materials and workmanship for a period of 12 months from date of first retail sale (6

months from date of first retail sale if the equipment is sold in the U.K.) subject to the

terms set out below.

1.4 C-Dax will at its option repair or replace the defective equipment (or part of the

equipment) or notify the retailer of the equipment to refund the purchase price for such

defective equipment to you in the event of a breach of this warranty, subject to the

terms set out below.

Liability

1.5 Except for the warranty set out in clause 1.2 above, all warranties and representations

(including those expressed or implied by law) in respect of the equipment or advice

relating to the equipment provided to you by C-Dax are excluded to the extent

permitted by law.

1.6 Notwithstanding anything else in this manual, C-Dax’s maximum liability to you (in the

event that such liability exists) in respect of any breach of warranty, any matter set out

in this manual, or for defective equipment or advice relating to the equipment provided

is limited at C-Dax’s option to:

2

(a) repairing or replacing the equipment (or part of the equipment); or

(b) notifying the retailer of the equipment to refund the price for the equipment paid

by you.

1.7 Notwithstanding anything else in this manual, in no event will C-Dax be liable, whether

in contract, tort (including negligence) or otherwise:

(a) where you have altered or modified the equipment, misused or misapplied the

equipment, or the equipment has been subjected to any unusual, excessive or

non-recommended use, service or handling (including as set out in this manual);

(b) where the equipment is not transported, stored, handled or used in accordance

with any directions given by C-Dax (or the retailer) to you (including as set out

in this manual);

(c) where the equipment:

(i) has been subject to neglect, accident or hireage, or the damage arises

from fair wear and tear, battery damage or chemical attack;

(ii) has been built to a customer’s specifications; or

(iii) has been dismantled, repaired or serviced other than by an authorised

service agent of C-Dax;

(d) for loss or damage caused by any factors beyond C-Dax’s control; or

(e) for any loss of profit or revenue, or for any special, indirect, incidental or

consequential damage, loss or injury of any kind suffered by you.

1.8 Where C-Dax elects to repair or replace the equipment it will use reasonable

endeavours to do so as soon as practicable but will not be liable for any delay in doing

so.

1.9 You agree that the transactions entered into between you and the retailer (and C-Dax)

are for the purposes of trade and that, having regard to all relevant circumstances of

the transactions, it is fair and reasonable that the provisions of the Consumer

Guarantees Act 1993 (NZ) do not apply to those transactions to the fullest extent

permitted by law.

3

CONTENTS

Part No. Description Quantity

N/A Tank assembly complete with; lid, pump,

suction filter, spray gun and hose. 1

8410-8450 Strap-Ratchet 1

1500-3700 Cable ASY-Battery-2.2M 1

INSTALLATION

Place the Sprayer 50 on the vehicle with the switch facing the operator. Secure the

tank in place using the ratchet strap. On ATV carriers the long strap should be

hooked onto the carrier frame and looped over the tank at the lid end. The short

strap with the ratchet is similarly placed at the opposite end. The long strap is then

run under the carrier frame and connected with the ratchet so that the ratchet is on

top of the tank. Pull the strap tight and apply tension using the ratchet. Connect the

cable assembly to the male connector on the pump then attach to the vehicle battery

ensuring that the red wire is connected to the positive terminal.

OPERATING INSTRUCTIONS

Place fluid in the tank then turn the switch on. The pump will run. Place the end of

the spray gun in the tank and press the trigger until all of the air has been expelled

from the hose. The pump will stop running when the trigger is released.

Operate the spray gun and adjust the tip until the pump runs smoothly and the

desired spray pattern is obtained.

4

MAINTENANCE

Cleaning Tank and Spray Gun

When spraying is finished rinse the tank with clean water and pump the contents out

through the spray gun. A triple rinse is recommended. The tank may also be drained

by removing the drain plug at the lid end.

Filter Maintenance

After each use or when the tank has been emptied (whichever comes first) it is

recommended that the suction filter located under the white nut at the tank outlet be

removed and cleaned.

Pressure Switch Adjustments

Adjustment should not be necessary under normal operating conditions. Increasing

the pressure setting will not increase pump flow but may reduce pump life. To adjust

the switch, remove the cover from the end of the pump beneath the power switch

and rotate the adjustment screw. Replace the cover after adjustment.

TROUBLE SHOOTING

Pump will not prime

Check that the suction filter nut is tight.

Operate the spray gun to release air from the pump.

Check that the suction filter is not blocked.

Pump pulses

Adjust the spray tip to increase pump flow.

Adjust pump switch off pressure.

Pump will not run

Check electrical connections and fuse.

5

EXPLODED PARTS DIAGRAM

6

PARTS LIST

Item

No.

QTY

Part No.

Description

1

1

7500-3550

Rota-Tank-50L-In-Ex-Natural-MDPE

2

1

2250-8200

Cover-Switch-Water Proof Boot-Toggle Lever-Rubber-Black

3

1

3110-0516

Fastener-Machine-Screw-Pan-M5x16-Pozi-ZP

4

4

3110-0520

Fastener-Machine-Screw-Pan-M5x20-Pozi-ZP

5

1

8450-2410

Switch-Electrical-Toggle-SPST-250V-16Amp

6

1

6200-5420

Pipe-Fitting-Nut-Back-11/16UNFM-Plastic

7

1

6200-8220

Pipe-Fitting-Straight-10 Shank-Swivel-Suit Fly Nut-Plastic

8

1

6200-5550

Pipe-Fitting-Nut-Swivel-11/16UNFF-Plastic

9

1

3700-9150

Gasket-Washer-25x17.4x1.4-Nylon

10

1

3400-5400

Filter-Nozzle Tip-50 Mesh-Plastic

11A

1

6800-4000

Pump-Flojet-LF12-12 Volt-3.8LPM-10mm Hose Shanks

11B

1

6800-5000

Pump-Flojet-Triplex-12 Volt-7.6LPM-Quad Ports

12

1

4000-6020

Hand Gun-Teejet-Trigger Jet X18-Shank 10mm

13

4

2000-2014

Clamp-Hose-Oetiker-Single Ear Stepless-14.5<>7.0mm-S/S

14

4

3310-6005

Fastener-Washer-Flat-M5-ZP

15

1

7500-1760

Rota-Flange-50L-Red-MDPE

16

1

1300-7200

Bracket-Sprayer Switch-50/100/200L-AL

17

1

6200-6260

Pipe-Fitting-Plug-Thumb Screw-3/8BSPM-Black-Plastic

18

1

3700-9130

Gasket-Washer-17x23x2-Rubber

19

6

3070-0300

Fastener-Machine-Screw-CSK-8Gx3/4-Pozi-Stainless

20

1

5450-2220

O'Ring-Imperial-1/8"x5/8"-N70

21

1

6200-9400

Pipe-Fitting-Thru Tank-Elbow-10 Shankx11/16UNFM-Nylon

22

1

8840-8410

Tube-Transluscent-10MM-100PSI (70LG)

23

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow (110LG)

24

1

4100-0008

Hose-Spray-Delivery-40 Bar-8.5mm ID-Yellow (5m)

25

1

8410-8450

Strap-Tie Down-Ratchet-Blue

26

1

3600-1010

Fuse Link-Electrical-Standard Blow-15 Amp-1"x1/4"-Glass

27

1

8427-6000

Sub-Lid & Ring Assembly-D150-In-Ex Vented-Nylon-Black

28

1

1500-3700

Cable-Electrical-Loom-Battery Feed-2.2M

29

1

1500-6500

Cable-Electrical-Loom-Sprayer 50/100/Sprayon 200/SM50-Flojet

30

1

3400-1110

Filter-Basket-D150-Mesh

7

FLOJET SPRAY PUMP RELACEMENT PARTS

The following replacement parts available for the 12V Flojet 3.8 L/Min pump are available from

any C-Dax dealer:

8

FLOJET SPRAY PUMP RELACEMENT PARTS

The following replacement parts for the 12V Flojet 7.6 L/Min pump are available from any C-Dax dealer:

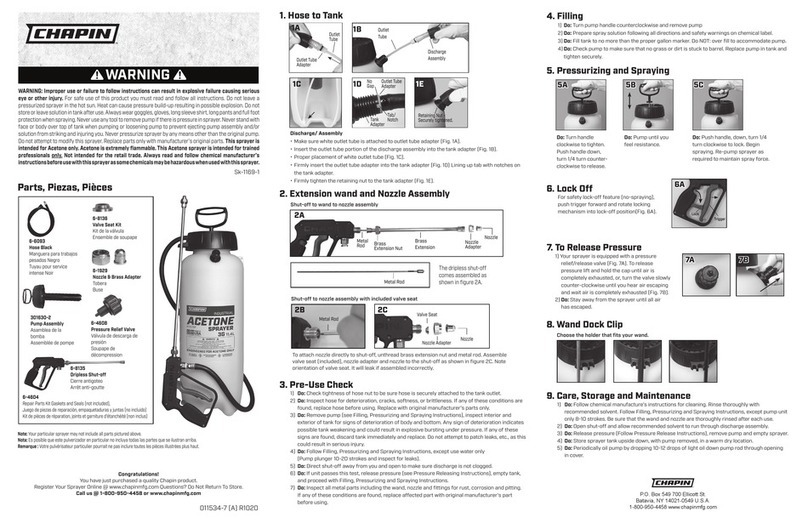

NOTE

Please select the correct hose connection type for your pump

The below pictures show the quadport type (Left hand photo) and threaded type (Right hand

photo). The threaded type is no longer available for ordering and should be replaced with a

quadport type. When replacing a threaded pump head with a quadport type you will require

replacement quadport hose fittings in addition to the pump head.

Quadport Type:

Screw Type:

ITEM

PART NO.

DESCRIPTION

1

6800-5160

Pumphead Kit (includes pressure switch)

To Suit Quadport Type

6800-5000

Replacement Pump

Quadport Type

6200-2980

Pipe-Fitting-Flojet-Elbow-10-13mm

ShankxQuad Port Pump-Nylon

6200-3020

Pipe-Fitting-Flojet-Straight-10-13mm

ShankxQuad Port Pump-Plastic

Table of contents

Other In-Ex Paint Sprayer manuals