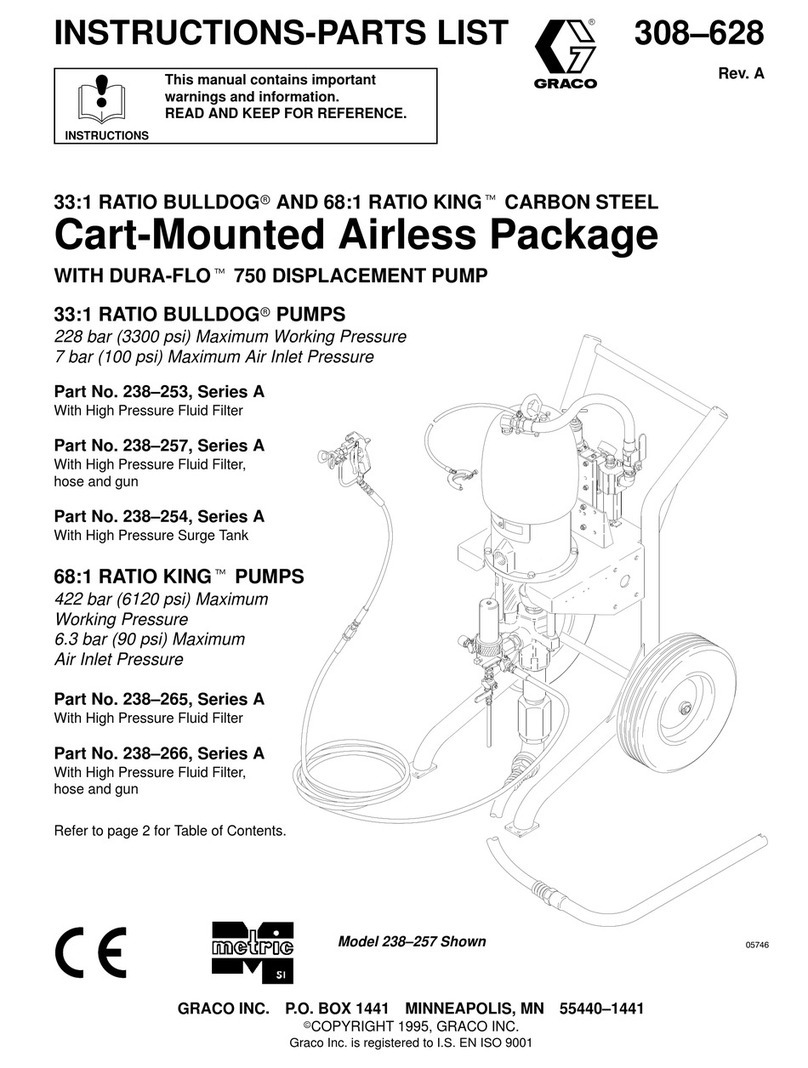

Ningbo Dino-power Machinery DP6388B User manual

Owner sManual

ForprofessionalUseonly

Donotusethisequipmentbeforereadingthismanual!

AirlessSprayer

InternationalModel

NOTE:Thismanualcontainsimportantwarnings

andinstructions.Pleasereadandretainfor

reference

DP6388B

Originalinstruction

NingboDino-powerMachineryCo.,Ltd www.dpairless.com

#606GuangboLijingCenter,TiantongS.Rd,YinzhouDistrict,Ningbo,China

TableofContents

SafetyPrecautions…………………………………..2

GeneralDescription……...………………………....4

TechnicalParameter………………………………...4

Operation…………………………..………...……....4

Setup……………………...……………….……........4

PreparingtoPaint………………………...…….......5

Painting….........……………………....………........5

ElectronicPressureControlIndicators….…….....5

PressureReliefProcedure………………….…......6

Spraying………………….……………………………6

SprayingTechnique…………............………….....6

Practice…………………………….........…….........7

ShutdownandCleaning………………………...…..7

Troubleshooting……………………………..……….8

PartsListings…………………………….…………..10

MainAssembly…………………………………...10

MotorAssembly…………………………...….....11

GearBoxAssembly…………………..………....12

SuctionSetAssembly………………….………..12

StandAssembly……………...………..………...12

FluidSectionAssembly………………….…......13

TipSelection……………………………………...14

SelectingTipHoseSize…………...…....…….......14

ChoosingTheCorrectTip…......………...............14

TipHoseSize…………….....………....……….......14

Fanwidth………..……………………….………......14

UnderstandingTipNumber…............……….......14

ReversibleTipSelectionChart............……….....15

SafetyPrecautions

ThismanualContainsInformationthatmustbereadand

understoodbeforeusingtheequipment,Whenyoucometoan

areathathasoneofthefollowingsymbols,payparticular

attentionandmakecertaintoheedthesafeguard.

WARNING

ThisSymbolindicatesapotentialhazardthatmaycause

seriousinjuryorlossoflife.Importantsafetyinformation

willfollow.

CAUTION

Thissymbolindicatesapotentialhazardtoyouortothe

equipment.Importantinformationthattellshowtoprevent

damagetotheequipmentorhowtoavoidcausesofminor

injurieswillfollow.

NOTE:Notesgiveimportantinformationwhichshouldbegivenspecial attention.

NOTE:Notesgiveimportantinformationwhichshould

begivenspecialattention.

WARNING

Airlessunitsdevelopextremelyhighsprayingpressures.

Neverputyourfingers,handsoranyotherpartsofthe

bodyintothesprayjet.

Neverpointthespraygunatyourselforanybodyelse.

Neverusethespraygunwithoutthesafetyguard.

Attention!Dangerofinjurybyinjection!

Incaseofinjurytoskincausedbycoatingmaterialsor

solventsconsultadoctorimmediately.Informthedoctorofthe

typeofcoationgmaterialorcleaningagentwithwhichtheinjury

wascaused.

Theoperatinginstructionsstatethatthefollowingpoints

mustalwaysbeobservedbeforestartingup:

1.Faultyunitsshouldnotbeused.

2.Securespraygunusingthesafetycatchonthetrigger

3.Ensurethattheunitisproperlyearthed.

4.Checkthepermissibleoperatingpressure.

5.Checkallconnectionsforleaks.

Theinstructionsregardingregularcleaningand

maintenanceoftheunitmustbestrictlyobserved.

Beforeanyworkisdoneontheunitorforeverybreakin

workthefollowingrulesmustbeobserved:

1.Releasethepressurefromthespraygunandhose.

2.Securethespraygunusingthesafetycatchonthe

trigger.

3.Turnoffthemotor.

Besafety-conscious!

Alllocalregulationinforcemustbeobserved.

Inordertoensuresafeoperationoftheairlesssystems

thesafetyregulationslistedbelowmustbefollowed:

1.Inordertoavoiddangers,readtheoperatinginstructions

carefullyandfollowtheinstructionslaiddowninthem.

2.Donotusematerialswithflashpointbelow2(7).

3.Theuseofthisunitisprohibitedinworkshopswhichare

coveredundertheexplosionpreventionregulations.

4.Neverspraynearsourcesofignition;e.g.openflames,

cigarettesalsocigarsandpipesaresourcesofignition

-sparks,hotwiresandhotsurfaces,etc.

5.Attention!Dangerofinjurybyinjection!

Neverpointthespraygunatyourselforanyoneelse.

Neverputyourfingersorhandsintothesprayjet.The

veryhighsprayingpressurescancauseveryserious

injuries.Neverusethespraygunwithoutthesafetyguard.

1℃0℉H

WhenInstallingandremovingthetipandduringbreaksin

workthespraygunmustalwaysbesecured,sothatit

cannotbeactivated.

6.Wearrespiratoryequipmentwhenspraying.Theoperator

mustbeprovidedwithaprotectivemask.

Inordertopreventworkrelatedillness,themanufacturers

agentsusedmustbeobservedwhenpreparing,working

withandcleaningtheunit.Protectiveclothing,glovesand

incertaincases,protectiveskincreamarenecessaryto

protecttheskin.

7.Thespraygunandhighpressurehosebetweentheunit

andspraygunmustbeofasufficientstandardforthe

pressureproducedintheunit.

Thepermissibleoperatingpressureforthehigh-pressure

hose,themanufacturerandthedateofmanufacturemustbe

indicatedbyapermanentidentificationmarkingonthe

hose.Furthermore,itmustbeconstructedsothatthe

electricalresistancebetweentheconnectionstotheunit

andthespraygunisequaltoorlessthanonemegohm.

8.Undercertainconditionsthefollowspeedcancausean

electrostaticchargeontheunit.Thiscouldcausesparks

orflamesondischarging.Itis,therefore,importantthat

theunitisalwaysearthedovertheelectricalinstallation.

Thecontactshouldbemadeusingashockproofsocket

earthedinaccordancewiththeregulations.

'

9.Forbiddentouseofelectrostaticatomisingandspraying

equipmentwithmachinesnotspecificallydesignedforthis

equipment,becauseitmayresultinserioushazardsfor

theoperators;

10.Payattentiontohazardsresultingfromcontactwithand/or

breathingoftoxicmaterials,gases,mistsandvapourswhich

maybecreatedbyoperationofthemachine.

11.Beforeinstallationandusage,visuallyinspectionfordamage

onhoseswhichmaybesubjectedtofrictionshouldbedone.

2.

9.Attention!Pleaseobservethefollowingwhenworking

insideandoutside:

NoSolventGassesShouldbecarriedtotheunit.No

solventgassesshouldfromneartheunit.Setuptheunit

ontheoppositesidetotheobjectbeingSprayed.When

sprayingoutdoors,takethewinddirectionintoaccount.

Whenworkingindoorstheremustbesufficientventilation

toensurethatthesolventgassesarecarriedaway.A

minimumdistanceof6.1m(20')mustbeobserved

betweentheunitandobjectbeingsprayed.

10.ExtractionequipmentShouldbeinstalledbytheuserin

accordancewiththelocalregulations.

11.Theobjectsbeingsprayedmustbeearthed.

12.Whencleaningtheunit,solventshouldneverbesprayed

intoacontainerwithonlyasmallopening(bunghole).An

explosivegas/airmixtureislikelytoform.Thecontainer

mustbeearthed.

13.Cleaningtheunit.

Aharshjetshouldneverbeusedtospraytheunit.In

particularahigh-pressurecleanerorhigh-pressuresteam

cleanershouldneverbeused.Thereisadangerthat

waterwillpenetrateintotheunitandcauseashort-circuit.

14.Pullingthetriggercausesarecoilforcetothehandthatis

holdingthespraygun.

Therecoilforceofthespraygunisparticularlypowerful

whenthetiphasbeenremovedandahighpressurehas

beensetontheairlesshigh-pressurepump.Therefore,

whencleaningwithouttipsetthepressurecontrolvalveto

thelowestpressure.

15.Themainsplugshouldonlybedisconnectedfromthe

socketwhenworkisbeingcarriedoutontheelectrical

components.

14.Workorrepairsshouldonlybecarriedoutonelectrical

equipmentbyatrainedelectrician,eveniftheworkis

describedintheoperatinginstructions.Noliabilitywillbe

acceptedforincorrectlyinstalledelectrics.

15.Positioningwhenthegroundisuneven.

Thefrontoftheunitmustpointdownwardsothatthe

machinedoesnotslipaway.

HAZARD:INJECTIONINJURY-Ahighpressurestream

ofpaintproducedbythisequipmentcanpierce

theskinandunderlyingtissues,leadingto

seriousinjuryandpossibleamputation.

DONOTTREATANINJECTIONINJURYASA

SIMPLECUT!Injectioncanleadto

amputation.Seeanphysicianimmediately.

PREVENTION:

Themaximumoperatingrangeoftheunitis221BAR

(3200PSI)fluidpressure.

Neveraimthegunatanypartofthebody.

Neverallowanypartofthebodytocomeincontactwith

streamcreatedbyaleakinthefluidhose.

NeverPutyourhandinfrontofthegun.Gloveswillnot

provideprotectionagainstandinjectioninjury.

ALWAYSlocktheguntrigger,shutthefluidpumpoffand

releaseallpressurebeforeservicing,cleaningthetip

guard,changingtips,orleavingunattended.Pressurewill

notbereleasedbyturningofftheengine.The

PRIME/SPRAYknobmustbeturnedtoPRIMEtorelieve

thepressure.RefertothePRESSURERELIEF

PROCEDUREdescribedinthismanual.

Thetipguardmustalwaysbeinplacewhilespraying.The

tipguardprovidessomeprotectionagainstinjection

injuriesbutismainlyawarningdevice.

ALWAYSremovethespraytipbeforeflushingorcleaning

thesystem.

Thepainthosecandevelopleakfromwear,kinkingand

abuse.Aleakiscapableofinjectingmaterialintotheskin.

Inspectthepainthosebeforeeachuse.

NOTETOPHYSICIAN:

Injectionintotheskinisatraumaticinjury.Itis

importanttotheattheinjurysurgicallyassoonas

possible.DONOTdelaytreatmenttoresearchtoxicity.

Toxicityisaconcernwithsomecoatingsinjected

directlyintothebloodstream.Consultationwitha

plasticsurgeonorreconstructivehandsurgeonmaybe

advisable.

HAZARD:EXPLOSIONORFIRE-Solventandpaintfumes

canexplodeorignite,causingpropertydamage

and/orsevereinjury.

PREVENTION:

Fireextinguishingequipmentmustbepresentandingood

workingorder.

Useonlyconductiveorearthedhighpressurefluidhoses

forairlessapplications,besurethatthegunisearthed

properlythroughhoseconnections.

Thepumpmustbeconnectedtoanearthedobject.Use

thegreenearthingwiretoconnectthepumptoawater

pipe,steelbeam,orotherelectricallyearthedsurface.

Whenflushingequipmentusethelowestpossible

pressure.

HAZARD:EXPLOSIONHAZARDDUETOINCOMPATIBLE

MATERIALS-Maycausepropertydamageor

severeinjury.

PREVENTION:

Donotusebleach.

Donotusehalogenatedhydrocarbonsolventssuchas

methylenechlorideand1,1,1-trichloroethane.Theyare

notcompatiblewithaluminumandmaycausean

explosion.Ifyouareunsureofamaterial'scompatibility

withaluminum,contactyourcoating'ssupplier.

HAZARD:GENERAL-Maycausepropertydamageor

severeinjury.

PREVENTION:

Thishighpressureairlesspumpisdesignedtobeused

withmanufacturerauthorizedpartsonly.Whenusingthis

pumpwithpartsthatdonotcomplywiththeminimum

specificationsandsafetydevicesofthepump

manufacturer,theuserassumesallrisksandliabilities.

Beforeeachuse,checkallhosesforcuts,leaks,abrasion

orbulgingofcover,aswellasdamageormovementof

couplings.Ifyouanyoftheseconditionexist,replacethe

hoseimmediately.Neverrepairapainthose.Replaceit

withanotherearthedhose.

Wearprotectiveeyewear.

Donotsprayonwindydays.

EarthingInstructions

Thisproductmustbeearthed.Intheeventofanelectrical

shortcircuit,earthingreducestheriskofelectricshockby

providinganescapewirefortheelectriccurrent.Thisproduct

isequippedwithacordhavinganearthingwirewithan

appropriateearthingplug.Theplugmustbepluggedintoan

outletthatisproperlyinstalledandearthedinaccordancewith

alllocalcodesandordinances.

DANGER-Improperinstallationoftheearthingplugcan

resultinariskofelectricshock.

Ifrepairorreplacementofthecordorplugisnecessary,donot

connectthegreenearthingwiretoeitherflatbladeterminal.

Thewirewithinsulationhavingagreenoutersurfacewithor

withoutyellowstripesistheearthingwireandmustbe

connectedtotheearthingpin.

Checkwithaqualifiedelectricianorservicemaniftheearthing

instructionsarenotcompletelyunderstood,orifyouarein

doubtastowhethertheproductisproperlyearthed.Donot

modifytheplugprovided.Iftheplugwillnotfittheoutlet,have

theproperoutletinstalledbyaqualifiedelectrician.

3.

GeneralDescription

Thisairlesssprayerisaprecisionpowertoolusedforspraying

manytypesofmaterials.Readandfollowthisinstruction

manualcarefullyforproperoperatinginstructions,

andsafetyinformation.

TechnicalParameter

Workingpressurerange

0-2800psi(0-19MPa,0-193bar)

Electricmotor 6.0A(openframe,universal)

Operatinghorsepower 1/2 hp 375w

Maximumdelivery(withtip) 0.25gpm(1.0lpm)

PaintHose 1/4inx25ft(6.4mmx7.5m)

MaximumTipholesize 0.015in.(0.38mm)

Weight,sprayeronly 16lb(7.3kg)

Weight,sprayer,hose&gun 19.2lb(8.7kg)

Dimensions(upright):

Length 14.5in(36.8cm)

Width: 12.4in(31.5cm)

Height: 17.9in(45.5cm)

Dimensions(Folded):

Length: 19.3in(49.0cm)

Width: 15.3in(38.9cm)

Height: 29.2in(74.2cm)

PowerCord: 18AWG,3wire,6ft(1.8m)

Fluidinletfitting

3/4in.internalthread(Standardgardenhosethread)

Fluidoutletfitting 1/4NPSMexternalthread

Inletscreen(onsuctiontube) 35mesh(450micro)

Wettedparts,pump&hose

Stainlesssteel,brass,leather,ultra-highmolecular

weightpolyethylene(UHMWPE),carbide,nylon,

aluminum,PVC,polypropylene,fluroelastomer

Wettedparts,gun Aluminum,brass,carbide,nylon,platedsteel,

stainlesssteel,UHMWPE,zinc

Generatorrequirement 1500Wattminimum

Electricalpowerrequirement 230V50Hz,15A1phase

Storagetemperaturerange -3to16(-35to70°0℉° 1℃)

Operatingtemperaturerange 40to115(4to46°℉°℃)

Operation: WARNING

Thisequipmentproducesafluidstreamatextremelyhigh

pressure.Readandunderstandthewarningsinthe

safetyprecautionssectionatthefrontofthismanual

beforeoperatingthisequipment.

Setup

Performthefollowingprocedurebeforeplugginginthepower

cordofanelectricunit.

1.Ensurethatthesuctionsetandthereturnhoseare

attachedandsecure.

2.Usingawrench,attachaminimumof7.5m24.6'x10mm

(1/4”)nylonairlesssprayhosetotheunit.Tighten

securely.

3.attachanairlesssprayguntothesprayhose.Usingtwo

wrenches(oneonthegunandoneonthehose),tighten

securely.

NOTE:Donotattachthetiptothespraygunyet.

Removethetipifitisalreadyattached.

WARNING

Makesureallairlesshosesandspraygunsareelectrically

groundedandratedforatleast228bar(3300psi)fluid

pressure.

4.MakesurethepressurecontrolknobisinitsOFFposition

5.MakesuretheON/OFFswitchisinitsOFFposition.

6.Filltheoilcupwith15g(onetablespoon)ofpistonseal

lubricant(pistonlube).

CAUTION

Neveroperateunitformorethantensecondswithout

fluid.Operatingthisunitwithoutfluidwillcause

unnecessaryweartothepacking.

7.Makesuretheelectricalserviceiscorrectfortheunit.

8.Plugthepowercordintoaproperlygroundedoutletat

least7.6m(25')fromthesprayarea.

CAUTION

Alwaysuseaminimum12gauge,three-wireextensioncord

withagroundedplug.Neverremovethethirdprongoruse

anadapter.

PreparingaNewSprayer

Ifthisunitisnew,itisshippedwithtestfluidinthefluidsection

topreventcorrosionduringshipmentandstorage.Thisfluid

mustbethoroughlycleanedoutofthesystemwithmineral

spiritsbeforeyoubeginspraying.

CAUTION

Alwayskeepthetriggerlockonthesprayguninthe

lockedpositionwhilepreparingthesystem.

1.Placethesuctiontubeintoacontainerofmineralspirits

thathasaflashpointof60140)orabove.

2.Placethereturnhoseintoametalwastecontainer.

3.TurnPressureControlKnoballthewayleft

(counter-clockwise)tominimumpressure.

℃(℉H

4.MovethePRIME/SPRAYvalvedowntothePRIME

position.

5.TurntheunitonbymovingtheON/OFFswitchtotheOn

position.

6.AllowtheSprayertorunfor15-30secondstoflushthe

testfluidoutthroughthereturnhoseandintothewaste

container.

7.TurntheunitoffbymovingtheON/OFFswitchtotheOFF

position.

Thepaintsprayeriscompatiblewiththefollowingwater

solublepaints:phenolaldehydepaintseries-nitrylpaint

seriesalkydpaintseriesepoxyresinpaintseriesoxidized

rubberpaintserieslatexpaintseriesetc.

Maximumallowablepressureforthe

coatingmaterialMPa

()

Maximumallowabletemperatureofthe

coatingmaterial()

℃

Typicalcoatingmaterialflowrate(l/min)

Soundpowerlevel(LWA4mhemisphere)dB(A)

Soundpressurelevel(LpAAirbornenoise

1mawayfromworkingstation)dB(A)

UncertaintydB(A)

Vibrationvalveforsprayinggun(

m/s2)

Uncertainty(

m/s2)

97.9

90

1.5

2.391

0.5

4.

PreparingtoPain

Beforepainting,itisimportanttomakesurethatthefluidinthe

systemiscompatiblewiththepaintthatisgoingtobeused.

NOTE:Incompatiblefluidandpaintmaycausethe

valvestobecomestuckclosed,whichwould

requiredisassemblyandcleaningofthe

sprayer'sfluidsection.

CAUTION

Alwayskeepthetriggerlockonthesprayguninthe

lockedpositionwhilepreparingthesystem.

1.placethesuctiontubeintoacontaineroftheappropriate

solventforthematerialbeingsprayed(referto

recommendationsofthematerialmanufacture).An

exampleoftheappropriatesolventiswaterforlatexpaint.

2.placethereturnhoseintoametalwastecontainer.

3.setthepressuretominimumbyturningthepressure

controlknoballthewayleft(counter-clockwise)to

minimumpressure.

4.movethePRIME/SPRAYvalvedowntothePRIME

position.

5.TruntheunitonbymovingtheON/OFFswitchtotheON

position.

6.Allowthesprayertorunfor15-30secondstoflushtheold

solventoutthroughthereturnhoseandintothemetal

wastecontainer.

7.TurntheunitoffbymovingtheON/OFFswitchtotheOFF

position.

NOTE:Makesurethatthespraygundoesnothavea

tiportipguardinstalled.

8.MovethePRIME/SPRAYvalveuptotheSPRAYposition.

9.Turntheuniton.

10.Unlockthegunbyturningtheguntriggerlocktothe

unlockedposition.

WARNING

Groundthegunbyholdingitagainstthe

edgeofthemetalcontainerwhileflushing.

Failuretodosomayleadtoastatic

electricdischarge,whichmaycauseafire.

11.Triggerthegunintothemetalwaste

containeruntiltheoldsolventisgone

andfreshsolventiscomingoutofthegun.

12.Lockthegunbyturnigthegun

triggerlocktothelockedposition.

13.Setdownthegunandincreasethe

pressurebyturningthepressure

controlknobslowlyclockwiseinto

thehighpressurespray.

14.Checktheentiresystemforleaks.

ifleaksoccur,followthePressure

ReliefProcedure”inthismanualbeforetighteningany

fittingsorhoses

15.Followthe “PressureReliefProcedure”inthismanual

beforechangingfromsolventtopaint.

Triggerlock

inlockedposition

WARNING

Besuretofollowthepressurereliefprocedurewhen

shuttingtheunitdownforanypurpose,including

servicingoradjustinganypartofthespraysystem,

changingorcleaningapraytips,orpreparingforcleanup.

Painting

1.Placethesuctiontubeintoacontainerofpaint.

2.Placethereturnhoseintoametalwastecontainer.

3.Setthepressuretominimumbyturningthepressure

controlknobtotheMinsettinginthelowpressurespray.

4.MovethePRIME/SPRAYvalvedowntothePRIME

position.

5.TurntheunitonbymovingtheON/OFswitchtotheON

position.

6.Allowthesprayertorununtilpaintiscomingthroughthe

returnhoseintothemetalwastecontainer.

7.TurntheunitoffbymovingtheON/OFFswitchtotheOFF

position.

8.Removethereturnhosefromthewastecontainerand

placeitinitsoperatingpositionabovethecontainerofpaint

9.MovethePRIME/SPRAYvalveuptotheSprayposition.

10.Turntheuniton

11.Unlockthegunbyturningtheguntriggerlocktothe

unlockedposition

WARNING

Groundthegunbyholdingitagainstthe

edgeofthemetalcontainerwhileflushing.

Failuretodosomayleadtoastatic

electronicdischarge,whichmaycauseafire.

12.Triggerthegunintothemetalwaste

containeruntilallairandsolventis

flushedfromthesprayhoseandpaintisflowingfreely

fromthegun.

13.Lockthegunbyturningthegun

triggerlocktothelockedposition.

14.Turntheunitoff.

15.Attachtipguardandtiptothegun

asinstructedbythetipguardortip

manuals.

Triggerlock

inlockedposition

WARNING

POSSIBLEINJECTIONHAZARD.Donotspraywithoutthe

tipguardinplace.Nevertriggerthegununlessthetipis

ineitherthesprayortheunclogposition.Alwaysengage

theguntriggerlockbeforeremoving,replacingor

cleaningtip.

16.Turntheuniton

17.Increasethepressurebyturningthepressurecontrol

knobslowlyclockwisetowardthehighpressuresprayand

testthespraypatternonapieceofcardboard.Ajust

thepressurecontrolknobuntilthesprayfromthegunis

completelyatomized.Trytokeepthepressurecontrol

knobatthelowestsettingthatmaintainsgood

atomization.

Note:Turningthepressureuphigherthenneededto

atomizethepaintwillcauseprematuretipwear

andadditionaloverspray

5.

PressureReliefProcedure

WARNING

Besuretofollowthepressurereliefprocedurewhen

shuttingtheunitdownforanypurpose,including

servicingoradjustinganypartofthespraysystem,

changingorcleaningspraytips,orpreparingforcleanup.

1.Lockthegunbyturningthegun

triggerlocktothelockposition.

2.Turntheunitoffbymovingthe

ON/OFFswitchtotheOFFposition.

3.Turnthepressurecontrolknob

counterclockwisetoitsOFFposition

4.Unlockthegunbyturningthegun

triggerlocktotheunlockedposition

5.Holdthemetalpartofthegunfirmlyto

thesideofametalcontainertoground

thegunandavoidabuildupofstatic

electricity.

6.Triggertheguntoremoveany

pressurethatmaystillbeinthehose

7.Lockthegunbyturningtheguntriggerlocktothelocked

position.

8.MovethePRIME/SPRAYvalvedowntothePRIME

position.

Triggerlock

inlockedposition

Spraying WARNING

POSSIBLEINJECTIONHAZARD.Donotspraywithoutthe

tipguardinplace.Nevertriggerthegununlessthetipis

ineitherthesprayortheunclogpostion,Alwaysengage

theguntriggerlockbeforeremoving,replacing,or

cleaningtip.

SprayingTechnique

Thefollowingtechniques,iffollowed,willassureprofessional

paintingresults.

Holdthegunperpendiculartothesurfaceandalwaysatequal

distancefromthesurface.Dependingonthetypeofmaterial,

surface,ordesiredspraypattern,thegunshouldbeheldata

distanceof30to50cm(12to14inches)

Movetheguneitheracrossorupanddownthesurfaceata

steadyrate.Movingthegunataconsistantspeedconserves

materialandprovidesevencoverage.Thecorrectsprayingspeed

allowsafull,wetcoatofpainttobeappliedwithoutrunsorsags.

Holdingthegunclosertothesurfacedepositsmorepainton

thesurfaceandproducesanarrowspraypatern..Holding

thegunfartherfromthesurfaceproducesathinnercoatand

widespraypattern.Ifruns,sags,orexcessivepaintoccur,

changetoaspraytipwithasmallerorifice.Ifthereisan

insufficientamountofpaintonthesurfaceoryoudesireto

sprayfaster,alargerorificetipshouldbeselected.

Maintainuniformspraystrokeaction,Sprayalternatelyfrom

lefttorightandrighttoleft.Beginmovementofthegunbefore

thetriggerispulled.

Avoidarcingorholdingthegunatanangle,Thiswillresultin

anunevenfinish.

Start

stroke

Pull

trigger

Release

trigger

End

stroke

Offspray

Toothick

Arcing Gunatangle

Properlapping(overlapofspraypattern)isessentialtoan

evenfinish.Lapeachstroke.Ifyouaresprayinghorizontally,

aimatthebottomedgeoftheprecedingstroke,soastolap

thepreviouspatternby50%.

Overlapedges

1st

pass 2st

pass 3st

pass 4st

pass 5st

pass

Forcornersandedges,splitthe

centerofthespraypatternonthe

corneroredgeandspray

verticallysothatbothadjoing

sectionsreceiveapproximately

evenamountsofpaint.

Whensprayingwithashield,holditfirmlyagainstthesurface.

Anglethespraygunslightlyawayfromtheshieldandtoward

thesurfaceThiswillpreventpaintfrombeingforcedunderneath.

Shrubsnexttohousedshouldbetiedbackandcoveredwitha

canvascloth.Theclothshouldberemovedassoonaspossible.

ourgunextensionsareextremelyhelpfulinthesesituations.

Nearbyobjectssuchasautomobiles,outdoorfurniture,etc.

shouldbemovedorcoveredwheneverinthevicinityofa

sprayjob.Becarefulofanyothersurroundingobjectsthat

couldbedamagedbyoverspray.

6.

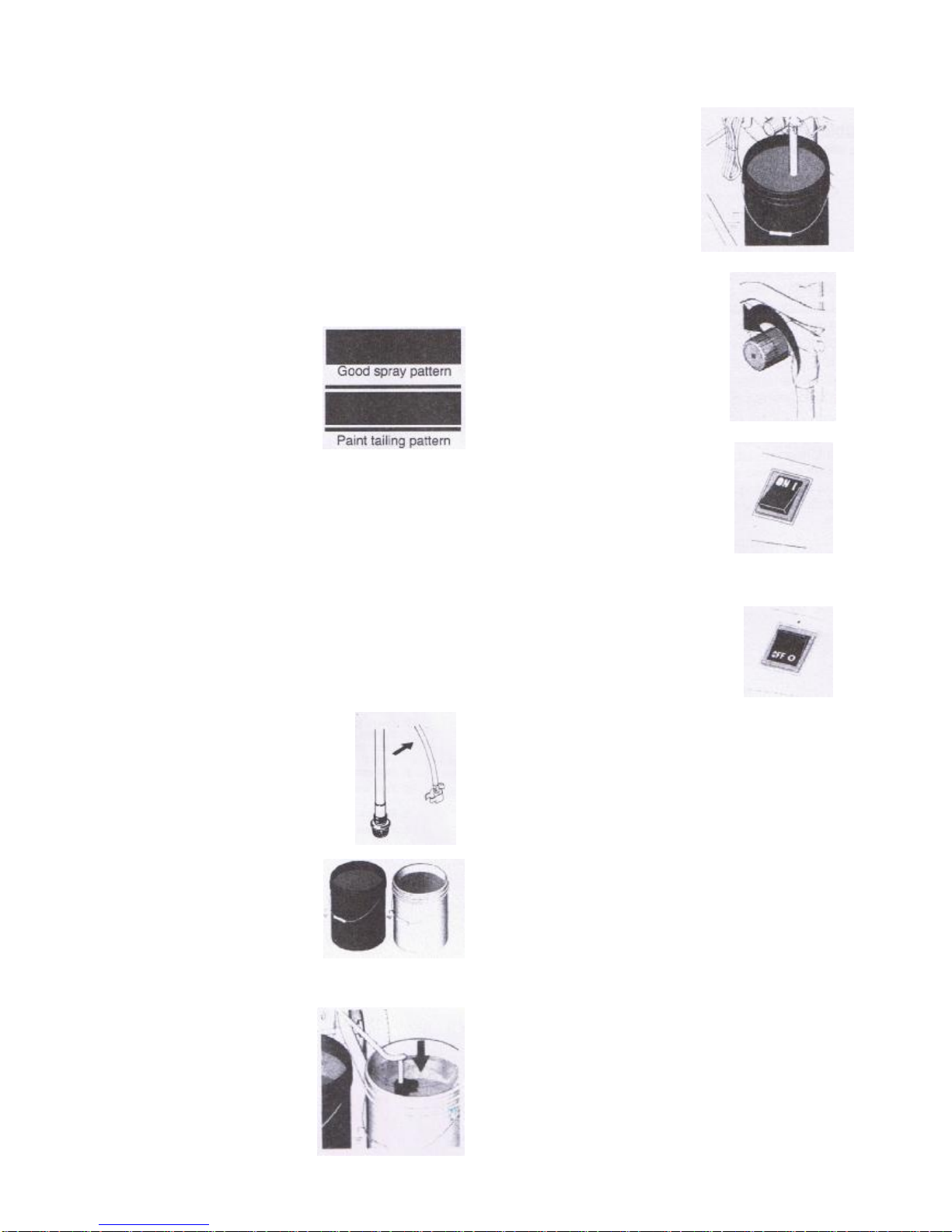

PRACTICE

1.Besurethatthepainthoseisfreeofkindsandclearof

objectswithsharpcuttingedges.

2.Turnthepressurecontrolknobcounterclockwisetoitsto

itslowestsetting.

3.TurnthePRIME/SPRAYvalveuptoitsSPRAYposition.

4.Turnthepressurecontrolknobclockwisetoitshighest

setting.Thepainthoseshouldstiffenaspaintbeginsto

flowthroughit.

5.Unlocktheguntriggerlock.

6.Triggerthesprayguntobleedairoutofthehose.

7.Whenpaintreachesthespraytip,sprayatestareato

checkthespraypattern.

Usethelowestpressuresetting

necessarytogetagoodspray

pattern,Ifthepressureissettoo

high,thespraypatternwillbetoo

light.Ifthepressureissettoo

low,tailingwillappearorthe

paintwillspatteroutingobs

ratherthaninafinespray.

ShutdownandCleaning

11.TurnpowerswitchOFF.

1.PressureControlKnobsSettings

2.Removetipandguardassemblyfromgunand

placeinflushingfluid.

3.Liftsuctiontubeandprimetubefrompaintpail

Letthemdrainintopaintpailforawhile.

4.Separateprimetube(smaller)

fromsuctiontube(larger)

5.Placeemptywasteand

waterorsolventpails

sidebyside.

6.Placeprimetubeinwaste

pail.

7.Submergesuctiontubein

waterorflushingsolvent.

8.Turnpressurecontrolknobto

thePRIME/CLEANsetting.

9.TurnthepowerswitchON.

10.Flushuntilapproximately1/3oftheflushing

fluidisemptiedfromthepail.

Whenstoringthepaintstationfor16hoursormore,a

thoroughcleaningisrecommended:

1.shutdownpaintsprayer

2.thoroughlycleanpaintsprayerandstationaccording

instruction;

3.besurethatmachineandtubesareclearanywateror

fluidasthesemayfreeze;

4.Coilhighpressurehoseandstoreonbackoftoolwith

hookandloopstraps;

5.Storefiltersprayinggun,andsprayerinplasticbag

andseal;

7.

Troubleshooting

Problem Cause Solution

Theunitwillnotrun

1.Theunitisnotpluggedin

2.Trippedbreaker

3.Thepressureissettoolow(pressure

controlknobsetatminimumsetting

doesnotsupplypowertounit)

4.Faultyorloosewiring.

5.Excessivemotortemperature.

6.ON/OFFswitchisdefective.

1.Plugtheunitin

2.Resetthebreaker.

3.Turnthepressurecontrolknob

clockwisetsupplypowertotheunit

andincreasethepressuresetting.

4.Inspectortaketoaauthorizedservice

center.

5.Allowmotortocool.

6.ReplacetheON/OFFswitch.

Theunitwillnotprime.

1.ThePRIME/SPRAYvalveisinthe

SPRAYposition

2.Airleakinthepositiontube/suctionset.

3.Thesiphontubefilterand/orinlet

screenisclogged.

4.Thesiphontube/suctionsetisclogged.

1.RotatethePRIME/SPRAYvalve

clockwisetothePRIMEposition.

2.Checkthesiphontube/suctionset.

Connectionandtightenorre-tape

theconnectionwithTeflontape.

3.Removetheinletscreenandclean.

Removethesiphontube/suctionset

andclearn.

Theunitwillnotbuildor

maintainpressure

1.Thespraytipisworn.

2.theSpraytipistoolarge

3.Thepressurecontrolknobisnotset

properly

4.Thepumpfilter,gunfilter,orinlet

screenisclogged.

5.Materialflowsformthereturnhose

whenthePRIME/SPRAYvalveisin

theSPRAYposition.

6.Thereisexternalfluidleak.

7.Airleakinthesiphontube/suction

set.

8.Thereisaninternalfluidsectionleak

(packingsarewornand/ordirty,valve

ballsareworn).

9.Wornvalveseats.

10.Motorpowerbutfailstorotate.

1.Replacethespraytipfollowingthe

instructionthatcamewiththespray

gun.

2.Replacethespraytipwithatipthat

hasasmallerorficefollowingthe

instructionsthatcamewiththespray

gun.

3.Turnthepressurecontrolknob

clockwisetoincreasethepressure

setting.

4.Removethepumpfilterselement

andclean.Removethegunfilterand

clean.Removetheinletscreenand

clean.

5.CleanorreplacethePRIME/SPRAY

valve.

6.Checkthesiphontube/suctionset

connectionandtightenorre-tapethe

conncetionwithTeflonTape.

7.Checkforexternalleaksatall

connections.Tightenconnections,

ifnecessary.

8.Cleanthevalvesandservicethe

fluidsection.

9.Reverseorreplancethevalveseats.

10.Takeunittoauthorizedservice

center.

Fluidleakageattheupper

endofthefluidsection. 1.Theupperpackingsareworn.

2.Thepistonrodisworn. 1.Repackthepumpfollowingthis

manual.

2.Replacethepistonrod.

8.

Troubleshooting

Problem Cause Solution

Excessivesurgeatthe

spraygun. 1.Wrongtypeofairlesssprayhose.

2.TheSpraytipwornortoolarge.

3.Excessivepressure.

1.Replacehosewithaminimumof5m

(50”)X10mm(1/4”)groundtextiled

braidairlesspaintsprayhose.

2.Replacethespraytipfollowingthe

instructionsthatcamewiththespray

gun.

3.Rotatethepressurecontrolknob

counterclockwisetodecreasespray

pressure.

Poorspraypattern. 1.Thespraytipistoolargeforthe

materialbeingused.

2.Incorrectpressuresetting.

3.Thematerialbeingsprayedistoo

viscous.

1.Replacethespraytipwithanewor

smallerspraytipfollingtheinstructions

thatcamewiththespraygun.

2.Rotatethepressurecontrolknobto

adjustthepressureforaproperspray

patter.

3.Addsolventtothematerialaccording

tothemanufacturesrecommendations.

Theunitlackspower.

1.Thepressureadjustmentistoolow.

2.Impropervoltagesupply.

1.Rotatethepressurecontrolknob

clockwisetoincreasethepressure

setting.

2.Connecttheinputvoltagetotheproper

voltagefortheunit.

9.

10.

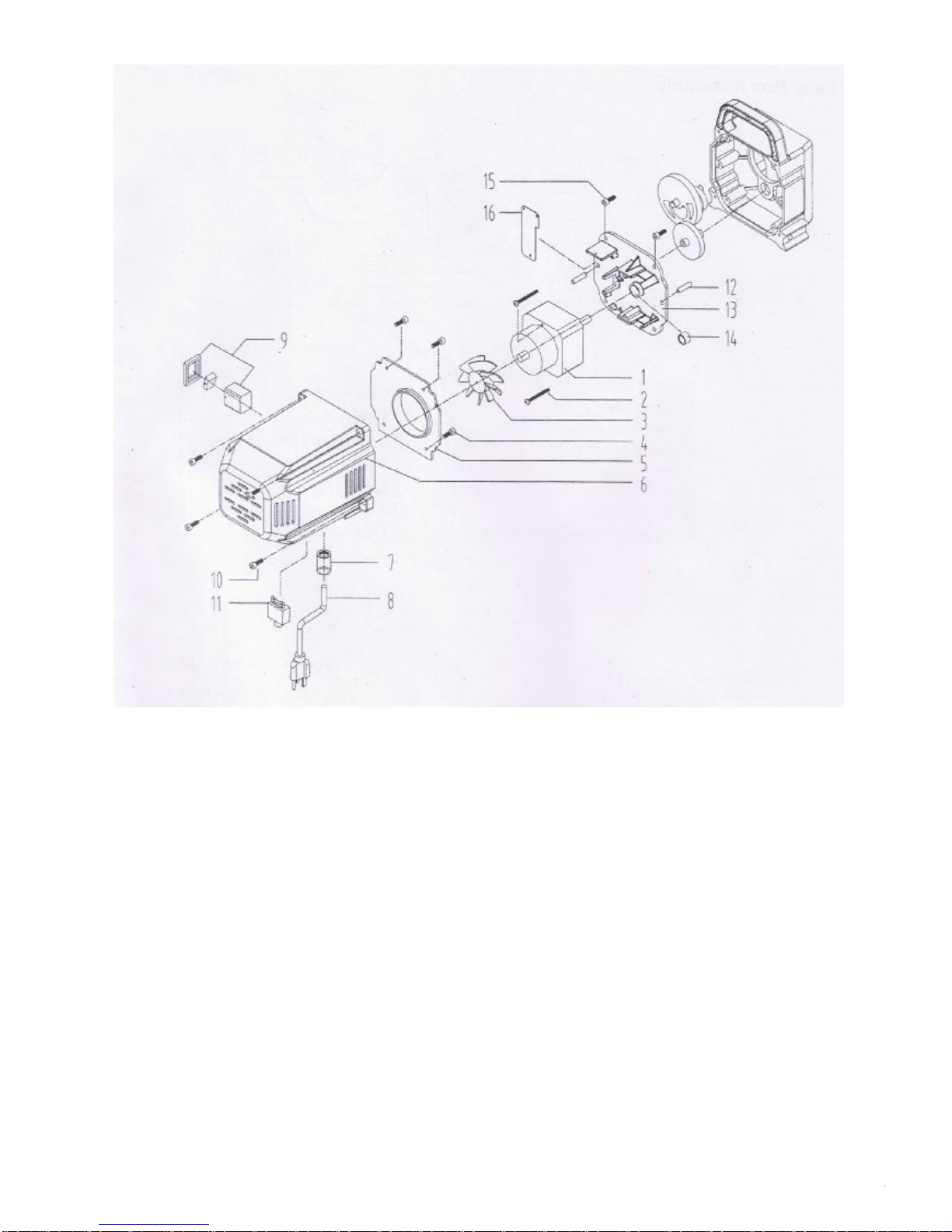

1.Motor.....................................

2.Screw....................................

3.Motorfan...............................

4.Screw....................................

5.Gasket..................................

6.Motorcoverlabels..................

7.Strainrelief............................

8.Powercord............................

MotorAssembly

MotorAssembly

9.ON/OFFswitch.......................

10.Screw....................................

11.Circuitbreaker........................

12.Pin........................................

13.Motorholder...........................

14.Couperoring..........................

15.Screw....................................

16.Electricmainboard.................

1

2

1

4

1

1

1

1

1

4

1

2

1

1

4

1

11.

GearBoxAssembly

GearBoxAssembly

1.Coverlaber..............................

2.Screw......................................

3.Frontcoverw/label...................

4.Rod.........................................

5.Rodcoupero-ring.....................

6.Pumphousing..........................

7.Crankshaft/gearassembly.........

........................

..............................

..................

................................

.......................

................................

........................

8.Gearwrap

9.Wrap

10.2ndstagegear

11.Pin

12.Gearwrap

13.Pin

14.Gearwrap

1

1

1

1

2

2

1

1

8

1

1

1

1

1

5

3

1

2

4

SuctionSetAssembly

SuctionSetAssembly

1.Returntubeassembly..............

2.RetainingClip.........................

3.Siphonhose...........................

4.Inletscreen............................

5.Clip........................................

1

1

1

1

1

StandAssembly

1.Leg........................................

2.Screw....................................

3.Cordwrap..............................

4.Nut........................................

5.Materwasher..........................

6.Dripcup.................................

7.Dripcup2...............................

StandAssembly

2

2

2

2

2

2

2

321

4

56

7

12.

FluidSectionAssembly

FluidSectionAssembly

1.Fluidsection..........................

2.Piston...................................

3.PistonwrapA.........................

4.O-ring...................................

5.PistonwrapB.........................

6.O-ring...................................

7.O-ring...................................

8.Lvasher.................................

9.Alloyslice..............................

10.Ball.......................................

1

1

1

1

1

1

1

1

1

1

11.Rocl.......................................

12.Spring....................................

13.Coupler..................................

14.O-ring....................................

15.Cover.....................................

16.O-ring....................................

17.Pressurerocl..........................

18.O-ring....................................

19.Switch....................................

20.Plasticcover...........................

1

1

1

1

1

2

1

1

1

1

13.

22.Coupler……………..........…..

23.Spring………………………….

24.HolderHNeedle……………...

25.Shell…………………………….

26.Spring…………………………..

27.Ball……………………………...

28.AllgSlice……………………….

29.O-ring……………………....….

30.Connector……………………..

31.O-ring,Viton…………………..

32.O-ring,Teflon………………….

33.Gasket………………………….

34.ValveHousing………………...

35.ValveStem………………….....

36.Spring…………………….…….

37.ValveRetainer………………...

38.Cambase……………………...

39.ValveHandle……………….….

40.Pin……………………………….

41.GroovePin………………….….

42.Fitting……………………….…..

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

NOTE:WhenUsing “HOT”solvents,replaceViton

O-ring(item32)withoptionalTeflono-ring

installwitho-ringtool

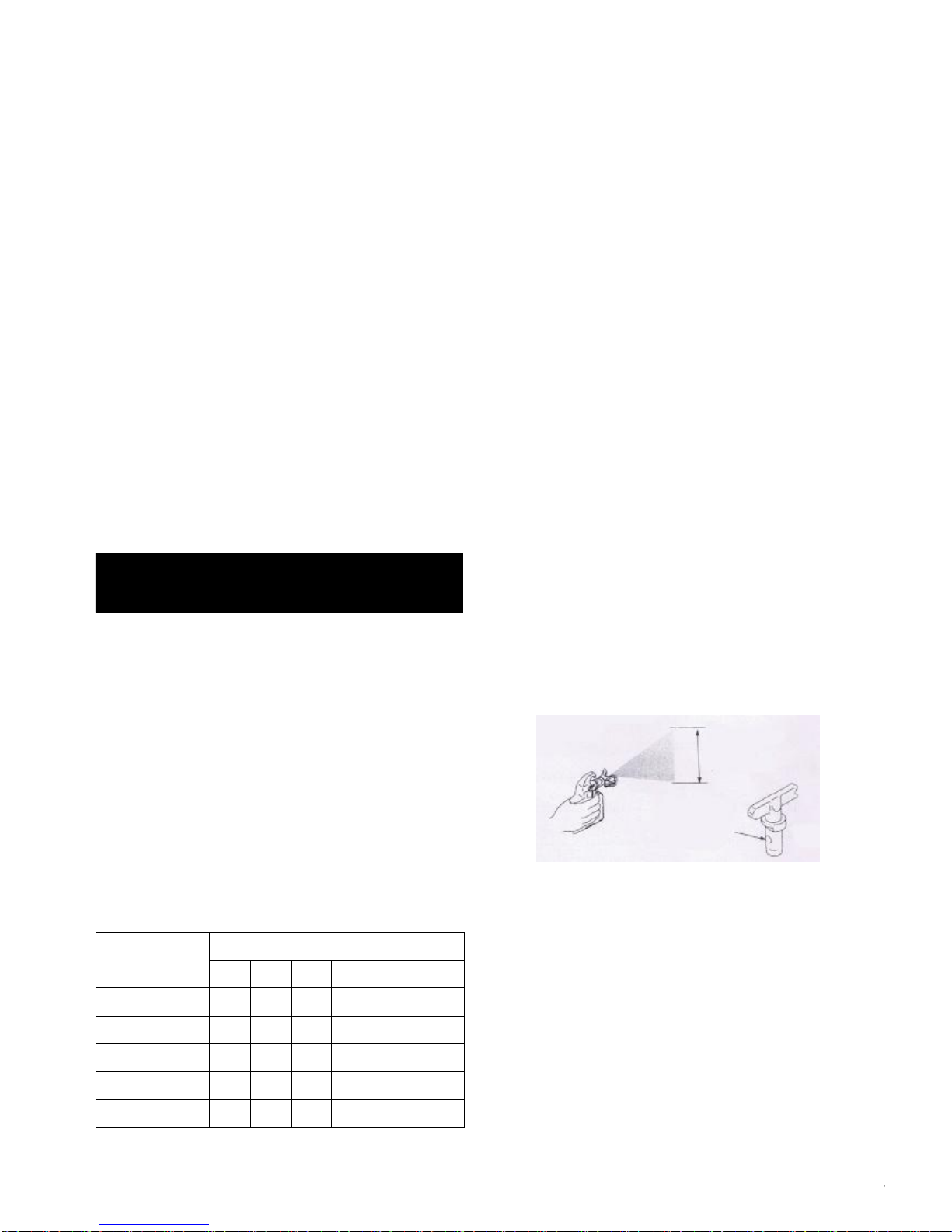

TipSelection

SelectingTipHoleSize

ReversibletipSelectionChart

Tipscomeinavarietyofholesizesforsprayinga

rangeoffluids.Yoursprayerincludesan0.015in

(0.38mm)tipforuseinmostsprayingapplications.

Usethefollowingtabletodeterminetherangeof

recommendedtipholesizesforeachfluidtype.If

youneedatipotherthantheonesupplied,seethe

onpage15.

HINTS:

Asyouspray,thetipwearsandenlarges,Starting

withatipholesizesmallerthanthemaximum

willallowyoutospraywithintheratedflow

capacityofthesprayer.

Maximumtipholesizessupportedbythesprayer.

0.015om(0.38mm)

TipHoleSize

0.011in.(0.28mm)

0.013in.(0.33mm)

0.015in.(0.38mm)

0.017in.(0.43mm)

0.019in.(0.48mm)

Coatings

Stains

Enamels

Primers

InteriorPaints

ExteriorPaints

√

√√

√

√

√

√

√

√

√

√

√

√

ChoosingTheCorrectTip

ConsiderCoatingandSurfacetobeSprayed.Make

sureyouusebesttipholesizeforthatcoatingand

bestfanwidthforthatsurface.

TipHoleSize

Tipholesizecontrolsflowratetheamountof

paintthatcomesoutofthegun.

HINTS:

Uselargetipholesizewiththickercoatings

andsmallertipholesizeswiththinnercoatings.

Maximumtipholesizessupportedbysprayer:

0.015in.(0.38mm)

Tipwearwithuseandneedperiodicreplace-ment.

Fanwidthisthesizeofthespraypattern,which

determinestheareacoveredwitheachstroke.

Narrowerfansdeliverathickercoat,andwiderfans

deliverathinnercoat.

FanWidth:

HINTS:

Selectafanwidthbestsuitedtothesurfacebeing

sprayed.

Widerfansallowprovidebettercoverageon

broad,opensurfaces.

Narrowerfansprovidebettercontrolonsmall,

confinedsurfaces.

UnderstandingTipNumber

TheLastThreedigitsoftipnumber(i.e.:221413)

Containinformationaboutholesizeandfanwidth

onsurfacewhengunisheld12in.(30.5cm)from

surfacebeingsprayed.

Firstdigitwhendoubled

=approximate

fanwidth 413tiphas

8-10in.

Fanwith

413tiphas

a0.013in

holesize

Lasttwodigits=tipholesizeinthousandsofaninch

14.

ReversibleTipSelectionChart

TipPartNo:

FanWidth12in

(305mm)from

surface

HoleSize

Alt311 6-8in.

(152-203mm) 0.011in.

(0.28mm)

Alt411 8-10in.

(203-254mm) 0.011in.

(0.28mm)

Alt313 6-8in.

(152-203mm) 0.013in.

(0.33mm)

Alt413 8-10in.

(203-254mm) 0.013in.

(0.33mm)

Alt415 8-10in.

(203-254mm) 0.015in.

(0.38mm)

Alt515 10-12in.

(254-305mm) 0.015in.

(0.38mm)

Alt417 8-10in.

(203-254mm) 0.017in.

(0.43mm)

Alt517 10-12in.

(254-305mm) 0.017in.

(0.43mm)

Alt519 12-14in.

(305-356mm) 0.019in.

(0.48mm)

Example:

Foran8to10in.(203to254mm)fan

widthand0.013(0.38mm)holesize,orderPart

No.alt413

SpeciallyFormulatedtopreventmaterials

fromadheringtothepistonrod,which

becomeabrasivetotheupperseals.

Pistonlubewillbreakdownanymaterial

thatmayaccumulateintheoilcupand

keepitfromdrying.

PistonLube

Part#Description

Alm-481.............4ouncebottle

Miscellaneous

PartNo.Description

Alm-012........Hosecoupling,1/4”x1/4”

Alm-397........HighPressureFl.Gauge

Alm-171........Lubriplate,14ounceindividual

Alm-172........Lubriplate,6lb.Can

Alm-1037......Electrostaticdischarge

(ESD)wriststrap

15.

Table of contents

Other Ningbo Dino-power Machinery Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

SAMES KREMLIN

SAMES KREMLIN SRV 028-2-TWIN 60 instruction manual

Westfalia

Westfalia 80 22 77 instruction manual

WAGNER

WAGNER WoodPerfect W 600 Original operating instructions

WALTHER PILOT

WALTHER PILOT PILOT Misch-Automatik operating instructions

Toro

Toro 41178 Multi-Pro 1200 Operator's manual

WAGNER

WAGNER FLEXIO 2500 owner's manual