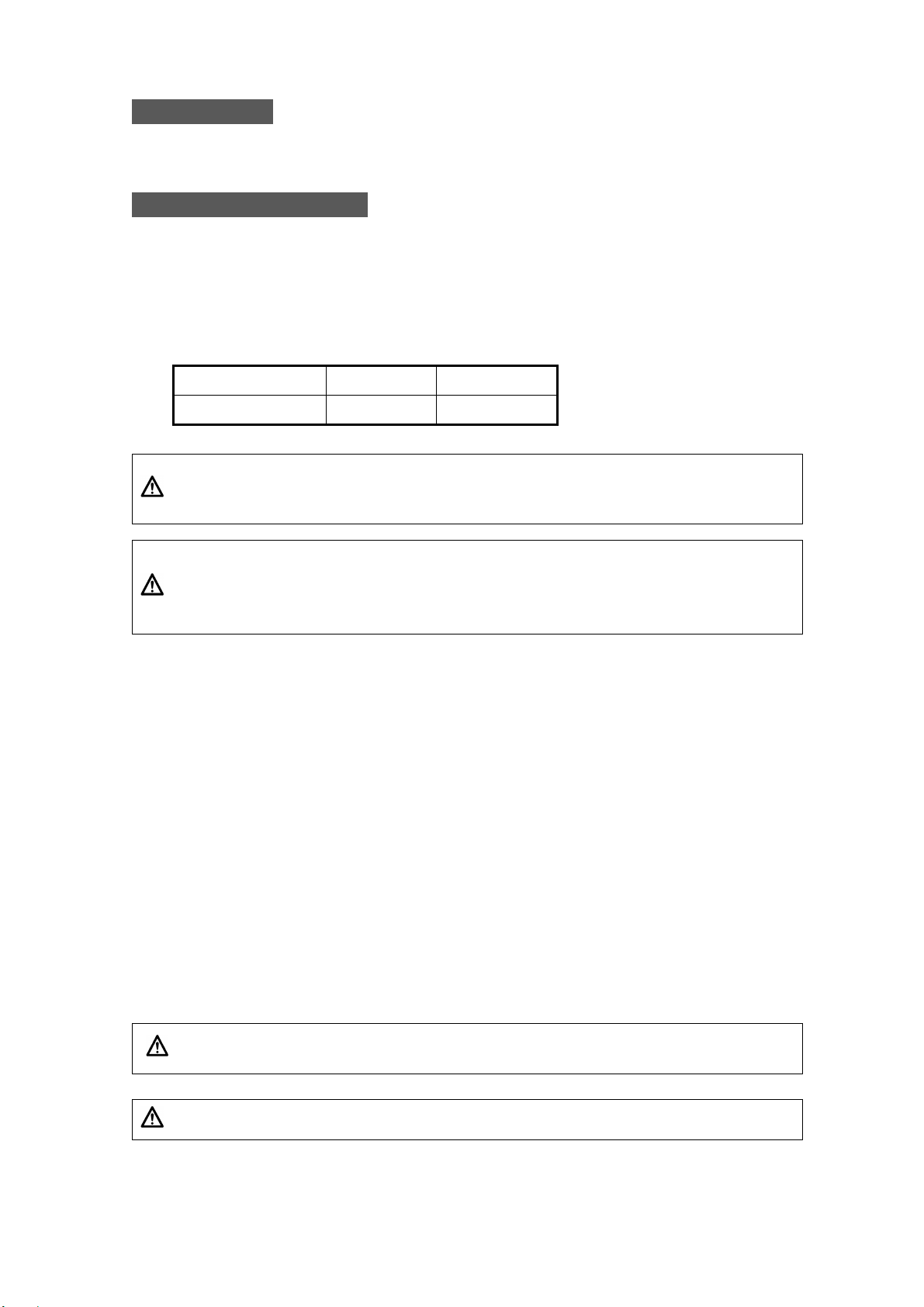

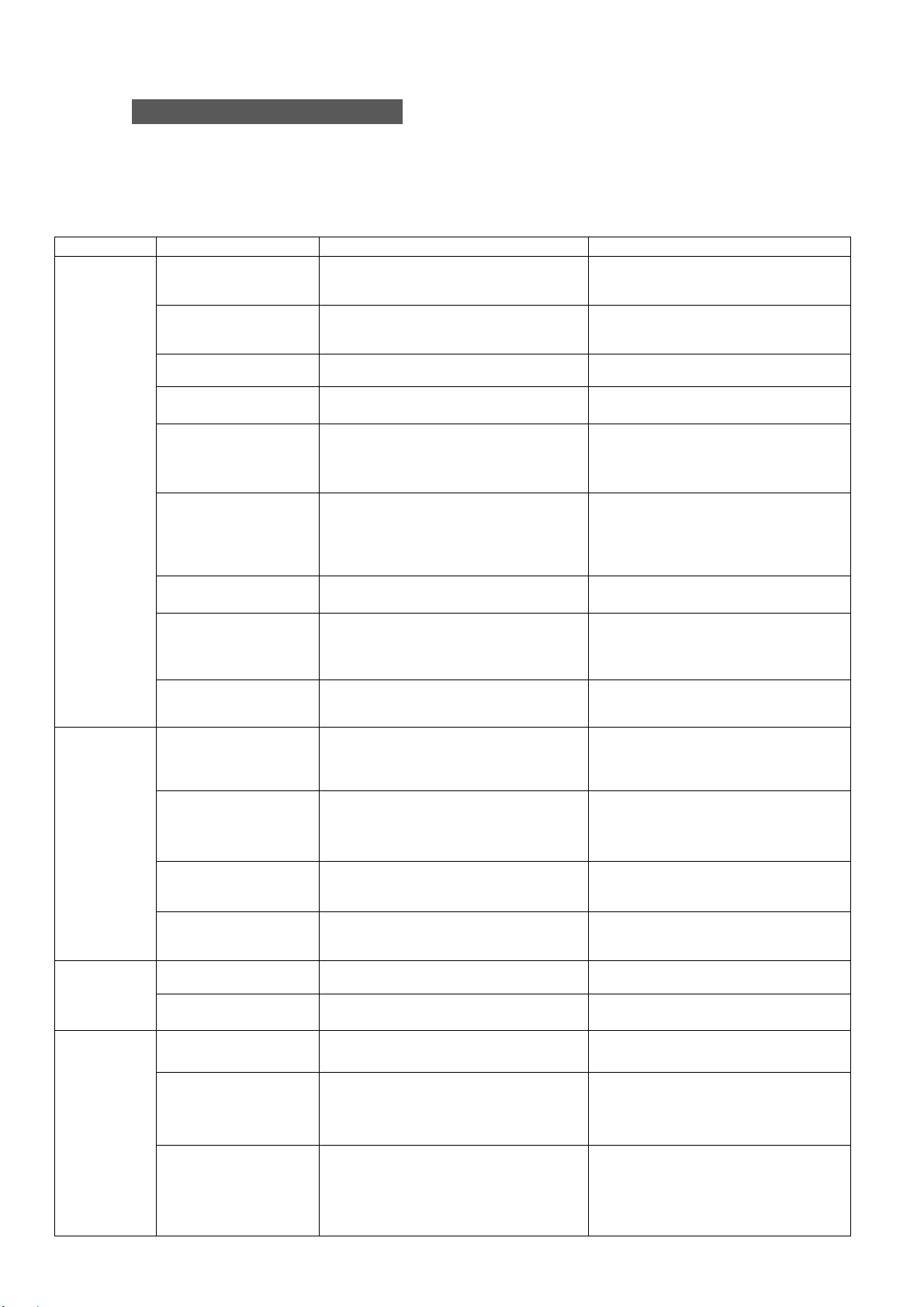

18

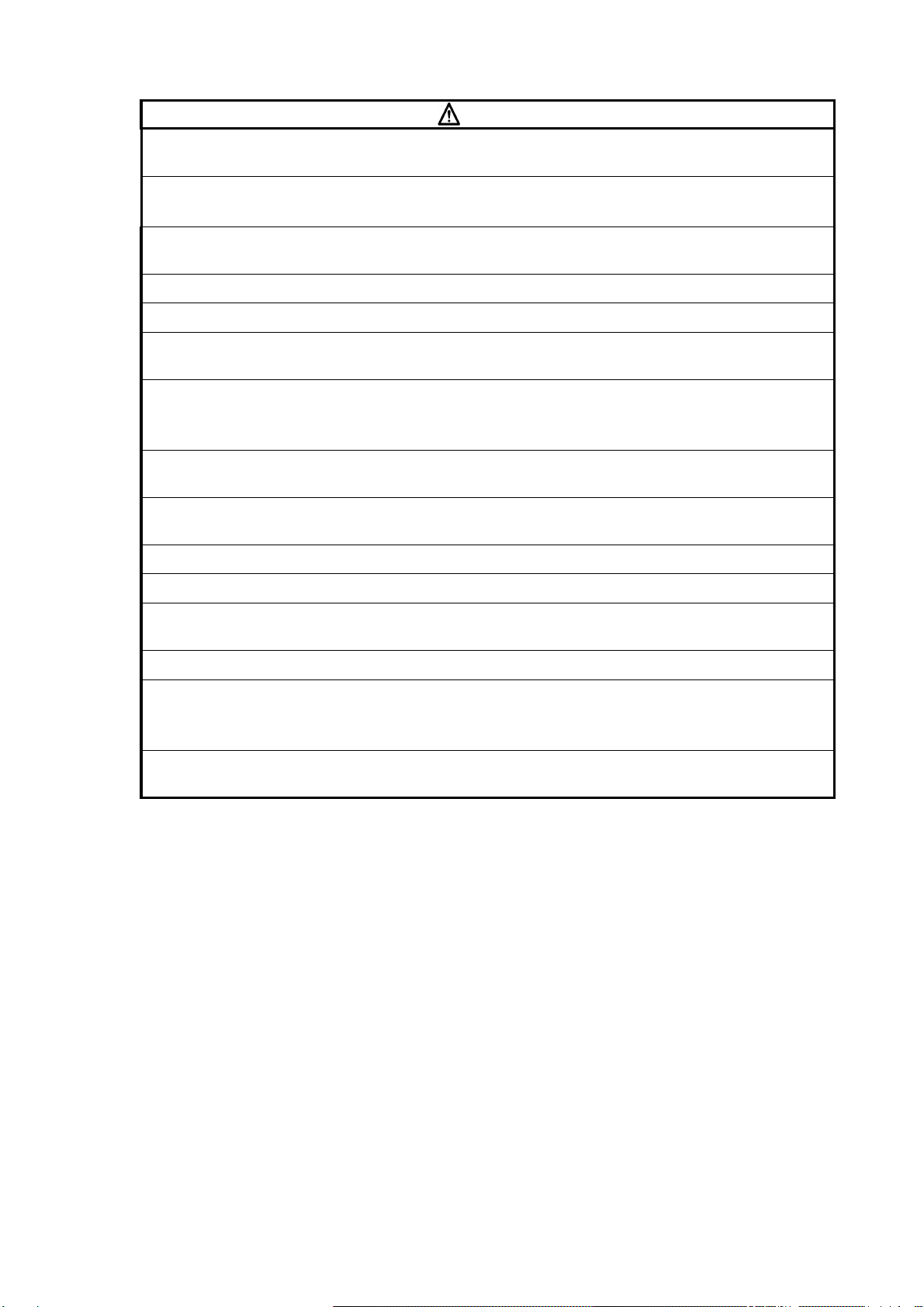

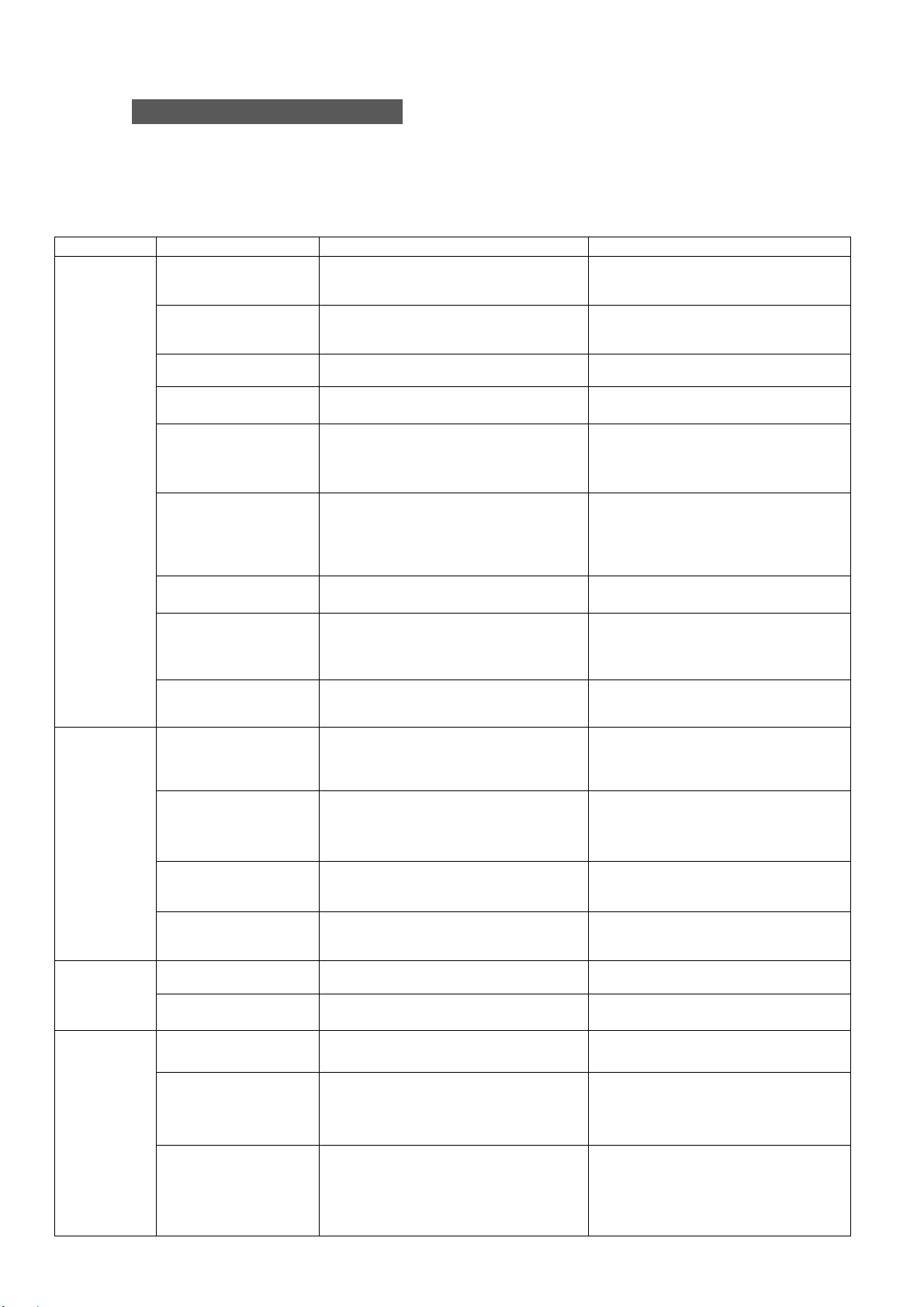

Troubleshooting Guide

If you experience no oil discharge, a high-pitched sound, or such other abnormal

phenomena soon after the installation, check the troubleshooting chart in the table

that follows.

If you cannot find out the cause of trouble, consult us or a dealer.

Table 4: Pump Troubleshooting Chart

No

discharge

from outlet

port.

Insufficient

flow or

pressure.

Abnormal

noise.

Motor failure.

Are wires at motor loose or

disconnected? Do operation test for

motor individually.

・Repair or replace pump.

Motor is wired

incorrectly or

disconnected.

Are wires at motor loose or

disconnected? Check direction of

rotation.

・Rewire motor in a correct rotation

indicated on label.

Coupling is damaged. Check connected area between pump

and motor.

・Replace coupling.

Liquid surface level

decreases.

Check liquid amount in tank.

・Refill tank with enough liquid.

・Control liquid level with level sensor.

Inlet port is clogged. Check the inlet port for clogging.

・Periodical cleaning on and

around inlet port.

・Insert a plate filter prior to the inlet

port as a pre-filtration.

Air drawn into pump

or pipes.

・On the first-run, after long term

storage or immediately after replacing

coolant

liquid, pump often doesn’t discharge

due to the trapped air.

・Perform air-bleeding on pump

or piping. Perform air-bleeding

in front of check valve if the one

is installed in outlet line.

Clogging or failure of

impellers. ・Check the impellers for clogging or

damage.

・Remove accumulated swarf.

・Repair or replace pump.

Aeration. ・Is pump sucking foam or air?

・Take measures to prevent suction

of air or tramp oil.

(ex. Change pump location, use

partition or defoamer )

Pipes connected to

outlet port is too

large.

Is outlet discharge flow rate sufficient?

・Use smaller pipes.

No

discharge

from

contaminant

drain port

Contaminant drain

port piping is too long

or

too high.

Pull off a pipe from the contaminant

drain port and check if liquid is being

delivered properly or not.

Piping must be no higher than

1 m from the tank bottom vertically,

and no longer than 3 m horizontally

.

Clogging of

contaminant drain

port.

Check inside the pipe for clogging. ・Clean inside the pipe periodically.

・Minimize the number of bends in

your pipe layout.

・Use larger pipe.

Clogging inside the

cyclone Check inside the cyclone for clogging. ・Remove swarf.

・Repair or replace pump.

Clogging or failure of

impellers. Check the impellers for clogging or

damage.

・Remove swarf.

・Repair or replace pump.

Liquid

leaks. Oil seal deterioration

or damage. Does liquid leak from drain

port (Rc 1/4)? Repair seal.

Repair or replace pump.

gasket deterioration

or damage. Does liquid leak from connected area? Repair or replace pump.

Breaker or

thermal

trips out.

・Motor failure.

・Wiring errors. ・Check motor wiring.

・Does motor start? ・Rewire motor.

・Repair or replace motor.

Overloading. Are motor output rating and coolant

viscosity adequate? ・Use motor with higher output rating.

・Use pump with lower capacity.

・Lower the pressure setting.

・Change the coolant types.

Coolant type is

incompatible.

(Viscosity is too high,

lubricity insufficient,

Pump failure)

・Is motor rotating?

・Are liquid viscosity and lubricity

adequate?

・Is there abnormal noise?

・Repair or replace pump.

・Change the types of coolant you use.