Nippon Oil Pump YTH Wire Mesh Bucket 135A User manual

Other Nippon Oil Pump Water Pump manuals

Popular Water Pump manuals by other brands

Wilden

Wilden PX820 user manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 06B3-B Installation, operation, and maintenance manual with parts list

Xylem

Xylem Lowara MP Installation, operation and maintenance instructions

SFA

SFA SANICOM 1 Operating & installation manual

Grundfos

Grundfos DMS 2 Installation and operating instructions

Wilo

Wilo Multivert MVISE-3G Installation and operating instructions

KMT

KMT STREAMLINE SL-IV PLUS Operation and service manual

Xylem

Xylem Bell & Gossett WEHT0311M Installation, operation and maintenance instructions

Xylem

Xylem e-1532 Series instruction manual

Samoa

Samoa LARIUS DALI' Operating and maintenance instructions

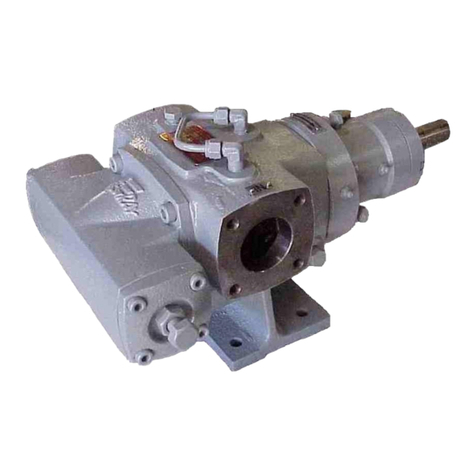

Ebsray

Ebsray E Series Installation, operation & maintenance instructions

CET

CET PFP-20HP-HND-1D Instruction handbook