1

E

EE

E-

--

-

Series E

Series ESeries E

Series ES

SS

S

User’s Instruction Manual

User’s Instruction Manual User’s Instruction Manual

User’s Instruction Manual

<

<<

<Contents

ContentsContents

Contents>

>>

>

For Safe Operation

For Safe OperationFor Safe Operation

For Safe Operation

................................

................................................................

................................................................

................................................................

................................................................

................................................................

.................................................

..................................

.................

2

22

2

Safety Precautions

Safety PrecautionsSafety Precautions

Safety Precautions

................................

................................................................

................................................................

................................................................

................................................................

................................................................

..................................................

....................................

..................

5

55

5

●Safety Equipment .................................................................................................................. 5

●Safety Measures .................................................................................................................... 5

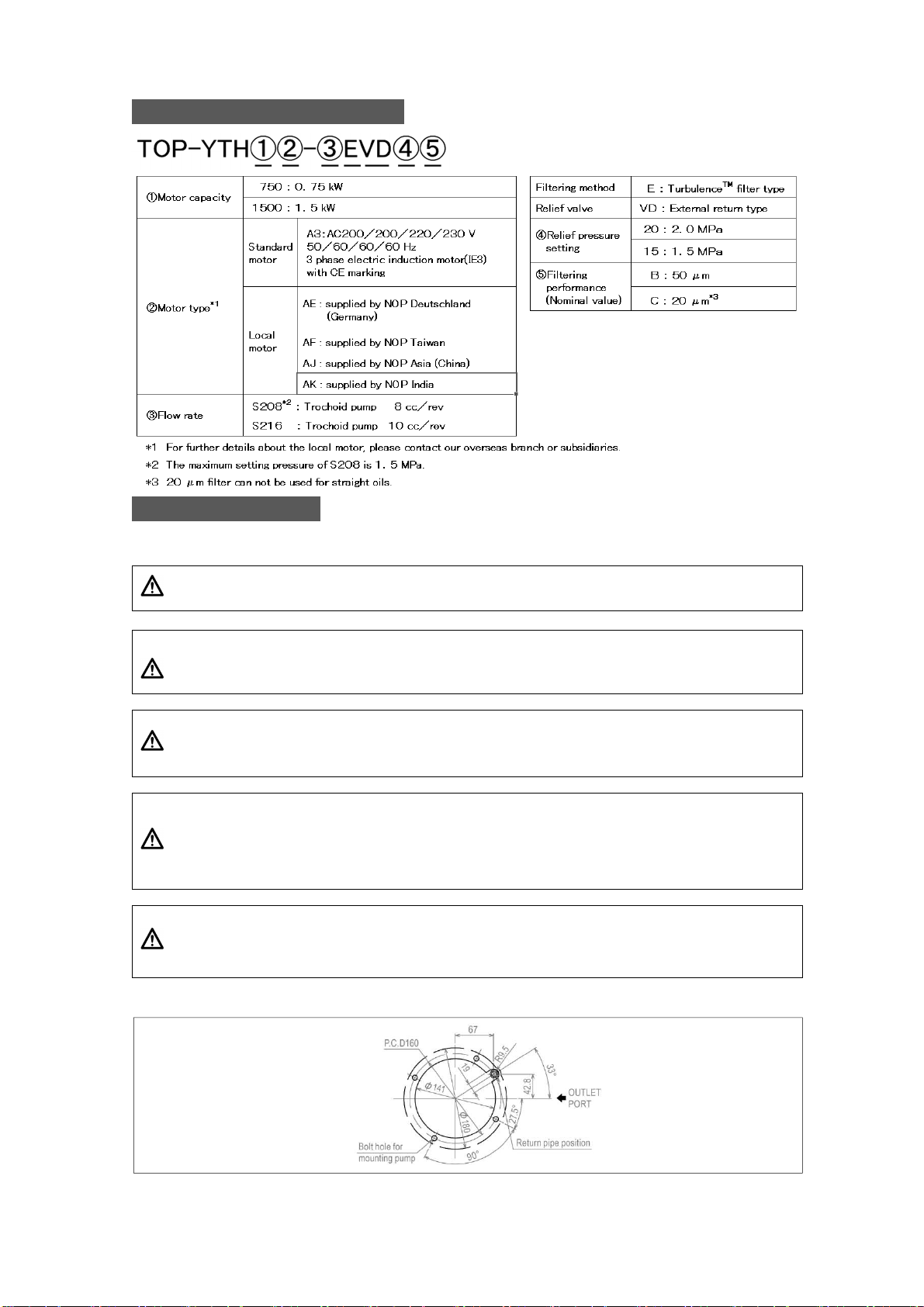

Model Numbering Sy

Model Numbering SyModel Numbering Sy

Model Numbering System

stemstem

stem

................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................

..............

.......

6

66

6

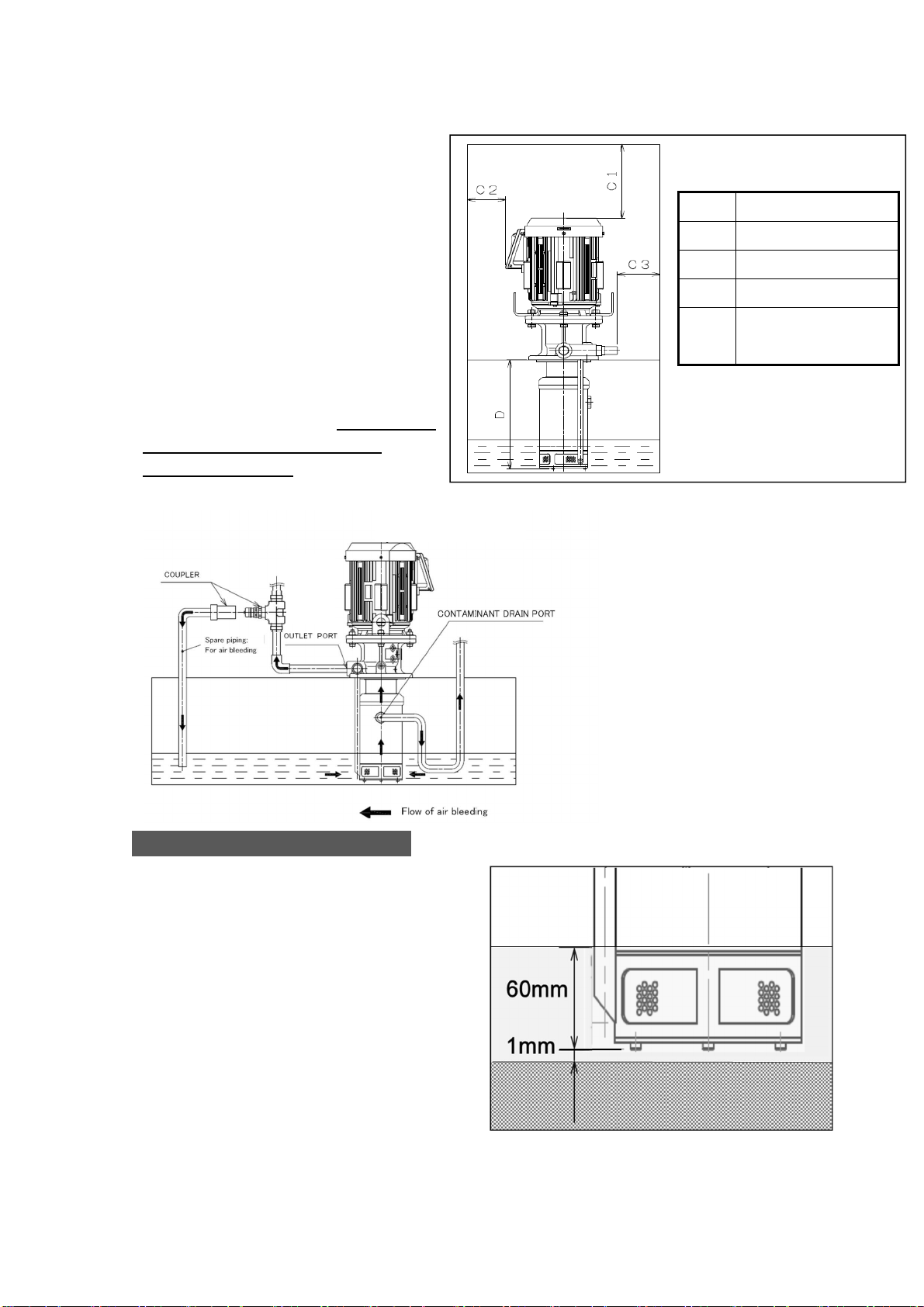

Pump Installation

Pump InstallationPump Installation

Pump Installation

................................

................................................................

................................................................

................................................................

................................................................

................................................................

....................................................

........................................

....................

6

66

6

●Installation Site ...................................................................................................................... 6

●Required Space for Installation ............................................................................................. 8

●Recommended Installation Circuit. ........................................................................................ 8

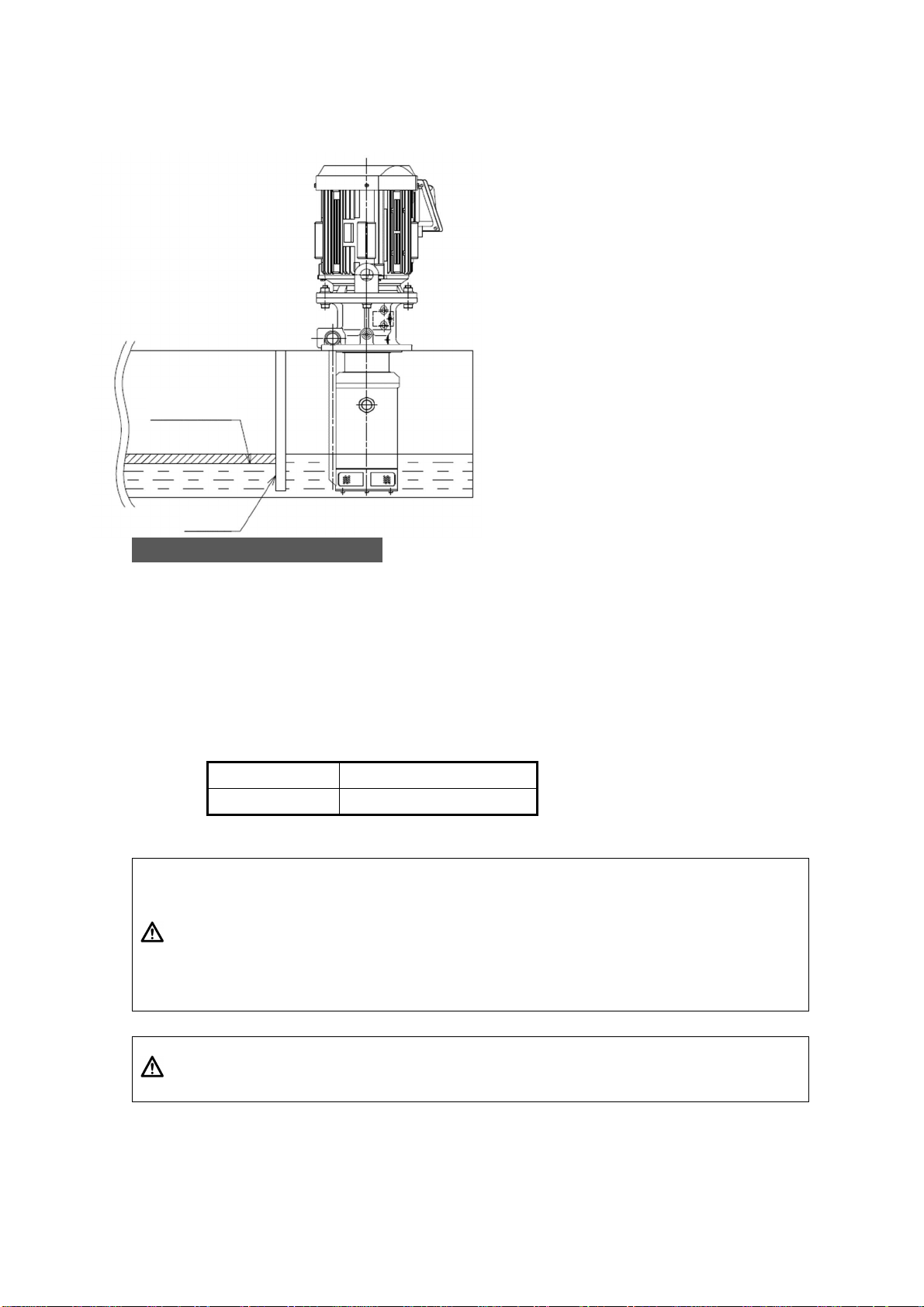

Position of Pump Inlet Port

Position of Pump Inlet PortPosition of Pump Inlet Port

Position of Pump Inlet Port

................................

................................................................

................................................................

................................................................

................................................................

................................................................

......................................

............

......

8

88

8

Filters

FiltersFilters

Filters

................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

......................................

............

......

9

99

9

●Performance of Turbulence Filter .......................................................................................... 9

Contaminant Drain Line

Contaminant Drain LineContaminant Drain Line

Contaminant Drain Line

................................

................................................................

................................................................

................................................................

................................................................

................................................................

........................................

................

........

10

1010

10

Outlet Port

Outlet PortOutlet Port

Outlet Port

................................

................................................................

................................................................

................................................................

................................................................

................................................................

............................................................

........................................................

............................

11

1111

11

Piping for the Pump

Piping for the PumpPiping for the Pump

Piping for the Pump

................................

................................................................

................................................................

................................................................

................................................................

................................................................

..............................................

............................

..............

12

1212

12

●Torque Applied on Pipe Connection .................................................................................... 12

●Connecting the Pipes .......................................................................................................... 12

●Pipes and Pipe Joints .......................................................................................................... 12

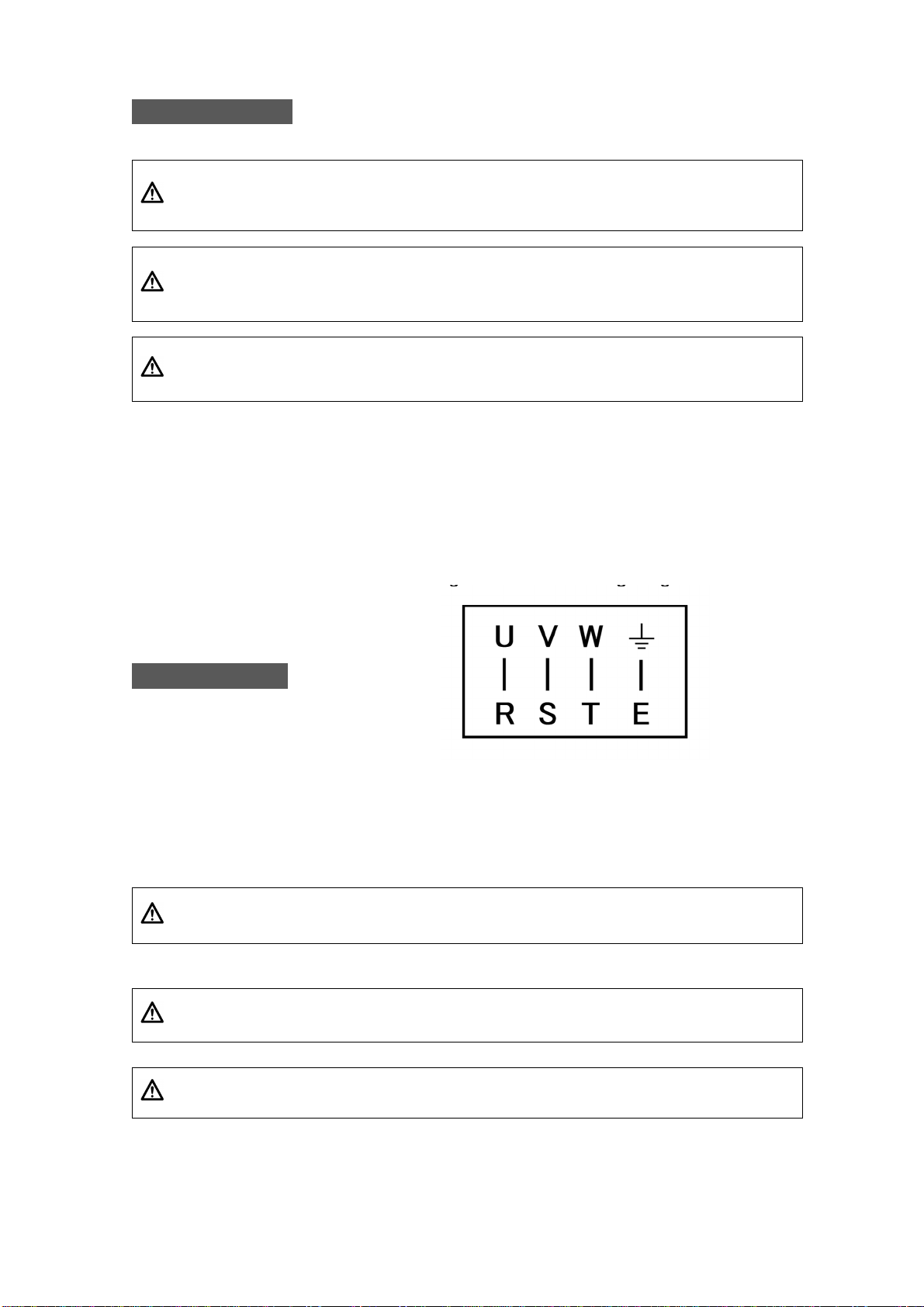

Electric Wiring

Electric WiringElectric Wiring

Electric Wiring

................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................................

..............................................

.......................

13

1313

13

For Operation

For OperationFor Operation

For Operation

................................

................................................................

................................................................

................................................................

................................................................

................................................................

........................................................

................................................

........................

13

1313

13

●Start-up Checklist ................................................................................................................ 13

●Test Run .............................................................................................................................. 13

Inspections

InspectionsInspections

Inspections

................................

................................................................

................................................................

................................................................

................................................................

................................................................

...........................................................

......................................................

...........................

14

1414

14

●Daily Startup Inspections ..................................................................................................... 14

●Periodical Inspections .......................................................................................................... 14

Storage

StorageStorage

Storage

................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.................................

..

.

14

1414

14

Warranty

WarrantyWarranty

Warranty

................................

................................................................

................................................................

................................................................

................................................................

................................................................

...............................................................

..............................................................

...............................

15

1515

15

For Selecting a Pump

For Selecting a PumpFor Selecting a Pump

For Selecting a Pump

................................

................................................................

................................................................

................................................................

................................................................

................................................................

...........................................

......................

...........

15

1515

15

●Operating Method ................................................................................................................ 15

●Required Flow Rate ............................................................................................................. 15

●Required Pressure ............................................................................................................... 15

●Relief Valve Pressure Setting. ............................................................................................. 15

●Selecting Coolant Type and Viscosity Range. .................................................................... 15

●Operating Ambient Temperatures ....................................................................................... 16

●Fluid Temperature Range .................................................................................................... 16

●Compatible Work Materials. ................................................................................................ 16

Motor Selection

Motor SelectionMotor Selection

Motor Selection

................................

................................................................

................................................................

................................................................

................................................................

................................................................

.....................................................

..........................................

.....................

17

1717

17

●Required Power for the Pump. ............................................................................................ 17

● Voltage and Frequency ...................................................................................................... 17

Suction Performance

Suction PerformanceSuction Performance

Suction Performance

................................

................................................................

................................................................

................................................................

................................................................

................................................................

............................................

........................

............

18

1818

18

Internal Structure

Internal StructureInternal Structure

Internal Structure

................................

................................................................

................................................................

................................................................

................................................................

................................................................

..................................................

....................................

..................

18

1818

18

Troubleshooting Guide

Troubleshooting GuideTroubleshooting Guide

Troubleshooting Guide

................................

................................................................

................................................................

................................................................

................................................................

................................................................

..........................................

....................

..........

19

1919

19

Backwashing

BackwashingBackwashing

Backwashing................................

................................................................

................................................................

................................................................

................................................................

................................................................

.........................................................

..................................................

.........................

20

2020

20