Nippon FB10P Instruction manual

INTRODUCTION

4Most accident happens due to the disregard of basic safety rules or

precautions. In order to prevent accidents from happening, the factors

responsible for accidents must be avoided beforehand.

For this reason, please read this manual and fully understand the

precautions for safety and the proper procedures and directions for

inspection and maintenance before starting operation.

Performing maintenance and repair without adequate knowledge may

cause inadvertent accidents.

4It is not possible to cover all the possible cases of accidents in this

"WORKSHOP MANUAL". Therefore, attention should be given to

precautions other than the ones mentioned in this "WORKSHOP

MANUAL". Especially, when repair and maintenance work which are not

covered in this "WORKSHOP MANUAL" are carried out, always work

under the direction of an instructor who understands the matter.

[Control System Transition]

Model IGBT Control FET Control CAN-BUS Control

FB10P~18P ~221AE1250 221AE1251~ 221AE3656~

FB20P~28P ~241AC4968 241AC4969~ 241AC6266~

FB30P ~251AC0880 - 251AC0881~

4Please note that the contents of the explanation in this manual are

different according to each control system.

Please refer to the applicable explanations.

https://www.forkliftpdfmanuals.com/

https://www.forkliftpdfmanuals.com/

Using this "WORKSHOP MANUAL"

This manual has information about the layout and names of main components, procedures for

disassembly, assembly, inspection, adjustment, maintenance, and hints for troubleshooting which are in

effect mainly for the model FB-75 series.

Since the parts used in this machine are subject to change for the sake of better quality, performance

enhancement and safety, some portions of the contents and illustrations of this "WORKSHOP MANUAL"

may not be identical.

Directions with and marks are very important, must be followed.

1. Personnel this "

WORKSHOP MANUAL"

is aimed at:

This "WORKSHOP MANUAL" is directed at personnel who possess sufficient knowledge and technical

expertise. If you do not understand any of the contents of this "WORKSHOP MANUAL", perform

operation under the guidance of personnel who does.

2. Conditions of a facility

The work conditions described in the "WORKSHOP MANUAL" are written on the assumption that the

work is performed at standard work facilities and tools for the maintenance of NICHIYU electric lift trucks

are available.

For safe and reliable maintenance, the work should be performed at a shop which is equivalent to these

described in this "WORKSHOP MANUAL" with following all instructions strictly.

Copyright©2008

NIPPON YUSOKI CO., LTD.

All Rights Reserved

DANGER Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

You must follow this instruction.

WARNING Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

You must follow this instruction.

CAUTION Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

You must follow this instruction.

NOTE Indicates suggestions, tips and hints related to the safety of a

operator and maintain of truck.

https://www.forkliftpdfmanuals.com/

CONTENTS

SAFETY WORK 1

1. Precautions for safe inspection and

maintenance work........................................ 1

2. Safety labels ................................................ 5

3. Model name and serial numbers.................. 9

4. Cautions for maintenance...........................11

5. Tightening torque for bolts ......................... 14

6.

Data of LOCTITE and THREEBOND products.......

15

1. GENERAL 16

1-1.Appearance................................................ 16

1-2.Specifications............................................. 17

2. FRONT AXLE (DRIVE) 19

2-1.Location and name .................................... 19

2-2.Disassembly and reassembly.................... 20

2-2-1. Front axle - removal and installation 20

2-2-2. Front axle - disassembly and reassembly 26

2-3.Inspection and adjustment......................... 34

2-3-1. Gears - Inspection and replacement 34

2-3-2. Wheel hub and hub bolt - Inspection 34

2-4.Troubleshooting ......................................... 35

2-4-1. Front axle - troubleshooting 35

3. REAR AXLE (STEERING) 36

3-1.Location and name .................................... 36

3-2.Disassembly and reassembly.................... 37

3-2-1.

Rear axle - removal and installation 37

3-2-2. Rear axle - disassembly and reassembly 39

3-2-3. Rear axle

- Reassembling method and attention 41

3-3.Inspection and adjustment......................... 44

3-3-1. Bushing - inspection 44

3-3-2. Center arm - inspection 44

3-3-3. Tie rod Comp. - inspection 44

3-3-4. Knuckle - inspection 44

3-3-5. King pin - inspection 45

3-3-6. Hub and hub bolt - inspection 45

3-3-7. Rear axle Comp. - inspection 45

3-4.Troubleshooting ......................................... 46

3-4-1. Rear axle - troubleshooting 46

4. TYRE 47

4-1.Location, name and tyre size..................... 47

4-1-1. Tyre - location and name 47

4-1-2. Tyre size 48

4-2.Inspection and adjustment......................... 49

4-2-1. Hub nut - inspection 49

4-2-2. Rim and rim bolt - inspection 49

4-2-3. Air pressure - inspection 50

4-2-4. Tyre - visual inspection and replacement 50

4-3.Troubleshooting ......................................... 51

4-3-1. Tyre - troubleshooting 51

5. STEERING 52

5-1.Location and name .................................... 52

5-2.Disassembly and reassembly.................... 53

5-2-1. Steering linkage - removal and installation 53

5-2-2. Steering linkage

- disassembly and reassembly 55

5-3.Inspection and adjustment......................... 57

5-3-1. Joint - inspection and replacement 57

5-3-2. Knob - inspection and replacement 57

5-3-3. Steering wheel - inspection and replacement 57

5-3-4. Torque sensor neutral - check and adjustment58

5-3-5. Checking by voltage 60

5-3-6. Actuator ass'y - inspection and adjustment 61

5-4.Troubleshooting ......................................... 62

5-4-1. Steering linkage - troubleshooting 62

https://www.forkliftpdfmanuals.com/

6. BRAKE 63

6-1.Location and name .................................... 63

6-1-1. Foot brake linkage - main part names 63

6-1-2. Parking brake linkage - main part names 64

6-2.Disassembly and reassembly.................... 65

6-2-1.

Wheel brake - removal and installation 65

6-2-2. Wheel brake - disassembly and reassembly 68

6-3.Inspection and adjustment......................... 69

6-3-1. Brake drum

- inspection, repair and replacement 69

6-3-2. Shoe & lining - inspection and replacement 69

6-3-3. Adjustor ass'y - inspection and replacement 70

6-3-4. Wheel cylinder ass'y

- inspection and replacement 70

6-3-5. Master cylinder ass'y

- inspection and replacement 71

6-3-6. Brake pedal - inspection 71

6-3-7. Parking lever - inspection and adjustment 72

6-3-8. Brake linkage - adjustment 72

6-3-9. Brake air bleeding 74

6-4.Troubleshooting ......................................... 76

6-4-1. Brake - troubleshooting 76

7. HYDRAULIC SYSTEM 77

7-1.Oil pipimng circuit....................................... 77

7a. HYDRAULIC PUMP 78

7a-1. Location and name.................................. 78

7a-2. Disassembly and reassembly.................. 79

7a-2-1.

Hydraulic pump - removal and installation 79

7a-3. Inspection and adjustment ...................... 80

7a-3-1.

Hydraulic pump - inspection 80

7a-4. Troubleshooting....................................... 81

7a-4-1.

Hydraulic pump - troubleshooting 81

7b. OIL TANK AND OIL PIPING 82

7b-1. Location and name.................................. 82

7b-1-1.

Plastic oil tank - main part names 82

7b-1-2.

Iron oil tank - main part names 82

7b-2. Disassembly and reasembly ................... 83

7b-2-1.

Oil tank - precautions 83

7b-2-2.

Oil piping replacement - precautions 83

7b-3. Inspection and adjustment ...................... 84

7b-3-1.

Oil - inspection 84

7b-3-2.

Recommended oil and quantity 84

7b-3-3.

Oil tank and filters - cleaning and check 85

7b-4. Troubleshooting....................................... 85

7b-4-1.

Oil tank - troubleshooting 85

7c. CONTROL VALVE 86

7c-1. Location and name.................................. 86

7c-2. Disassembly and reassembly.................. 88

7c-2-1.

Control valve - removal and installation 88

7c-2-2.

Inner kit of control valve - replacement 91

7c-3. Inspection and adjustment....................... 92

7c-3-1.

Relief pressure - measurement 92

7c-3-2.

Microswitch - adjustment 93

7c-4. Troubleshooting....................................... 94

7c-4-1.

Control valve - troubleshooting 94

7d. CYLINDER 95

7d-1. Location and name.................................. 95

7d-1-1.

Lift cylinder - main part names 95

7d-1-2.

Tilt cylinder - main part names 97

7d-2. Disassembly and reassembly.................. 98

7d-2-1.

Lift cylinder - removal

: P - mast (2 - stage simplex) 98

7d-2-2.

Lift cylinder - removal : PFL-mast (2-stage

duplex), M-mast (3-stage triplex) 100

7d-2-3.

Tilt cylinder - removal 103

7d-2-4.

Lift cylinder - installation and adjustment 104

7d-2-5.

Tilt cylinder - installation 105

7d-2-6.

Lift cylinder - disassembly and reassembly 106

7d-2-7.

Tilt cylinder - disassembly and reassembly 116

7d-3. Inspection and adjustment .....................117

7d-3-1.

Cylinder comp. - inspection 117

7d-3-2.

Piston rod - inspection 117

7d-3-3.

Drift for lift and tilt - inspection 118

7d-4. Variation of the tilt cylinder .....................119

7d-4-1.

Tilt angle by masts 119

7d-5. Troubleshooting..................................... 120

7d-5-1.

Cylinder - troubleshooting 120

https://www.forkliftpdfmanuals.com/

8. MAST 121

8-1.Location and name .................................. 121

8-2.Disassembly and reassembly.................. 123

8-2-1. Lift bracket - removal 123

8-2-2. Mast ass'y - removal 123

8-2-3. Mast - disassembly and reassembly 125

8-3.Inspection and adjustment....................... 128

8-3-1.

Mast, lift bracket and roller shaft - inspection

128

8-3-2. Back shoe - inspection 129

8-3-3.

Lift chain - inspection and replacement 129

8-3-4. Chain bolt - inspection 130

8-3-5. Chain wheel - inspection 130

8-3-6. Hose pulley - inspection 131

8-3-7. Roller - inspection and replacement 131

8-3-8. Fork - inspection and replacement 132

8-3-9. Lift chain - inspection and adjustment 133

8-3-10.

Mast lean- adjustment 134

8-4.Troubleshooting ....................................... 135

8-4-1. Mast · Lift bracket · Fork - troubleshooting 135

9. MOTOR 136

9-1.Location and name .................................. 136

9-1-1. Traction motor - main part names 136

9-1-2. Hydraulic motor - main part names 137

9-1-3. EPS motor - main part names 137

9-1-4. Motors - specifications 138

9-2.Disassembly and reassembly.................. 139

9-2-1. Traction motor - removal and installation 139

9-2-2. Hydraulic motor - removal and installation 140

9-2-3. EPS motor - removal and installation 142

9-2-4. Traction motor -

disassembly and reassembly

143

9-2-5. Hydraulic motor -

disassembly and reassembly

144

9-2-6. EPS motor - disassembly and reassembly 144

9-3.Inspection and adjustment....................... 145

9-3-1. Rotor comp. - inspection and replacement

(Traction and Hydraulic motor) 145

9-3-2. Armature comp.

- inspection and replacement 146

9-3-3. Brush, Brush holder and Spring (EPS motor)

- inspection and replacement 146

9-3-4.

Motor ASS'Y (Traction/Hydraulic motor)

- inspection 148

9-3-5.

Motor ASS'Y (EPS motor) - inspection 149

9-3-6.

Oil seal and permanent magnet (EPS motor)

- inspection and replacement 150

9-4.Troubleshooting ....................................... 150

9-4-1. Motor - troubleshooting 150

10. ELECTRIC PARTS 151

10-1. Location and name................................ 151

10a. CONTROL UNIT 152

10a-1. Location and name.............................. 152

10a-2. Disassembly and reassembly.............. 154

10a-2-1.

Control unit - removal and installation 154

10a-2-2.

Control unit - disassembly and reassembly 156

10a-3. Check and replacement ...................... 160

10a-3-1.

IGBT module - inspection and replacement 160

10a-3-2.

FET module comp.

- inspection and replacement 162

10a-3-3.

Capacitor - inspection and replacement 163

10a-3-4.

EPS controller - specifications 164

10b.

DISPLAY PANEL AND DIRECTIONAL SWITCH

165

10b-1. Display panel

- Disassembly and reassembly........... 165

10b-1-1.

Display panel - disassembly and reassembly165

10b-2. Directional switch

- Disassembly and reassembly........... 167

10b-2-1.

Display panel - disassembly and name 167

10b-2-2.

Wiring of directional switch 168

10c. ACCELERATOR 169

10c-1. Disassembly and reassembly.............. 169

10c-1-1.

Accelerator linkage - removal and installation169

10c-2. Inspection and adjustment................... 170

10c-2-1.

Potentiometer - adjustment 170

10c-2-2.

Accelerator linkage - adjustment 171

https://www.forkliftpdfmanuals.com/

10d. MAIN CONTACTOR AND FUSE 172

10d-1. Disassembly and reassembly.............. 172

10d-1-1.

Control unit - removal and installation 172

10d-2. Inspection and replacement................ 174

10d-2-1.

Main contactor

- inspection and replacement 174

10d-2-2.

Fuse - replacement 174

10e. BUILT-IN CHARGER (OPTION) 175

10e-1. Disassembly and reassembly.............. 175

10e-1-1.

Charger ass'y

- disassembly and reassembly 175

10e-1-2.

Transformer - disassembly and reassembly 177

10e-1-3.

Built-in charger - specification 178

10e-2. Inspection and replacement................ 180

10e-2-1.

Magnetic contactor - inspection 180

10e-2-2.

Plug comp. and receptacle

- inspection and replacement 180

10e-2-3.

Fuse and fuse base - inspection 180

10e-2-4.

Transformer - inspection 181

10e-2-5.

Diode - inspection 181

10e-3. Inspection After Assembly................... 182

10e-3-1.

Timer - inspection 182

10e-3-2.

Earth - inspection 183

10e-3-3.

Reserve function - inspection 183

10e-4. Charging procedure............................. 184

10e-4-1.

Automatic charge (Daily charge) 184

10e-4-2.

Reserve charge 188

10e-4-3.

Balancing charge 197

10e-5. Voltage tap .......................................... 199

10e-5-1.

Power supply voltage - check 199

10e-5-2.

Voltage tap - selection 199

10e-5-3.

Voltage tap - changing 200

10e-5-4.

Fuse (three-phase voltage) - replacement 200

10f. BATTERY 201

10f-1. Disassembly and reassembly............... 201

10f-1-1.

Battery - removal and installation 201

10f-2. Inspection and adjustment ................... 202

10f-2-1.

Battery - inspection 202

10f-2-2.

Battery - Cleaning 203

10g. MPU BOARD 204

10g-1. Location and name.............................. 204

10g-1-1.

MPU board 204

10g-1-2.

Display board 205

10g-1-3.

EPS controller board (EPS / DSP board) 205

11. LASER POINTER (OPTION) 206

11-1. Adjustment............................................. 206

11-1-1.

Fork level - adjustment 206

11-1-2.

Laser optical axis - adjustment 206

12. SERVICE DATA 207

12-1. Annual Inspection Service Data ............ 207

12-2. Standard work hours............................. 208

https://www.forkliftpdfmanuals.com/

1

CAUTION

WELL-VENTILATED AREA

lWork such as welding painted components or

sanding down coated parts should be carried

out in well-ventilated areas.

If this is not observed, harmful toxic gas or dust

may be inhaled.

CAUTION

LOCATION EQUIPPED WITH FIRE

EXTINGUISHING EQUIPMENT

lEquipment such as first-aid boxes and fire

extinguishers should be nearby when work is

performed.

CAUTION

PROPER ARRANGEMENT

lArrange and clean always at a working place to

work safety.

lEspecially, arrange disassembled parts well.

CAUTION

ADEQUATE SPACE WITH FLAT SURFACE:

lThe floor area of the shop (location) where

inspection and maintenance are performed

must have adequate floor space, and have level

surfaces without holes.

If these conditions are not met, unexpected

accidents, such as a roll-over of the forklift

truck, may result.

CAUTION

SAFE AND WELL-LIGHTED AREA

lThe work area should be safe and well lighted.

When working inside the machine or underneath

of it, always use a safety lamp with a shielded

light bulb.

If this is not observed, leaked oil may catch fire

when a light bulb pops.

SAFETY WORK

Precautions for safe inspection and

maintenance work

1.

Maintenance shops

https://www.forkliftpdfmanuals.com/

2

Work clothing

Tools and gauges

CAUTION

lThe worker should wear a safety hat, work

clothes, and safety shoes that are suitable for

safe work. The work clothes should be close-

fitting.

If this is not observed, loose clothing may

become caught in a machine, resulting in

serious injury.

WARNING

When working under a forklift truck, use a pit or

proper safety precautions.

WARNING

Apply wheel chocks to tyres to prevent the truck

from moving.

WARNING

After lifting or jacking up a forklift truck, support it

with safety blocks or rigid stands.

WARNING

lWhen hoisting a forklift truck or a heavy

component, use ropes or cable with correct

capacity.

lDo not use ropes or cables which are kinked.

CAUTION

lAlways use tools that are suitable for the work

being performed. Use proper size tools when

tightening and loosening the parts of the forklift

truck.

Failure to observe the above could result in

serious injury or damage to machines.

CAUTION

Prepare tools and gauges before starting to work.

Safety work

WARNING

lDo not lift the forklift truck by using other

forklift. The bottom of the truck may be

damaged by hitting the forks.

https://www.forkliftpdfmanuals.com/

3

Parts

Repair of electrical components

CAUTION

lDiluted sulfuric acid is used as the battery's

electrolyte . Keep clothing and skin away from

contact with battery fluid.

If this is not observed, the fluid may corrode

clothing or cause burns.

NOTE

Record the places of lead wire connection when

disassembling.

CAUTION

Be sure to jack up the drive wheel when trouble

shooting electrical operations.

CAUTION

CHARGING BATTERY

lBatteries produce flammable gas during

charging. Do not allow batteries in the vicinity of

fire or flames.

Failure to observe the above could result in an

explosion.

CAUTION

When replenishing battery electrolyte, be sure to

use refined water.

CAUTION

When replacing any parts, be sure to use NICHIYU

genuine parts.

CAUTION

Be sure to disconnect the battery plug when

replacing electrical component.

Do not pull the electric cable when disconnecting

the battery plug.

Hold the battery plug and disconnect it.

https://www.forkliftpdfmanuals.com/

4

Hydraulics

Tightening torque

CAUTION

lObserve tightening torque specified in this

manual.

If not specified, refer to the table [Tightening

torque for bolts] on page 14.

CAUTION

Before disconnecting hydraulic hoses, release internal oil pressure. To release

the pressure, follow next procedures.

1 Sit on the seat and turn on the key switch.

2 Push the lift lever forward to lower the fork on the ground.

3 Repeat pushing forward and releasing the lift lever a few times between

lowering and neutral positions to release the internal pressure.

4 Do not pull the lift lever nor operate any other hydraulic levers. (If the hydraulic

motor runs, high pressure is applied to all hydraulic circuits.)

5 You must sit on the seat and turn on the key switch to follow above steps 1, 2

and 3. Otherwise, the internal hydraulic pressure is not released because of the

OIS. (Operation Interlock System)

CAUTION

When disassembling and assembling the

hydraulic components, work at clean place and do

not damage the parts.

CAUTION

When removing the hydraulic pipes, cap them

to prevent dust from entering into the hydraulic

components and pipes.

Marks and Symbols

: Tightening torque

B: Apply THREEBOND product or equivalent

L:Apply LOCTITE product or equivalent

G: Apply grease

MG

:Apply molybdenum grease

S: Apply Silicone glue

C: Apply thermal conductive compound

N: Not reusable

Refer to the page 15 for details.

https://www.forkliftpdfmanuals.com/

5

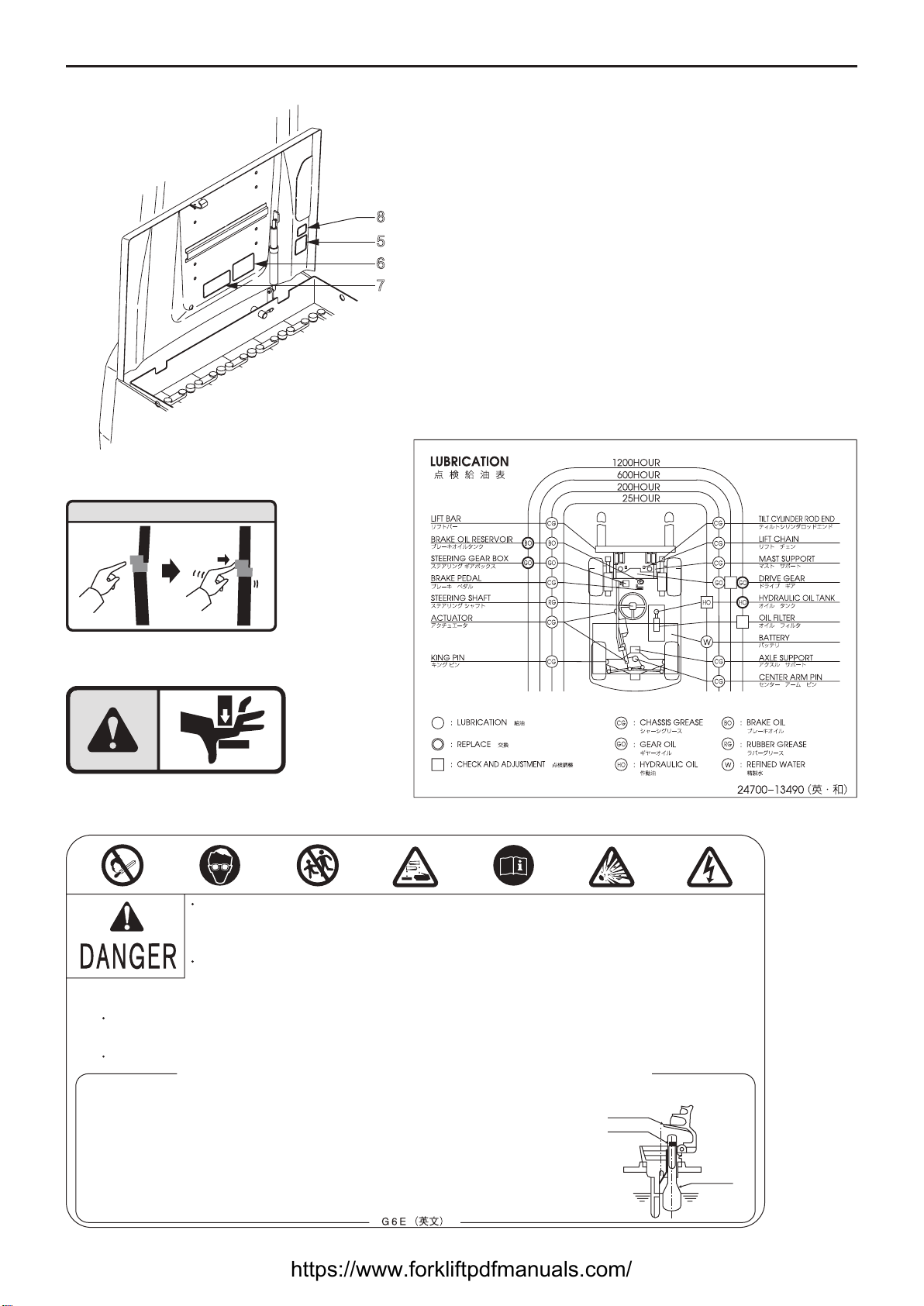

Safety labels2.

The illustration below shows the location of safety labels for safe operation.

Always protect the safety labels from contamination and damage.

If they are damaged or lost, replace with new ones.

1

10

12

11

29 3 410

221W074E

No. Parts No. Parts Name Q'ty Notes

1 50004-65160 Plate, caution 1 Safety operation

2 50004-65170 Plate, caution 1 Parking brake

3 50004-65050 Plate, caution 2 No person on / under for

4 50004-65060 Plate, warning 1 Shearing point

5 50004-65180 Plate, caution 1 Battery cover lock

6 24700-13490 Plate, lubrication 1 Lubrication

738540-00630 Label, caution 1 w / battery, SHINKOBE

38540-00520 w / battery, G6E

8 50004-65220 Plate, caution 1 Caution for fingers

90902-69954 Label, tyre 1 Air pressure (bar) FB10P-15P

0902-69964 Air pressure (bar) FB15P-28P

0902-69944 Air pressure (bar) FB30P

10 0902-69944 Label, tyre 1 Air pressure (bar) FB10P-18P

0902-69964 Air pressure (bar) FB20P-28P

0902-69914 Air pressure (bar) FB30P

11 50004-65190 Label, hook 3 Hook position

12 24700-04830 Plate, warning 1 In case of tipover

https://www.forkliftpdfmanuals.com/

6

1

PRECAUTIONS FOR SAFETY OPERATION

1

Do not overload. observe allowable load (blue zone).

2 Prior to operation, check performance of brake

or turn quickly.

3 Do not make a sudden start and brake or turn

quickly.

4 Do not make a sudden valve lever operation at a

high lift.

5 Do not run sideways or handle on an incline.

6 When the red lamp of battery capacity indicator

turns on, charge battery.

7

Check electrolyte every week and replenish water.

8 Be sure to use the prescribed fuses.

2

Apply parking brake before

leaving truck. Make adjust

to provide adequate braking.

3

50004-65050

WARNING

4

警告

WARNING

1

Name plate

(page 9)

221W0001

https://www.forkliftpdfmanuals.com/

7

7

GASES produced by this battery can be explosive.

Cigarettes, flames or sparks could cause battery to explode.

Make sure batteries are stored and charged in a wellÐventilayed area.

Batteries contain SULFURIC ACID can cause severe burns.

Avoid contact with skin, eyes or clothing.

In event of accident flush with water and call a physician immediately.

Wear rubber gloves to prevent ELECTRIC SHOCK during checking.

and maintaining.

Keep out of reach of children.

IMPORTANT POINT FOR MAINTENANCE

Keep the electrolyte level at proper height.

(When electrolyte decreased, fill purified water

and stop filling immediately if confirmed the white line of the

float as shown herein, for overÐfilling causes overflow.)

Always give the battery an adequate charge and

do not use the battery at overdischarged condition.

Keep the surface of battery clean and dry.

1.

2.

3.

(EX.) VENT PLUG

White line

Stopper

FLOAT

8

5

Lock release method of gas spring

5

8

6

7

(with Japnese

battery only)

221W0002 6

https://www.forkliftpdfmanuals.com/

8

11

50004-65190

12

WARNING

Fasten

Seatbelt

Do Not Jump ! Lean Forward

Hold

On

Tight

Brace

Feet

IN CASE OF TIPOVER

Lean

Away

From

Impact

Truck can

TIP OVER !

Risk of serious

INJURY

or DEATH

1.

2.

3.

Lateral tipover can occur when unloaded if the combination of speed

and sharpness of turn produces an overturning moment which exceeds

the stability of the truck.

Lateral tipover can occur if overloaded or loaded within capacity and the

load is elevated and if turning and/ or braking when traveling rearward

or if turning and/ or accelerating when traveling forward produces an

overturning moment which exceeds the stability of the truck.

Rearward tilt and/ or off-center positioning of the load and / or uneven

ground conditions will further aggravate the above conditions.

Longitudinal tipover can occur if overloaded or when loaded within capacity

and the load is elevated if forward tilt. braking in forward travel. or

commencing rearward travel produces an overturning moment which

exceeds the stability of the truck.

Serious injury or death can occur to the operator if he/ she is trapped

between the truck and the ground.

4.

The operator should stay with the truck if lateral or longitudinal tipover

occurs. The operator should hold on firmiy and lean away from the point

of impact.

The operator should stay with the truck if it falles off a loading dock or

ramp. There are other situations where the environment of the landing

area presents a severe hazard. In those incidents. it may be prudent for

the operator to leave the truck.

1.

2.

FOR SAFETY NOTICE FOLLOWING WARNINGS

24700-04830

IN CASE OF TIPOVER

9: for Front tyre (only for EEC)

FB10P / 14P FB15P ~ 28P FB30P

10: for Rear tyre (only for EEC)

FB10P ~18P FB20P ~ 28P FB30P

https://www.forkliftpdfmanuals.com/

9

Maximum lifting height [cm]

Mast type

Capacity code

Classification

of tyre

B : Large capacity battery

equipped

C : Stationary charger

D : Dust resistant

P : Pneumatic tyre

PN : No puncture tyre

PC : Cushion tyre

U : High speed type

NO CODE

:

Two stage full visibility (simplex) mast

M :

Three stage full free lift (triplex) mast

(Full visibility mast)

PFL : Full free lift (duplex) mast

(Full visibility mast)

CS : Cold storage use for -35°C

FCS : Cold storage use for -50°C

RP : Rust resistant

Z : Special type

Attachment etc.

FB 75

10 : 1000kg

14 : 1350kg

15 : 1500kg

18 : 1750kg

20 : 2000kg

25 : 2500kg

28 : 2750kg

30 : 3000kg

Model name and serial numbers3.

lName plate

Model name

MODEL

MAXIMUM

LOAD/LC

LIFT HEIGHT

SERIAL NO.

MFG.YEAR

VOLTAGE

SERVICE WEIGHT

W/O BATTERY

BATTERY WEIGHT

50006-95900

kg

kgMIN.

V

kgMAX.

mm

LOAD CHART

LIFT HEIGHT

LOAD CENTER mm

CAPACITY kg

kg /

kg /

mm

mm

mm

mm

MODEL

MAXIMUM

LOAD/LC

LIFT HEIGHT

SERIAL NO.

MFG.YEAR

VOLTAGE

SERVICE WEIGHT

W/O BATTERY

BATTERY WEIGHT

50006-91510

kg

kgMIN.

V

kgMAX.

mm

LOAD CHART

LIFT HEIGHT

LOAD CENTER mm

CAPACITY kg

kg /

kg /

mm

mm

mm

mm

(For Standard)

(For CE)

https://www.forkliftpdfmanuals.com/

10

Serial numbers

8

1

3

5

7

6

2

221W072E

MODEL

MAXIMUM

LOAD/LC

LIFT HEIGHT

SERIAL NO.

MFG.YEAR

VOLTAGE

SERVICE WEIGHT

W/O BATTERY

BATTERY WEIGHT

50006-95900

kg

kgMIN.

V

kgMAX.

mm

LOAD CHART

LIFT HEIGHT

LOAD CENTER mm

CAPACITY kg

kg /

kg /

mm

mm

mm

mm

lLocation of serial numbers

No. Serial numbers Stamped position

1 Serial No. of a truck Stamped on the name plate

2 Serial No. of a chassis Stamped on the right chassis

3 Serial No. of a mast Stamped on the mast name plate

4 Serial No. of a front axle Stamped on the gear case

5 Serial No. of a traction motor Stamped on the motor name plate

6 Serial No. of a hydraulic motor Stamped on the motor name plate

7 Serial No. of a EPS motor Stamped on the motor name plate

8 Serial No. of lift cylinders Stamped on lift cylinders

9 Serial No. of tilt cylinders Stamped on tilt cylinders

https://www.forkliftpdfmanuals.com/

11

152E101

Cautions for maintenance

4.

General precautions

152E102

152E103

152E104

lWhen replacing any parts, be sure to use genuine

NICHIYU parts.

lWhen parts are assembled, always replace old

packing and O-rings with new ones. In addition, be

sure to apply a light coat of grease on the O-rings and

oil seals before installing them.

lAs shown in the illustration, face the flat side of the

C-shape retainer in the direction the force is applied

when installed.

lAs shown in the illustration, face the slit side in the

direction the force is applied when driving in a spring

pin.

lThe split pin must be replaced with a new one and

split so it will not come out.

lWhen using a thrust washer with oil grooves cut,

observe the direction of installation.

lWhen connecting and disconnecting couplers of

electrical harnesses, always disconnect the battery

plug.

Retainer for a

groove Retainer for a

hole

Oil grooves

https://www.forkliftpdfmanuals.com/

12

Using liquid packing

Applying liquid packing

l

152E105

152E106

152E107

Scraper

Liquid packing

3 -3.5 mm

Good

Apply liquid packing

Within 15 minutes

Wait for 30 minutes or more

Assembly

Filling oil/Operation

Not Good

Key to evacuate

liquid packing

3 - 3.5 mm

Mating surface

Cut the nozzle at the

second section

Remove the sealer adhered on the mating surface of the

casing by using a scraper or equivalent tool. Be careful

not to make scratches of 0.3 mm or deeper. If scratches

are made, repair the area by using an oil stone.

Wipe off the mating surfaces using a cloth soaked in

gasoline to remove oil and contamination.

* Do not use kerosene, light oil, or crude oil.

1.

Cut the nozzle of the liquid packing tube at about the

second section so that the bead width will be 3 to 3.5

mm.

2.

Attach a key for rolling up the tube, and apply the liquid

packing to the mating surface while rolling up the tube.

* Do not smooth out the bead; doing so may cause

leakage.

* When applying the liquid packing to bolt holes, apply it

on the internal portion of the mating surface.

3.

Close the mating surfaces within 15 minutes after the

liquid packing is applied.

4.

When tightening the bolts, always tighten temporarily

first, and then tighten them gradually, moving from one to

the next in a diagonal pattern.

5.

Wait for more than 30 minutes before adding oil or

operating the machine.

* Failure to do so may cause oil leakage.

6.

Scraping before application of seal

l

https://www.forkliftpdfmanuals.com/

13

152E108

Deterioration of liquid packing

l

Once the tube has been opened, the liquid packing

anchoring the tip part of the nozzle might be cured and

deteriorated. Squeeze out that portion and discard it

before reusing the packing.

1.

If oil (filler) was separated from the liquid packing and

the packing appears shiny when it is squeezed out, this

indicates that the liquid packing has deteriorated.

* Although the oil may have been separated from a

liquid packing opened before its expiration date, this is

not an indication of deterioration.

2.

* If the oil has separated, the

packing has deteriorated.

Squeeze out the

bead about 20

mm and check.

CAUTION

If the state of the packing is normal, it will be

cured within approximately 2 hours. However, a

deteriorated packing will not.

https://www.forkliftpdfmanuals.com/

This manual suits for next models

7

Table of contents

Popular Forklift manuals by other brands

Presto Lifts

Presto Lifts Power Stak PPS2200-62NAS Installation, operation and service manual

Doosan

Doosan D110S-5 with OCDB Disassembly/Assembly

TMG

TMG TMG-PJ45S product manual

Jungheinrich

Jungheinrich ERE 224 operating instructions

Still

Still RX60-60 Original instructions

Crown

Crown Pallet Truck PC 4500 Series Operator's manual