CONTENT

1. Instruction manual..............................................................................................3

1.1 Range of application........................................................................... ........3

1.2 Operational order........................................................................................3

1.3 Safety precautions.......................................................................................3

2. Product Description............................................................................................4

2.1 Brief Introduction.........................................................................................4

2.2 Technical data.............................................................................................4

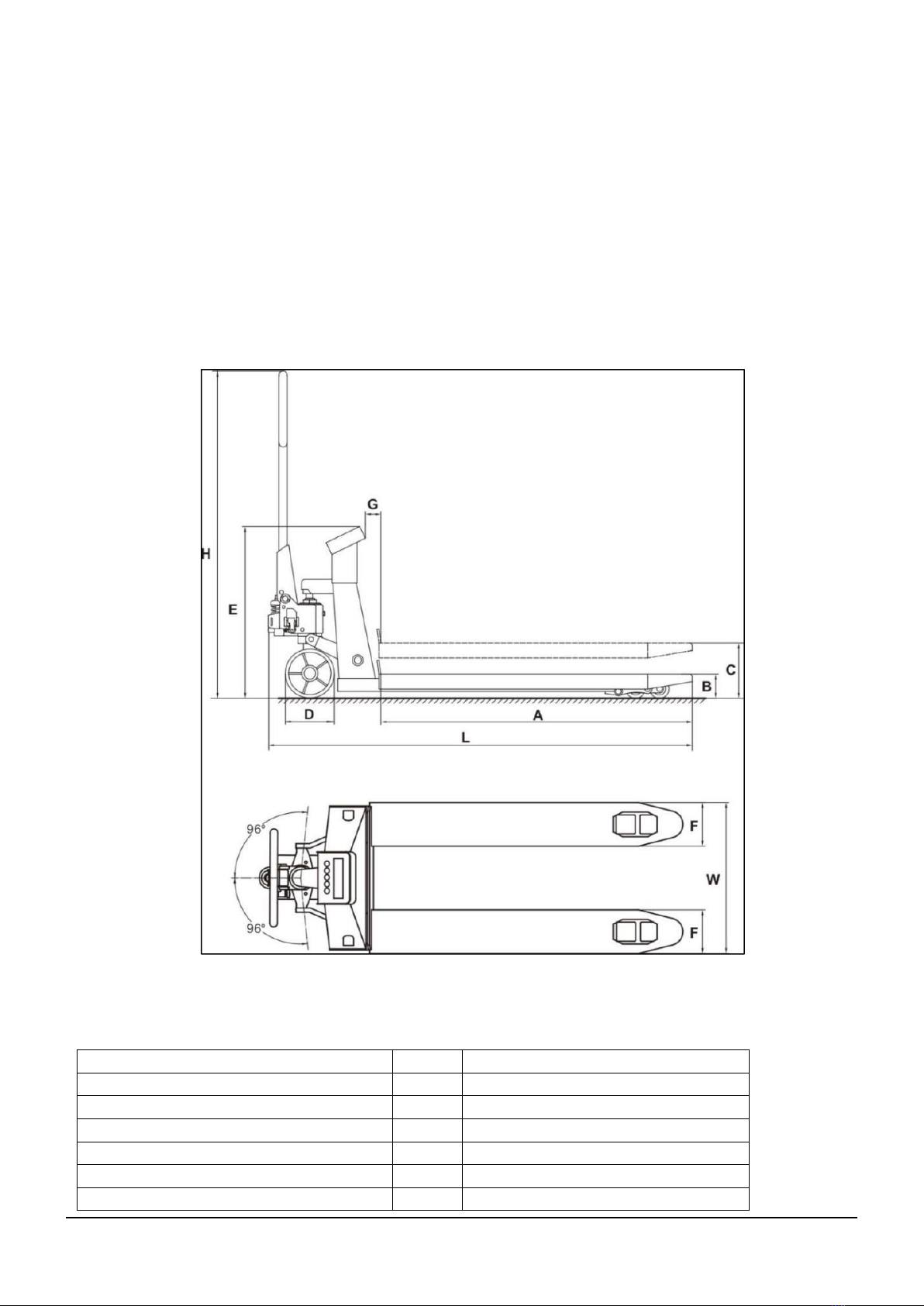

2.3 Diagram of Assembly..................................................................................5

3. Operating instruction...........................................................................................7

3.1Test run.........................................................................................................7

3.2 Adjustment of control handle knob.............................................................8

3.3Safety shutdown...........................................................................................8

4. Display instruction...............................................................................................8

4.1 Technical data of display.............................................................................8

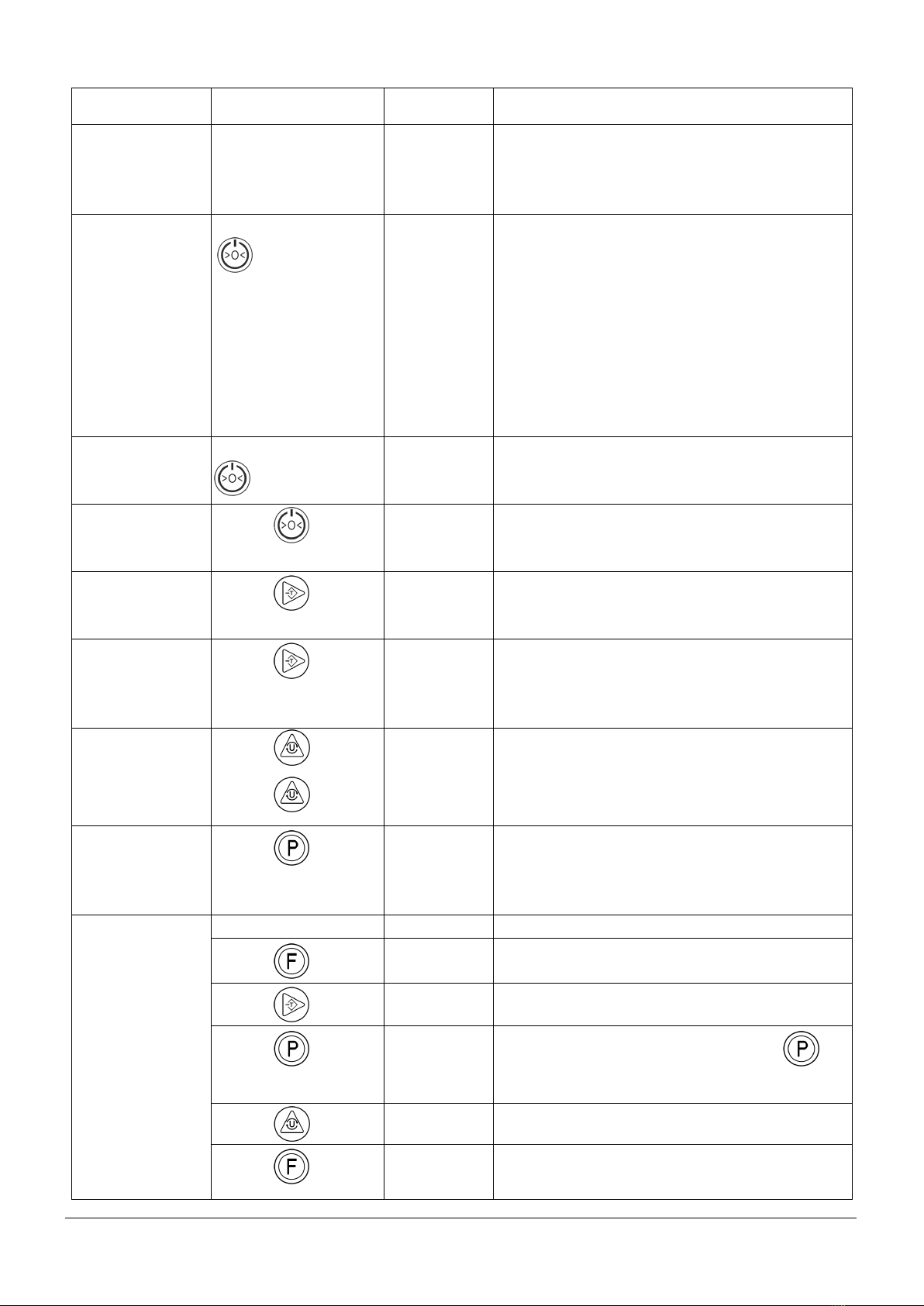

4.2 Display area introduction.............................................................................9

4.3 Button Function Introduction.......................................................................9

4.4 Calibration Introduction.............................................................................10

4.5 Recharging Power.....................................................................................11

4.6 Warning......................................................................................................11

5. Trouble shooting................................................................................................12

6. Routine Maintenance and Cleaning..................................................................13

7. Exploded Drawings and Parts List....................................................................15