Vehicle System Index3

INDEX

Forks........................................................5

Remove & Install Forks.....................................5

Carriage...................................................6

Remove & Install Carriage.................................6

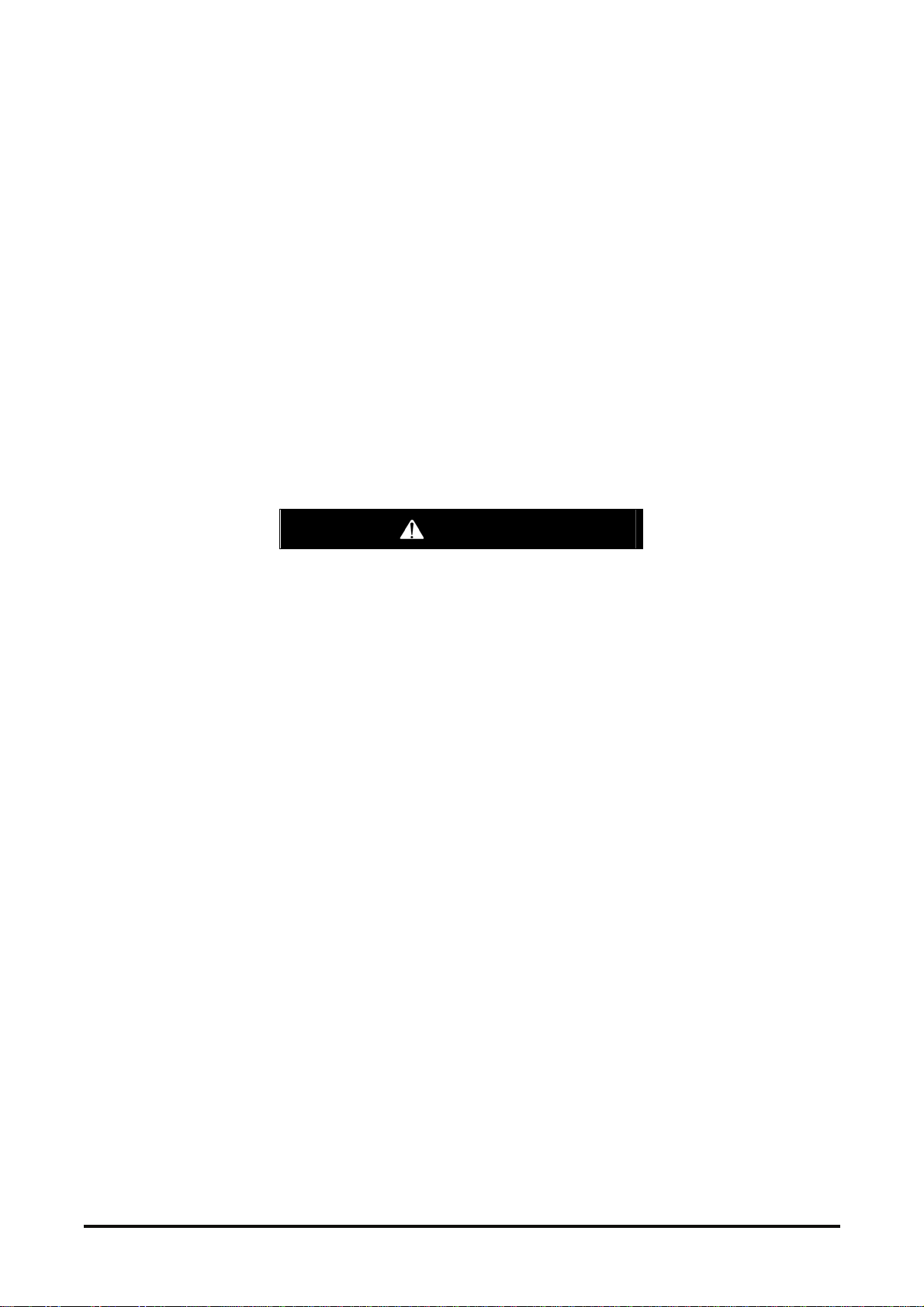

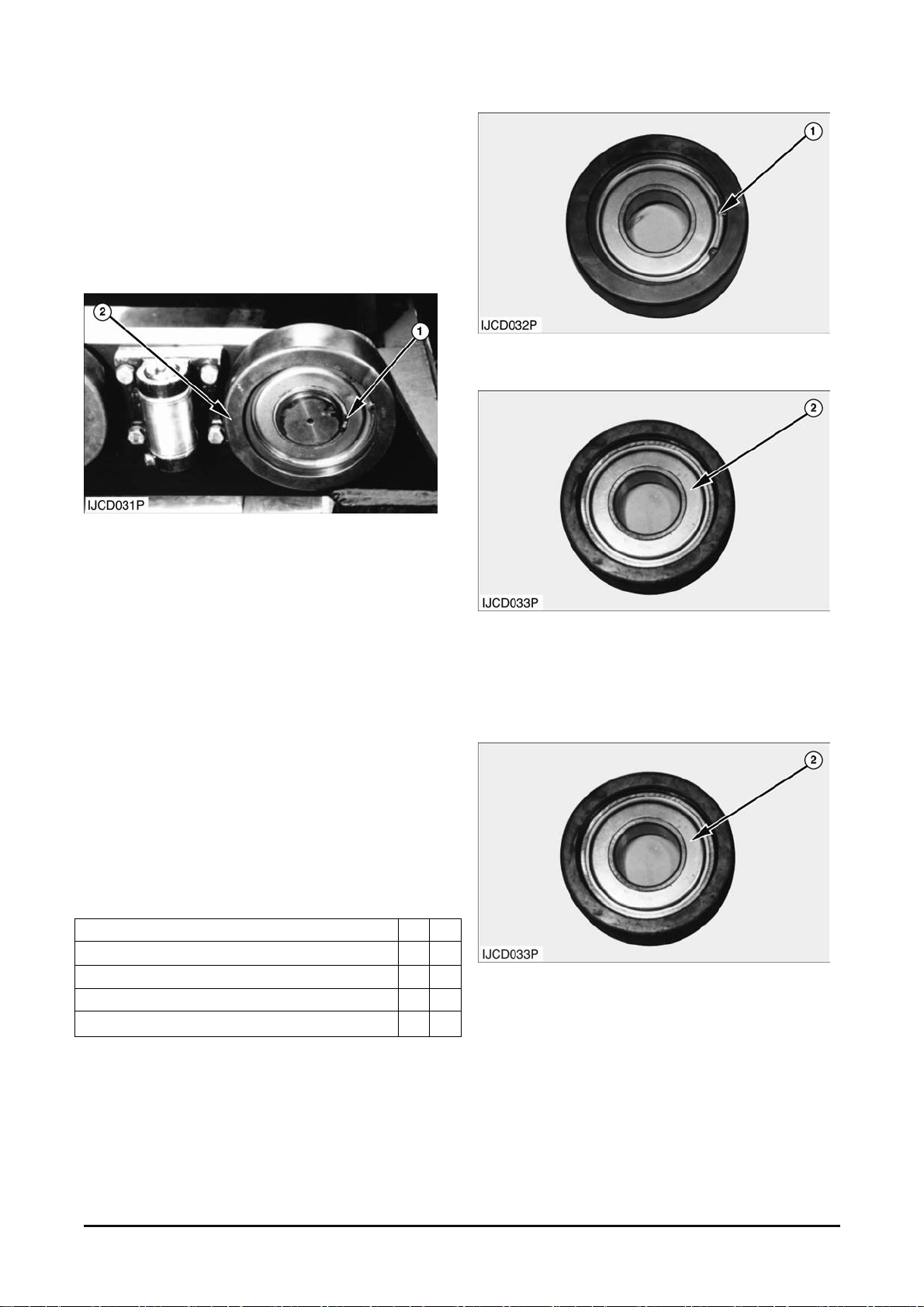

Carriage Rollers......................................7

Remove & Install Carriage Rollers.....................7

Disassemble & Assemble Carriage Rollers........7

Disassemble & Assemble Carriage....................8

Mast .........................................................9

Remove Mast....................................................9

Install Mast......................................................10

STD Mast........................................................11

Disassembly................................................11

Assembly........................................................14

FFT Mast.........................................................18

Lift Cylinder...........................................20

Removal & Installation.....................................20

Disassembly....................................................22

Assembly........................................................24

Tilt Cylinder...........................................25

Removal & Installation.....................................25

Disassembly & Assembly ................................26

Brake Assembly....................................29

Removal & Installation.....................................29

Remote Control Valve ..........................31

Replacing the parts .........................................31

Attachment Carriage ............................33

Lift Cylinder and Mast..........................33

Hydraulic Pump ....................................35

Removal & Installation.....................................35

Start-up Instructions & Recommendations.......36

Rotation & Ports Indication...........................36

Start-up :......................................................36

Removal of Air in Pump – Motor line................36

Pump & Cartridge Breakdown Drawing............37

Disassembly....................................................38

Reassembly ....................................................43

Seal Driver......................................................48

Dimension of Protective Cone .........................48

Hydraulic Oil Filter................................49

Removal & Installation.....................................49

Disassembly & Assembly ................................49

Universal Joint......................................50

Removal & Installation.....................................50

Disassembly & Assembly.................................51

Steering Wheel & Gear.........................52

Steering Wheel................................................52

Removed & Disassembly of Steering Gear.......52

Assembly of Steering Gear..............................54

Steer Axle ..............................................58

Removal & Installation.....................................58

Steering Cylinder..................................60

Removal & Installation.....................................60

Disassembly & Assembly.................................62

Steering Knuckle, Kingpin And Bearings

................................................................64

Removal & Installation.....................................64

Steer Tire And Rim................................67

Removal & Installation.....................................67

Removal of Wheel Bearing ..............................67

Installation of Wheel Bearing............................68

Drive Tire And Rim................................69

Removal & Installation.....................................69

Counterweight.......................................70

Removal of Air.......................................71

Pump – Motor line............................................71

After changing main pump ...............................71

Air in Brake system..........................................72

Removal of the High Pressure in accumulator..72

Emergency Lowering.......................................73

Removal and installation of Engine and

Transmission...................................................74