Nippon DENON DR-M20 User manual

Hi-Fi

Component

CK

STEREO

CASSETTE

TAPE

DE

|

TABLE

OF

CONTENTS

FEATURES

.......5-::

fy

ted

date

deeievacn

dteats41d

gIB

oe

tease

PES

EE

oe

nota

SBECIPICATIONS

inci

np

ie

cin

ptealeiesaa

cod

wenb

is

samvdensn

aaah

“BLOCK

DIAGRAMLcs

o<tt0

LOM

aseed

eevee

aoe

eha

etenak

Bde

eee

EVEL

DING

RAM

Gicaeut

ora

de

cunsd

tan

soucei

tastes

mites

eines

ea

PART

NAMES

AND

FUNCTIONS

........ccsccecceescceececeseveueses

OUTLINE

OF

THE

MECHANISM

CONTROL

MICROCOMPUTER........

rhe

raals

lactate

estat

ane

este

eal

nace

a

DISASSEMBLY

INSTRUCTIONS

|

ocxakit

ob

oacteseaituredesiwasaad

ets

ADJUSTING

AND

CHECKING

THE

MECHANISM

SECTION

inci

catdiatvcat

teens

edeeaawiad

exo

eeae

es

ADJUSTING

THE

ELECTRICAL

SECTION

2...

0...

cece

eee

e

cence

teen

eeees

PARTS

iST

OPP

WsBOARD:

fi

aryccPeed

gous

sx

tee

tedinns

Gate

weaes

PARTS

LIST

OF

EXPLODED

VIEW

......

cc

cece

cee

c

cece

cece

enenenenees

EXPLODED

VIEW

OF

CABINET

AND

CHASSIS

GROUP............2.0005-

EXPLODED

VIEW

OF

MECHANISM

VM860

UNIT

..........000

cee

eee

eens

PARTS

LIST

OF

MECHANISM

VM860

UNIT

AND

OTHER

PAR

TS

¥.cosneal

eee

nessa

tenes

Bae

oad

wae

aecen'

SCHEMATIC

DIAGRAM

OF

AUDIO

AMP

UNIT

.........0.00c

cece

eee

e

ees

P.W.

BOARD

OF

KU-5880

AUDIO

AMP

UNIT

.........

cee

cee

c

cece

neces

SCHEMATIC

DIAGRAM

OF

POWER/LOGIC

UNIT........0.0000

eee

eee

ee

P.W.

BOARD

OF

KU-5870

POWER/LOGIC

UNIT

AND

KU-5890

MECHANISM

UNIT

.....60

4000

h005

cueeeeeawcaesanaaes

SCHEMATIC

DIAGRAM

OF

COUNTER

METER

UNIT.......

00.000

eee

eee

SEMICONDUCTORS

as'sctaautasan

toca

eee

eeghardwawhte

eee

teed

WIRING

DIAGRAM.

casi

tues,

times

ontye

arson

wnat

eseaetendeeas

FEATURES

(2)

=

Computer-controlled

servo

technology

*

Closed-loop

dual-capstan

tape

transport.

*

Silent,

soft-touch

controls

provide

maximum

ease-of-use.

-

Computer-controlled,

full-logic

tape

controls

enable

fool-proof

operation.

s

Three-head

design

utilizes

DENON’s

new

SF

record/playback

combination

head

assembly.

=

Computing

tape

counter

with

4-digit

readout

and

memory

stop.

s

Dolby-C

noise

reduction

systems

(Double

Dolby

System).

as

Extended

range,

dual-color

fluorescent

peak

meters.

=

Auto

tape

selector.

s

Recording

Bias

adjustment.

23

24

25

26

27

28

29

30

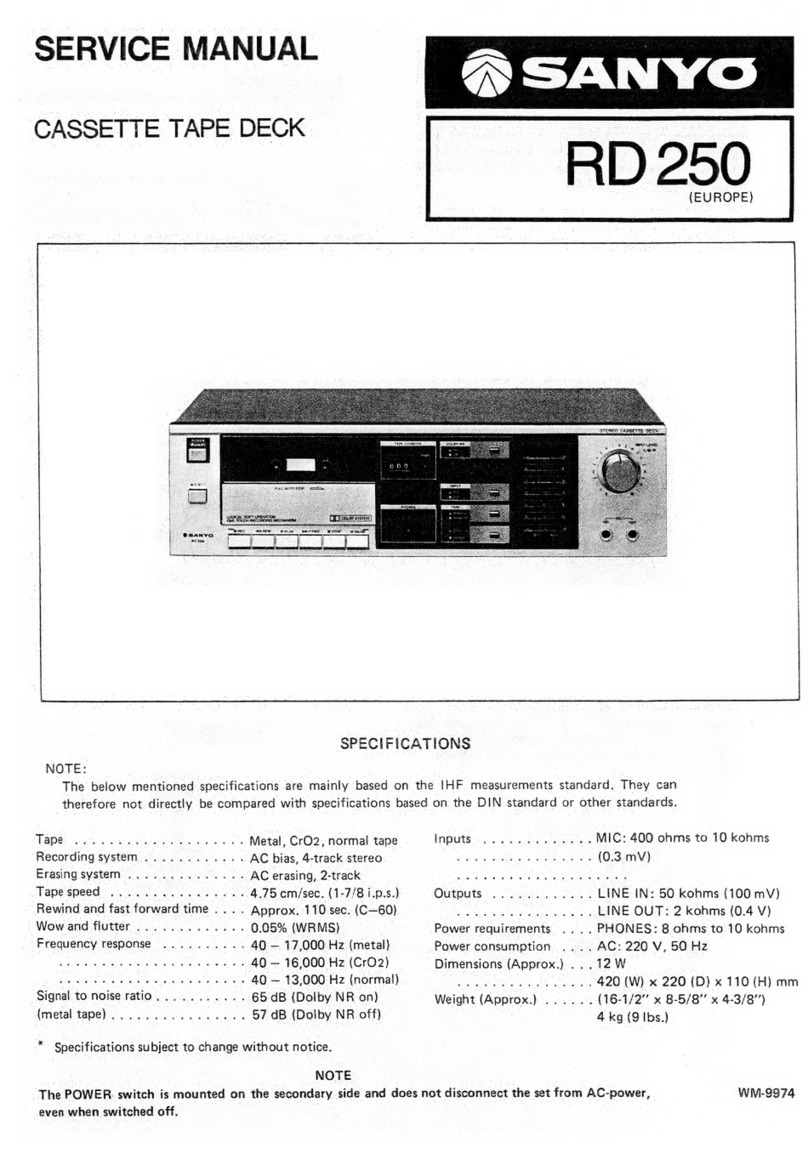

SPECIFICATIONS

OTYPE

Shido

se

aoa

ee

a

peas

Vertical

tape

loading

4-track

2-channel

stereo

cassette

tape

deck

eHeads

.

1...

ee

eee

ee

eet

SF

Record/Playback

combination

head

x

1

Erase

head

(Ferrite)

x

1

eMotors

....-

0-2

e

seen

eee

Electronic

servo

DC

motor

(for

capstan)

x

1

DC

motor

(for

reel

winding)

x

1

eTape

Speed

.............

4.8

cm/sec.

e

Fast

forward,

rewind

time

...

Approx.

90

sec.

with

a

C-60

cassette

e

Recording

bias

...........

105

kHz

e

Overall

S/N

ratio

.........

Dolby

C

NR

on...

more

than

73

dB

(CCIR/ARM)

(at

3%

THD

level)

e

Overall

fequency

response.

...

25

~

19,000

Hz

+3dB

(at

~20

dB

METAL

tape)

eChannel

separation

........

More

than

40

dB

(at

1

kHz)

eCrosstalk...

2...

-

eee

ee

eee

More

than

65

dB

{at

1

kHz)

eWow

&

flutter

...........

0.045%

wrms

(JIS

method)

e

Inputs

WTO

Bean

he

Wee

orang

Gi

etane,

eRe

100mV

(—18

dB)

input

level

at

maximum

Input

impedance:

50

kohm

unbalanced

e

Outputs

ING.

epee

ee

ew

775mV

(0

dB)

output

level

at

maximum

(with

47

kohm

load,

recorded

level

of

200

pwb/mm)

Headphone

...........

1,.2mW

output

level

at

maximum

(optimum

load

impedance

8

ohm

~

1.2

kohm)

eAccessories

...

+--+

eee

eee

Parallel

pin

cord

x

2

@Power

supply

......-...-6-

50

Hz/60

Hz

compatible,

voltage

is

shown

on

rating

label

ePower

consumption

.......

18W

eDimensions

.........+00

434

(W)

x

115

(H)

x

286

(D)

mm

e@eWeight

...-

2.

ee

eee

eee

5.6

kg

=

Above

specifications

and

design

styling

are

subject

to

change

for

improvement.

™Dolby

noise

reduction

manufactured

under

license

from

Dolby

Laboratories

Licensing

Corporation.

“Dolby”

and

the

double-D

symbol

are

trademarks

of

Dolby

Laboratories

Licensing

Corporation.

WARNING:

1.

Component

parts

Parts

marked

with

Z\

and/or

shading

in

this

service

manual

have

special

characteristics

important

to

safety.

Besure

to

use

the

specified

parts

for

replacement.

2.

Leakage

current

Before

returning

the

appliance

to

customer,

test

the

leakage

current

when

the

power

plug

is

connected.

Use

a

calibrated

(with

an

error

of

not

more

than

5%)

leakage

current

tester

and

measure

the

leakage

current

from

any

exposed

metal

to

the

earth

ground.

Reverse

the

power

plug

polarity

and

test

the

above

again.

Any

current

measured

MUST

NOT

EXCEED

0.5

milliamps.

Corrective

measure

must

be

taken

if it

exceeds

the

limit.

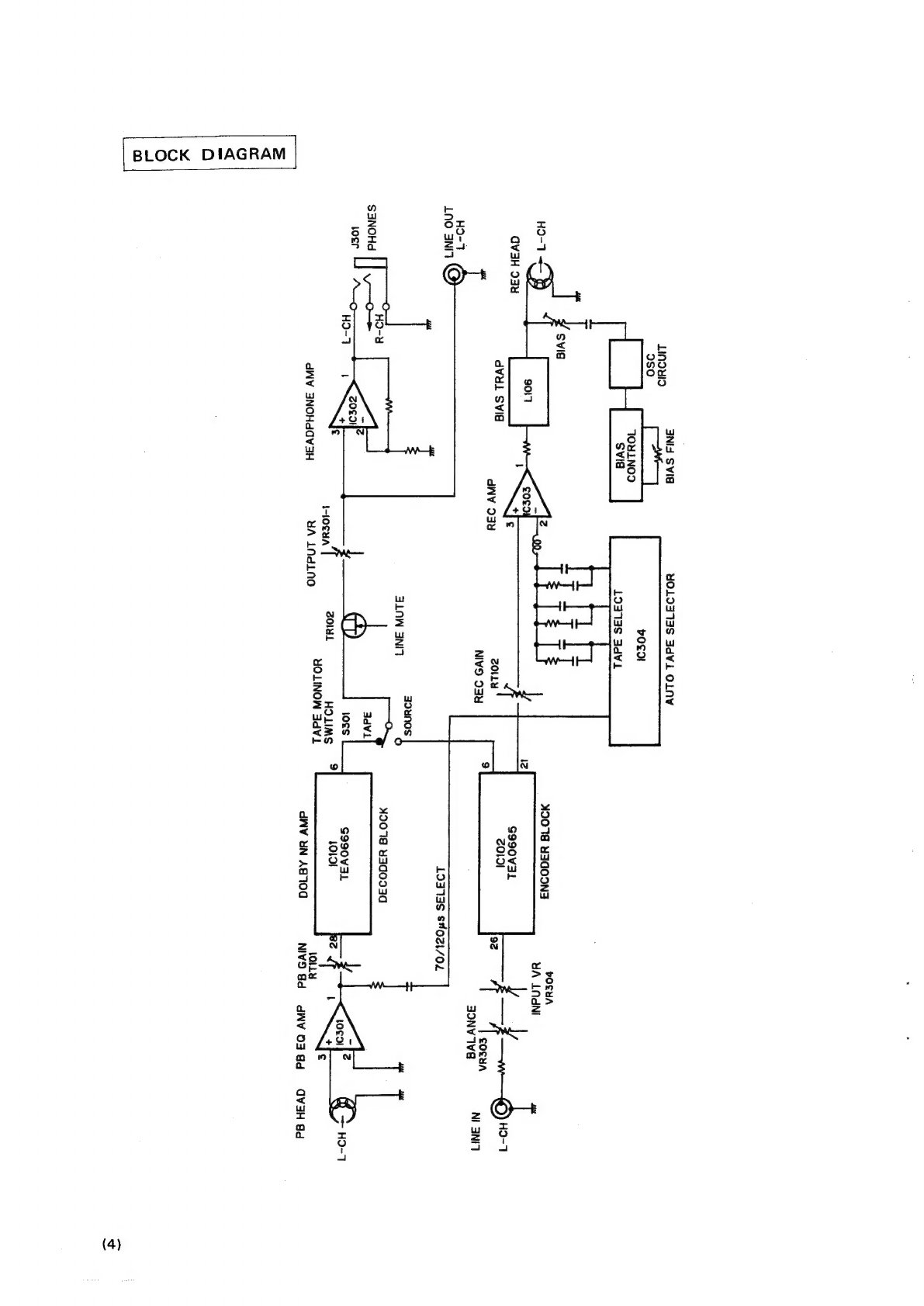

{3)

SNId

SvVIa

YOLOITES

3dVi

OLNV

LINDUIS

/

980

ia

7JOYLNOD

svia

vost

L9373S

adVL

7

pOCUA

RRO

5

19078

YAGOONS

aA

TaN

GV3H

934

Ss990V3L

ie

dVul

Svid

Prrepeet

Z01LY

fee

cOeUA

|

NIV

O3Y

3ONV

Iva

ial

HO-1_

LNO

3NIT

L19373S

st0z1/02

39ynNos

SLAW

3NIT

M9018

¥300930

S3NOHd

tloer

9

{-lOLUA

YOLINOW

3dV

dWV

SNOHdOV3H

YA

LNdLNd

t

s990v3L

-

e

&

>

HO-7

HOLIMS

10101

Bz

\

:

b

1a1Ly

dN

UN

A100

NIV]

Gd

dNVO3ad

dV3H

ad

|

BLOCK

DIAGRAM

(4)

LEVEL

DIAGRAM

PLAYBACK

SYSTEM

TCcC-BO

(400Hz)

DOLBY

B-Type

200mWb/m

Lamv

(et

82)

PB

HEAD

PBEQ

AMP

PBGAINN

DOLBY

NR

AMP

(DECOOER)

OUT PUT

VR

HEADPHONE

AMP

TRIO2

|

po

32)

m

28

6

cTR202)

305)

!

PRONES:

LY

P

216)

rare)

OD

2s

me

en)

RTIO1

.

VR301

:

(RT2ZOn)

source

LINE

TAPE

MUTE

$301

(68)

(©)

LINE

out

é

CG)

@

©

@)

©)

©)

@)

ose

dB

dB

6

LINE

OUT

7

Gag

PHONES

OUT

1848

-20

2408

-30

-40

-50

60

-7008

-70

Od8=0.775V

RECORDING

SYSTEM

INPUT

FREQUENCY

400Hz

DOLBY

NR

SYSTEM

LINE

{ENCODER}

SOURCE

rr

BALANCE

VR

INPUT

VR

REC

AMP

BAND

TRAP

FILTER

REC

HEAD

L-106

(L-206)

TAPE

SELECTOR

TAPE

(dB)

70.808

(METAL)

~2.8dB

(CHROME)

-5.5dB

(NORMAL)

0dB=0.775V

(5)

(6)

|

PART

NAMES

AND

FUNCTIONS

|

®

®

DENON

orccision

aur

recimanpc¥/S

TEREO

CASSETTE

DECx

DA-w20

©@

©

®@

®

©

eS")

]

@

1.

POWER

switch

Controls

the

supply

of

AC

power

to

the

deck.

One

push

turns

the

deck

on,

a

second

push

turns

it

off.

The

deck

remains

in

a

stand-by

(non-operative)

mode

for

approxi-

mately

4

seconds

after

it

is

switched

on.

2.

EJECT

button

Press

this

button

to

eject

the

cassette.

When

the

deck

is

operating

(tape

is

running),

press

the

stop

(

®)

key

first

to

stop

the

tape

transport;

then

press

the

EJECT

button.

3.

COUNTER

RESET

button

Operation

of

the

button

resets

the

counter

to

all

zero.

4.

MEMORY

STOP

button

During

rewinding

operations,

the

tape

will

stop

at

the

“9000”

counter

point

automatically

when

this

button

is

pressed

in.

5.

DOLBY

NR

switches

The

left

Dolby

NR

switch

activates

(in)

or

deactivates

(out)

the

deck’s

Dolby

noise

reduction

circuitry.

The

right

switch

selects

between

Dolby

B-Type

(out)

or

C-Type

NR

(in).

6.

MPX

FILTER

switch

The

MPX

FILTER

switch

should

be

used

to

prevent

inter-

ference

with

the

Dolby

NR

circuit

when

making

Dolby

NR

encoded

recordings

of

FM

stereo

programs.

When

making

Dolby

NR

encoded

recordings

from

any

program

source

other

than

FM

stereo,

leave

this

switch

in

the

“off”

(out)

position.

G@@G@OG

©

D

OOP

BIAS.FIME

BALANCE

@

7.

MONITOR

switch

The

SOURCE

(in)

position

of

this

switch

allows

you

to

monitor

the

source

program

before

it is

recorded.

The

TAPE

(out)

position

of

this

switch

is

used

for

tape

play-

back

monitoring

or

simultaneous

monitoring

during

record-

ing.

8.

BIAS

FINE

ADJ

control

(for

NORMAL

and

CrO,

tape)

Adjust

the

bias

according

to

the

tape

characteristics.

Standard

biasing

is

obtained

at

the

center

click-stop

posi-

tion.

9.

BALANCE

controls

This

is

the

Knob

to

adjust

the

recording

level

balance

be-

tween

the

left

and

right

channels.

Turn

it

counterclock-

wise

to

reduce

the

right

channel’s

level

and

clockwise

to

reduce

the

left

channel's.

Usually,

put

the

knob

at

the

center

click

position.

10.

PHONES

jack

For

private

music

enjoyment

without

disturbing

others,

or

for

monitoring

a

recording,

a

set

of

headphones

may

be

plugged

in.

Impedance

should

be

from

8

to

1200

ohms.

11.

OUTPUT

LEVEL

control

This

control

adjusts

playback,

recording

monitor,

and

headphones

output

levels

for

the

both

channels

simultane-

ously.

12.

INPUT

LEVEL

controls

The

recording

input

level

is

adjusted

by

this

knob.

The

levels

in

the

left

and

right

channels

can

be

changed

sim-

ultaneously.

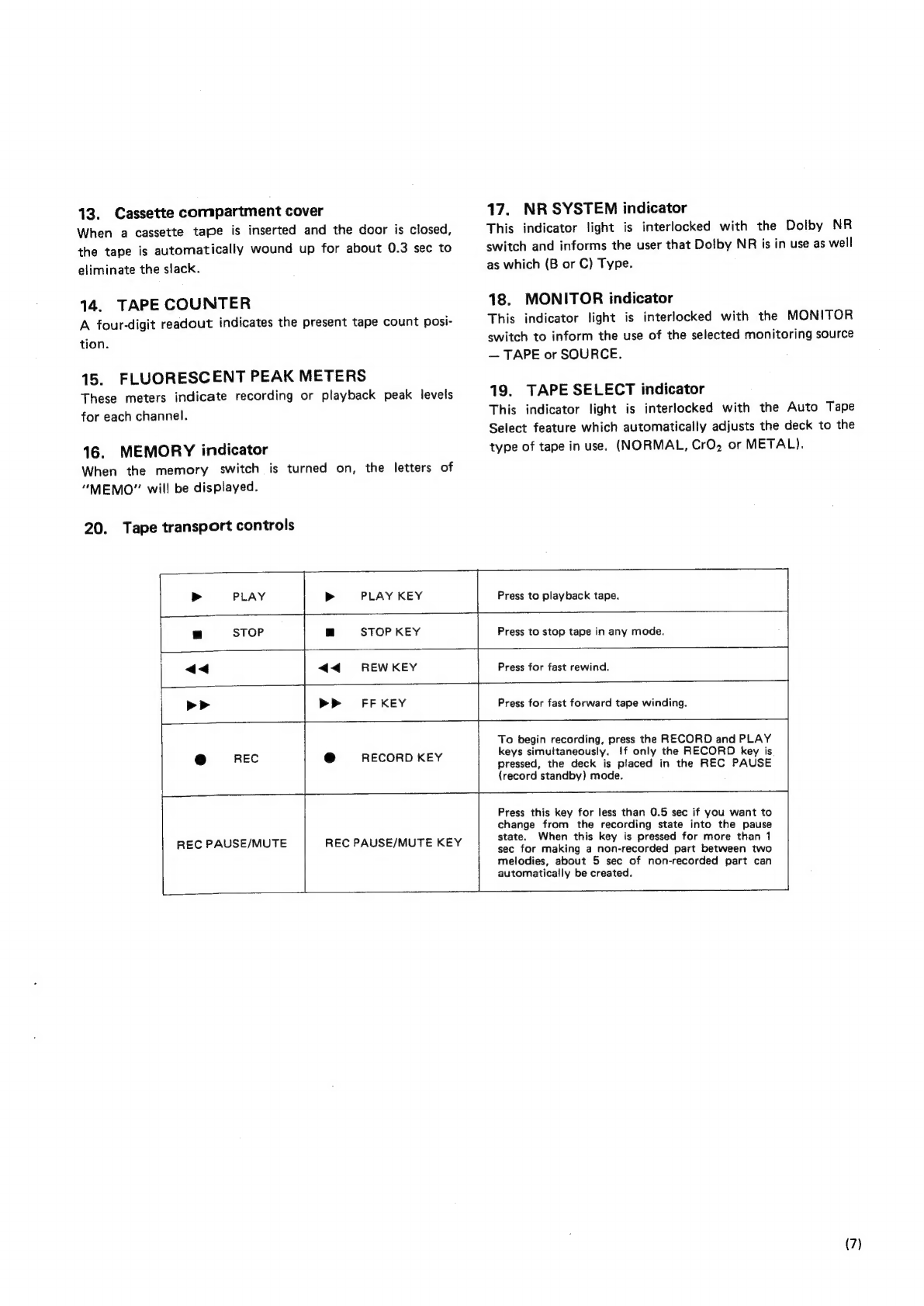

13.

Cassette

compartment

cover

When

a

cassette

tape

is

inserted

and

the

door

is

closed,

the

tape

is

automatically

wound

up

for

about

0.3

sec

to

eliminate

the

slack.

14.

TAPE

COUNTER

A

four-digit

readout

indicates

the

present

tape

count

posi-

tion.

15.

FLUORESCENT

PEAK

METERS

These

meters

indicate

recording

or

playback

peak

levels

for

each

channel.

16.

MEMORY

indicator

When

the

memory

switch

is

turned

on,

the

letters

of

“MEMO”

will

be

displayed.

20.

Tape

transport

controls

>

PLAY

>

PLAY

KEY

>P

FFKEY

e@

REC

e

RECORD

KEY

17.

NR

SYSTEM

indicator

This

indicator

light

is

interlocked

with

the

Dolby

NR

switch

and

informs

the

user

that

Dotby

NR

is

in

use

as

well

as

which

(B

or

C)

Type.

18.

MONITOR

indicator

This

indicator

light

is

interlocked

with

the

MONITOR

switch

to

inform

the

use

of

the

selected

monitoring

source

—

TAPE

or

SOURCE.

19.

TAPE

SELECT

indicator

This

indicator

light

is

interlocked

with

the

Auto

Tape

Select

feature

which

automatically

adjusts

the

deck

to

the

type

of

tape

in

use.

(NORMAL,

CrO2

or

METAL).

a

STOP

KEY

<0

REWKEY

Press

to

playback

tape.

Press

to

stop

tape

in

any

mode.

Press

for

fast

rewind.

Press

for

fast

forward

tape

winding.

To

begin

recording,

press

the

RECORD

and

PLAY

keys

simultaneously.

!f

only

the

RECORD

key

is

pressed,

the

deck

is

placed

in

the

REC

PAUSE

{record

standby)

mode.

REC

PAUSE/MUTE

REC

PAUSE/MUTE

KEY

Press

this

key

for

less

than

0.5

sec

if

you

want

to

change

from

the

recording

state

into

the

pause

state.

When

this

key

is

pressed

for

more

than

1

sec

for

making

a

non-recorded

part

between

two

melodies,

about

5

sec

of

non-recorded

part

can

automatically

be

created.

(7)

(8)

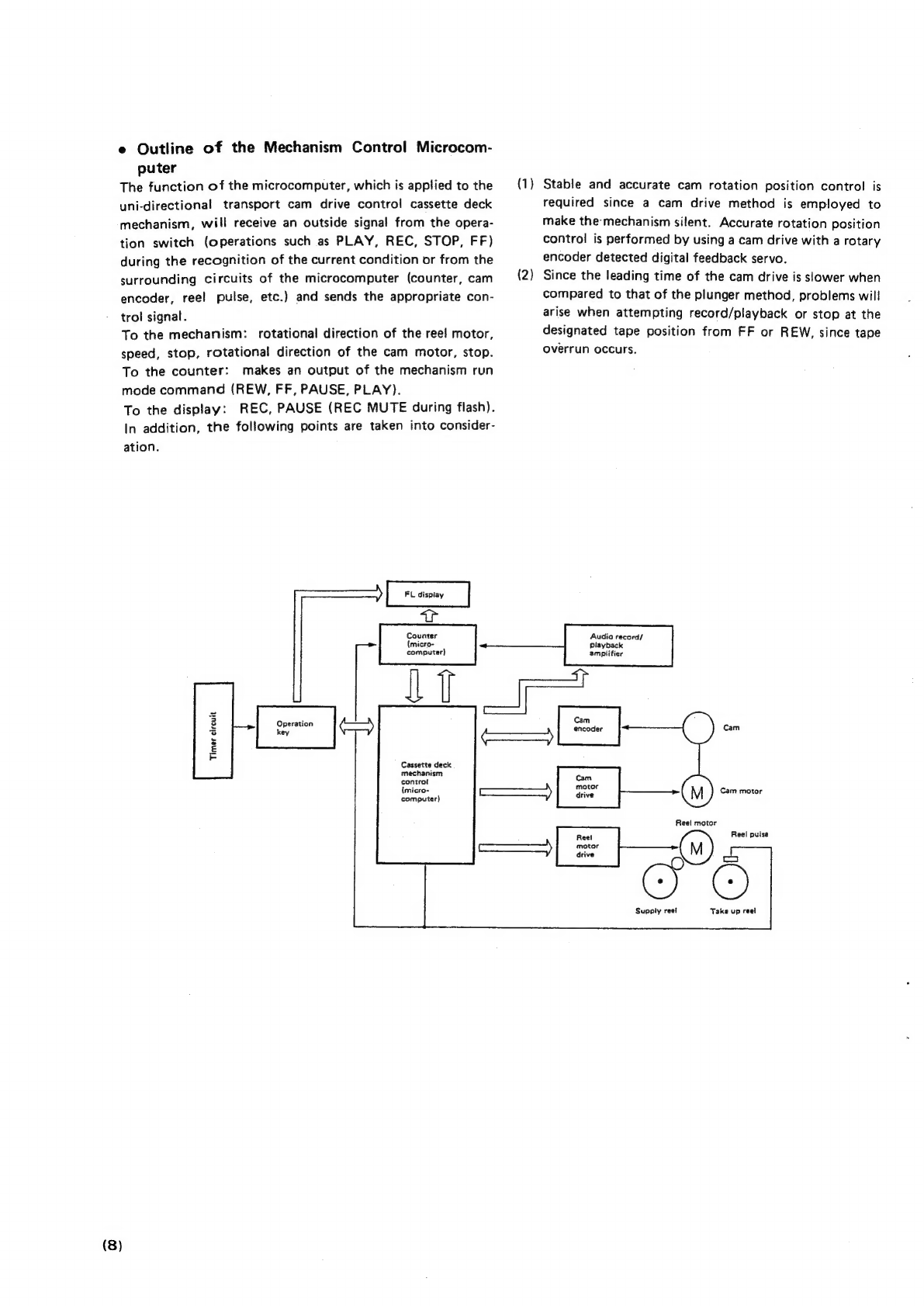

e

Outline

of

the

Mechanism

Control

Microcom-

puter

The

function

of

the

microcomputer,

which

is

applied

to

the

uni-directional

transport

cam

drive

control

cassette

deck

mechanism,

will

receive

an

outside

signa!

from

the

opera-

tion

switch

(operations

such

as

PLAY,

REC,

STOP,

FF)

during

the

recognition

of

the

current

condition

or

from

the

surrounding

circuits

of

the

microcomputer

(counter,

cam

encoder,

reel

pulse,

etc.)

and

sends

the

appropriate

con-

trol

signal.

To

the

mechanism:

rotational

direction

of

the

ree!

motor,

speed,

stop,

rotational

direction

of

the

cam

motor,

stop.

To

the

counter:

makes

an

output

of

the

mechanism

run

mode

command

(REW,

FF,

PAUSE,

PLAY).

To

the

display:

REC,

PAUSE

(REC

MUTE

during

flash).

In

addition,

the

following

points

are

taken

into

consider-

ation.

Counter

|

Se,

|

Se,

can

can

Timer

circuit

Cassette

deck

mechanism

controt

(micro-

computer)

(1)

Stable

and

accurate

cam

rotation

position

control

is

(2)

———)]

omer

drive

required

since

a

cam

drive

method

is

employed

to

make

the

mechanism

silent.

Accurate

rotation

position

control

is

performed

by

using

a

cam

drive

with

a

rotary

encoder

detected

digital

feedback

servo.

Since

the

leading

time

of

the

cam

drive

is

slower

when

compared

to

that

of

the

plunger

method,

problems

will

arise

when

attempting

record/playback

or

stop

at

the

designated

tape

position

from

FF

or

REW,

since

tape

overrun

occurs.

|

se

|

record/

|

se

|

amplifier

Ea

Ea

|

S|

Cam

motor

|

S|

Reel

motor

Reet

Reel

pulse

oge

Supply

reei

Take

up

reel

[DISASSEMBLY

INSTRUCTIONS

|

1.

How

to

Remove

the

Front

Panel

(1)

Unscrew

the

4

screws

309

from

both

sides

of

the

top

cover

240 and

take

off

the

top

cover

by

pulling

it

up.

(2)

Press

the

eject

knob

231,

open

the

cassette

window

338

and

take

off

the

mechanism,

as

shown

in

the

dia-

gram.

Note:

Be

careful

when

handling

the

cassette

window,

as

it

is

easily

scratched.

(3)

The

front

panel

can

be

removed

by

unscrewing

the

3

upper

screws

(3x8

CFTS

S

tight)

307

from

the

front

panel

233 and

the

3

lower

screws

(3x8

CBTS

P

tight)

308.

@Q

3.

How

to

Remove

the

Meter

Window

and

the

Color

Filter

2.

How

to

Remove

the

Mechanisms

(1)

Remove

the

top

cover

240

and

the

front

panel

233.

(Refer

to

section

1)

(2)

Unscrew

the

2

mechanism

holding

screws

(3x6

CBTSS

tight)

304

from

the

bottom

surface

of

the

chassis

201.

(3)

Unscrew

the

2

screws

(3x6

CBTS

§S

tight)

304

holding

the

angle

210

and

the

mechanism

207

and

the

3

chassis

holding

screws

301,

310

and

remove

the

angle.

(4)

Remove

the

connectors

with

lead

wires,

which

runs

from

the

mechanism

section,

from

the

circuit

board.

Audio

circuit

board

side

4P

connector

CN301

6P

connector

CN302

Logic

circuit

board

side

6P

connector

CN1

7P

connector

CN3

(1)

Remove

Top

Cover

(240)

and

Front

Panel

(233)

(Refer

to

Section

1)

(2)

Meter

Window

(220)

can

be

removed

by

pulling

up.

(3)

Color

Filter

(221)

can

be

removed

after

Meter

Window

(220)

is

removed.

4.

How

to

removed

the

Meter

Holder

and

the

8P

connector

CN2

Note:

When

assembling,

check

to

make

sure

the

con-

Counter/Meter

Circuit

Board,

the

LED

circuit

Board.

nectors

are

inserted

correctly.

(5)

Pull

out

the

power

switch

lever

230

from

the

power

switch

259.

(6)

Remove

the

eject

knob

231.

(1)

Remove

the

top

cover

(240)

and

the

front

panel

(233).

(Refer

to

section

1)

(2)

Remove

the

angle

(210).

(Refer

to

section

2)

(3)

Remove

the

2

screws

(3x8CFTS

S

tight)

(307)

which

(7)

The

mechanism

can

be

removed

by

holding

the

mecha-

nism

and

pulling

up.

Note:

When

assembling,

do

so

after

checking

to

make

sure

the

2

stay

holes

on

the

lower

side

of

the

mechanism

unit

are

matched

with

the

chassis

protrusions.

secure

meter

holder

(242).

Then

the

meter

holder

can

be

removed.

(4)

By

unscrewing

the

2

screws

(3x6

CBS)

(303)

holding

the

counter/meter

circuit

board,

it

can

be

removed.

(5)

By

unscrewing

the

1

screw

(3x6

CBS)

(303)

holding

the

LED

circuit

board,

it

can

be

removed.

(9)

(10)

(1)

(2)

(3)

(4)

(1)

(2)

(3)

(4)

(5)

(6)

7.

(1)

(2)

(3)

(4)

(5)

How

to

Remove

the

Front

Esc

Ass’y

Remove

the

top

cover

(240)

and

the

front

panel

(233).

(Refer

to

section

1)

Remove

the

angle

(210).

(Refer

to

section

2)

Remove

the

meter

window

(220)

and

the

color

filter

(221).

(Refer

to

section

3)

Unscrew

the

2

nuts

holding

the

output

volume

(237)

and

the

headphone

jack

(255).

Then

the

front

esc

ass’'y

(206)

can

be

removed.

How

to

Remove

the

Volume

Circuit

Board

Remove

the

top

cover

240

and

the

front

panel

233.

(Refer

to

section

1)

|

Remove

the

angle

210

(Refer

to

section

2)

Remove

the

meter

window

220

and

the

color

filter

221.

(Refer

to

section

3)

Remove

the

front

escuchion

206.

(Refer

to

section

4)

By

unscrewing

the

3

screws

(3x8

CBTS

P

tight)

301

holding

the

Volume

plate

245

and

loosening

the

2

hooks

on

the

front

escuchion

ass’y

206

holding

the

Volume

circuit

board

244,

it

can

be

removed.

Unscrew

the

3

nats

holding

the

3

Volumes.

Then

the

Volume

circuit,

board

244

can

be

removed.

How

to

Remove

the

Control

Circuit

Board

Remove

the top

cover

240

and

the

front

panel

233.

(Refer

to

Section

1)

Remove

the

angle

210.

(Refer

to

section

2)

Remove

the

meter

window

220

and

the

color

filter

221.

(Refer

to

section

3)

Remove

the

front

escuchion

206.

(Refer

to

section

4)

By

unscrewing

the

3

screw

(3x8

CBTS

P

tight)

301

holding

the

control

circuit

board

and

loosening

the

2

hooks

on

the

front

escuchion

Ass’y

206

holding

the

control

circuit

board

204,

it

can

be

removed.

Note:

8.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

When

replacing

the

tact

switch

224,

always

check

to

make

sure

that

it is

not

floating

above

the

circuit

board.

If it

is

floating,

the

switch

will

be

in

the

on

condition

when

the

set

is

assembled.

O

x

Be

cca

ges

How

to

Remove

the

Audio

Circuit

Board

Remove

the

top

cover

240

and

the

front

panel

233.

(Refer

to

section

1)

Remove

the

angle

210

(Refer

Remove

the

meter

holder

242,

Remove

the

front

escuchion

206.

Remove

the

volume

plate

245.

(Refer

to

section

6)

Remove

the

control

circuit

board

204.

(Refer

to

section

7)

Remove

the

connectors

from

the

audio

circuit

board

203.

to

section

2)

(Refer

to

section

4)

Unscrew

the

4

bottom

cover

holding

screws

(3x8

CBTS

P

tight)

301

on

the

back

side

of

the

chassis

201

and

remove

the

bottom

cover

218.

By

loosening

the

2

hooks

on

the

chassis

holding

the

audio

circuit

board

203,

the

audio

circuit

board

can

be

removed.

Note:

Most

repairs

to

the

audio

circuit

board

can

be

performed

by

removing

the

bottom

cover

on

the

chassis.

Refer

to

the

above

procedure

only

when

necessary.

When

reassembling,

follow

the

procedures

in

reverse

order;

however,

if

each

of

the

various

parts

are

not

assembled

properly

in

their

respective

position,

the

set

cannot

be

assembled.

When

assembling,

check

the

work

of

each

step

carefully.

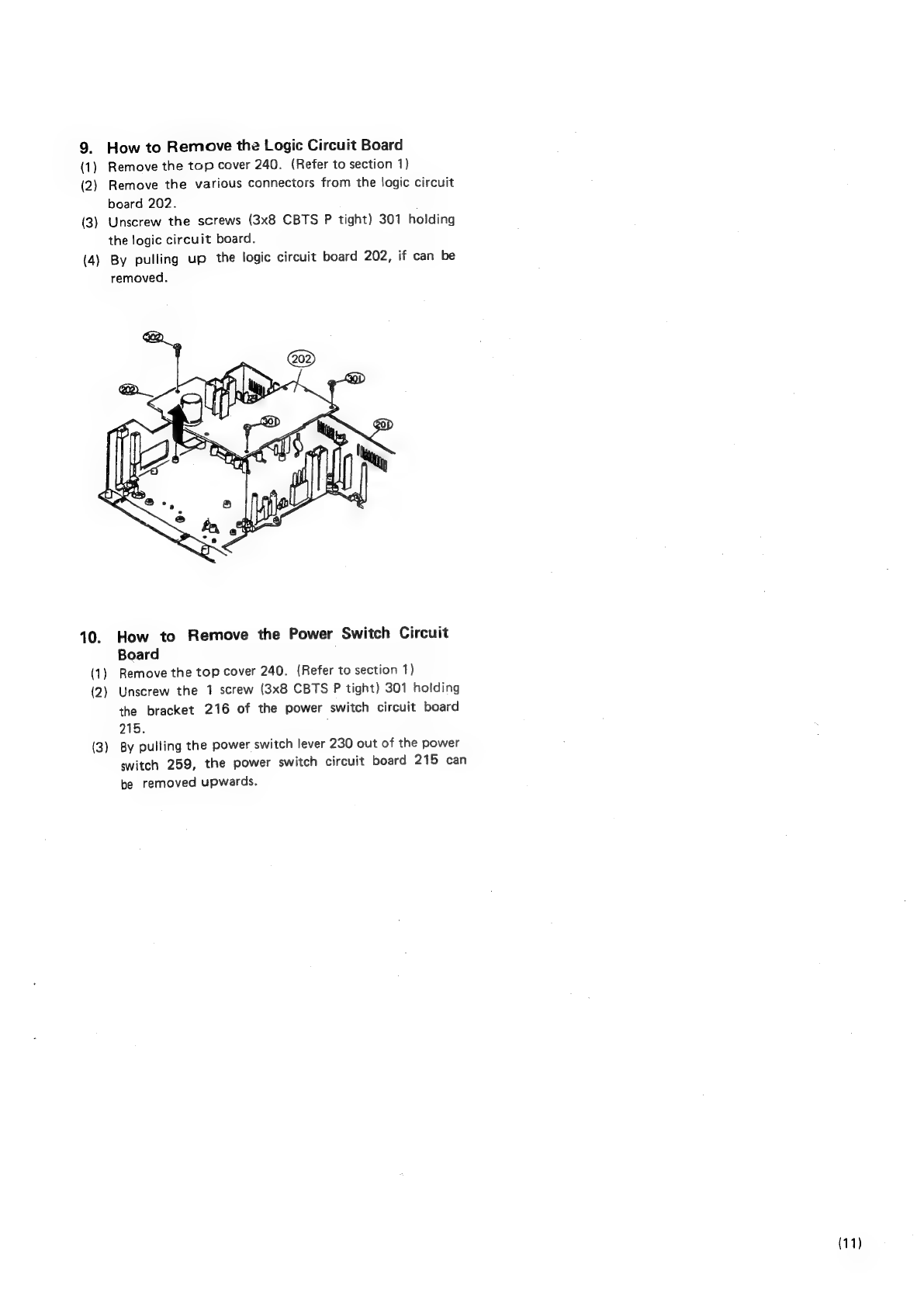

(1)

(2)

(3)

(4)

How

to

Remove

the

Logic

Circuit

Board

Remove

the

top

cover

240.

(Refer

to

section

1)

Remove

the

various

connectors

from

the

logic

circuit

board

202.

Unscrew

the

screws

(3x8

CBTS

P

tight)

301

holding

the

logic

circuit

board.

By

pulling

up

the

logic

circuit

board

202,

if

can

be

removed.

10.

(1)

(2)

(3)

How

to

Remove

the

Power

Switch

Circuit

Board

Remove

the

top

cover

240.

(Refer

to

section

1)

Unscrew

the

1

screw

(3x8

CBTS

P

tight)

301

holding

the

bracket

216

of

the

power

switch

circuit

board

215.

,

By

pulling

the

power

switch

lever

230

out

of

the

power

switch

259,

the

power

switch

circuit

board

215

can

be

removed

upwards.

(11)

ADJUSTING

AND

CHECKING

THE

MECHANISM

SECTION

1.

Replacing

the

Pinch

Roller.

Before

replacing

the

pinch

roller,

clean

the

tape

contact

surface

of

the

pinch

roller

and

the

capstan

shaft.

Most

causes

of

poor

tape

transport

can

be

traced

to

dirty

pinch

rollers

and

capstan

shafts.

The

right

side

pinch

roller

23

can

be

taken

out

by

remov-

ing

spring

24

and

slit

washer

317.

In

the

same

manner,

the

left

side

pinch

roller

104

can

be

taken

out

by

remov-

ing

spring

106

and

slit

washer

317.

After

replacing,

play

a

padiess

C-90

tape

and

check

for

tape

curls

at

the

head

tape

guide

section.

In

addition,

in

the

playback

mode,

check

to

make

sure

that

the

right

side

pinch

roller

contacts

the

capstan

shaft

before

the

left

side

pinch

roller

contacting.

Correct

P,

Rolter

arm

L

C_]

/

2

nut

Tape

guide

P.

Roller

arm

R

2

nut

E.

head

Special

nut

Reha

Defective

Curled

Curled

Tape

travel

2.

Checking

the

Pressure

Force

of

the

Pinch

Roller

In

the

playback

mode,

hook

a

spring

weight

onto

the

bracket

at

the

center

of

the

pinch

roller.

After

separating

the

pinch

roller

from

the

capstan

shaft,

allow

the

pinch

roller

to

contact

the

capstan

shaft

again.

When

the

pinch

roller

starts

to

rotate,

check

to

make

sure

the

rod

type

spring

weight

reading

is

350g—450g

for

the

right

side

and

150g

~

250g

for the

left

side.

Hf

it

is

not

within.the

normal

range,

replace

the

pinch

roller

spring

24

or

106.

Pinch

roller

spring

Capstan

shaft

Pinch

roller

Left

side

{50g

~

250g

(12)

3.

Replacing

the

Record/Playback

Head

*

Before

replacing,

remove

the

front

panel

233.

(1)

How

to

remove

the

R/P

HEAD.

1)

Next,

Take

out

the

azimuth

adjustment

NUT

311,

tilt

adjustment

NUT

311,

and

the

height

adjustment

Special

nut

10

loosening

them

alternately.

If

they

are

not

loosened

alternately,

the

R/P

HEAD

base

may

become

warped.

2)

By

unsoldering

the

HEAD

WIRES

on

the

circuit

board

section

of

the

R/P

HEAD,

the

entire

R/P

HEAD

can

be

taken

off

the

mechanism

unit.

C@

R/P

head

er

(Azimuth

adj,

nut)

(Tilt

adj.

nut)

(2)

How

to

assemble

the

R/P

HEAD.

Reverse

the

above

(1)

procedures

for

removing

the

R/P

HEAD.

“Solder

the

HEAD

WIRES

according

to

the

diagram

above.

4.

Adjusting

the

R/P

HEAD

(1)

Height

adjustments

(Use

the

head

adjusting

jig

THG-801

1)

Set

the

THG-801

tooi

plate

on

the

mechanism

unit;

turn

the

height

adjustment

Special

nut

10

and

adjust

so

that

the

3.8

mm

measure

section

of

the

THG-801

(tool

grip)

can

pass

without

contacting

the

tape

guide

of

_

the

R/P

HEAD

9.

2)

When

adjusting

the

height,

make

sure

the

R/P

HEAD

is

not

tilted

by

turning

the

azimuth

adjustment

nut

311

nut,

and

checking

with

your

eyes.

*Never

allow

the

THG-801

(tool

grip)

to

hit

the

tape

contact

surface

of

the

R/P

HEAD

strongly.

It

may

scratch

the

surface.

(2)

Adjusting

Tilt

Angle

1)

Set

the

THG-801

Tool

Plate

on

the

Mechanism

Unit

and

then

place

the

THG-801

Tool

Grip

on

the

R/P

Head,

and

check

the

Tilt

Angle

between

THG-801

Tool

Plate

and

THG-801

Tool

Grip.

If

the

THG-801

Tool

Grip

is

tilting

toward

the

front,

loosen

Tilt

with

nut

(311).

If

the

THG-801

(Tool

Grip)

is

tilting

toward

the

rear,

tighten

it.

Adjust

the

Tilt

Adjustment

nut

(311)

until

the

THG-801

Tool

Grip

becomes

parallel

with

the

THG-801

Tool

Plate.

lf

the

Tilt

Angle

is

adjusted

more

than

once,

height

Adjustment

may

slip.

Always

make

sure

to

check

height

adjustment.

—

If

height

has

slipped,

adjust

it

again.

After

adjustment,

fix

screw.

2)

E\

Tilt

Angle

Tool

grip

Tool

grip

B-

Tool

Plate

Tool

Plate

Tilt

Angle

(3)

Azimuth

adjustments

Play

back

the

A*‘BEX

TCC-153

test

tape.

Turn

the

azimuth

adjustment

nut

and

adjust

so

that

A

of

the

resurge

wave

form

is

maximum

and

B

is

minimum.

After

the

azimuth

adjustments,

re-check

the

head

height

with

the

THG-801

to

make

sure

the

height

has

not

deviated.

MTT

114

*

After

the

adjustments,

apply

anaerobic

adhesive

on

the

positions

indicated

in

the

diagram.

Anaerobic

adhesive

Anaerobic

adhesive

5.

Adjustment

and

Replacement

of

Erasing

Head

(1)

Height

Adjustments

Set

the

THG-801

Tool

Plate

on

the

mechanism

unit.

Using

a

surface

measure

of

3.8

mm

from

the

THG-801

Tool

Grip,

turn

adjustment

nut

(311)

and

(171)

and

adjust

the

height

of

Erasing

Head’s

center

to

coincide

with

the

center

of

the

THG-801

Tool

Grip.

After

adjustment,

place

the

THG-801

Tool

Grip

on

the

Erasing

Head,

check

to

see

that

the

THG-801

Tool

Plate

and

the

THG-801

Tool

Grip

are

parallel,

and

that

the

Tilt

Angle

has

not

changed.

Lock

after

adjustment.

Tilt

Angle

Adjustment

Set

the

THG-801

Tool

Plate

on

the

mechanism

unit.

Place

the

THG-801

Tool

Grip

on

the

Erasing

Head,

and

check

the

gap

between

the

THG-801

Tool

Plate

and

the

Tool

Grip.

tf

the

THG-801

Tool

Grip

is

tilting

toward

the

front,

loosen

the

Tilt

adjustment

nut

(311).

\f

it

is

tilting

toward

the

rear,

tighten

it

and

adjust

the

Tilt

adjustment

nut

(311)

until

the

THG-801

Tool

Grip

becomes

parallel!

with

the

THG-801

Tool

Plate.

(2)

CAUTION:

After

adjusting

the

Tilt

Angle,

height

adjust-

ment

may

sometimes

be

warped.

Recheck

height

adjustment.

If

it

is

warped,

readjust

the

height.

After

adjusting,

fix

nuts

(311)

and

(171).

(3)

Erasing

Head

Replacement

Erase

Head

may

be

replaced

after

removing

nuts

(311)

and

(171)

which

affix

it

to

the

deck

mechanism,

After

replacement,

adjust

the

height

and

the

Tilt

angle.

3.8mm

Tilt

Angle

6.

Height

Adjustment

of

the

Tape

Guide

Set

the

THG-801

jig

plate

onto

the

mechanism

unit

and

ad-

just

the

height

by

rotating

the

height

adjustment

nut

311

so

that

the

3.8mm

section

of

the

THG-801

jig

can

pass

through

without

contacting

the

tape

guide

section

of

tape

guide

103.

7.

Checking

the

Take-up

Torque

Load

the

cassette

type

torque

meter.

Check

to

make

sure

that

the

torque

meter

average

reading

is

within

40

~

80

g-cm

during

playback.

If

it

is

not

within

this

range,

check

the

voltage

(4.3V

+

0.3V)

of

the

reel

motor.

If

the

voltage

is

low,

the

torque

will

be

weak;

if

it

is

high,

the

torque

will

be

strong.

in

addition,

check

for

reel

thrust

movement

in

section

8.

(13)

8.

Adjusting

the

Reel

Thrust

Movement

Check

to

make

sure

that

the

reel

thrust

movement

is

within

0.2—0.4

mm.

9.

Checking

the

FF

and

REW

Torques

*

When

using

the

cassette

type

torque

meter.

Check

to

make

sure

the

torque

meter

indicates

more

than

80

~

160

g-cm

at

the

end

of

FF

and

REW.

*

When

using

a

modified

cassette

half.

Load

the

modified

cassette

half;

hook

the

end

of

the

dial

tension

meter

(full

scale

100—300

g)

onto

the

triangle

section.

In

the

FF

(REW)

mode,

feed

the

tape

in

at

a

rate

somewhat

slower

than

the

take

up

speed.

Check

to

make

sure

the

dial

tension

meter

reads

more

than

60

g-cm.

10.

Checking

the

Back

Tension

Torque

During

Record/Playback

Load

the

cassette

type

torque

meter;

check

to

make

sure

the

torque

meter

reads

between

5

~

13

g-cm

during

play-

back

and

that

there

js

rio

unevenness.

If

it

is

not

within

this

range,

check

the

section

on

adjust-

ing

the

reel

trust

movement;

or

replace

the

spring

109.

11.

Checking

the

FF

and

REW

Times

Load

a

C-60

cassette

tape;

check

to

make

sure

the

tape

is

fast

forwarded

or

rewound

within

70—110

seconds.

If

it

is

not

within

this

range,

check

sections

8

and

10.

12.

Checking

the

Operation

of

the

Erase

Preven-

tion,

Metal

and

Chrome

Switch

Operation

Arms

Check

to

make

sure

the

operation

arms

58,

59

operate

the

switches

positively;

depending

on

whether

or

not

there

are

holes.

13.

Checking

the

EJECT

Switch

To

check

the

operation

of

the

EJECT

SW

with

only

the

mechanism

unit,

make

sure

the

angle

205

operates

the

switch

positively

when

the

hook

lever

203

is

operated.

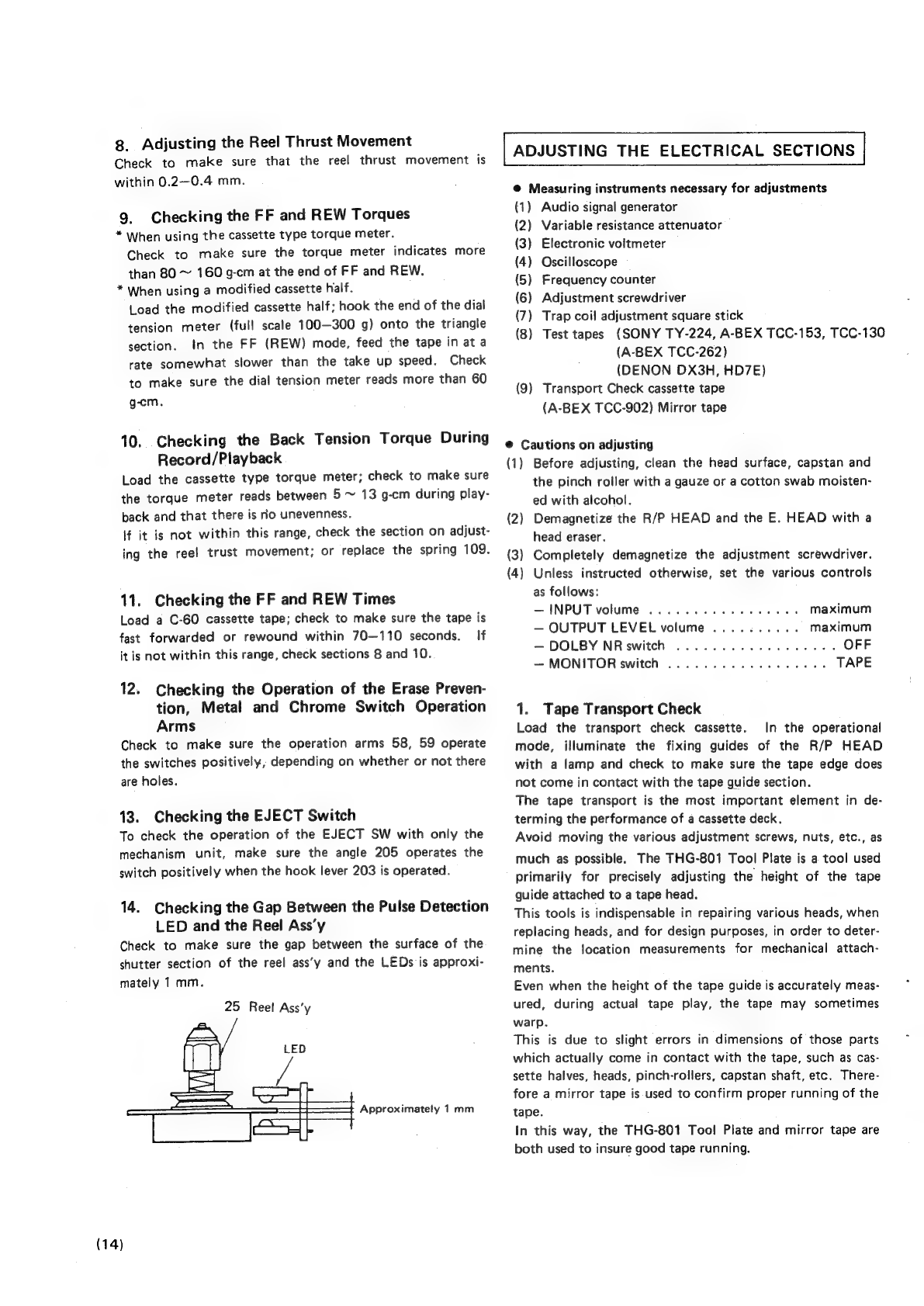

14.

Checking

the

Gap

Between

the

Pulse

Detection

LED

and

the

Reel

Ass’y

Check

to

make

sure

the

gap

between

the

surface

of

the

shutter

section

of

the

reel

ass’y

and

the

LEDs

is

approxi-

mately

1

mm.

25

Reel

Ass’y

LED

Z

Approximately

1mm

(14)

ADJUSTING

THE

ELECTRICAL

SECTIONS

@

Measuring

instruments

necessary

for

adjustments

(1)

Audio

signal

generator

(2)

Variable

resistance

attenuator

(3)

Electronic

voltmeter

(4)

Oscilloscope

(5)

Frequency

counter

(6)

Adjustment

screwdriver

(7)

Trap

coil

adjustment

square

stick

(8)

Test

tapes

(SONY

TY-224,

A-BEX

TCC-153,

TCC-130

(A-BEX

TCC-262)

(DENON

DX3H,

HD7E)

(9)

Transport

Check

cassette

tape

(A-BEX

TCC-902)

Mirror

tape

@

Cautions

on

adjusting

(1)

Before

adjusting,

clean

the

head

surface,

capstan

and

the

pinch

roller

with

a

gauze

or

a

cotton

swab

moisten-

ed

with

alcohol.

Demagnetize

the

R/P

HEAD

and

the

E.

HEAD

with

a

head

eraser.

(2)

(3)

Completely

demagnetize

the

adjustment

screwdriver.

(4)

Unless

instructed

otherwise,

set

the

various

controls

as

follows:

—

INPUT

volume

..........-.--0065

maximum

—

OUTPUT

LEVEL

volume

..........

maximum

—

DOLBY

NRswitch

...............06.

OFF

—

MONITOR

switch

............0.0005

TAPE

1.

Tape

Transport

Check

Load

the

transport

check

cassette.

In

the

operational

mode,

illuminate

the

fixing

guides

of

the

R/P

HEAD

with

a

lamp

and

check

to

make

sure

the

tape

edge

does

not

come

in

contact

with

the

tape

guide

section.

The

tape

transport

is

the

most

important

element

in

de-

terming

the

performance

of

a

cassette

deck.

Avoid

moving

the

various

adjustment

screws,

nuts,

etc.,

as

much

as

possible.

The

THG-801

Tool

Plate

is

a

tool

used

primarily

for

precisely

adjusting

the

height

of

the

tape

guide

attached

to

a

tape

head.

This

tools

is

indispensable

in

repairing

various

heads,

when

replacing

heads,

and

for

design

purposes,

in

order

to

deter-

mine

the

location

measurements

for

mechanical

attach-

ments.

Even

when

the

height

of

the

tape

guide

is

accurately

meas-

ured,

during

actual

tape

play,

the

tape

may

sometimes

warp.

This

is

due

to

slight

errors

in

dimensions

of

those

parts

which

actually

come

in

contact

with

the

tape,

such

as

cas-

sette

halves,

heads,

pinch-rollers,

capstan

shaft,

etc.

There-

fore

a

mirror

tape

is

used

to

confirm

proper

running

of

the

tape.

In

this

way,

the

THG-801

Tool

Plate

and

mirror

tape

are

both

used

to

insure

good

tape

running.

After

having

confirmed

that

the

setting

is

correct,

the

mir-

ror

tape

may

warp

anyway.

In

order

to

establish

the

titit

angles

of

the

recording/plaback

head

and

the

erase

head,

adjust

(by

turning

1

/4

—

1/2

turns)

the

level

adjustment

nut

(811)

of

the

tape

guide

(103).

Refer

to

the

pages

on

“Adjusting

and

checking

the

Mechanism

Section’

when

replacing

or

adjusting

the

R/P

HEAD.

2.

Adjusting

the

Azimuth

(1)

After

completing

the

tape

transport

check

load

the

test

tape

(A-BE

X

TCC-153)

(2)

Play

back

the

test

tape;

adjust

the

azimuth

nut

so

that

section

A

of

the

resurge

wave

form

is

maximum

and

section

B

is

minimum.

MTT

=114

3.

Checking

and

Adjusting

the

Tape

Speed

1)

Connect

the

frequency

counter

to

the

LINE

OUT

terminal

and

load

the

test

tape

(SONY

TY-224).

2)

Playback

a

test

tape.

At

about

halfway

through

the

tape,

where

the

tape

transport

is

stable,

adjust

the

adjustment

points

on

the

back

of

the

capstan

motor

so

that

the

frequency

counter

will

have

a

reading

with-

in

the

the

range

of

3,000

Hz

+

6Hz.

F

Counter

PB

Amp

LINE

OUT

3000

Hz

,6Hz

MTT-Ii

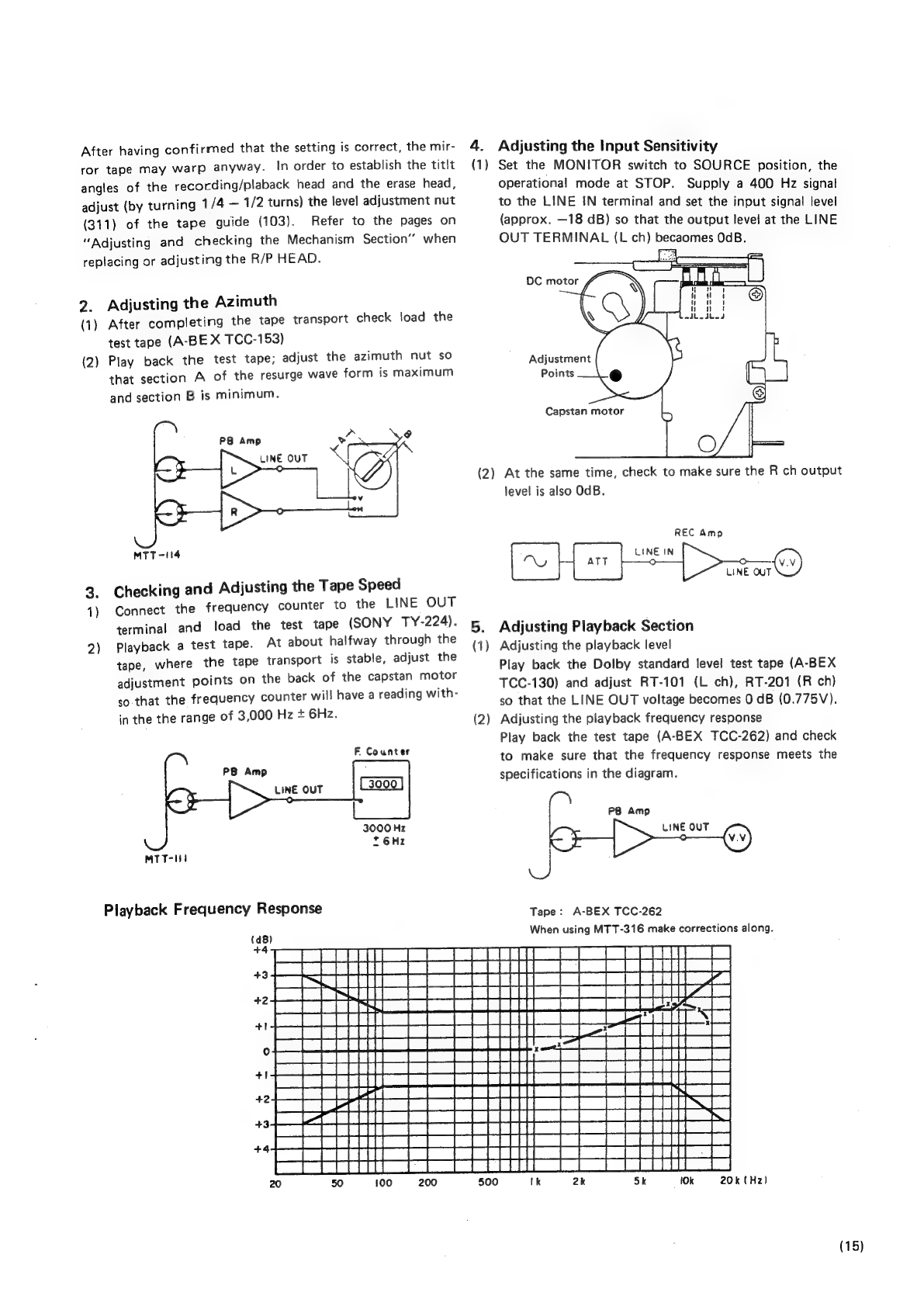

Playback

Frequency

Response

4.

Adjusting

the

Input

Sensitivity

(1)

Set

the

MONITOR

switch

to

SOURCE

position,

the

operational

mode

at

STOP.

Supply

a

400

Hz

signal

to

the

LINE

IN

terminal

and

set

the

input

signal

level

(approx.

—18

dB)

so

that

the

output

level

at

the

LINE

OUT

TERMINAL

(L

ch)

becaomes

OcB.

DC

motor

#

VA

Adjustment

Points

Capstan

motor

(2)

At

the

same

time,

check

to

make

sure

the

R

ch

output

level

is

also

OdB.

REC

Amp

LINE

IN

:

©

LINE

OUT

5.

Adjusting

Playback

Section

(1)

Adjusting

the

playback

level

Play

back

the

Dolby

standard

level

test

tape

(A-BEX

TCC-130)

and

adjust

RT-101

(L

ch),

RT-201

(R

ch)

so

that

the

LINE

OUT

voltage

becomes

0

dB

(0.775V).

Adjusting

the

playback

frequency

response

Play

back

the

test

tape

(A-BEX

TCC-262)

and

check

to

make

sure

that

the

frequency

response

meets

the

specifications

in

the

diagram.

(2)

PB

Amp

LINE

OUT

J

Tape:

A-BEX

TCC-262

When

using

MTT-316

make

corrections

along.

10k

20k

(Hz)

(15)

6.

Adjusting

the

FL

Meter

After

adjusting

the

playback

level,

playback

the

test

tape

(A-BEX

TCC-130)

and

adjust

RT401

(L

ch),

RT402

(R

ch)

so

that

the

FL

meter

indicates

OdB

when

the

LINE

OUT

terminal

level

is

OdB

(0.775V).

LINE

OUT

MTT-150

7.

Adjusting

the

Recording

Section

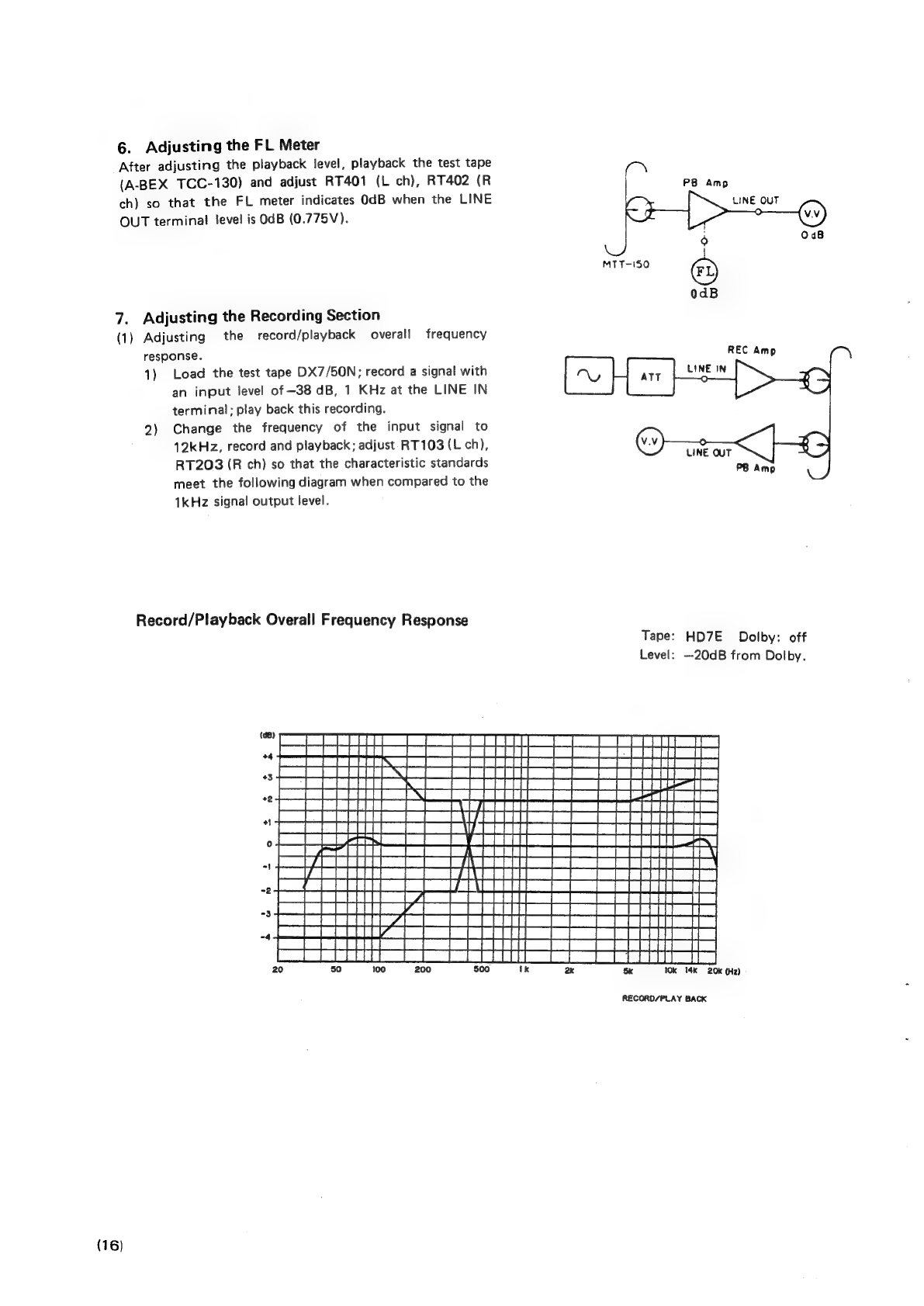

(1)

Adjusting

the

record/playback

overall

frequency

response.

1)

Load

the

test

tape

DX7/50N;

record

a

signal

with

an

input

level

of

-38

dB,

1

KHz

at

the

LINE

IN

terminal;

play

back

this

recording.

2)

Change

the

frequency

of

the

input

signal

to

12kHz,

record

and

playback;

adjust

RT103

(L

ch),

RT203

(R

ch)

so

that

the

characteristic

standards

meet

the

following

diagram

when

compared

to

the

1kHz

signal

output

level.

Record/Playback

Overall

Frequency

Response

Tape:

HD7E

Dolby:

off

Level:

—20dB

from

Dolby.

Sk

10k 14k

20k

(Hz)

RECORD/PLAY

BACK

(16)

(2)

Adjusting

the

record/playback

levels

1)

Load

the

test

tape

HD7E/C-60

and

record

a

signal

of

1kHz

(—38

dB).

2)

Adjust

RT102

(L

ch),

RT202

(R

ch)

so

that

the

output

level

is

the

same

when

the

MONITOR

switch

is

switched

from

SOURCE

to

TAPE

position.

LINE

OUT

PB

Amp

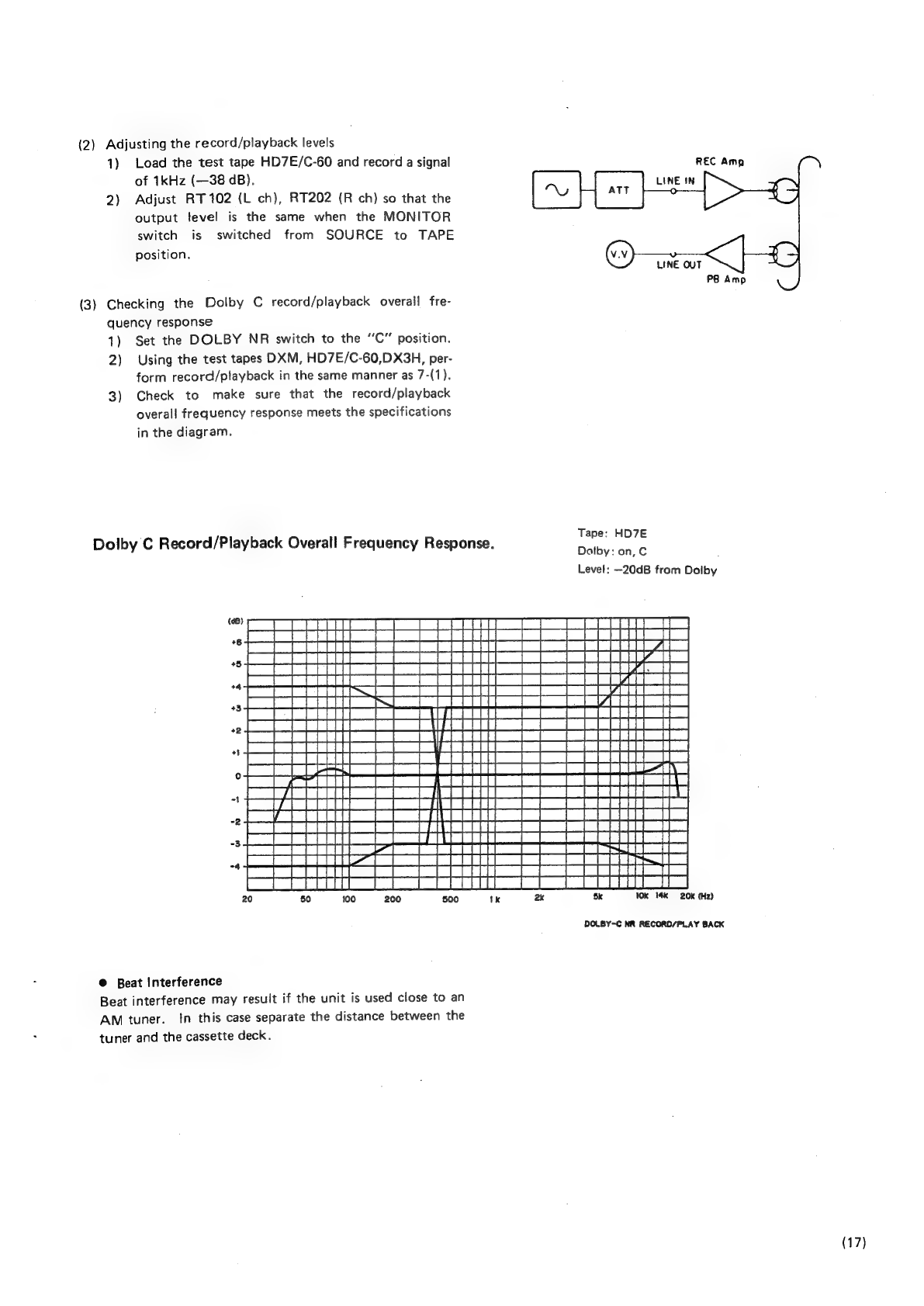

(3)

Checking

the

Dolby

C

record/playback

overall

fre-

quency

response

1)

Set

the

DOLBY

NR

switch

to

the

“C”

position.

2)

Using

the

test

tapes

OXM,

HD7E/C-60,DX3H,

per-

form

record/playback

in

the

same

manner

as

7-(1).

3)

Check

to

make

sure

that

the

record/playback

overall

frequency

response

meets

the

specifications

in

the

diagram.

Tape:

HD7E

Dolby:

on,

C

Level:

—20dB

from

Dolby

Dolby

C

Record/Playback

Overall

Frequency

Response.

(<8)

i

fm

_tttitt

|

[|

TT

a

oe

Ee

Tr

+4

+3

+2

+1

al

-3

aa

i

“4

ee

eee

Pai

ERR

Se

En

FS

Ol

(Fa

ett

aaa

PS)

tH

4

a

sO

De

20 50

100

200 500

1k

2k

5k

Wk

14k

20k

(Hz)

DOLBY~C

NR

RECORD/PLAY

BACK

@

Beat

Interference

Beat

interference

may

result

if

the

unit

is

used

close

to

an

AM

tuner.

In

this

case

separate

the

distance

between

the

tuner

and

the

cassette

deck.

(17)

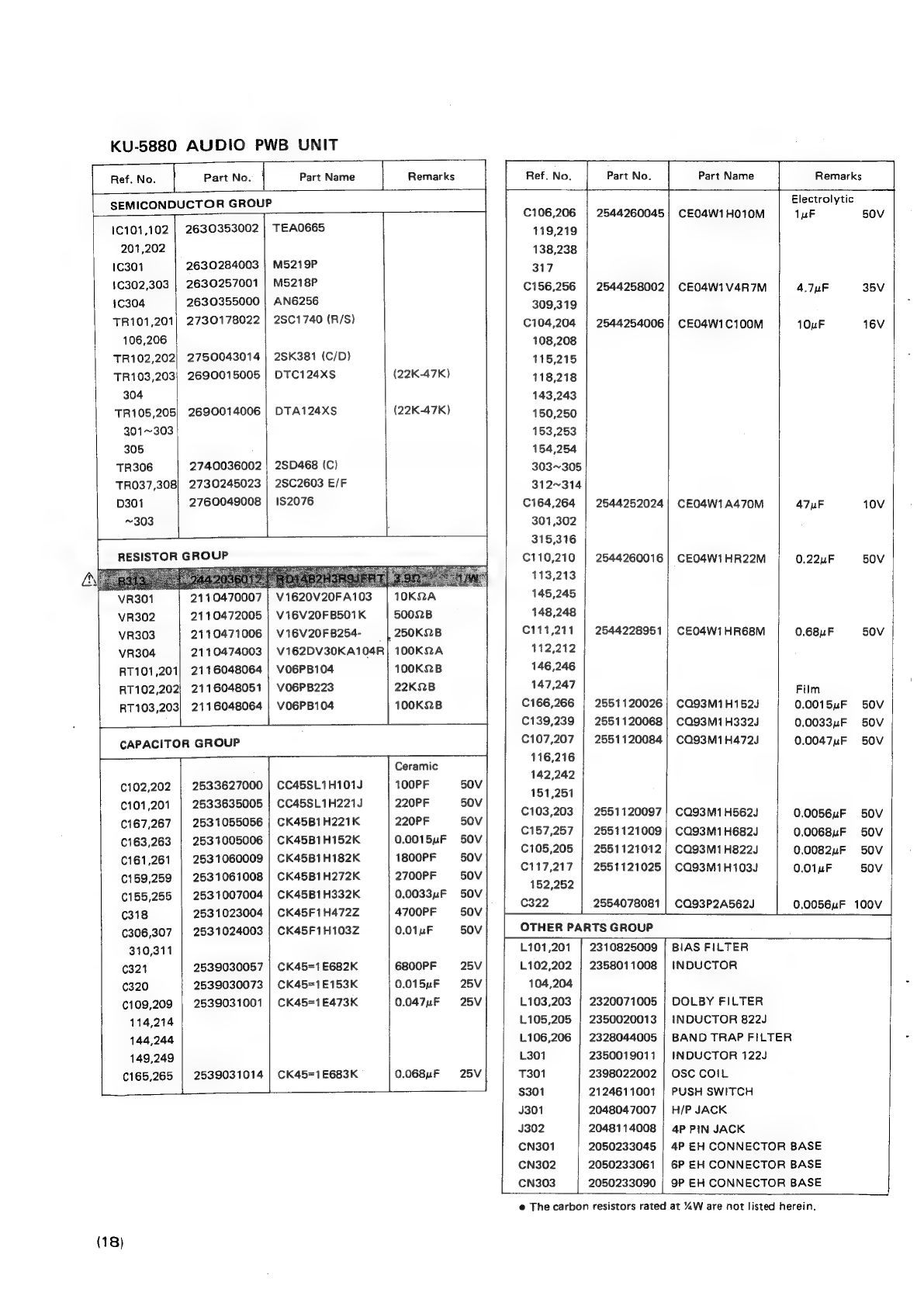

KU-5880

AUDIO

PWB

UNIT

Ref.

No.

Part

No.

Part

Name

Remarks

Ref.

No.

Part

No.

[te

Name

Remarks

_—_t

Electrolytic

Semone

ere

7

C106,206

|

2544260045|

CE04W1H010M

1uF

:

50V

1c101,102

|

2630353002

|}

TEAO6ES5

119,219

201,202

138,238

1C301

2630284003

|

M5219P

317

1C302,303

|

2630257001

|

M5218P

C156,256

|

2544258002)

CEO4W1V4R7M

4.7nF

35V

1C304

2630355000

|

AN6256

309,319

TR101,201)

2730178022

|

2SC1740

(R/S)

C104,204

|

2544254006!

CE04W1C100M

10uF

16V

106,206

108,208

TR102,202|

2750043014

|

2SK381

(C/D)

115,215

TR103,203}

2690015005

|

DTC124xs

(22K-47K)

118,218

304

143,243

TR105,205|

2690014006

|

DTA124XS

(22K-47K)

150,250

301~303

153,253

305

154,254

TR306

2740036002

|

2SD468

(C)

303~305

TRO37,308)

2730245023

}

2SC2603

E/F

312~314

D301

2760049008

|

1S2076

C164,264

|

2544252024|

CE04W1A470M

47uF

10V

~303

301,302

315,316

RESISTOR

C110,210

|

2544260016]

CEO4W1HR22M

0.22uF

50V

3

113,213

VR301

2110470007

|

V1620V20FA103

|

10KQA

145,245

VR302

2110472005

|

V16V20FB501K

50028

148,248

VR303

2110471006

|

V16V20FB8254-

=

|

250K2.B

C111,211

|

2544228951}

CEO4W1HR68M

0.68uF

50V

VR304

2110474003

|

Vi62DV30KA104R|

100KQA

112,212

RT101,201}

2116048064

|

VO6PB104

100K2B

146,246

RT102,202/

2116048051

|

Vo6PB223

22K2B

147,247

Film

RT103,203}

2116048064

|

VO6PB104

100K2.B

C166,266

|

2551120026;

CQ93M1H152J

0.0015uF

50V

C139,239

|

2551120068|

CQ93M1H332J

0.0033uF

50V

CAPACITOR

GROUP

C107,207

|

2551120084]

CQ93M1H472J

0.0047uF

50V

oat

Ceramic

Bae

142,242

¢102,202

|

2533627000

|

CC45SL1H101J

100PF

151.251

C101,201

|

2533635005

|

CC45SL1H221J

=|

220PF

=

50V

C103,203

|

2551120097!

CQ93M1H562J

0.0056uF

50V

C18

7267

|||

ee

Onan

Oe

Glee

beats

are

oY

C157,257

|

2551121009}

CQ93M1H682J

0.0068uF

50V

C163,263

|

2531005006

|

CK45B1H152K

0.0015uF

50V

"

;

c1et261

|

2831060009

|

cK4sB1H182K

1GOORE:.

600

C105,205

|

2551121012)

CQ93M1H822J

0.0082uF

50V

'

C117,217

|

2551121025|

CQ93M1H103J

0.01uF

50V

¢159,259

|

2531061008

|

CK45B1H272K

2700PF

50V

eye

C155,255

|

2531007004

|

CK45B1H332K

0.0033uF

SOV

(318

2531023004

|

CK45F1H472Z

4700PF

50V

ie

P5080

R081)

COBSEZABG2I.

|

0.0056uF

-190¥

|

¢306,307

|

2531024003

|

CK45F1H103Z

0.01uF

50V

OTHER

PARTS

GROUP

310,311

101,201

|

2310825009

|

BIAS

FILTER

|

(321

2539030057

|

CK45=1E682K

6800PF

25V

L102,202

|

2358011008

|

INDUCTOR

320

2539030073

|

CK45=1E153K

0.015uF

25V

104,204

€109,209

|

2539031001

|

CK45=1E473K

0.047uF

25V

L103,203

|

2320071005

|

DOLBY

FILTER

114,214

L105,205

|

2350020013

|

INDUCTOR

822J

144,244

L106,206

|

2328044005

|

BAND

TRAP

FILTER

149,249

L301

2350019011

|

INDUCTOR

122J

€165,265

|

2539031014

|

CK45=1E683K

0.068uF

25V

7301

2398022002

|

OSC

COIL

—!

i

$301

2124611001

|

PUSH

SWITCH

J301

2048047007

|

H/P

JACK

J302

2048114008

|

4P

PIN

JACK

CN301

2050233045

|

4P

EH

CONNECTOR

BASE

CN302

2050233061

|

6P

EH

CONNECTOR

BASE

CN303

2050233090

|

9P

EH

CONNECTOR

BASE

(18)

@

The

carbon

resistors

rated

at

%“W

are

not

listed

herein.

KU-5870

POWER

LOGIC

UNIT

|

Part

No.

|

Part

Name

Remarks

Tr

|

RESISTOR

GROUP

yPD7506C-69

BA6109U1

BA6146

pPD554C-136

2S8D468

(C)

2SD882

(Q/P)

28C1740

(R/S)

288772

Q/P

2S8A933

(R/S)

2SA966

(Y)

DTA143ES

DTC124XxS

2S8C1740

(R/S)

DTC124XS

DTA143ES

28C1740

(R/S)

28C1740

(R/S)

RN1204

DTC124xS

DSM1A2

1S2076A

1S2076

HZ11A-3

H2Z18-3

HZ5B-3

HZ7B-3

HZ9B-1

HZ3C-2

Ref.

No.

F

SEMICONDUCTOR

GROUP

1C1

2620674005

1C2,3

2620447009

1C401,

402

|

2620440006

1C403

2620580005

TR1

2740036002

TR2

2740078031

TR3

2730178022

TR4

2720055029

TRS

2710183927

TR6

2710105002

TR7

2690022904

TR8

2690015005

TRO

2730178022

TR11

269001

5005

TR12

2690022904

TR13

2730178022

TR404

27301

78002

TR405

2690029004

TR451

2690015005

D1~10

2760433009

D11

2760049011

D12~20

2760049008

D401,

402

D451~456

ZD1,

2

2760052082

ZD3

2760249015

ZD5

2760236015

ZD6

2760254000

ZD7

2760218046

ZD8

2760299007

=

4,.7K-4.7K

22K-47K

22K-47K

4,.7K-4.7K

47K-47K

22K-47K

R29

Src

ere

een

182

R427

2412313082

|

RD14B2E4R7JFRF|

4.72

RB401

2462013002

|

RK99=2B473MP5

|

47K2x5

RB402

2462010092

|

RK99=28104mMP4

|

100K2x4

RB403

2462012032

|

RK99=2B104MP8

|

100K2x8

RT401,

402]

2116048019

|

VO6PB473

47KQB

CAPACITOR

GROUP

poe

C1,9

|

254284006

CE04W1C100M

10nF

16V

408

C2

2544260045

|

CEO4W1H010M

1yF

50V

C3,6

2544252024

|

CE04W1A470M

47uF

10V

C4,

7

2544254938

|

CE04W1C470M

47uF

16V

C5,

8

2544254080

|

CE04W1C102M

1000uF

16V

15

C10,

11

2544256033

|

CE04W1E470M

47uF

25V

c12

2544258086

|

CE04W1C471M

470uF

35V

C13

2544163003

|

CE04W1C221M

220uF

16V

C14

2544255018

|

CE0Q4W1C472M

4700zF

=

16V

C16,

17

2544258002

|

CEO4W1V4R7M

4.74uF

35V

20,

401,

i

AOA»

-A)-¢

2

aes

Ref.

No.

Part

No.

C18

2539031014

|

CK45=1E683K

30,

33

c19

2544250055

|

CE04W0J471M

C21~25

2531004007

|

CK45B1H102K

C28~32

2531024003

|

CK45F1H103Z

C402,405

|2544260058

|

CE04W1H2R2M

C403,

406

|

2544254019

|

CEO04W1C220M

C407

2544252943

|

CEO04W1A221M

C409,

410

|2531006005

|

CK45B1H222K

C411

2531025002

|

CK45F1H223Z

CB1

2531153000

|

CK99B1H102MP4

__

OTHER

PARTS

GROUP

4170253013

|

RADIATOR

2050233061

|

6P

EH

CONNECTO

BASE

CN2

2050233087

|

8P

EH

CONNECTOR

BASE

CN3

2050233074

|

7P

EH

CONNECTOR

BASE

CN401

2050233090

|

9P

EH

CONNECTOR

BASE

CN402

2050233045

|

4P

EH

CONNECTOR

BASE

,

LE451

3939355001

|

LN224RP

(LS)

LE452

3939354002

|

LN424YP

(LS)

LE453

3939352004

|

LN324GP

(LS)

SW451~458]

2124388004

|

TACT

SWITCH

4430537000

|

LED

GUIDE

L401

2358014034

|

tNDUCTOR

3934010008

|

FL

METER

4410667107

|

METER

HOLDER

Part

Name

Remarks

0.068uF

470uF

1000PF

0.01uF

2.2nF

22uF

220uF

2200PF

0.022uF

0.001

uF

25V

6.3V

50V

50V

50V

16V

10V

50V

50V

50V

1

2204

H

@

The

carbon

resistors

rated

at

“W

are

not

listed

herein.

WARNING

Se

Parts

marked

with

/\

and/or

shading

have

special

charac-

teristics

important

to

safety.

Be

sure

to

use

the

specified

parts

for

replacement.

(19)

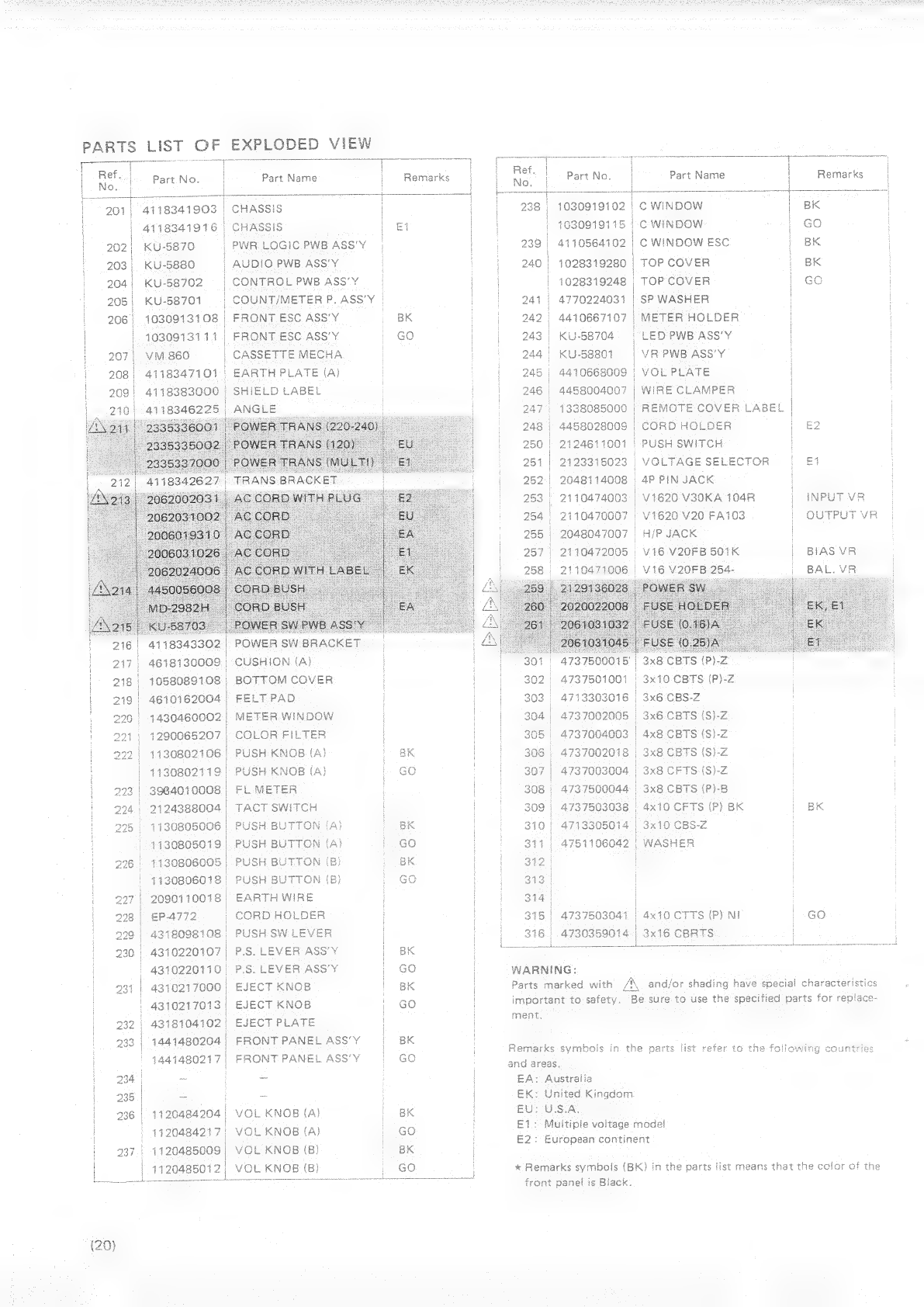

PARTS

LIST

OF

EXPLODED

VIEW

fee

tee

ek

|

oe

T

Ref.

|

Part

No.

|

Part

Name

|

Remarks

No.

\

|

201}

4118341903

|

CHASSIS

|

|

4118341916

|

CHASSIS

Et

|

202

|

KU-5870

|

PWR

LOGIC

PWB

ASS'Y

|

|

203}

KU-5880

|

AUDIO

PWB

ASS'Y

|

|

204)

KU-58702

|

CONTROL

PWBASS'Y

|

|

208)

KU-58701

|

COUNT/METER

P.

ASS’Y

|

|

206|

1030913108

|

FRONT

ESC

ASS'Y

|

BK

|

1030913111

FRONT

ESC

ASS'Y

|

Go

|

207

VM

860

|

CASSETTE

MECHA

|

|

208

4118347101

|

EARTH

PLATE

(A)

|

209|

4118383000

|

SHIELD

LABEL

210|

41183

5

4118343302

|

4618130009

1058089108

4610162004

|

1430460002

|

1290065207

|