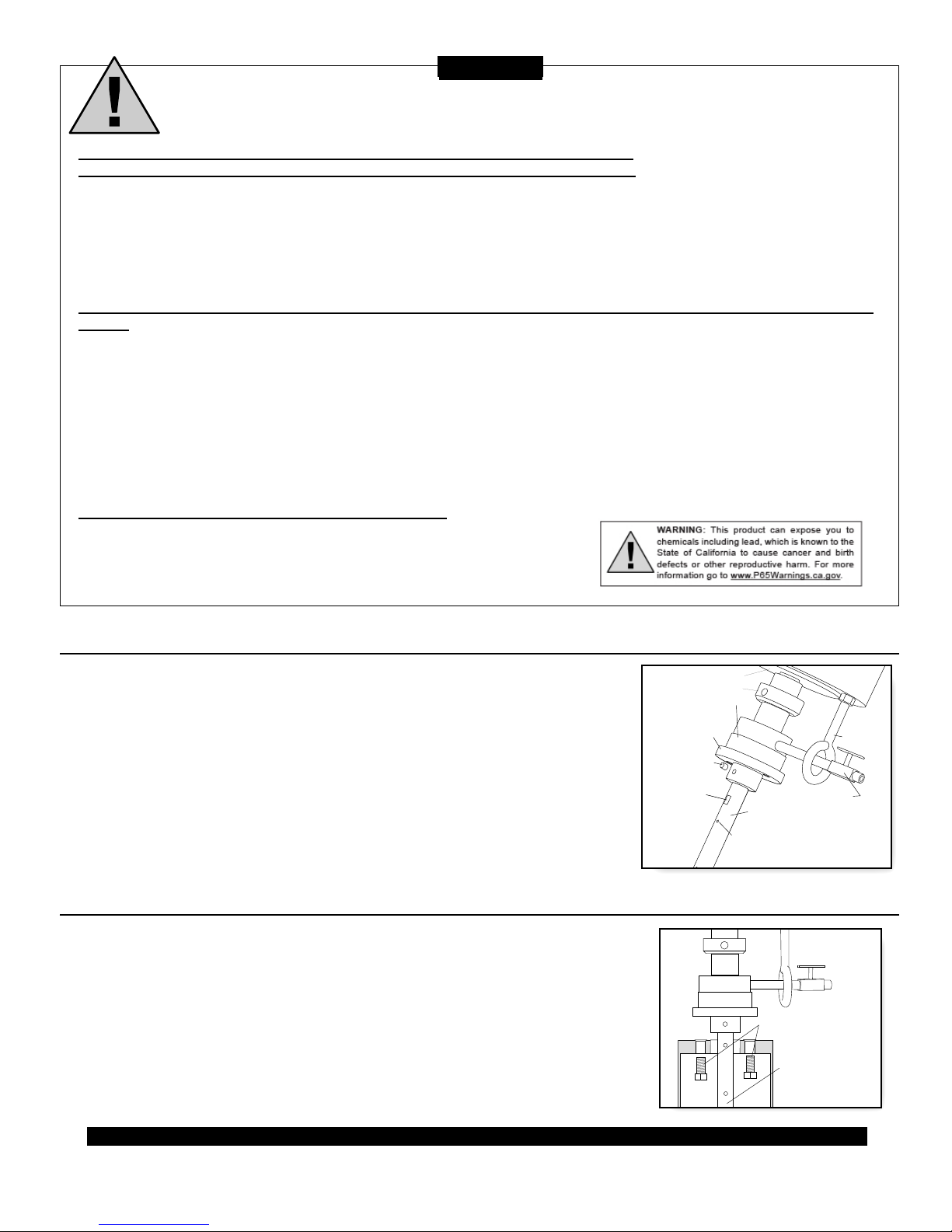

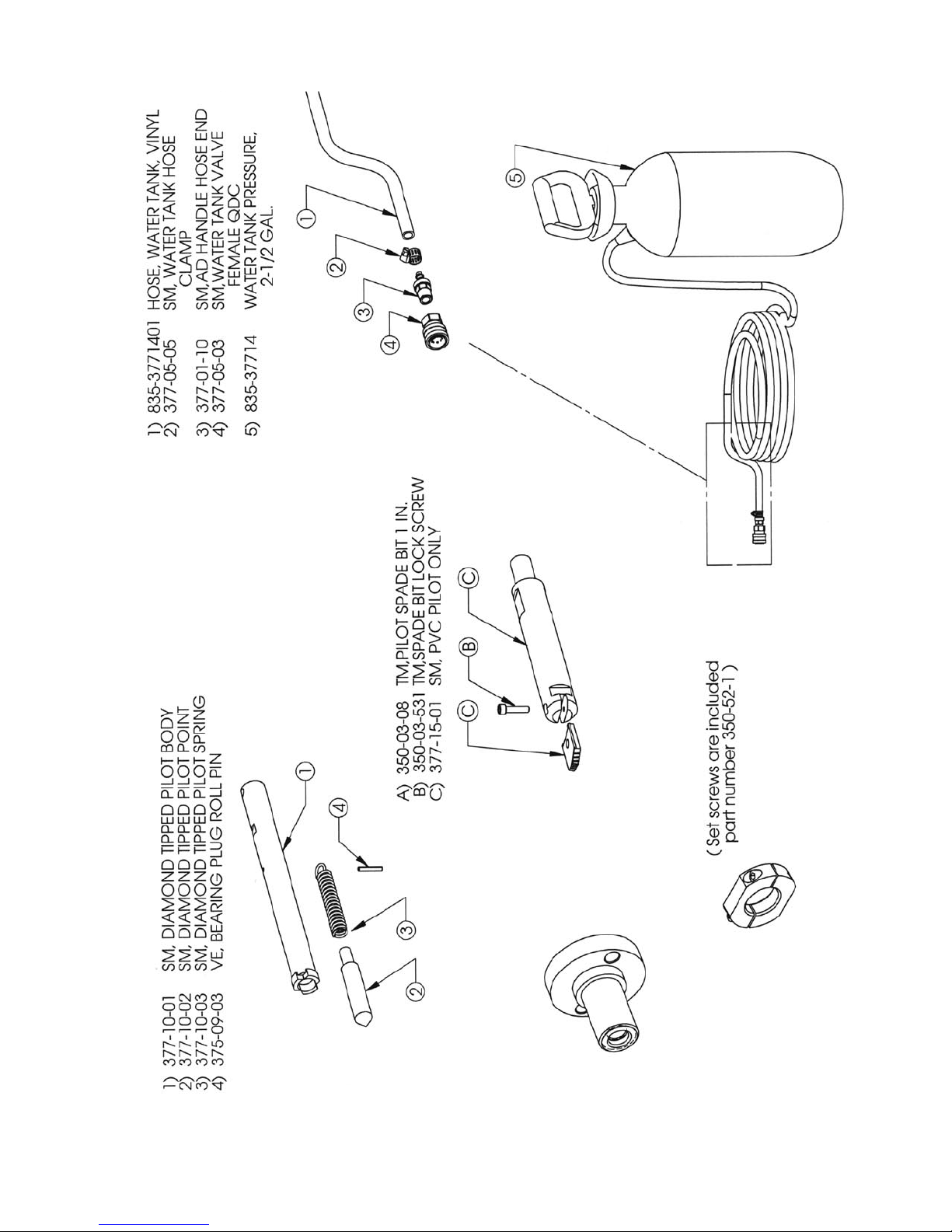

• Mark the cutting site using a center punch and hammer to make a dimple in the pipe wall.

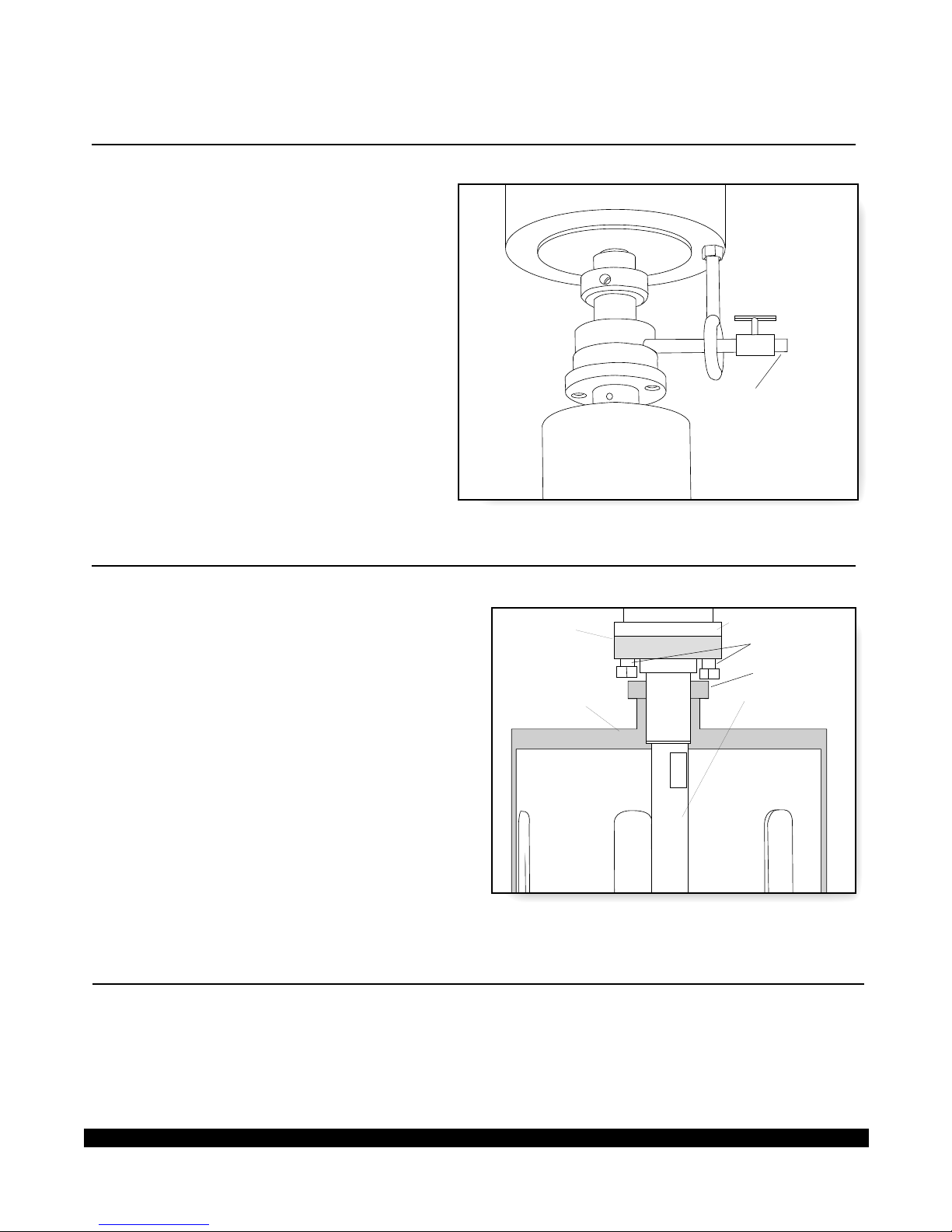

• Turn on the pressurized water tank by rotating the water valve that is connected to the bearing housing.

• Set the end of the diamond tipped pilot bit into the dimple in the pipe.

• Start machine and continue cutting until hole is completed. Caution: Do NOT press down on the machine. Let the

speed and weight of the machine do the cutting.

• Remove machine and turn off the water.

The “coupon” in almost all cases will remain in the holesaw.

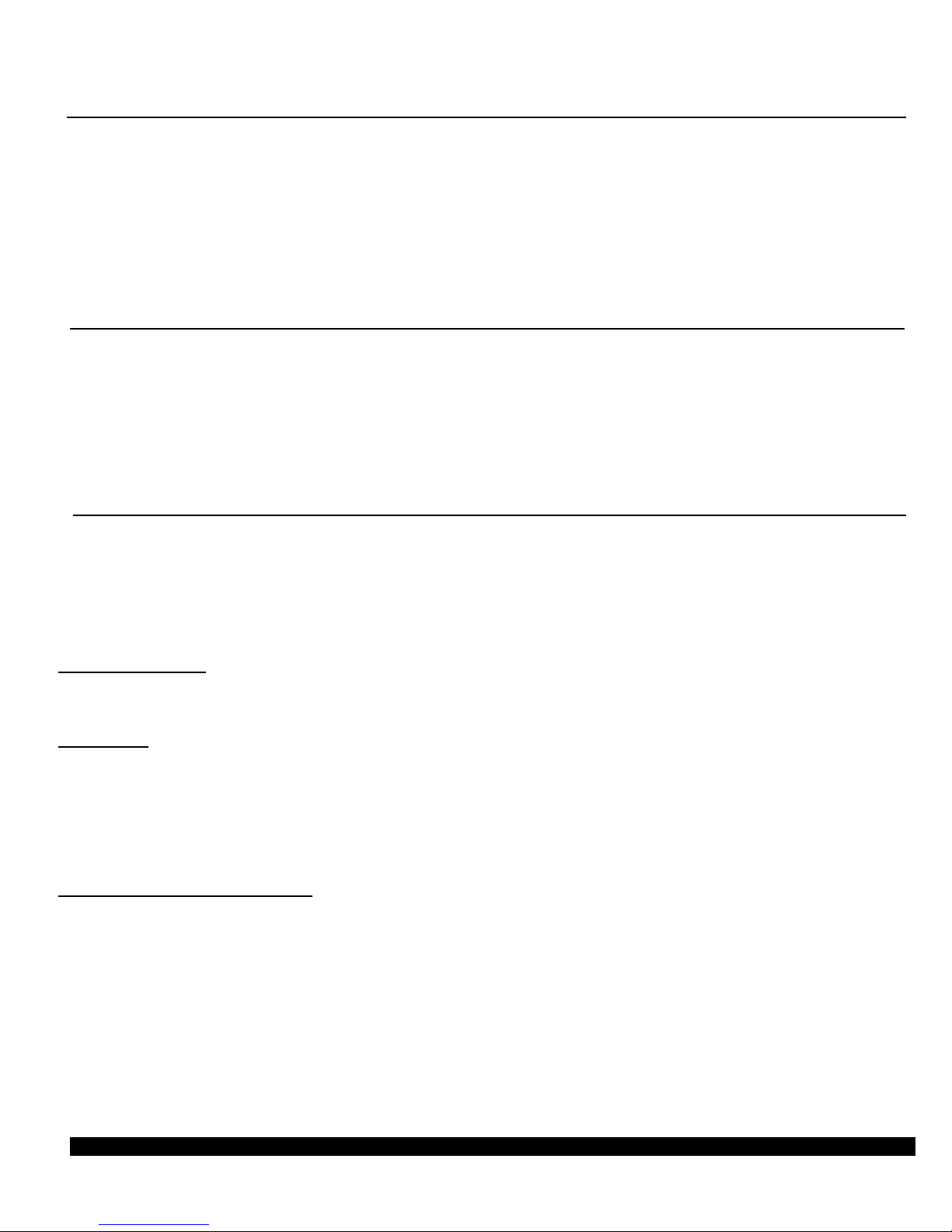

The point on the PVC is self starting. Put the point of the bit on the pipe. Pull up on the lever to start the cutter rotating

then push down on the machine to start the pilot. Once the pilot bit breaks through the pipe wall, ease up on the feed rate to

allow the hole saw to cut through the pipe wall at maximum speed. If you push down on the holesaw, its speed will decrease

and the cut will take longer.

Once the cut is complete release the lever and pull the holesaw out of the pipe. In most cases the “coupon” will remain

in the holesaw. If handled properly, the PVC pilot should last for many cuts.

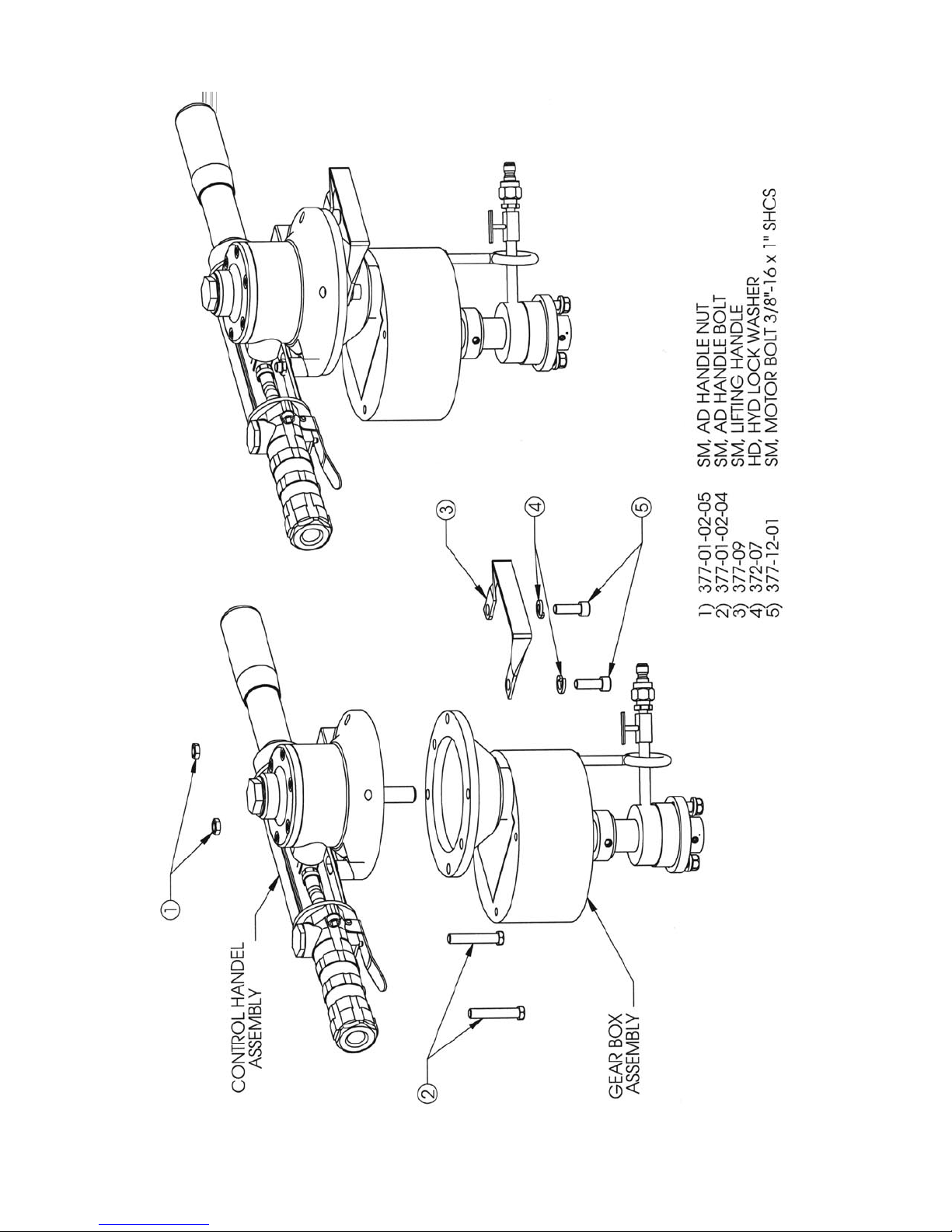

If handled properly this unit should last for many years with little maintenance. The gearbox is lubricated for life. In the

case that the gearbox lubrication is lost, please refer to the literature provide with this manual.

The air motor (Gast - Model # 4AM) literature provided with this manual should be read and carefully followed. Damage

to the air motor will result if this information is not followed.

Manual Lubrication:

Shut the air motor down and oil after every 8 hours of operation. Add 10-20 drops of oil to the air motor intake port.

Lubrication:

Use Gast # AD220 or a detergent SAE # 10 automotive engine oil for lubrication. Lubrication is necessary to prevent rust

on all moving parts. Excessive moisture in the air line may cause rust or ice to form in the mufer when air expands as

it passes through the motor. Install a moisture separator in the air line and an after cooler between compressor and air

receiver to help prevent moisture problems.

Shutdown and storage Procedure:

1) Disconnect the air source from the drive.

2) Remove the mufer from the drive.

3) Use clean, dry air at low pressure to “ush out” condensates, such as water.

WARNING: Solid or liquid material exiting the unit can cause eye or skin damage. Keep away from the air stream

4) Re-lubricate the air motor with a squirt of oil in the air intake port (Recommended oil, Mobil Almo 525).

Rotate the shaft by hand several times (10 complete revolutions min).

5) Replace the mufer and cap or plug the intake port. The unit is now ready for storage.

CUTTING PVC / HDPE PIPE

CUTTING CEMENT PIPE

MAINTENANCE AND CARE OF THE MACHINE