Nirax SPTC 400-110-10 User manual

Page 1 of 16

1.0 SAFETY INSTRUCTIONS

Important Safety Instructions

This manual contain important safety and operating instruction for Rectifier.

Model : SPTC 400-110-10.

1. Before using the Rectifier/Charger, read all instructions and cautionary marking for the

equipment.

2. DO NOT expose the Rectifier/Charger to rain or snow.

3. Use of an attachment not recommended or sold by the Rectifier/Charger manufacturer may

result in a risk of fire, electric shock or injury to persons.

4. DO NOT operate the Rectifier/Charger ; take it to a qualified service center when service or

repair is required. Incorrect assembly may result in a risk of electrical shock or fire. Unless

otherwise is instructed by the factory with a qualified service engineer.

Page 2 of 16

2.0 GENERAL INSTRUCTIONS

2.1 INTRODUCTION

Please read this manual thoroughly prior to use in order to become familiar with the unit’s features

and operating procedures. To obtain a maximum degree of safety, follow the prescribed sequences as

outlined.

This manual incorporates warnings and notes to the user. Points that are vital to the proper operations

or safety of the operators are indicated by the heading.

The Rectifier/Charger is designed to provide a fully regulated and constant DC Output Voltage from

AC Mains to the DC load or Electrical Equipment.

The complete DC system consist of 2 unit of SPTC 400-110-10 & Battery Banks. The unit, SPTC

400-110-10, is connected in parallel to charge the Battery Banks and supply power to the equipment

under normal operating mode.

Upon power failure, the battery will take over to supply the loads without any interruptions. The

backup time is depending on the battery sizing and its capacity.

2.2 TECHNICAL SPECIFICATION FOR RECTIFIER/CHARGER

AC INPUT :

Voltage System Input 400VAC, Three Phase , 4 Wire

Frequency 50Hz

DC OUTPUT SPTC 400-110-10

Voltage 110VDC nominal

Current 10 Amps DC nominal

Power 1100 Watt

Voltage Range 98.5 – 121.5 VDC

Voltage Tolerance Less than 1%

Characteristic Constant Voltage with Current Limiting

Page 3 of 16

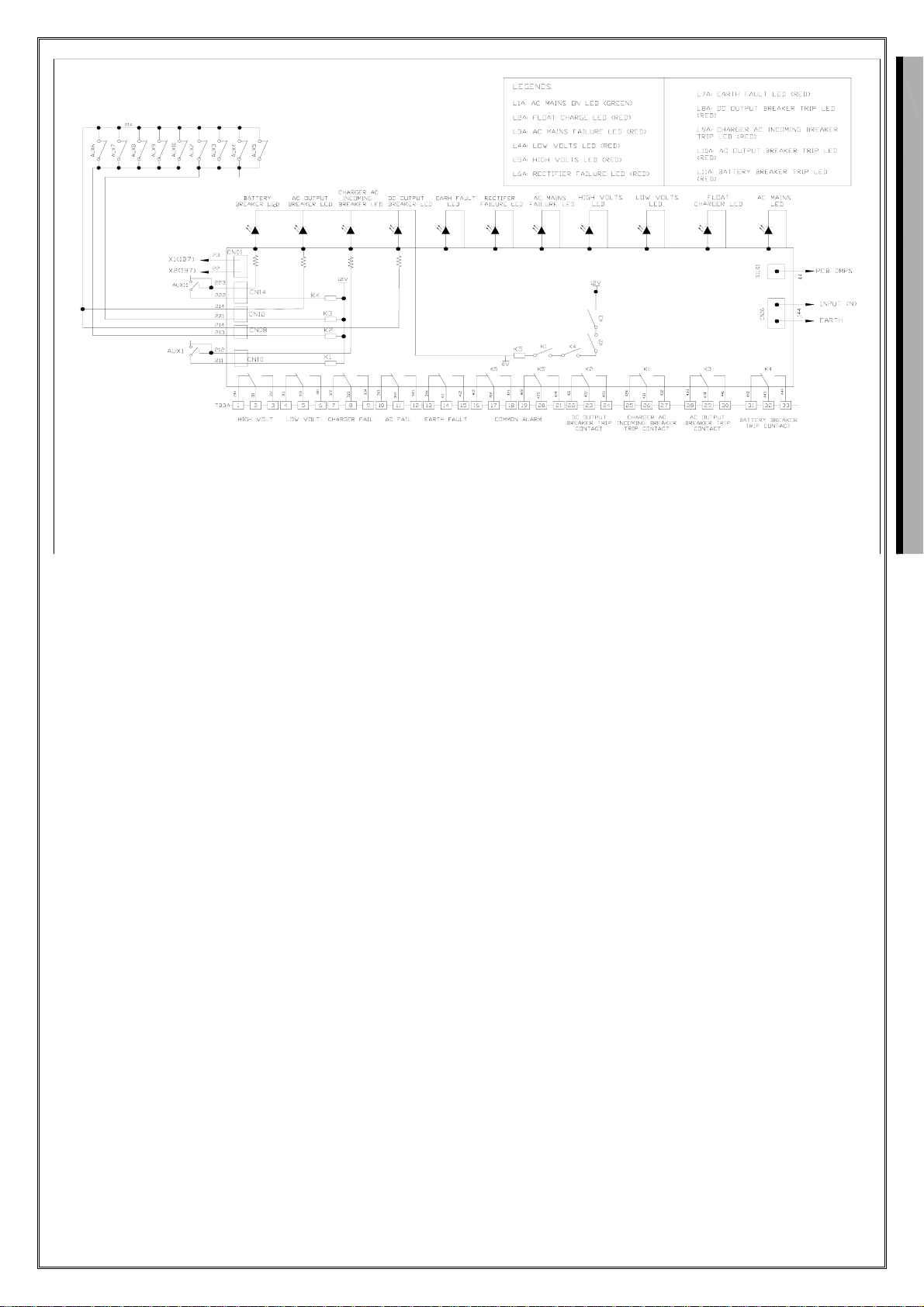

Indications AC Main On Led (Green)

Float Charge Led (Red)

Low Volts Led (Red)

High Volts Led (Red)

AC Main Failure Led (Red)

Rectifier Failure Led (Red)

Earth Fault Led (Red)

DC Output Breaker Led (Red)

Charger AC Incoming Led (Red)

AC Output Breaker Led (Red)

Battery Breaker Led (Red)

Alarm AC Main On

Rectifier Failure

High Volts

Low Volts

Earth Fault

DC Output Breaker

AC Input Breaker

AC Output Breaker

Battery Breaker

Common 1

Common 2

Protection DC Output Breaker

AC Input Breaker

AC Output Breaker

Battery Breaker

Current Limit Protection

Cabinet Protection Class IP31

Finishing Epoxy Power Coating

Cabinet Mounting Floor Mounting Type

Cable Entrance Bottom Entrance

MISCELLANEOUS :

Accoustic Noise Less than 54dBA at three feet

Cabinet Size H x W x D = 1190 x 500 x 400 mm

Weight Approx. 100 Kg

Ambient Temperature 25-65 degree C

ENVIRONMENTAL

Temperature 0 - 65 degree C (Operating)

-20 to +60 Degree C (Storage)

Humidity 0 - 95 % Non-Condensing

Elevation 500m below to 2800m above sea level

Warning :

Confirm that the battery and load current polarity connection is correct to prevent damage to the

load to the Rectifier/charger.

2.3 OUTPUT DC VOLTAGE AND OUTPUT DC CURRENT LIMIT ADJUSTMENT

To adjust the output dc voltage, trim the VR01 at PCB control modul (CMPS-06T1)

Output dc current limit, trim the VR02 at PCB control modul (CPMS-06T1)

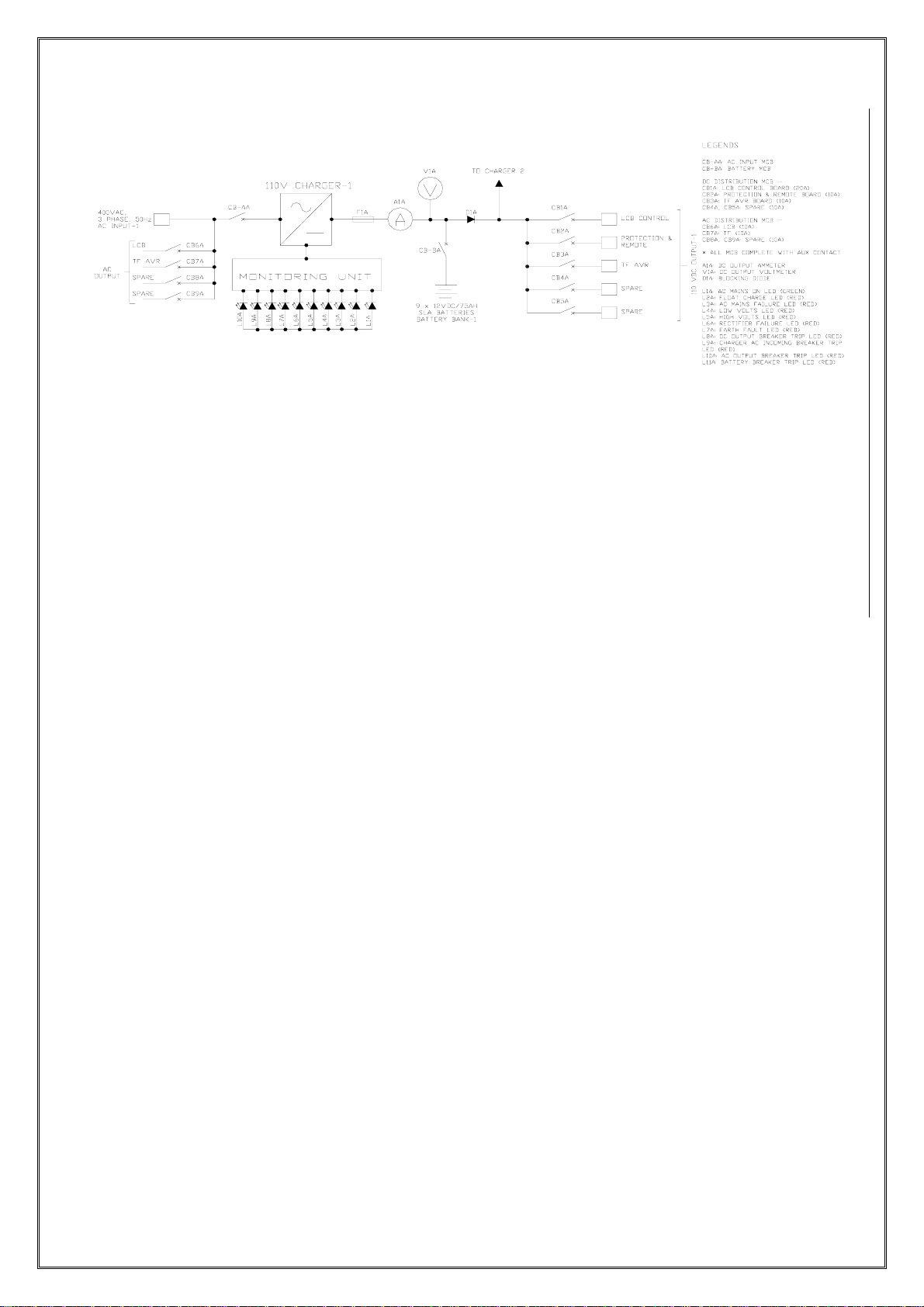

3.0 CIRCUIT CONFIGURATION

3.1 CURRENT PATHS DIAGRAM

(Refer to Single Line Diagram)

1. The unit is controlled by the input breakers. Rectifier units can be connected in parallel with

battery to form a DC power supply system.

2. Under normal condition, the Rectifier input breakers are closed and the AC power is converted

into DC power to charge the batteries as well as supply power to the equipment.

3. In the event of AC power failure, the battery will supply all loads without any interruption.

Page 4 of 16

CMPS-06T1

Current float adjust

Float voltage adjust

SIL02

SIL03

VR101

CN04

CN03

VR02

VR01 CN01

CN02

SIL01

PCB

VR102

Forsensor output

dc Voltage low adjust Forsensor output

dcVoltage high adjust

3.2 SINGLE LINE DIAGRAM

3.3 FEATURES OUTLINES DESCRIPTIONS

The following are the description of the major components for the power supply system.

Input Breaker To switch on the input supply to the unit as well as to provide over

current protection upon any failure of the units.

Ouput Breaker a. To switch on the output supply from the unit as well as to

provide over current protection upon any failure of the unit.

b. To provide control and short protected for the Load Circuit.

Battery Breaker

To provide over load protection when charging of battery and

discharge to the load as well as provide isolation for maintenance.

Alarm Contact

Relay dry contact output for remote monitoring of AC input voltage

,Rectfier failure , High Volts , Low Volts , Earth Fault , DC Ouput

Breaker , AC Input Breaker , AC Output Breaker , Battery Breaker

Page 5 of 16

3.4 SCHEMATIC DIAGRAM

Page 6 of 16

3.5 Rectifier Specifications

Page 7 of 16

Page 8 of 16

The following specifications are tested under the conditions of AC 400V/50Hz Three phase and 25°C

ambient temperature besides additional declarations.

AC Input

Input Voltage Range 380 – 410V

Phase 3 Phase

Frequency Range 50Hz

Efficiency > 80% (> 50% Load)

Protections Input Breaker

Ouput AC Breaker

Ouput DC Breaker

Over Current Protection

Surge Protections

DC Output

Output Power 1100W max

Output Voltage 110V (Float Charge Mode)

Output Current 10A (typical)

Load Regulation ± 1% of output voltage setting

Line Regulation ± 0.5% of output voltage setting

Stability ± 1% of output voltage setting

Soft start Time < 5 seconds

4.0 INSTALLATION INSTRUMENTS

Page 9 of 16

4.1 SAFETY PRECAUTION

1. DOT NOT expose the Rectifier/ Charger to rain or snow or below air-condition unit.

2. DOT NOT operate the Rectifier/ Charger of it received a sharp blow, being dropped or

otherwise damaged in any way; take it to a qualified service center.

3. Before any connection, read marking on all terminal blocks with reference to the Schematic

diagram.

4.2 INSPECTION

All Rectifier products are shipped in rugged, wooden crated and “foamed in place” to minimize shock

that may occur during transportation.

Prior to uncrating, note any damaged to the shipping container. Uncrate the Rectifier and inspect the

exterior. If any damage is observed, contact the carrier immediately.

4.3 PREPARATION/MOUNTING

The Rectifier/ Charger unit has been designed for floor mounting or floor standing type or cubicle.

The unit must be mounted in a clean and dry environment sufficient access to an uninterrupted air

source must be provided in the surrounding area of the unit.

Allow at least 200mm on the side of the unit for ease of airflow.

The AC input and DC output cable entry is at the bottom of the unit.

The battery cable entry is at the bottom of unit.

4.4 INPUT CONNECTION

WARNING

The input breaker must be in the “OFF” position before attempting to install the Rectifier/Charger.

1. The Rectifier/Charger shall only be connected with input voltage of 400VAC, 3 Phase, 50Hz.

Confirm the operating voltage before proceeding.

2. Input wires can be routed through the cable entry hole at the bottom of the cabinet.

3. Input cable for Rectifier/Charger shall be connected to Terminal Block marks “R” (Red), “Y”

(Yellow), “B” (Blue), and “N” (Neutral).

WARNING

Ensure that the input and output breakers are in “OFF” position prior to any work being performed

on the AC and DC connections.

4.5 OUTPUT CONNECTION

WARNING :

Ensure that all Output Loads Breaker and Battery Breaker are in “OFF” position before attempting

work on the output cable assembly.

1 The DC Load Breakers (for equipment) are provided for this system output.

2. The DC Output Cable shall be at least 2mm sq. per 10A outlet for equipment DC Output. The

breaker is rated at 10A.

3. The Positive Load Cables shall be connected to the Load Positive Terminal and the Negative

Load Cables shall be connected to the Load Negative Terminal.

4. Connect the 9 block (12V per block) of batteries in the series to form 108V Battery Bank.

5. Connect the Battery Positive Terminal and Battery Negative Terminal to Battery Bank. Ensure

the polarity is correct.

WARNING :

Observe the correct polarity of the output cable when terminating.

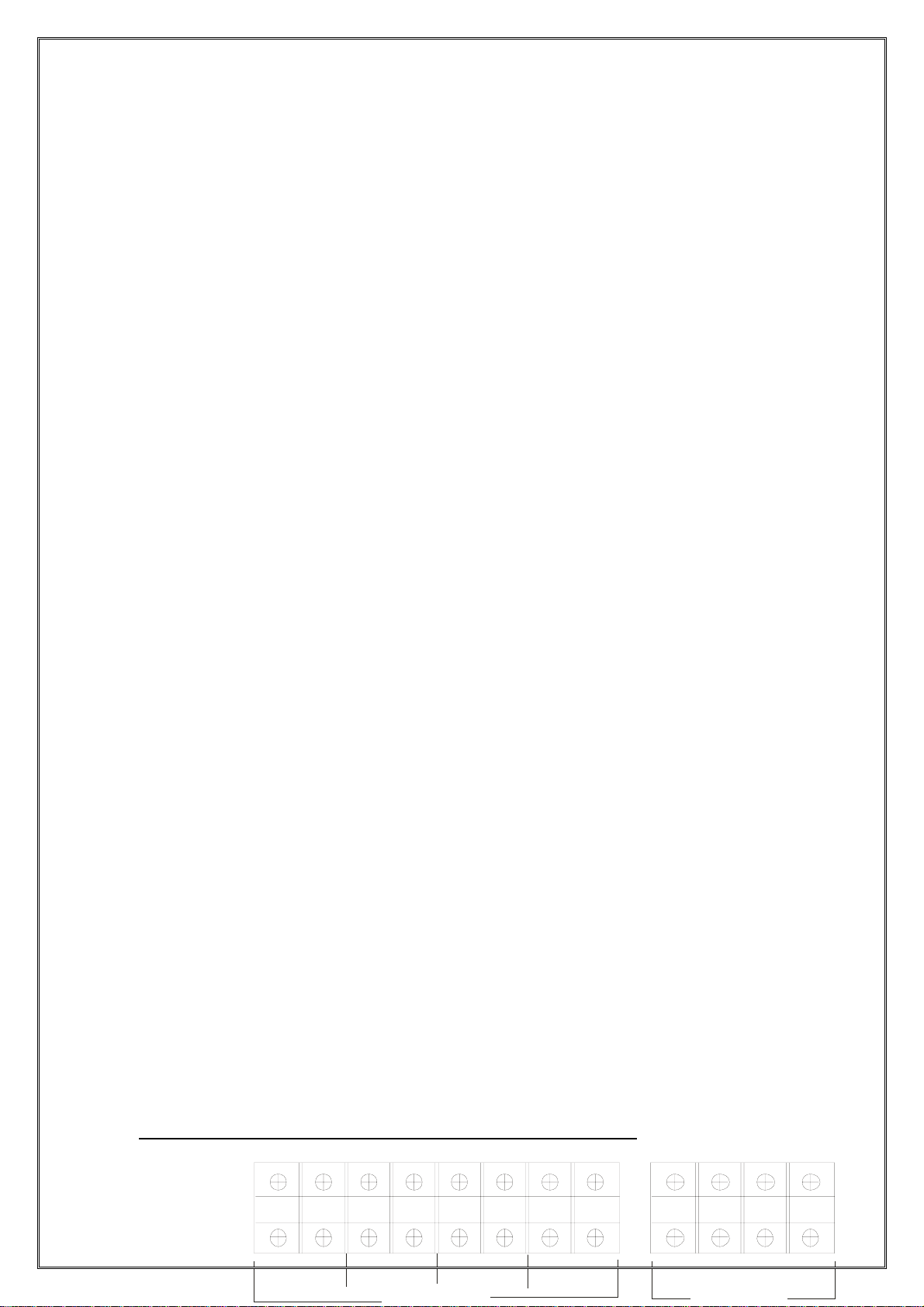

5.0 TERMINAL BLOCK ARRANGEMENT DIAGRAM

Page 10 of 16

LNLNLNLN RYBN

A

C OUTPUT AC INPUT

LCB

CONTROL TF AVR SPARE SPARE

ALARM

CONTACT

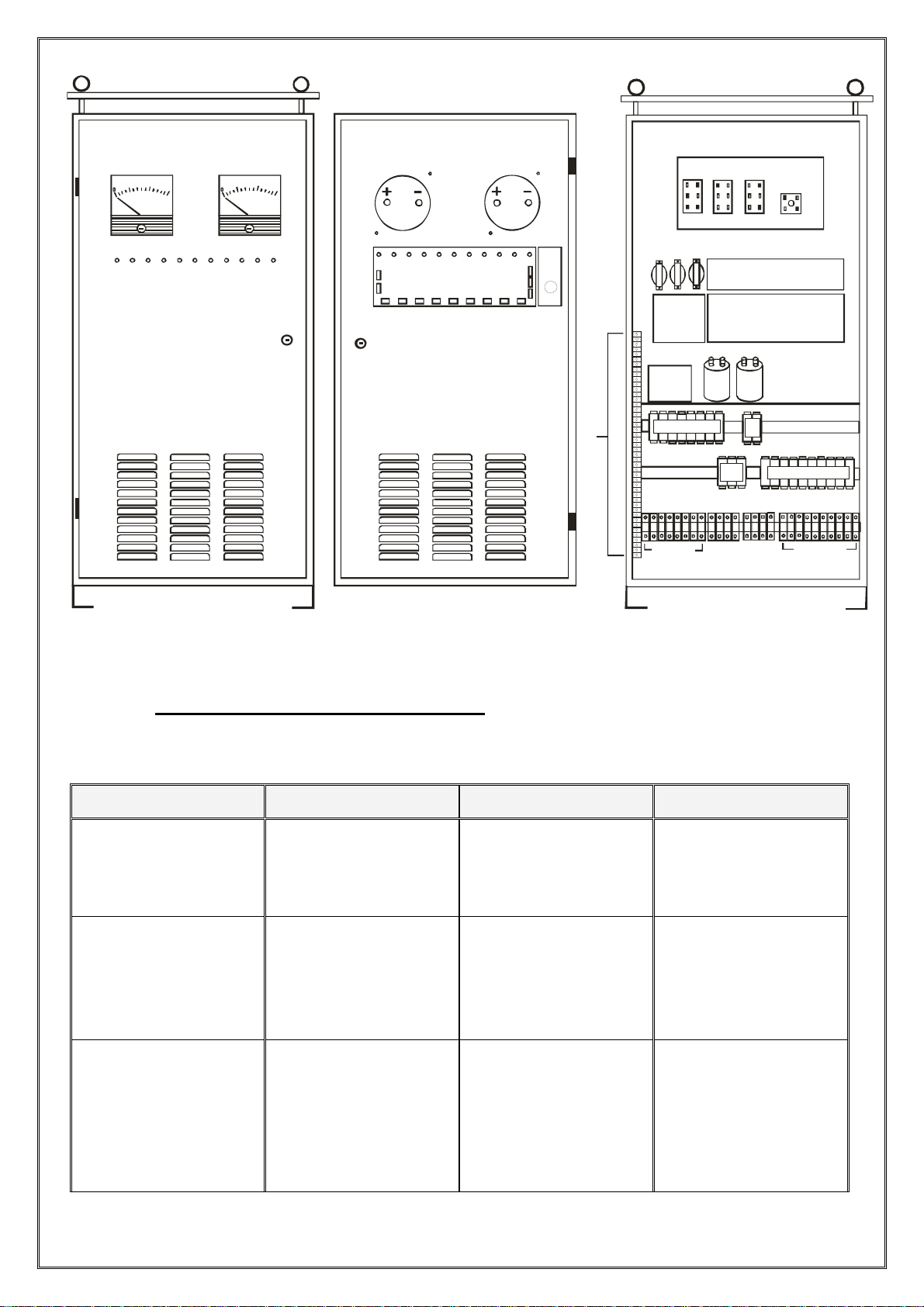

6.0 CABINET DIMENSION

FRONT VIEW BEHIND THE PANEL DOOR IN SIDE VIEW

Page 11 of 16

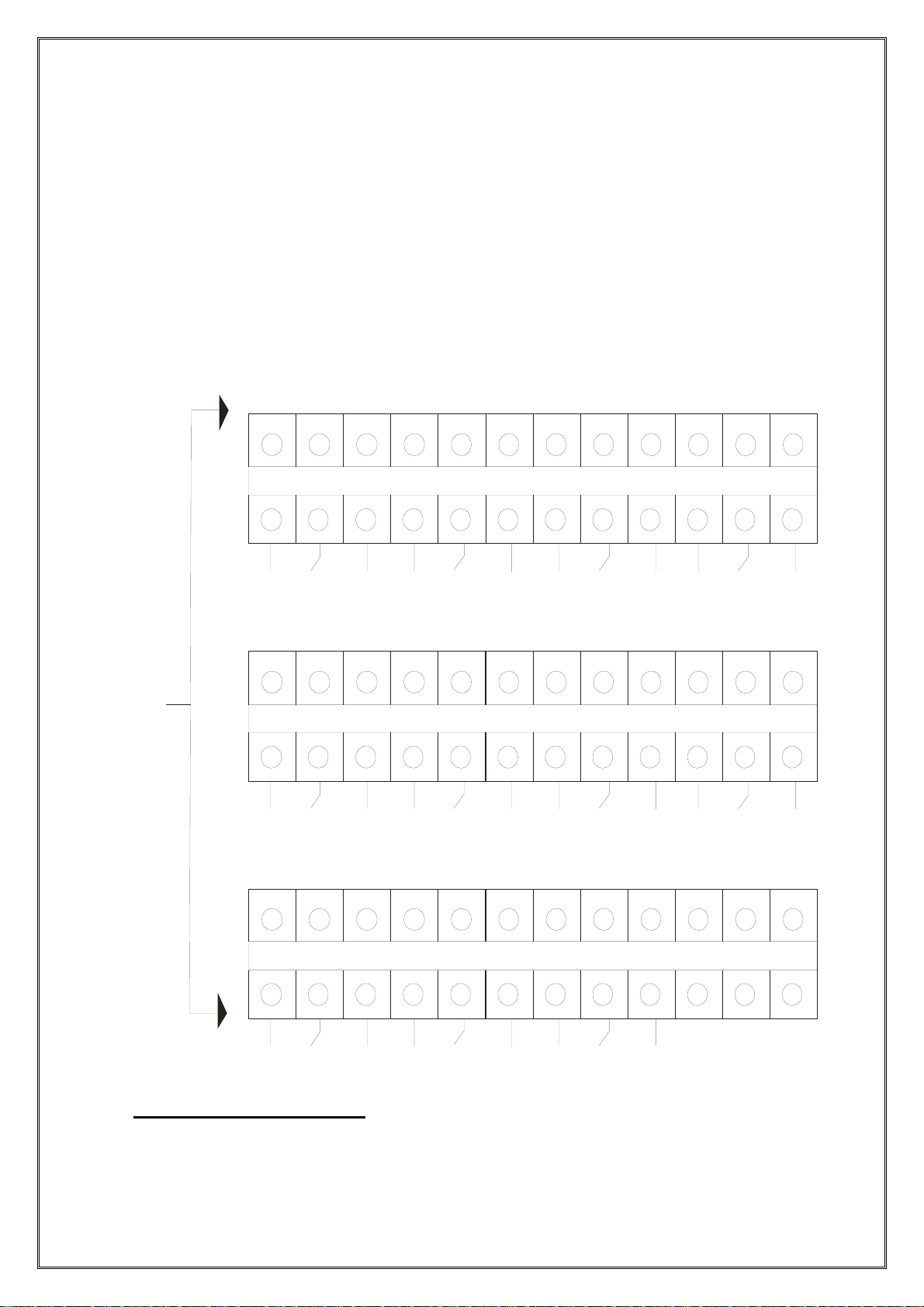

123456789

10 11 12

AC MAINS RECTIFER

FAILUR

E

HIGH VOLTS LOW VOLTS

123456789

10 11 12

EARTH FAULT DC OUTPUT

BREAK

DC INTPUT

BREAK

AC OUTPUT

BREAK

123456789

10 11 12

BATTERY

BREAK

COMMON 1 COMMON 2

7.0 SYSTEM TROUBLE SHOOTING

Diagnostic - general

Operating Condition Symptoms Possible Causes Remedy

Input Breaker ON, no

DC Output Voltage.

AC Main Failure Led

ON

Rectifier failure led on

No mains supply.

Rectifier faulty.

Turn On mains supply.

Replace Rectifier.

400V Input Voltage

available.

AC Input MCB always

trip off and cannot be

reset.

Faulty MCB.

Faulty Rectifier

Replace Breaker.

Replace Rectifier

System function

normal during AC

input ON.

System shut down

during AC failure.

Battery Breaker open

Faulty Battery cable or

connection.

Faulty Battery.

Replace Breaker

Check cable and

connection

Replace Battery

Page 12 of 16

DC OUTPUT VOLT METER

DC O U TP UT A M M ETE R

50 100 150

V

510 15

A

T

E

R

M

I

N

A

L

B

L

O

K

PCB CLPS

PCB DMPS

PCB

CH G 1A CC

POWER MODUL

TRAFO

TERMINAL BLOK

CMPS

R

M

A

L

A

PCB IDPS

FUS E D C

OUTPUT

AC OUTPUT IN PUT

BATT TO

CH ARG ER 2

DC OUTPUT

MCB DC OUTPUT

MCB

INPUT

MCB AC OUTPUT

MCB

BATT

Page 13 of 16

Input Breaker is ON.

No DC supply to

equipment.

Load Breaker Open.

Load Cable Open.

ON the Breaker

Check load wires for

loose connection.

110V System function

normal.

Received Low Voltage

Alarm Failure or AC

Failure Alarm.

Input AC Voltage not

stable.

Consult Building M &

E staff.

7.0 MAINTENANCE PROCEDURE

8.1 Maintenance Procedures For Charger System

1. Record the data on the Monthly Maintenance Record Sheet monthly.

Description

Criteria

Result

Remarks

Confirm AC Input Voltage

400VAC +/- 10%

Confirm DC Output Voltage

110VDC +/- 1%

Confirm and Record DC Output

Current

10 ADC Max.

Confirm and Record Alarm

functional

Check the alarm status

Note: Please consult the factory for advice if the result is not within Specified Criteria

2. Check the tightness of the Terminal Points at the output of the system

3. Perform General Cleaning on the Cabinet half yearly. Ensure that the air flow is not blocked by

the Dust at the front and rear side of the Cabinet.

4. Test the module separately or individual and see the function.

5. Perform the Alarm Functional Check. Record the Remote Alarm Status.

6. In order to check the status of the battery, off the system to let the battery discharge for 5 min.

Ensure the battery bank did take over to supply power to the customer equipment and record the

system Battery Total Voltage (After 5 minutes with load connected). This data shall be check

with previous monthly record. Consult factory for advise the if the different in reading are greater

than 5%.

7. Power On the Charger System.

8.2 Battery Maintenance Procedures

The following checks should be completed quarterly.

Page 14 of 16

1. Visually inspect the battery for :

- Cleanliness

- Terminal Damage or Evidence of Heating.

- Container or Cover Damage

- Evidence of Overheating

- Grease on the battery terminals

2. Measure and record the Battery system DC boost and float charging voltage at the battery.

3. Measure and record the individual unit DC boost and float charging voltage.

4. If possible, measure and record the battery system DC and AC boost and float charging current.

8.0 TRANSPORTATION & STORAGE

Units must be suitable packed in the original shipping container (or equivalent) prior to reshipping.

The box should completely enclosed and constructed of wood.

Units must be stored in a dry environment.

DOT NOT stack heavy objects on top of the unit.

Contents

1). Safety Instructions ……………………………………………………………………………… 1

2). General Instruction

2.1). Introduction …………………………………………………………………………… 2

2.2). Technical Specification for Rectifier/Charger ....................................................... 2

Page 15 of 16

2.3). Output DC Voltage and Output DC Current Limit Adjustment ……………………….. 4

3). Circuit Configuration

3.1). Current Paths Diagram ………………………………………………………………. 4

3.2). Single Line Diagram …………………………………………………………………. 5

3.3). Features Outlines Descriptions ………………………………………………………. 5

3.4). Schematic Diagram …………………………………………………………………. 6

3.5). Rectifier Specifications ……………………………………………………………….. 8

4). Installation Instrument

4.1). Safety Precaution ……………………………………………………………………. 9

4.2). Inspection ……………………………………………………………………………. 9

4.3). Preparation/Mounting ……………………………………………………………….. 9

4.4). Input Connection …………………….………………………………………………. 9

4.5). Output Conection ……………………………………………………………………. 10

5). Terminal Block Arrangement Diagram ……………………………………………………… 11

6). Cabinet Dimension …………………………………………………………………………... 12

7). System Trouble Shooting ……………………………………………………………………. 12

8). Maintenance Procedure

8.1). Maintenance Procedure For Charger System .………………………………………. 13

8.2). Battery Maintenance Procedure …………………………………………………….. 14

9). Transportation & Storage ……………………………………………………………………. 14

OPERATIONAL AND INSTRUCTION

Page 16 of 16

MANUAL

RECTIFIER SYSTEM

SPTC 400-110-10

Table of contents