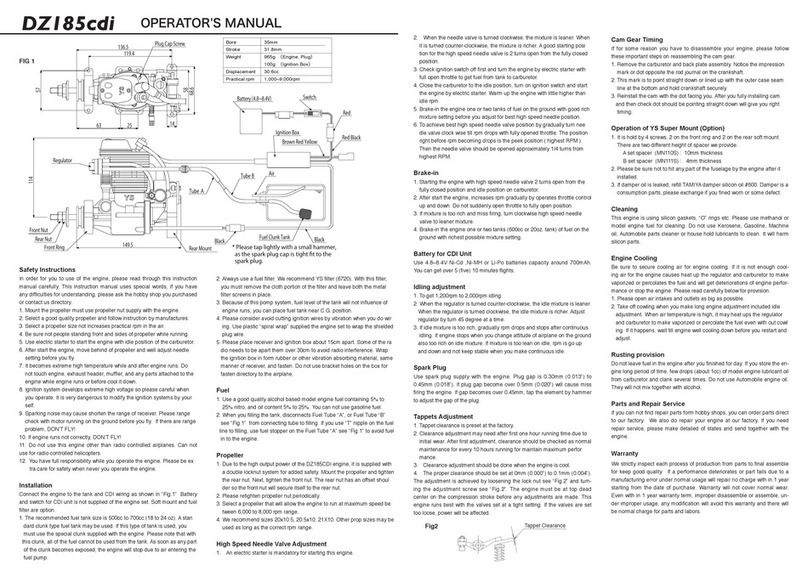

Nissei F2 Series User manual

SmallSize/

SmallWater-resistantGearmotor

15W■25W■40W■60W■90W

InstructionManual

ForSafeOperation

●TheGearmotorshouldbeoperatedbyaskilledandqualifiedperson.Andthe

contentsofthisInstructionManualshouldbecarefullyreadandunderstood

beforeoperatingthisproduct.

●ThisInstructionManualshouldbedeliveredtoapersonwhoactually

operatesthisproduct.

●ThisInstructionManualshouldcarefullybekeptinaconvenientplaceforthe

operator'seasyreference.

≪F2Series≫

≪H-Type・Water-resistant≫

≪GT-Type≫

≪G-type・Water-resistant≫

≪F2Series・Water-resistant≫

≪G-Type≫

≪H-Type≫

Manufacturer NISSEICORPORATION

Address 1‐1InoueIzumi‐choAnjo‐shi,Aichi,444‐1297JAPAN

TEL +81‐566‐92‐5262

FAX +81‐566‐92‐1159

ONLINESPAREPART

2

Thankyouforyourpurchasingourproduct.

Danger

Caution

Danger

●Besuretouseanexplosion-proofmotorwhereanyexplosiveorflammablegases

exist.Failuretoobservethiswarningmaycauseexplosion,spark,fire,electric

shock,physicalinjury,and/ordamagetotheequipment.

●Theoperatorsinchargeoftransportation,installation,wiring,operation,

maintenance,andinspectionoftheequipmentshouldhaveenoughknowledgeand

technicalskillfortheproduct.Failuretoobservethiswarningmaycauseexplosion,

spark,fire,electricshock,physicalinjury,and/ordamagetotheequipment.

●Donotrepairorwiretheequipmentwiththeelectricpoweron.besuretocutthe

poweroffthepowersupplybeforegettingtowork.Failuretoobservethiswarning

maycauseelectricshock.

●Iftheequipmentistobeusedinasystemforhumantransport,besuretofurnishit

withaprotectivedeviceforsafety.Failuretoobservethiswarningmaycause

physicalinjuryand/ordamagetotheequipmentbyaccidentalfalling.

●Iftheequipmentistobeusedwithanelevator,besuretofurnishwithasafety

devicetopreventtheelevatorfromaccidentalfalling.Failuretoobservethiswarning

maycausephysicalinjuryand/ordamagetotheequipment.

●Besurenottogetwateroroil/greaseintothebrakeunitFailuretoobservethis

warningmaycauseaccidentalfallingand/orrunawayaccidentbythedecreased

braketorque.(Incaseofwater-resistanttype,atthetimeofadjustingbrakegap)

InthisManual,injuriesanddamagesanticipatedincaseofmishandlingoftheequipment,

areclassifiedintotwocategories,"Danger"and"Caution".Thedefinitionofthe

classificationaregivenbelowwiththecorrespondinggraphicsymbols.

Thecasethatmishandlingoftheequipmentmay

resultindangeroussituationandmayleadto

seriousorfatalinjurytopersonnel.

Thecasethatmishandlingoftheequipmentmay

resultindangeroussituationandmayleadto

mediumtolightinjury,orthecasethatmayresultin

damagetotheequipment.

Pleasebeawarethatevenitemsmarkedwith"CAUTION"maycausefatalaccidents.

Therefore,besuretofollowtheinstruction,foreveryitemdescribedisveryimportant.

ONLINESPAREPART

3

Caution

1

2

3

4

5

6

7

Checkattheunpacking

Transportation

Storage

Installation

ConnectingwithOtherEquipment

DirectionofRotation

Wiring

……P.3

P.4

P.4

P.5

P.6

P.8

P.8

………

……………

……………

…

…

…………………

8

9

10

11

12

13

Operation

InspectionandAdjustment

Troubleshooting

Disposal

Appendix(GearmotorcertifiedbyT¨

UV)

Warranty

…………P.17

P.19

P.23

P.24

P.25

P.27

…

…

……………

…

……………

Contents

1 Checkattheunpacking

Caution

●Donotuseagearmotorunderconditionsotherthanspecifiedinthenameplateorthe

productspecifications.Failuretoobservethiswarningmaycauseelectricshock,

physicalinjuryand/ordamagetotheequipment.

●Donotinsertyourfingersoranyotherobjectintotheapertureofthegearmotor.

Failuretoobservethiswarningmayresultinelectricshock,physicalinjury,fire

and/ordamagetotheequipment.

●Donotusethedamagedgearmotor.Failuretoobservethiswarningmayresultin

physicalinjuryand/orfire.

●Donottakeoffthenameplate.

●Themanufacturerwillnotwarrantandwillnotresponsiblefortheproductmodifiedor

repairedbytheuserhimself.

Whenunpackingacarton,pleasecheckupthefollowings.Ifyouhaveanyproblemsor

questions,pleasedonothesitatetocontactthedealerfromwhichtheproductwas

suppliedorasalesoffice.

Checkwhethertheproductisthesameproductasordered.Installingawrong

equipmentmaycausephysicalinjuryand/ordamagetotheequipment.

(1)Theorderedproductsandthecontentsindicatedinthenameplatearecorrect.(Type,

Reductionratio,Motorcapacity,Voltage,Frequency,etc.)

(2)Noaccidentaldamagetotheproductduringtransportationexist.

(3)Screwsornutsarenotloose.

(4)Incaseofgearmotorattachedwithbrake,rectifierisenclosed.

(Notnecessaryincaseofgearmotorwithbuilt-inrectifierattachedwithterminalbox.)

(5)In case of gearmotor with clutch/brake, one rectifier and two surge

suppressorareenclosed.

(6)Incaseofsingle-phasemotor,capacitorisenclosed.

(7)IncaseofF2series,saftycapisenclosed.

ONLINESPAREPART

4

2 Transportation

Danger

Caution

3 Storage

●Whenaproductisliftedupfortransportation,besurenottoenterunderneathofthe

liftedproduct.Fallingofproductmaycauseseriousinjury.

●Becarefulwhentransportingproductstoavoidfallingdown.

●Before lifting the gearmotor up, be sure to confirm its weight by nameplate,

packingbox,externalconfiguration,catalogue,etc.Donotliftupgearmotorwhich

hasmoreweightthantheonespecifiedinthelift.Failuretoobservethiswarning

maycausephysicalinjurybybreakingofbolt,fallingortumblingofproduct,and/or

damagetotheequipment.

●Locationforstorage

In case of storing gearmotors for more than 6 months, be sure to store them

indoorswellventilated and dry, free from directsunlight,excessivetemperature

change,humidity,dustandcorrosivegas.

(1)Besurenottoputgearmotorsdirectlyontheground.

Bearings may be damaged by fretting corrosion caused by vibrations during

storage,thereforebesuretostoregearmotorsinthelocationfreefromvibration.

●Dutiesduringstorage

(1)Inordertoavoidanyoxidizationonbearings,besuretogiveatrialrunevery6

monthtoconfirmiftheyrotatesmoothlyorifthereisanyabnormalnoise.

(2) Be sure to measure the insulating-resistance by 500V tester(megger) every 6

monthtomakesureifitshowsmorethan1MΩ.

(3) Be sure to provide anticorrosive treatment every 6 month on the machined

surfacesuchasoutputshaftandflangesurfacenotpainted.

●Operationsjustafterstorage

(1) Before operation, be sure to measure the insulating-resistance by 500V tester

(megger)tomakesureifitshowsmorethan1MΩ.

(2)Checkifthereisanyabnormalnoise,vibrationortemperatureriseatthestartof

operation.

(3)Incaseofgearmotorwithbrake,besuretoconfirmifthebrakefunctionsproperly.

Inanyabnormality,pleasecontactourofficenearesttoyou.

ONLINESPAREPART

Caution

4 Installation

●Do not place any object inflammable near the gearmotor. Failure to observe this

warningmaycausefire.

●Do not place any object which may interfere with the ventilation around the

gearmotor. Failure to observe this warning may result in abnormal overheating

causedbytheblockoffofthecoolair,whichmaycauseburninjuryand/orfire.

●Donotsteponagearmotororhangtoit.Failuretoobservethiswarningmaycause

physicalinjury.

●Donottouchtheedgeoftheshaftofgearmotororkeygrooveintheborewithbare

hands.Failuretoobservethiswarningmaycausephysicalinjury.

●Inequipmentslikefoodmachines,whichmustavoidoilorgrease,furnishwithprotective

deviceslikeoilpan,inordertoprotectfromtheoilleakagecausedbyfailureorlifeofthe

manufacturedproducts.Leakingoilmaycausedefectiveproducts.

●Thereispossibilityscattertheweardebrisorironpowders.

Incaseofinstallingtoequipmentwhichwillhaveanyissueduetocontaminationof

foreign substance such as food equipment, please install preventive equipment.

Thiscouldharmtheproducts.

●Vibrationscomeoutfromtheinstallationsurfaceofgearmotororfromothersource

shouldbeminimizedtounderabout0.5G.

●Inthehotandhumidenvironment,whenambienttemperaturechangessuddenly,

internal condensation may occur in the terminal box. Especially, in the ocean

transportofthemachinebyvessel,condensationmayoccur,therefore,paycareful

attentiontothetransportatmosphere.Internalcondensationisaphenomenonthat

inthehotandhumidenvironment,iftemperaturesuddenlydropsfromhightolow,

or if a reducer is suddenly moved from low-temperature place to hot and humid

place,steamcondensationoccursandthedropletlandontheterminal.

●In the low temperature of below 0℃, pay careful attention to the freezing. The

droplets land on the terminal by condensation or by abnormally high humidity

atmospheres, and when temperature drops below freezing point, the droplets

becomeice.ThisiswhatwecallFreezing.Youmustnotethatthereisadanger

ofelectrificationcausedbytheshortcircuitbetweenterminalsbyfreezing.

Properinstallationofaproductwillensurereliableserviceandmaximumlife.

5

ONLINESPAREPART

6

(1) Properlocationforinstallation

AmbientTemperature:−10℃to40℃

AmbientHumidity:85%max.

Altitude:Sealevelto1,000mmax.

Environment:

[StandardType]:Wellventilatedplacefreefromcorrosivegas,

explosivegas,vaporand/ordust.

[Water-resistantType]:Placefreefromcorrosivegasandexplosivegas.

Operationinwaterorinthehigh-hydrostaticpressure

environmentisnotpermitted.

InstallationLocation:Indoors

(2) DirectionofInstallation

Thisproductcanbeinstalledinanydirectionduetoagreaselubricationsystem.

(3) MethodforInstallation

①Attachingthemountingfootandflange

Fixtheproductwiththefourboltsonaflatandmachinedsurfacefreefromvibration.

(Roughnessofthesurfaceshouldbelessthan0.3mm.)

②Attachingtheshaft

●gearmotor'sweightshouldbesupported

bythedrivenshaft.

(Forcesotherthanturningreactiveforce

shouldneverbeimposedtothetorquearm.)

●Incasestart/stopandforward/reverseactions

arefrequent,tightnupthetorquearmwith

boltstokeepthelockingholenotloose.

tighteningtorqueboltsizefixinghole

4.9N・m

{ 0.5kgf・m}

13 { 1.3}

25 { 2.6}

44 { 4.5}

69 { 7.0}

108 {11.0}

M6

M8

M10

M12

M14

M16

6.5m m

8.5

11

13

15

18

5 Connectingwithotherequipment

Caution

●Whenconnectingthegearmotorwithaload,makesureofthealignmentofshaft,the

tension of the belt and parallelism of pulleys. In direct coupling, be sure to check

whetherthealignmentofshaftisextremelyprecise.

Ifabeltistobeused,besuretoadjustitstensionproperly.

Also,beforeoperation,inspectwhetherthesettingboltsforpulleysandcouplingare

securelytightened.Failuretoobservethiswarningmaycauseseriousinjury and/or

damagetotheequipmentduetobrokenparts.

●Safeguardsshouldbefurnishedaroundrotatingpartstoavoiddangertopersons.

Loosefitisrecommendedforthecouplerssuchascouplings,sprockets,pulleys,gears,

etc.,whenattachingtothereducer,usingthedesignatedkeymaterials.

ONLINESPAREPART

1 DirectConnection

2 AttachingChains,V-Belts,Gears,etc.

3 AttachingandRemovingofF2SeriesHollowShaft

①AttachingtoHollowShaft ②RemovingfromHollowShaft

③FixingtoHollowShaft

○

a

Incasethedrivenshafthasashoulder

○bIncaseofnoshoulderonthedrivenshaft

Note:Firmlyfixthedrivenshafttothehollowshaft.

Note:Inorderforsmoothremoving,designthedrivenshaftshorter

withthelengthequaltotheamountofthethicknessof○

c.

●Specificationsforthefixingpartsofdrivenshaft

Nominal

Designation

oftheC-Type

SnapRing

MeasurementofSpacer

Bolt

Size WidthBore

Outer

Diameter

Note:

1) At attaching, apply agent such as molybdenum disulfide on the

drivenshaftandtheboreofthehollowshafttoavoidseizing.

2)Incasethefittingistootight,taptheedgeofthehollowdriveshaft

with wooden hummer. With this device, smooth insert can be

obtained.

3)Theboreofthehollowshaftismachinedtoconform to"JISH8"

tolerance.Ifstrongimpactorheavyradialloadis tobeimposed

to the shaft, the fit should be tighter. In general, loose fit is

recommendedforthefittoleranceofdrivenshaft

4) The key should be conformed toJIS B 1301-1976or

equivalent. Refer to the JIS standard B 1301-1976 for the

details.

Connectthereducertotheotherequipmentprecisely,sothatthecenteroftheshaftof

bothmachineswillbefullyaligned.

(1)Inanyconnection,connecttheunitsprecisely,sothatthecenteroftheshaftofthe

reducerandthatoftheotherequipmentareparallel.

(2)ThetensionoftheChains/V-Beltsandthecouplingofthegearmustbeperpendicular

tothecenteroftheshaft.

(3)TensionoftheV-Belt:Excessivetensioningmayresultindamagetothebearingsoftheshaft.

TensionoftheChain:Excessivetensioningmayresultindamagetothebearingsof

theshaft.Ifthechainisinstalledloosely,shockloadwilloccurwhenthedriveshaft

startsrotation,andthiscanresultindamagetothereducerandtheotherequipment.

Therefore,adjustthetensionofthechainproperly.

cross-sectionof

inthedrawing

○

c

123 611.5M5F2S −12

153 714.5M6F2S −15

7

ONLINESPAREPART

6 DirectionofRotation

Caution

IntheGTRReducer,therelationsbetweentheinputshaftandtheoutputshaftareas

shownbelow:

●G-Type

1/5〜1/60samedirection 1/80〜1/1800counterdirection

●H-Type

15W・25W 1/10〜1/60And1/300〜1/1800

40W・60W 1/10〜1/60And1/300〜1/900

90W 1/10〜1/60And1/300〜1/450

●F2Series

1/5〜1/60

15W・25W 1/80〜1/240

40W・60W

1/80〜1/240

And

1/1200〜1/1800

90W

1/80〜1/240And1/600〜1/1800

●G-Type

15W・25W 1/5〜1/25 samedirection 1/30〜1/200 counterdirection

40W 1/5〜1/30 samedirection 1/40〜1/200 counterdirection

60W 1/5〜1/15 samedirection 1/20〜1/120 counterdirection

7 Wiring

Danger

●Whenconnectingthemachinetothepowercable,besuretofollowtheinstructions

shownintheconnectiondiagramintheterminalboxorintheInstructionManual.

Failuretoobservethiswarningmaycauseelectricshockorfire.(Incaseofthetype

ofnoterminalbox,besuretoinsulateawireattheterminalarea.)

●Donotbend,pullortuckdownpowercables,motorleadwiresorcabtirecable

forcibly.Failuretoobservethiswarningmaycauseelectricshock.

●Besuretogroundtheterminaloftheearthwire.Failuretoobservethiswarningmay

causeelectricshock.

●Besuretousetheelectriccurrentsourcespecifiedinthenameplate.Failureto

observethiswarningmaycauseburnoutofthemotorand/orfire.

●Donotdamagetheleadwireinsidewhenpeelingofftheoutersheathofcabtyre

cable.Failuretoobservethiswarningmaycauseelectricshockorfire.

●Besuretoavoidanywatertotheterminalorpowerrectifierofcabtyrecableor

capacitor.Failuretoobservethiswarningmaycauseelectricshock,damagetothe

equipmentorfire.

[Note]Donotopenthecoverofthewateranddust-resistantbox.

Failuretoobservethiswarningmaycauseelectricshock,damagetotheequipmentor

firecausedbylackofwateranddust-resistantfunction.

Beforecouplingwiththeothermachine,besuretocheckthedirectionofrotation.Unexpected

operationinwrongdirectionmaycauseseriousinjuryand/ordamagetotheequipment.

1/80〜1/240

8

ONLINESPAREPART

Caution

●Donottouchterminalswheninspectingtheinsulationresistance.

Failuretoobservethiswarningmaycauseelectricshock.

●Wiringshouldbeproperlymadeunderthespecifiedelectricalequipmentengineering

standardorthesafetycode.Failuretoobservethiswarningmaycauseelectricshock,fireor

physicalinjury.

●Ourmotorisnotequippedwithprotectivedevices.Theelectricalequipmentengineering

standardsprovidethatanoverloadprotectiondeviceshouldbeinstalledinaunit.Other

protectiondevicessuchascircuitbreakerarealsorecommendedtobeinstalled.Failureto

observethiswarningmaycausedamagetotheequipment,electricshock,fireorphysicalinjury.

●Whenrotatinggearmotoralone,takeoffthekeyattachedtemporarilytotheoutputshaft.

Failuretoobservethiswarningmaycausephysicalinjury.

●Checkupthedirectionofrotationbeforeconnectingwiththeothermachine.Rotationinwrong

directionmaycausephysicalinjuryand/ordamagetotheequipment.

●Ifa400Vclassinverterisemployedformotordrive,besuretoattachacontrolfilterorareactor

totheinverter.Thebreakdownofinsulationmaycausedamagetotheequipmentorfire.

●Donotmisuseacapacitorforstartingastheoneforcontinuousmotorrunning.Thismisuse

maycausedamagetothecapacitor.

●Donothurtthevinylcoatingofstartercapacitor.Thehurtmaycauseelectricshock.

●Voltagedropsinthewiringshouldbekeptwithin2%.Excessivelengthofwiringmaycause

steepvoltagedropandthismakesthemotordisabletostartup.

●Whenreversingagearmotorisrequiredinoperation,besuretostoprotatingandthenstart

reversing.Reversingwithoutcompleterestmaycausedamagetotheequipment.

●Asforagearmotorwithbrake,donotenergizecontinuouslytothebrakeunitduringtherestof

motor.Thecontinuoussupplymaycauseburningofthebrakecoilandfire.

●Ifagearmotorwithbrakeisusedfortheapplicationsuchaslift,"DCSwitching"wiringshould

beemployedtoavoidaccidentalfalling.

(1)Astherectifierunitcontainsdiodes,improperwiringmaycausefatalshort-circuiting

andbreakageoftheunit.So,specialcareshouldbetakenforwiring.

(2)IncaseofDCswitchisadopted,DC110V,contactratedDC13classisrecommended

inordertocutofftheinductiveload(DCcoil).Pleasecontactusfordetails.

Also,incaseofemployinganoncontactrelay,itisrecommendedtousetherated

voltageofAC240Vequivalent(Half-waverectificationswitchingavailable).

*ContactratedDC13classisthecategorizedinJISC8201-5-1forlow-pressure

switchgearandcontroldevice.

(3)Incaseofgearmotorwithclutch/brakeusetherelaywiththecapacityofmorethantherated

currentof1A(DC110V)atthecontactpointofbrakeandclutch.

(4)Thedirectionofrotationoftheoutputshaftvariesaccordingtothespeedreduction

ratioofthegearhead.Therefore,besuretoconfirmthespeedreductionratiobefore

wiring.

(5)Thevoltagebetweenthecapacitorterminalsofthesingle-phasemotorwillbecomenearlytwice

asmuchasthatinthepowersourceofthemotor.Thereforebesuretoinsulatewiresatthe

terminalsforsafety.

9

ONLINESPAREPART

2 Wiringofgearmotor

●LeadWireType

200V

100V

400V

3-Phasemotor Single-phase

200V

●TerminalBoxType

Single-Phase100V,200V3-Phase200V,400V

MS:Electro-MagneticSwitchC:Capacitor

MS:Electro-MagneticSwitchC:Capacitor

R

Motor

S

T

Fwd

Rev

Power

source

gray

black

white

R

Motor

S

T

black

brown

white

Fwd

Rev

Power

source

Motor

C

blue

black

gray

Fwd

Rev

Power

source

Power

source

MS

Motor

C

brown

black

gray

Fwd

Rev

MS

R

S

T

Fwd

Rev

W

V

U

C

1

2

3

Rev

Fwd

MS

Forstandardgearmotors,wiringsdescribedbelowarerecommended:

Thedirectionofrotationshownbelowisasviewedfromthebackwardofthemotor.Inthe3-phase

motor,theforwardrotationisacounterclockwisedirection,andinthesingle-phasemotor,theforward

rotationisaclockwisedirection.

Power

source

Power

source

10

ONLINESPAREPART

3

Wiringforgearmotorwithbrake

0.005〜0.015DCSwitching

0.03〜0.10ACSwitching(A)

0.1〜0.2ACSwitching(B)

■3-phase

(1)Ifagearmotorisusedintheapplicationswherequickbrakingisrequired,suchaslift,"DCSwitching"

wiringshouldbeemployed.

(2)Incaseof"DCSwitching"wiring,itisrecommendedtoinsertthesurgesuppressorin-betweenthe

connectingpoints.(varistorvoltage423˜517V)

(3)ThebrakevoltagesareDC90Vincaseof3-phaseandsingle-phase200V,andDC45Vincaseof

single-phase100V.

(4)Incaseofsingle-phase100V,thevoltageoftheinputterminalofrectifier(A200-D90[A100-D45])

correspondstoAC100V,andthevoltageoftheoutputterminalcorrespondstoDC45V.

(5)IncaseofDCswitchisadopted,DC110V,contactratedDC13classisrecommendedinorder

tocutofftheinductiveload(DCcoil).Pleasecontactusfordetails.

Also,incaseofemployinganoncontactrelay,itisrecommendedtousetheratedvoltageof

AC240Vequivalent(Half-waverectificationswitchingavailable).

*ContactratedDC13classisthecategorizedinJISC8201-5-1forlow-pressureswitchgearand

controldevice.

(6)Astherectifierunitcontainsdiodes,improperwiringmaycausefatalshort-circuitingandbreakageof

theunit.So,specialcareshouldbetakenforwiring.

(7)Whenwiringspecialvoltageofover220V,sincethe200Vterminal(red,red)istakenoutofthe

motor,connectthis200Vterminalwiththeinputterminaloftherectifier(white,yellow).

Also,besurenottoconnectthepowersourceofover220Vdirectlytotheinputterminalofthe

rectifier.

(8)Whenoperatingthemachinewithinverter,pleaserefertothe"Cautionsinoperationwithinverter"in

page17.

(9)Brakelag(second)

400V200V

DCSwitching ACSwitching(A)

R

Motor

S

T

black

brown

white

Fwd

Rev

A200-D90

(A100-D45)

Brake

blue

blue

blue

blue

black

red

yellow

white

Fwd

Rev

red red

Rectifier

Rev

T

Rev

Fwd

black

(A100-D45)

A200-D90

red

blue

blue

yellow white

S

R

Brake

blue

blue

Motor

gray

white

black

Rectifier

The"blue"to"blue"intherectifiercorrespondstotheshortcircuit

R

Motor

S

T

black

brown

white

Fwd

Rev

A200-D90

(A100-D45)

Brake

blue

blue

blue

blue

black

red

yellow

white Fwd

Rev

red red

Rectifier

The"blue"to"blue"intherectifiercorrespondstotheshortcircuit

R

S

T

A200-D90

(A100-D45)

・Thisisthetimeconsumedfromthemoment

of"switchoff"tothemomentofstartbraking,

andisdifferentfromthebrakingtime.

・Thelengthoftimevariesfromthatofthe

water-resistantgearmotorwithbrake.

Power

source

Powersource

Fwd

Fwd

Rectifier

white yellow

blue

blue

blue Brake

Motor

gray

black

white

black

red

Fwd

Rev

Power

source

Power

source

Rev

11

ONLINESPAREPART

DCSwitching ACSwitching(A)

ACSwitching(B) ACSwitching(B)

■Single-phase

200V100V

R

Motor

S

T

black

gray

white

Fwd

Rev

A200-D90

(A100-D45)

Brake

blue

blue

blue

blue

black

red

yellow

white

Rectifier

The"blue"to"blue"intherectifiercorrespondstotheshortcircuit

R

Motor

S

T

black

brown

white

Fwd

Rev

A200-D90

(A100-D45)

Brake

blue blue

blue

blue

red

yellow

white

red red

Rectifier

The"blue"to"blue"intherectifier

correspondstotheshortcircuit

white

blue

blue

(A100-D45)

A200-D90

red

black

yellow

Brake

red

red

Rev

Fwd

MS

Motor

C

black

gray

blue

Rectifier

white

blue

(A100-D45)

A200-D90

blue

red

black

yellow

Brake

blue

blue

Rev

Fwd

MS

Motor

C

black

gray

brown

Rectifier

Brake

(A100-D45)

A200-D90

blue

black

red

blue blue

blue

red

red

white

yellow

Rev

Fwd

MS

Motor

C

black

gray

blue

Rectifier

Brake

(A100-D45)

A200-D90

blue blue

blue

blue

black

red

blue

blue

white

yellow

Rev

Fwd

MS

Motor

C

black

gray

brown

Rectifier

The"blue"to"blue"intherectifiercorrespondstotheshortcircuit The"blue"to"blue"intherectifiercorrespondstotheshortcircuit

Brake

(A100-D45)

A200-D90

black

red red

red

white

yellow

Rev

Fwd

MS

Motor

C

black

gray

blue

Rectifier

Brake

(A100-D45)

A200-D90

black

red

blue

blue

white

yellow

Rev

Fwd

MS

Motor

C

black

gray

brown

Rectifier

The"blue"to"blue"intherectifiercorrespondstotheshortcircuit The"blue"to"blue"intherectifiercorrespondstotheshortcircuit

400V200V

MS:Electoro-MagneticSwitch C:Capatitor :SurgeSuppressor(option)

:SurgeSuppressor(option)

Power

source

Power

source

Power

source

Power

source

Power

source

Power

source

Power

source

Powersource

black

12

ONLINESPAREPART

●Wiringmethodtoaterminalbox

■3-phase

400V200V

DCSwitching ACSwitching(A) ACSwitching(B)

R

S

T

U

V

W

Fwd

Rev

Powersource Powersource

Powersource

Powersource

Powersource Powersource

Fwd

Rev

SWITCH

R

S

T

U

V

W

Fwd

Rev

Fwd

Rev

SWITCH

R

S

T

U

V

W

Fwd

Rev

AC

AC

Fwd

Rev

R

S

T

U

V

W

Fwd

Rev Fwd

Rev

AC

AC

red

red 200V

Moter

Lead

Wire

R

S

T

U

V

W

Fwd

Rev

SWITCH

connecting

board

R

S

T

U

V

W

Fwd

Rev

SWITCH

connecting

board

(1)Inaterminalbox,arectifierisbuilt-in,sothatthewiringissetas"ACSwitching(B)".

Therefore,thebrakebecomeseffectiveonlybyconnectingtheterminalto3-phase

currentorsingle-phasecurrent.(Theconnectingboardisattachedtotheswitch.)

(2)Whenchangingto"DCSwitching"wiring,removetheconnectingboard.

(3)Incaseof3-phase"ACSwitching(A)"400V,the200Vterminal(redleadwire)istaken

outfromthemotor.(Butitisnotfixedtotheterminalboard.)

(4)Whenusinginverter,connectionbetween"ACSwitching(B)"and"DCSwitching"is

notfeasible.Fordetails,pleaserefertothewiringdiagramofthegearmotorwith

brakeinoperationwithinverter(page17)orthehandlingmanualofinverter.(This

doesnotapplytothesingle-phase.)

:SurgeSuppressor(option)

13

ONLINESPAREPART

■Single-phase

200V100V

4

Wiringforthewater-resistantgearmotor

single-phase100V3-phase200V

Rev

Fwd

MS

C

SWITCH

3

2

1

B

Rev

Fwd

MS

C

SWITCH

3

2

1

B

Rev

Fwd

MS

C

SWITCH

3

2

1

connectingboard

Rev

Fwd

MS

C

SWITCH

3

2

1

connectingboard

Rev

Fwd

MS

C

SWITCH

3

2

1

B

connectingboard

Rev

Fwd

MS

C

SWITCH

3

2

1

B

connectingboard

R

Motor

S

T

Fwd

Rev

gray

black

white

Motor

C

blue

black

gray

Fwd

Rev

MS

(1)Besurenottodamagetheleadwireinsidewhenpeelingofftheoutersheathof

cabtyrecable.

(2)Whenusingthemachineinthecircumstancewherewatermayspatterduring

operation,itisrecommendedtousecircuitbeakerforsafety.

(3)Donotopenthecoverofthewater/dust-resistantbox.Failuretoobservethiswarning

mayresultinlackofwater/dust-resistantfunction.

(4)Thevoltagebetweenthecapacitorterminalsofthesingle-phasemotorwillbecome

nearlytwiceasmuchasthatinthepowersourceofthemotor.Thereforebesureto

insulatewiresattheterminalsforsafety.

B

B

MS:Electro-Magneticswitch C :Capacitor :SurgeSuppressor(option)

MS:Electro-MagneticswitchC:Capacitor

DCSwitching

ACSwitching(A) ACSwitching(B)

Powersource

Powersource

Powersource Powersource

Powersource Powersource

Powersource

Powersource

14

ONLINESPAREPART

5 Wiringforthegearmotorwithwater-resistantbrake

0.01〜0.02DCSwitching

0.05〜0.15ACSwitching(A)

0.1〜0.2ACSwitching(B)

single-phase100V3-phase200V

DCSwitching

R

Motor

S

T

black

gray

white

Fwd

Rev

A200-D90

(A100-D45)

Brake

blue

blue

blue

blue black

red

yellow

white

Fwd

Rev

Rectifier white

blue

(A100-D45)

A200-D90

blue

red

black

yellow

Brake

red

red

Rev

Fwd

MS

Motor

C black

gray

blue

Rectifier

(1)Whenagearmotorisusedintheapplicationswherequickbrakingisrequired,suchaslift,

"DCSwitching"wiringshouldbeemployed.

(2)Incaseof"DCSwitching"wiring,itisrecommendedtoinsertthesurgesuppressorin-between

theconnectingpoints.(varistorvoltage423〜517V)

(3)ThebrakevoltagesareDC90Vincaseof3-phaseandDC45Vincaseofsingle-phase.

(4)Incaseofsingle-phase,thevoltageoftheinputterminalofrectifier(A200-D90[A100-D45])

correspondstoAC100V,andthevoltageoftheoutputterminalcorrespondstoDC45V.

(5)IncaseofDCswitchisadopted,DC110V,contactratedDC13classisrecommended

inordertocutofftheinductiveload(DCcoil).Pleasecontactusfordetails.

Also,incaseofemployinganoncontactrelay,itisrecommendedtousetherated

voltageofAC240Vequivalent(Half-waverectificationswitchingavailable).

*ContactratedDC13classisthecategorizedinJISC8201-5-1forlow-pressure

switchgearandcontroldevice.

(6)Astherectifierunitcontainsdiodes,improperwiringmaycausefatalshort-circuitingand

breakageoftheunit.So,specialcareshouldbetakenforwiring.

(7)Therectifierdoesnotcorrespondtowater-resistantstructure.

(8)Brakelag(second)

・Thisisthetimeconsumedfromthemoment

of"switchoff"tothemomentofstart

braking,andisnotthebrakingtime.

・Thelengthoftimevariesfromthatofthe

nonwater-resistantgearmotor.

Powersource

Powersource

15

(5)Besuretoprotecttheterminalofcabtyrecablefromsplashingwater.Splashedwater

maypenetratethroughthesheathofcabtyrecableandreachtotheinsideofmotor,which

maycausetroubleinmotor.

Terminalofcabtyrecable

leadwire

Sheath(cablejacket)

ONLINESPAREPART

6 Wiringforthegearmotorwithclutch/brake

black

gray black

blue

blue

blue

blue

yellow

white

yellow

white F

blue

red

black

blue

blue

red

black brown

brown

gray

white

M:motorCL:clutchBR:brakeMC:relaycoilC:capacitorMCa:electromagneticcontactor-acontact

MCb:electromagneticcontactor-bcontact:surgesuppressor(attachmentERZV10D471)

PB:pushbuttonswitchF:fuse

3-phase[200V] single-phase[100V]

The"blue"to"blue"intherectifiercorrespondstotheshortcircuit. The"blue"to"blue"intherectifiercorrespondstotheshortcircuit.

R

Motor

S

T

black

gray

white

Fwd

Rev

A200-D90

(A100-D45)

Brake

blue

blue

blue

blue

blue

blue

black

red

yellow

white

Rectifier

Brake

(A100-D45)

A200-D90

black

red red

red

white

yellow

Rev

Fwd

MS

Motor

C

black

gray

blue

Rectifier

ACSwitching(B)

(1)Incaseofwiringmotorwithvoltageofover200V,sincethe200Vterminal(red,red)

istakenoutofthemotor,connectthis200Vterminalwiththeinputterminalofthe

rectifier(white,yellow).

Also,besurenottoconnectthepowersourceofover220Vdirectlytotheinput

terminaloftherectifier.

(2)BrakevoltagecorrespondstoDC90V.

(3)Besuretoavoidtheusageofupanddownoperations.(Failuretoobservethis

warningmaycauseaccidentalfallingwhenpowercutoccurred.)

(4)Incaseofenergizingcontinuouslytotheclutchorbrake,besuretoaskourlocal

office.

MS:Electro-MagneticSwitch C:Capacitor :SurgeSuppressor(option)

Powersource

Powersource

The"blue"to"blue"intherectifiercorrespondstotheshortcircuit.

16

The"blue"to"blue"intherectifiercorrespondstotheshortcircuit. The"blue"to"blue"intherectifiercorrespondstotheshortcircuit.

Rev

Fwd

T

blue

Rev

Fwd

black

(A100-D45)

A200-D90

red

blue

yellow white

S

R

Brake

blue

blue

Motor

gray

white

black

Rectifier

Brake

(A100-D45)

A200-D90

blue

blue

black

red red

red

white

yellow

Rev

Fwd

MS

Motor

C

black

gray

blue

Rectifier

ACSwitching(A)

Powersource

Powersource

ONLINESPAREPART

7 Cautionsinoperationwithinverter

■Examplesofwiringinthegearmotorwithbrakewhenusinginverter

3-phase200Vleadwiretype 3-phase200Vterminalboxtype

ACSwitching(A) DCSwitching

*DCSwitchingwiringisfeasibleonly

forleadwiretype.

8 Operation

Danger

T

white

(A100-D45)

A200-D90

MS blue

red

black

yellow

S

R

Brake

blue

blue

Motor

gray

white

black

T

white

black

(A100-D45)

A200-D90

blue blue

blue

red

yellow

MS

S

R

Inverter

Inverter

Brake

blue

blue

Motor

gray

white

black

Inverter

T

S

R

W

AC

AC

U

V

MS

(1)Highertemperaturerise,noiseandvibrationthanthatfromthegeneralpowersource

willbeobserved.Especially,lowspeedrotationwhichnaturallyreducethefuneffect,

maycauseabnormalriseoftemperature.(Morethan90℃atthesurfaceofthemotor)

(2)Inthegearmotorwithbrakeorwithclutch/brake,malfunctionofthebrakemaybe

observedduetothevoltagedrop.Inordertoavoidthisdisadvantage,besureto

bypasstheinverterwhenwiringthebrakeandclutch.

(3)Itisnotfeasibletouseinverterinthesingle-phasemotor.

(4)Whenusinginverterinthe3-phase400Vmotorwithbrake,donotusethe200V

terminal(redleadwire)takenoutfromthemotor.

●Donotoperategearmotorswiththeterminalboxcoveropened.Besuretoclosethe

coverjustafterthewiringiscompleted.Failuretoobservethiswarningmaycause

electricshock.

●Donotapproachortouchrotatingpartssuchasashaftwhilethemachineis

running.Failuretoobservethiswarningmaycausewind-inandphysicalinjury.

●Ifpowercutoccurs,besuretoswitchoffthepowersupplyofamachinepromptly,

otherwiseunexpectedrecoveryofelectricservicemaycausephysicalinjuryand/or

damagetotheequipment.

:SurgeSuppressor(option)

powersource

powersource

powersource

17

ONLINESPAREPART

Caution

1 Checkupmattersbeforeturningthepowerswitchon:

2 Checkupmattersattestrunning:

3 Checkupmattersduringoperation:

●Thegearmotorbecomesratherhotduringoperation,sodonottouchitwithbare

hands.Failuretoobservethiswarningmaycauseburninjury.

●Whenagearmotorisfoundabnormal,stoprunningimmediately.Failuretoobserve

thiswarningmaycauseelectricshock,physicalinjuryorfire.

●Donotoverloadagearmotor.Failuretoobservethiswarningmaycausephysical

injuryand/ordamagetotheequipment.

●Donottouchthecurrent-carryingpartofthestartercapacitorinsingle-phasemotor

untilithasbeendischargedcompletely.Failuretoobservethiswarningmaycause

electricshock.

●Whenasingle-phasemotoristobereversed,besuretostartreversingafter

completerestofthemotor.Otherwise,directionofrotationmaynotchangeandmay

causerunningoutofcontrol.

●Donotstopamotorforcibly.Itmaycausedamagetotheconnectingmachine.Ina

single-phasemotor,thismaymakethemotorrotateintheoppositedirectionand

maycauserunningoutofcontrol.

(1)Wiringsandconnectionsaredoneproperly.

(2)Fusesandthermalrelaysofpropercapacitiesareused.

(3)Installationsandtheconnectionswithothermachinesareproperlydone.

(4)Earthterminalisproperlygrounded.

[Note]Whenusingthewater-resistantmotorinthecircumstancewherewatermayspatter

duringoperation,itisrecommendedtousecircuitbeakerforsafety.

(1)Confirmthedirectionofrotationfor1〜2secondsafterstartingthemotorwith

unloadedcondition.Whenyoufindtherotationintheoppositedirection,change

thewiringaccordingtothediagramsshowninpage10.

(2)Practicerunning-inofthemotorwithunloadedcondition.Whennodefectis

observed,addloadgraduallyandeventuallystartoperationwithfullload.

(1)Confirmthattherisnoabnormalnoiseandvibrationatall.Whensuchdefects

areobserved,stopoperationimmediately.Failuretoobservethiswarningmay

causephysicalinjuryand/ordamagetotheequipment.

(2)Confirmifthesurfacetemperatureofthegearcaseormotorframedoesnot

exceed90℃.Donottouchthesurfacewithbarehands.Failuretoobservethis

warningmaycauseburninjury.

18

ONLINESPAREPART

9 InspectionandAdjustment

Danger

●Wheninspectingand/oradjustingthemachinewhileitisinoperation,donottouch

rotatingpartssuchasashaft.Failuretoobservethiswarningmaycausewind-inand

physicalinjury.

●Donotremovethecoverofinspectionwindowwhilethemachineisinoperation.

Otherwise,blowoutofhotlubricantmaycauseburninjury.

●Wheninspectingthegeartouchsurface,besuretolockupthedriveanddrivenunits

beforehand.Failuretoobservethiswarningmaycausewind-intothegear-teethand

physicalinjury.

●Incaseofgettingintoclosedequipmenttoinspectitscondition,besuretolockup

driveanddrivenunitsandconfirmwhethertheequipmentissufficientlycooleddown

beforehand.Also,keeponventilatingwhileinspectinginside.Furthermore,while

inspection,besuretostaffsupportingpersonneloutsidetowatchthesafety

conditionsandkeepintouchwiththeinspectorinside.Itcanbeveryslipperywith

lubricantinsidetheequipment,sospecialattentionshouldbegiventosafety.Failure

toobservethiswarningmaycausephysicalinjury.

●Donotoperatetheequipmentwiththesafeguardoffforinspection.Failureto

observethiswarningmaycausewind-inandphysicalinjury.

[InspectionandMaintenanceofBrakePart]

●Beforeactualoperationoftheequipment,makesurethebrakeisfunctioning

properlybyturningtheswitchonandoff.Failuretoobservethiswarningmaycause

accidentalfallingandrunoutofcontrol.

●Donotoperatetheequipmentwithoutfancover(orbrakecover)afterinspection

andadjustmentofbrakegap.Failuretoobservethiswarningmaycausewind-inand

physicalinjury.

●Donotreleasethebrakewhiletheequipmentisbeingloadedintheapplicationsuch

aslift.Failuretoobservethiswarningmaycauseaccidentalfalling.

19

ONLINESPAREPART

Caution

1 DailyInspection:Followingitemsshouldbeinspectedeveryfewdays.

DetailsofinspectionMethod

InspectionItem

Withintheratedcurrentspecifiedinthenameplate.

Noabnormalsoundsuchasrumbling

soundorperiodicsound.

Acousticdetectionrodmakesiteasierto

catchtheabnormalsound.

Noabnormalvibrationinthegearcase

andmotorframe.

Shouldbelessthan90℃.

Nolubricantleakagefromthejointpart

suchascase,oilsealorbracket,etc.

Ammeter

Hearingby

person

Detectionrod

Touchingby

person.

Thermometer

VisualCheck

Loadcurrent

Noise

Vibration

Surfacetemperature

OilLeak

●Whenmeasuringtheinsulationresistance,donottouchtheterminals.Failureto

observethiswarningmaycauseelectricshock.

●Surfaceofagearmotorbecomesveryhot.Therefore,donottouchitwithbare

hands.Failuretoobservethiswarningmaycauseburninjury.

●Whenoperationbeingfoundabnormal,diagnosethefaultaccordingtotheinstruction

manual.Donotoperatethemachineuntilthecausesoffaultarefoundandproper

measuresaretaken.

●Repairing,disassemblingandassemblingoftheequipmentshouldbedonebyan

experiencedtechnician.Failuretoobservethiswarningmaycauseelectricshock,

physicalinjuryorfire,etc.

[Note]Incaseyouneedtochangegrease,oilsealoro-ringforthepurposeofmaintenance

orinspection,besuretoaskourlocalofficenearesttoyou.Pleasebenotedthatwe

willnotberesponsibleforthedefectscausedbyuser'schangingofabovelubricant

orparts.

20

ONLINESPAREPART

This manual suits for next models

3

Table of contents

Other Nissei Engine manuals

Popular Engine manuals by other brands

Marine Power Solutions

Marine Power Solutions MP-214 Operation manual

SOMFY

SOMFY Tilt Only 50 RTS Central Pack instructions

YAMADA

YAMADA DZ185cdi Operator's manual

GAPOSA

GAPOSA XQ5E instructions

Mile HaoXianG Model Technology

Mile HaoXianG Model Technology DLE-55 user manual

MTU

MTU 12 V 4000 S83L operating instructions