Nissei GTR-AR Series User manual

APQTypeGearmotor

InstructionManual

FOREWORD

ThankyouforyourpurchasingoftheGTR-ARSeriesAPQType.

●

Allinformationcontainedinthismanualissubjecttochangewithoutnoticeduetorevisionormodification.

●

Thoughweelaboratedthecontents,pleaseadviseusifanyerrorisfoundinthismanual.

ForSafeOperation

●

●

ThisInstructionManualshouldbedeliveredtoapersonwhoactuallyoperatesthisproduct.

●

ThisInstructionManualshouldcarefullybekeptinaconvenientplacefortheoperator'seasyreference.

●

(

General

)

(

Wiring

)

●

●

●

●

●

●

(

Operation

)

●

●

(

DailyInspection

,

Maintenance

)

●

●

●

●

(

InspectionandMaintenanceofBrakePart

)

●

(

Transportation

)

●

●

●

Beforeactualoperationoftheequipment,makesure

thebrakeisfunctioningproperlybyturningtheswitch

onandoff.Failuretoobservethiswarningmaycause

accidentalfallingandrunoutofcontrol.

Donotreleasethebrakewhiletheequipmentisbeing

loadedintheapplicationsuchaslift.Failuretoobserve

thiswarningmaycauseaccidentalfalling.

Besurenottogetwateroroil/greaseintothebrake

unit.Failuretoobservethiswarningmaycause

accidentalfallingand/orrunawayaccidentbythe

decreasedbraketorque.

Whenaproductisliftedupfortransportation,besure

nottoenterunderneathoftheliftedproduct.Fallingof

productmaycauseseriousinjury.

Donotoperatetheequipmentwithoutbrakecoverafter

inspectionandadjustmentofbrakegap.Failureto

observethiswarningmaycausewind-inandphysical

injury.

Donotrepairorwiretheproductwiththeelectric

poweron.Besuretocutthepoweroffthepower

supplybeforegettingtowork.Failuretoobservethis

warningmaycauseelectricshock.

Iftheproductistobeusedinasystemforhuman

transportation,besuretofurnishitwithaprotective

deviceforsafety.Failuretoobservethiswarningmay

causephysicalinjuryand/ordamagetotheequipment

byaccidentalfalling.

Iftheequipmentistobeusedwithanelevator,besure

tofurnishwithasafetydevicetopreventtheelevator

fromaccidentalfalling.Failuretoobservethiswarning

maycausephysicalinjuryand/ordamagetothe

equipment.

Theoperatorsinchargeoftransportation,installation,

wiring,operation,maintenance,andinspectionofthe

equipmentshouldhaveenoughknowledgeandtechnical

skillfortheproduct.Failuretoobservethiswarning

maycauseexplosion,spark,fire,electricshock,physical

injury,and/ordamagetotheequipment.

PleasebesuretoreadthisInstructionManualbeforeusingtheproducts,asitprovidesyouwithinformationforproper

usageofthismotor.

TheGearmotorshouldbeoperatedbyaskilledandqualifiedperson.AndthecontentsofthisInstructionManual

shouldbecarefullyreadandunderstoodbeforeoperatingthisproduct.

InthisManual,injuriesanddamagesanticipatedincaseofmishandlingoftheequipment,areclassifiedintotwo

categories,"Danger"and"Caution".Thedefinitionoftheclassificationaregivenbelowwiththecorresponding

graphicsymbols.

Thecasethatmishandlingoftheequipmentmayresultindangeroussituationandmayleadtoserious

orfatalinjurytopersonnel.

Thecasethatmishandlingoftheequipmentmayresultindangeroussituationandmayleadtomedium

tolightinjury,orthecasethatmayresultindamagetotheequipment.

Pleasebeawarethatevenitemsmarkedwith"CAUTION"maycausefatalaccidents.Therefore,besuretofollowthe

instruction,foreveryitemdescribedisveryimportant.

Danger

Donotusetheproductinexplosivenessatmosphere.

Failuretoobservethiswarningmaycauseexplosion,

spark,fire,electricshock,physicalinjury,and/or

damagetotheequipment.

Danger

Caution

Whenconnectingtheproducttothepowercable,be

suretofollowtheInstructionManual.Failuretoobserve

thiswarningmaycauseelectricshock,fireand/or

malfunction.

Donotbend,pullortuckdownthepowercableorsignal

cableforcibly.Failuretoobservethiswarningmay

causeelectricshock.

Wheninspectingand/oradjustingthemachinewhileitis

inoperation,donottouchrotatingpartssuchasa

shaft.Failuretoobservethiswarningmaycausewind-

inandphysicalinjury.

Donotoperatetheequipmentwiththesafeguardoff

forinspection.Failuretoobservethiswarningmay

causewind-inandphysicalinjury.

Besuretousetheappropriatepowersupplyspecified

inthenameplate.Failuretoobservethiswarningmay

causeburnoutofthemotorand/orfire.

Donotapproachortouchrotatingpartssuchasashaft

whilethemachineisrunning.Failuretoobservethis

warningmaycausewind-inandphysicalinjury.

1

(

General

)

(

Wiring

)

●

●

●

●

●

●

●

●

●

●

(

Checkattheunpacking

)

●

●

(

Transportation

)

(

Operation

)

●

●

(

Installation

)

●

●

●

●

●

●

(

DailyInspection

,

Maintenance

)

●

●

●

●

●

(

DisassembleandAssemble

)

●

(

Connectingwithotherequipment

)

●

●

●

(

Disposal

)

●

●

●

Donotinspectthecontinuityofthewiringwhilethe

powerisON.Failuretoobservethiswarningmaycause

electricshock.

Whendisposingoftheproducts,treatthemasgeneral

industrialwaste.

Donotusethedamagedgearmotor.Failuretoobserve

thiswarningmayresultinphysicalinjuryand/orfire.

Themanufacturerwillnotwarrantandwillnot

responsiblefortheproductmodifiedorrepairedbythe

userhimself.

Whenconnectingthegearmotorwithaload,makesure

ofthealignmentofshaft,thetensionofthebeltand

parallelismofpulleys.Indirectcoupling,besureto

checkwhetherthealignmentofshaftisextremely

precise.Ifabeltistobeused,besuretoadjustits

tensionproperly.Also,beforeoperation,inspect

whetherthesettingboltsforpulleysandcouplingare

securelytightened.Failuretoobservethiswarningmay

causeseriousinjuryand/ordamagetotheequipment

duetobrokenparts.

Thegearmotorbecomesratherhotduringoperation,so

donottouchitwithbarehands.Failuretoobservethis

warningmaycauseburninjury.

Checkupthedirectionofrotationbeforeconnecting

withtheothermachine.Rotationinwrongdirectionmay

causephysicalinjuryand/ordamagetotheequipment.

Besuretosecurethemotortotheequipment.Failure

toobservethiswarningmaycausephysicalinjuryby

unexpectedmovementwhenitstarts/stopsrotating.

Surfaceofagearmotorbecomesveryhot.Therefore,

donottouchitwithbarehands.Failuretoobservethis

warningmaycauseburninjury.

Whenoperationbeingfoundabnormal,diagnosethefault

accordingtotheinstructionmanual.Donotoperatethe

machineuntilthecausesoffaultarefoundandproper

measuresaretaken.

Donottouchtheedgeoftheshaftofgearmotororkey

grooveintheborewithbarehands.Failuretoobserve

thiswarningmaycausephysicalinjury.

Donotapplyanystrongimpact.Failuretoobservethis

warningmaycausemalfunction.

Inequipmentslikefoodmachines,whichmustavoidoil

orgrease,furnishwithprotectivedeviceslikeoilpan,in

ordertoprotectfromtheoilleakagecausedbyfailure

orlifeofthemanufacturedproducts.Leakingoilmay

causedefectiveproducts.

Safeguardsshouldbefurnishedaroundrotatingparts

toavoiddangertopersons.

Beforecouplingwiththeothermachine,besureto

checkthedirectionofrotation.Unexpectedoperationin

wrongdirectionmaycauseseriousinjuryand/or

damagetotheequipment.

Beforeservicing,disconnectallpowertothemotor,

confirmthemotorisstopped,thenwaitatleastthree

minutes.Failuretoobservethiswarningmaycause

electricshock.

Becarefulwhentransportingproductstoavoidfalling

down.

Donotplaceanyobjectinflammablenearthe

equipment.Failuretoobservethiswarningmaycause

fire.

Donotplaceanyobjectwhichmayinterferewiththe

ventilationaroundtheproduct.Failuretoobservethis

warningmayresultinabnormaloverheatingcausedby

theblockoffofthecoolair,whichmaycauseburn

injuryand/orfire.

Donotsteponagearmotororhangtoit.Failureto

observethiswarningmaycausephysicalinjury.

Caution

Checkwhethertheproductisthesameproductas

ordered.Installingawrongproductmaycausephysical

injuryand/ordamagetotheequipment.

Voltagedropsinthewiringshouldbekeptwithin2%.

Excessivelengthofwiringmaycausesteepvoltagedrop

andthismakesthemotordisabletostartup.

Whenreversingagearmotorisrequiredinoperation,be

suretostoprotatingandthenstartreversing.Reversing

withoutcompleterestmaycausedamagetothe

equipment.

Whenagearmotorisfoundabnormal,stoprunning

immediately.Failuretoobservethiswarningmaycause

electricshock,physicalinjuryorfire.

Donottakeoffthenameplate.

Donotmeasuretheinsulationresistance.Failureto

observethiswarningmaycausemalfunction.

Wiringshouldbeproperlymadeunderthespecified

electricalequipmentengineeringstandardorthesafety

code.Failuretoobservethiswarningmaycauseelectric

shock,fireorphysicalinjury.

Whenrotatinggearmotoralone,takeoffthekey

attachedtemporarilytotheoutputshaft.Failureto

observethiswarningmaycausephysicalinjury.

Donotinsertyourfingersoranyotherobjectintothe

apertureofthegearmotor.Failuretoobservethis

warningmayresultinelectricshock,physicalinjury,fire

and/ordamagetotheequipment.

Donotuseagearmotorunderconditionsotherthan

specifiedinthenameplateortheproductspecifications.

Failuretoobservethiswarningmaycauseelectric

shock,physicalinjuryand/ordamagetotheequipment.

Donotsupplythecommercialpowersourcedirectlyto

themotor.Failuretoobservethiswarningmaycause

burnoutofthemotor.

Besuretoaskourbranchofficeorfactoryforrepairing,

disassemblingandassemblingequipment.Failureto

observethiswarningmaycausephysicalinjuryorfire.

2

Tableofcontents

1.BeforeOperation ・・・・・・・・・・・・ P.3

2.Installation ・・・・・・・・・・・・・・・・・ P.4

3.Specifications ・・・・・・・・・・・・・・・ P.11

4.MaintenanceandLifetime ・・・・・・ P.11

5.Troubleshooting ・・・・・・・・・・・・・ P.13

6.Warranty ・・・・・・・・・・・・・・・・・・・ P.14

1.BeforeOperation

1

-

1

.

PartsNameandFunctions

1

-

2

.

InitialChecks

(1)

(2) Noaccidentaldamagetotheproductduringtransportationexist.

(3) Screwsornutsarenotloose.

(4) Components

a) Gearmotor

b) InstructionManual

c) Accessory

Theorderedproductsandthecontentsindicatedinthenameplatearecorrect.

(Type,Reductionratio,Motorcapacity,Voltage,Frequency,etc.)

Whenunpackingacarton,pleasecheckupthefollowings.Ifyouhaveanyproblems

orquestions,pleasecontactthedealerfromwhichtheproductwassuppliedora

salesoffice.

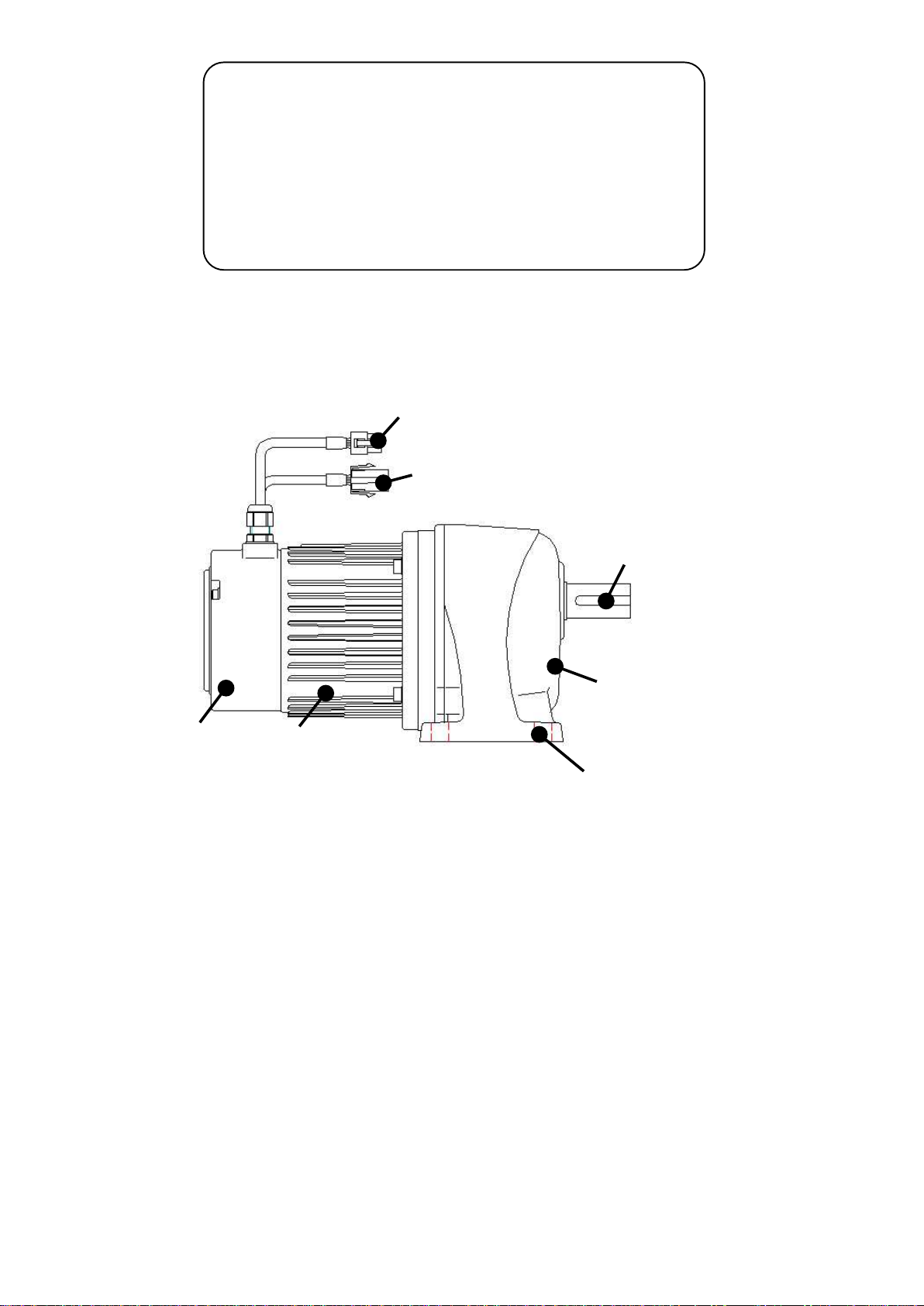

Output

Shaft

MotorPowerCable

(IncludeBrakeLeads)

MotorSignalCable

Gearhead

Foot

Motor

Brake

3

2.Installation

2

-

1

.

Connection

Connecteachdevicesasshownbelow.

Besuretoinsertthecorrectconnectorsurely.

※

※ Thecablethatcomeswiththegearmotorextends200mm.

※ Donotconnectordisconnectwiringwhilethepowerison.

Itmaycausemalfunctionoftheproduct.

※

ExtensionPowerCableandExtensionSignalCablearerequiredtoconnect

GearmotorandDriver.

WhenQtype(withbraketype)isused,thepowersupplyof24VDC(10mAor

more)isnecessaryasidefromoptionalbrakepowersupplydevice.

ToON・OFFthebrake,ourregularoptionisnotalwaysnecessary.Itis

possibletoaddDC24VbetweenBandBofthepowercable.However,the

varistor(82Vand1Jormore)orthediode(100Vand1Aormore)is

necessarybetweenBandBtoprotectthebrakecoilandcontactpointof

therelay.

BrakePowerSupplyDevice

BrakeControl

Wire

APQGearmotor

RegenerativeResistor

Extension

PowerCable

Extension

SignalCable

APQDriver

PowerSupply

Cable

+24V

0V

24VDC

(customer

preparation)

QType(withBrake)

4

2

-

2

.

InstallationofGearmotor

(

1

)

Properlocationforinstallation

(

4

)

TighteningTorque

AmbientTemperature:0℃to40℃

AmbientHumidity:85%max.

Altitude:Sealevelto1,000mmax.

Environment:Wellventilatedplacefreefrom

corrosivegas,explosivegasvapor

and/ordust.

InstallationLocation:Indoors

(2) DirectionofInstallation

(3) MethodforInstallation

① Attachingthemountingfootandflange

(Roughnessofthesurfaceshouldbelessthan0.3mm.)

② Attachingtheshaft

● Gearmotor'sweightshouldbesupportedbythedrivenshaft.

●

2

-

3

.

Connectingwithotherequipment

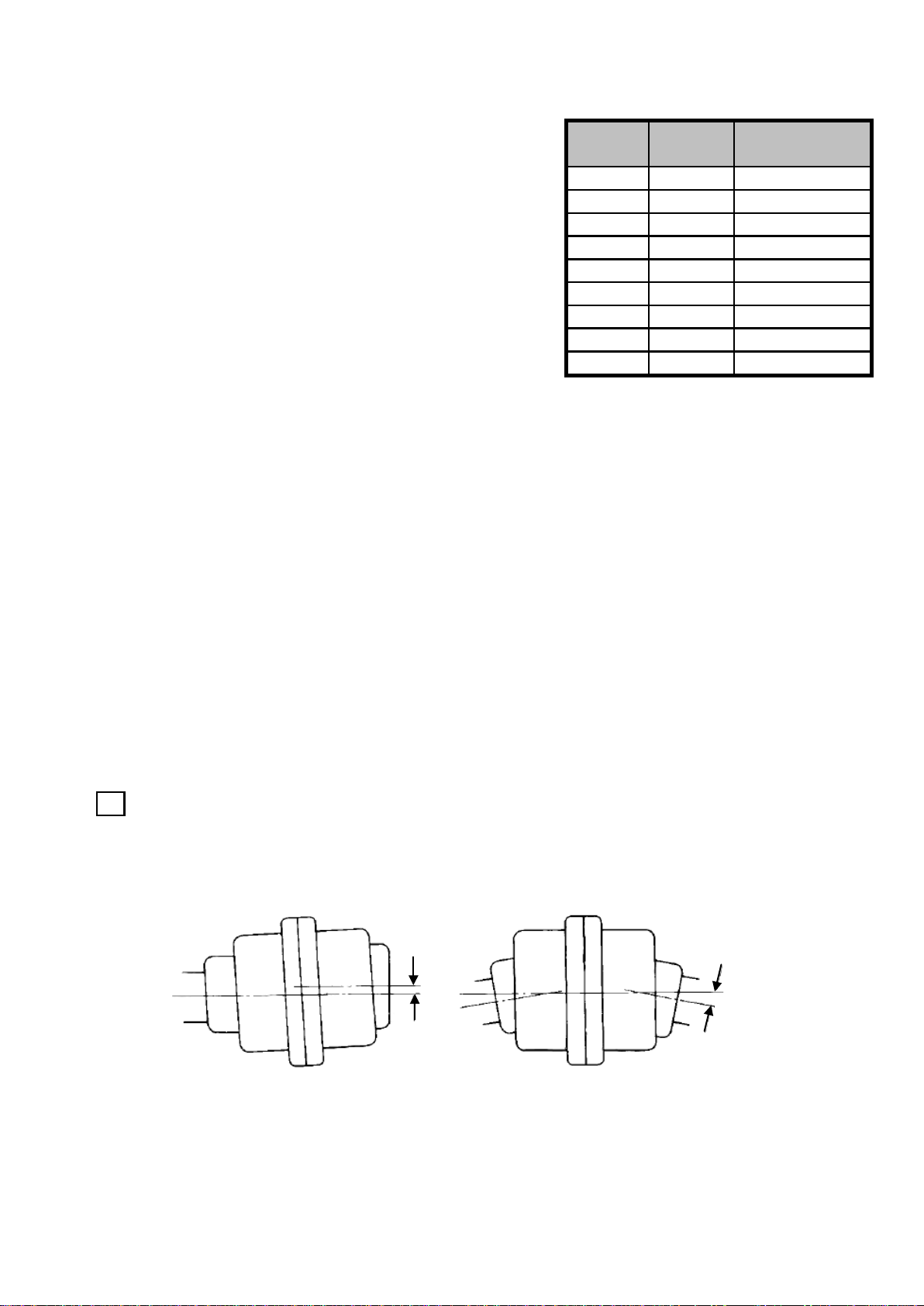

1 DirectConnection

●Anexampleofgearcoupling

● Thedisplacementsδandθshouldbeminimizedasmuchaspossible.

●

Loosefitisrecommendedforthecouplerssuchascouplings,sprockets,pulleys,

gears,etc.,whenattachingtothereducer,usingthedesignatedkeymaterials.

Thisproductcanbeinstalledinanydirection

duetoagreaselubricationsystem.

Thedisplacementsδandθdifferaccordingtothetypeofcoupling.

Therefore,theyshouldbewithintheallowablevaluedefinedbytherespective

manufacturer.(Reference:Incaseofchaincoupling,δshouldbewithin2%of

therollerchainpitchandδshouldbewithin1°.)

M5

M16 294{30}

(Forcesotherthanturningreactiveforceshouldneverbeimposedto

thetorquearm.)

108{11}

BoltSize

Incasestart/stopandforward/reverseactionsarefrequent,tightenup

thetorquearmwithboltstokeepthelockingholenotloose.

M12

5.5

6.5

8.5 M8 13{1.3}9 13{1.3}

11

13

15 M14

M10

(N・m){(kgf・m

)}

Connectthereducertotheotherequipmentprecisely,sothatthe

centeroftheshaftofbothmachineswillbefullyaligned.

18

22 M20

69{7.0}

fixinghole

(mm)

25{2.6}

44{4.5}

M6

M8

TighteningTorque

2.9{0.3}

4.9{0.5}

Fixtheproductwiththefourboltsonaflatandmachinedsurfacefree

fromvibration.

δθ

5

2 AttachingChains,V-Belts,Gears,etc.

①

②

③

・

・

・

Thechainistooloose.

・

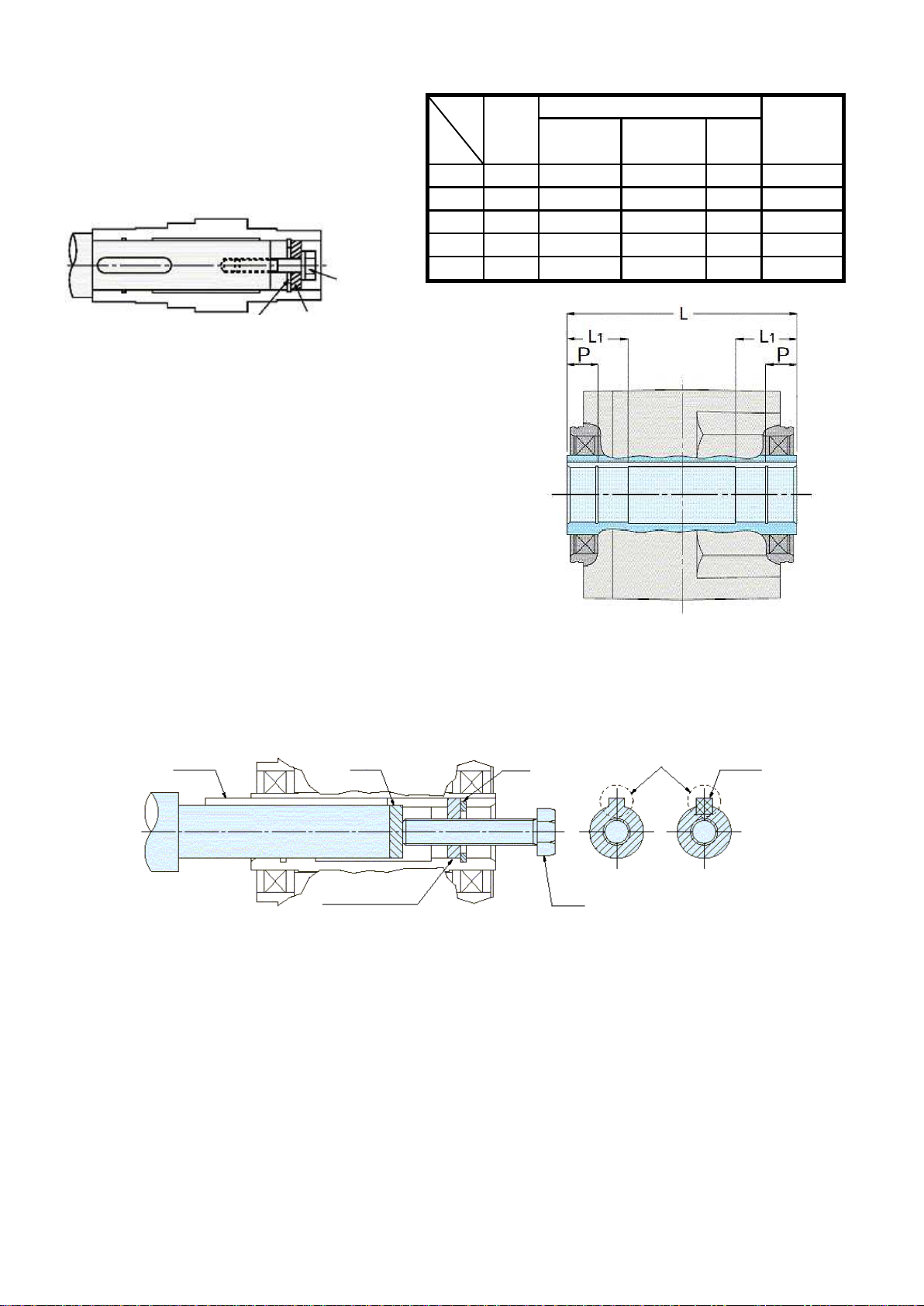

3 AttachingandDetachingaDrivenShaftto/fromAF3STypeHollowShaft

●AttachingaDrivenShafttotheReducerHollowShaft

①

②

③

④

⑤

Tensionsforbeltandchain

arecorrect.

ThetensionoftheChains/V-Beltsandthecouplingofthegearmustbeperpendiculartothe

centeroftheshaft.

Inanyconnection,connecttheunitsprecisely,sothatthecenteroftheshaftofthereducer

andthatoftheotherequipmentareparallel.

Thepositionsofpulleyand

sprocketarealsocorrect.

Incaseimpactdoesnotapplyintheuniformload,loosefitisrecommendedforthefittolerance

ofdrivenshaft.Incaseshockloadorheavyradialloadisappliedtotheshaft,thefitshouldbe

tighter.Theboreofthehollowshaftismachinedtoconformto"JISH8"tolerance.

Thelengthofthedrivenshaftandthefixingkeyarerecommendedtobewithinthearea

where"H8"toleranceforthefixedsideboreisrequired.

Itisrecommendedtominimizethefluctuationofthedrivenshaftbelow0.05attheshaft

edge.Thegreaterfluctuationmaygiveharmfuleffecttothereducer.

Thesprocketispositioned

inthereversedirectionso

thattheloadpointmoves

totheshaftedge.

Whenattaching,besuretosmearextremepressureagent(molybdenumdisulfide,etc.)onthe

surfaceofdrivenshaftandtheboreofthehollowshafttoavoidseizing,andinsertthereducer

tothedrivenshaft.

Ifthefittingistootight,forsmoothinsertion,knockonthehollowdriveshaftendgentlywith

plastichammer.Inthiscasebesurenottohitthecasing.Smootherinsertioncanbeobtainedif

youpreparejigsshowninthefigurebelow.

TensionoftheV-Belt:Excessivetensioningmayresultindamagetothebearingsoftheshaft.

TensionoftheChain:Excessivetensioningmayresultindamagetothebearingsoftheshaft.If

thechainisinstalledloosely,shockloadwilloccurwhenthedriveshaftstartsrotation,andthis

canresultindamagetothereducerandtheotherequipment.Therefore,adjustthetensionof

thechainproperly.

DrivenShaft

Key

Areawherethetolerance

oftheboreshouldbe

within"H8" Hollow

Shaft

Areawherethetolerance

oftheboreshouldbe

within"H8"(fixedside).

Spacer

Nut (Outputshaftcanbe

insertedbytightening

thenut.)

Bolt

Bearing

OilSeal

Figue-1

※Spacer,nut,bolt,keyand

otherpartsforbearingshould

bepreparedbycustomer.

Connecting

machine

sprocket

Connecting

machine

ProperWayofUse

BadExample

6

●ConnectingReducerwithDrivenShaft

① Drivenshaftwithashoulder

Note)Excessivetighteningoftheboltmaycausethedeformationofthesnapring,whichcarefullynote.

② Drivenshaftwithoutashoulder

Note) Besuretohavespaceintheouterdiameterofspacerandintheboreofhollowshaft.Excessive

tightnessofthefittingorinaccuracyofthespacer'sdiametermaybeacauseofscrubbingwhichmay

leadtoagreaterfluctuationbetweenthedrivenshaftandthehollowshaft.Positioningspacerisused

whendecidingthepositionofthereducer.Incasethelengthofthedrivenshaftisalreadyclarified,

positioningspacerisnotnecessary.Byhavingapositioningspacer,smootherdetachmentfromthe

hollowshaftcanbeobtained.(Formoredetailsaboutthedetachmentfromthehollowshaft,referto

Figure-5.)

Spacer

SnapRing

Fixthedrivenshaft

betweenthepillows

Bolt

Figure-2 Fixingbyspacerandsnapring

connecting

machine

Fixingthedrivenshaft

betweenthepillows.

Bolt

Endplate

Figure-3FixingbyEndplate

connecting

machine

※Spacer,boltandsnapring

shouldbepreparedbycustomer.

※Endplateandboltparts

shouldbepreparedbycustomer.

Fixingthedrivenshaft

betweenthepillows

Figure-4Fixingbyspacerandsnapring

Positioning

spacer

Bolt

Spacer

Snap

Ring

connecting

machine ※Spacer,positioningspacer,

boltandsnapringshould

bepreparedbycustomer.

7

●Recommendedsizeforthedriven

shaftfixingpart

〈

Recommendedsizeforthedrivenshaftfixingpart

〉

●Aboutthelengthofdrivenshaft

●Aboutthelengthofkeyforthedrivenshaft

●Detachingfromthehollowshaft

Figure-5

Thelengthofthekeyshouldbemorethan1.5timesof

thediameterofhollowshaft.Also,thekeyinserting

positionshouldbetheplacewheremorethan1/2of

thetotalkeylengthcanbereachedtoL1.(Referto

thefigureontheright)

Thedrivenshaftmustbereachedtothebothsideof

theL1part.(Asshownontherightfigure)However,be

suretohaveallowanceforthespacer'sdimension

necessaryatthe"detachmentfromthehollowshaft".

φ45

M6

M6

M8

M10

M12

φ30

φ25

φ20

φ35

Makesuretoavoidexcessiveforcebetweenthecasingandthehollowshaft.Smoother

detachmentcanbeobtainedbyusingajigasshowninthefigurebelow.

4

5

Width

φ7

35

45

φ34.5

φ44.5 φ11

φ11 5

φ29.5

Bolt

Size Inner

Diameter

φ19.5

φ24.5

Outer

Diameter

φ9

Fortheattachmentofthehollowshaft

ingeneraluse,werecommendyouto

refertothedimensionsshownonthe

rightasaguidelineforthestrength

whendesigning.

Nominal

Designation

forC-Type

SnapRing

20

25φ7 30

SpacerDimension

3

5

Bolt

Spacer

C-typesnapring

Key1

Disk

Snapring Key2

(Theconvexitypartisfor

thefixingpartofthe

Crosssectionofthespacer

Bolt

Spacer(withtap) (Bytighteningthebolt,

outputshaftcomesout.)

※Spacer,disk,boltandsnapring

shouldbepreparedbycustomer.

8

●AttachingReducer

Meritsanddemeritsofflangemountedandtorquearmmounted.

●AF3STypeHollowShaft・FlangeMounted

●DetailedDrawingfortheTappedHoleforFaceMount(StandardSpecification)

13 25 φ8.6 38

15 25 φ8.6 40

16 25 φ8.6 41

16 30 φ10.6 46

18 30 φ10.6 48

18 40 φ14 58

23 50 φ17.5 73

※

Valuesintheparenthesisinthe"FrameNumber"arethatforAF3F.

Thenecessaryholdingpartoftheboltarerecommendedtobetwiceasmuchasthe

nominaldesignation(boltdiameter)ofthescrew.

(Example:IncaseofM10,over20mmisrecommended.)

●Alignmentwiththe

connectingmachineisneeded.

Demerits

Flange

Mounted

45(40) φ16.5

1/80〜1/240 M16×P2

M20×P2.50.75kW φ20.5

0.4kW

35(32) 1/80〜1/240 φ12.5

0.4kW

1/80〜1/240 φ12.50.2kW

0.75kW

30(28)

WhentheAF3STypeunitisdirectlycoupledwiththe

flangefaceoftheothermachine,thealignmentshould

bedonepreciselytoavoidburnoutofmotor,damage

tothebearings,etc.causedbymisalignment.Inthe

AF3Series,thereisaborefortheattachmentas

showninthediagramontheright.Thedimension

toleranceoftheborefortheattachmentφAis"h7".

Thefixingboltsaretobeusedasshowninthe

diagramontheright.Fixby4bolts.

M10×P1.5

M10×P1.5

M12×P1.75

ReductionRatio Capacity A

1/10〜1/60 φ10.5

TorqueArm

Mounted

0.1kW

0.2kW

15(18)

25(22) 1/10〜1/160

1/10〜1/60

●Onlyonefixingpointisneededfor

fixingwithothermachine

φ10.5

φ10.5

●Torquearmisneeded.

F

●Spaceforattachingtorque

armisneeded.

M12×P1.75

M10×P1.5

B

●Easyalignmentwiththe

connectingmachine

1/5〜1/60

Frame

No. C D E

●Spacesaving

●Directattachmenttothemachine

ispossible.

Merits

4−B

CEFD

4−A

AF3SType

(HollowShaft)

Drivenshaftofthe

othermachine

Flangefaceofthe

othermachine

Boreforattachment

Fixingbolt(4pcs.)

φA

9

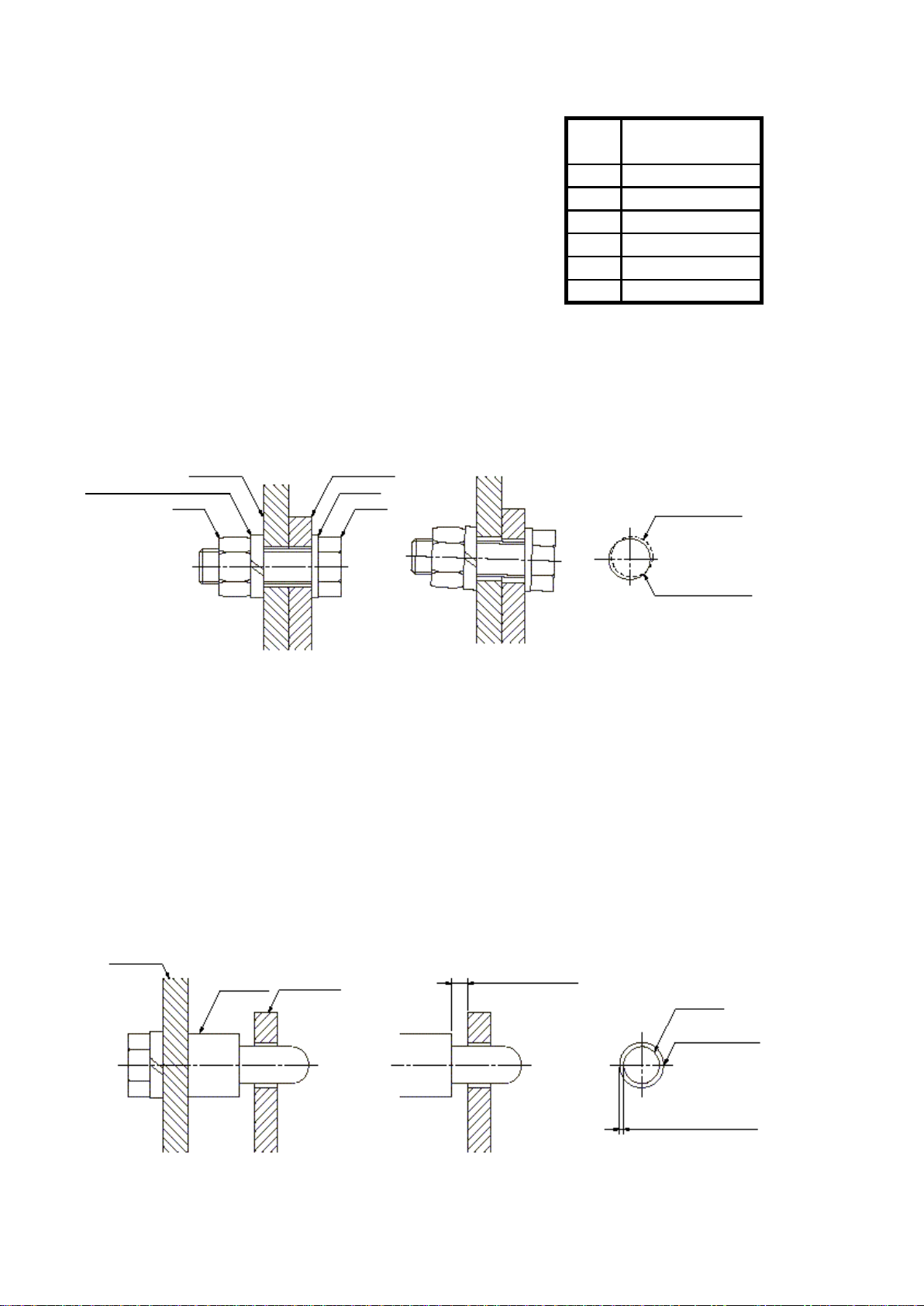

●FixingaReducerandaTorqueArm

BoltSizeandRespective

①

TighteningTorque

②

●HowtofixtheTorqueArmFixingPart

① IncaseofForward/ReverseOperation

Badexample

Figure-6Attachingthefixingpart

Note)

② IncaseofOne-DirectionOperation

Figure-7Exampleofusingpinwithshoulder

Excessforceariseninthedrivenshaftandthehollowshaftmay

causefailureofthemachine.

M14

13{1.3}

M12 25{2.6}

44{4.5}

69{7.0}

TighteningTorque

N・m{kf・m}

108{11}

294{30}

Bolt

Size

M20

M8

M10

Torquearmsaresubjectedtorotationreactiontorque,

therefore,theymustbestrongbyusingmaterialsof

enoughthicknessandboltstoenduretheshockload

onstarting/braking.Choosingouroptionaltorquearms

isthemostappropriatesolution.

Wheninstallingareducerwithatorquearm,besureto

tightentheboltusinghelicalspringlockwashersand

plainwashers.Forpropertighteningtorque,referto

thetableshownontheright.

Firmlyfixthefixingpartofthetorquearm.Makesurethatthereisnoradialload

(suspendingload)imposedbetweenthedrivenshaftandthehollowshaftofthereducer,

causedbypooralignmentbetweentheholeoffixingpartandtheconnectingmachine.

(RefertotheFigure-6)

Whenabacklashintheattachingpartarosebyforward/reverseoperationsorbyhighfrequencyof

starting/stopping,theintenseimpactgiventothetorquearmineachstartingmaycausethefailuressuch

aslooseningofthetighteningbolt.

Ifthefrequentstaringtorquelikeintheforward/reverseoperation,isnotobserved,

operationwiththereleasedfixingpartoftorquearmispossible.However,itisnecessary

tofixthedrivenshaftandthehollowshaft.(RefertotheFigure2,3and4)Inthiscase,

besuretosecureenoughspacebothforradialdirectionandforthrustdirectioninthe

alignmentbetweentheconnectingmachineandthefixingpart.

M16

holeofthetorquearm

pinwithshoulder

Securespacetoavoidtheradialload.

Securespaceforthehole

toavoidshouldering.

torquearm

pinwith

shoulder

connectingmachine

nut

connectingmachine

helicalspringlockwasher torquearm

plainwasher

bolt holeoftheconnecting

machineside

holeofthetorque

armside

10

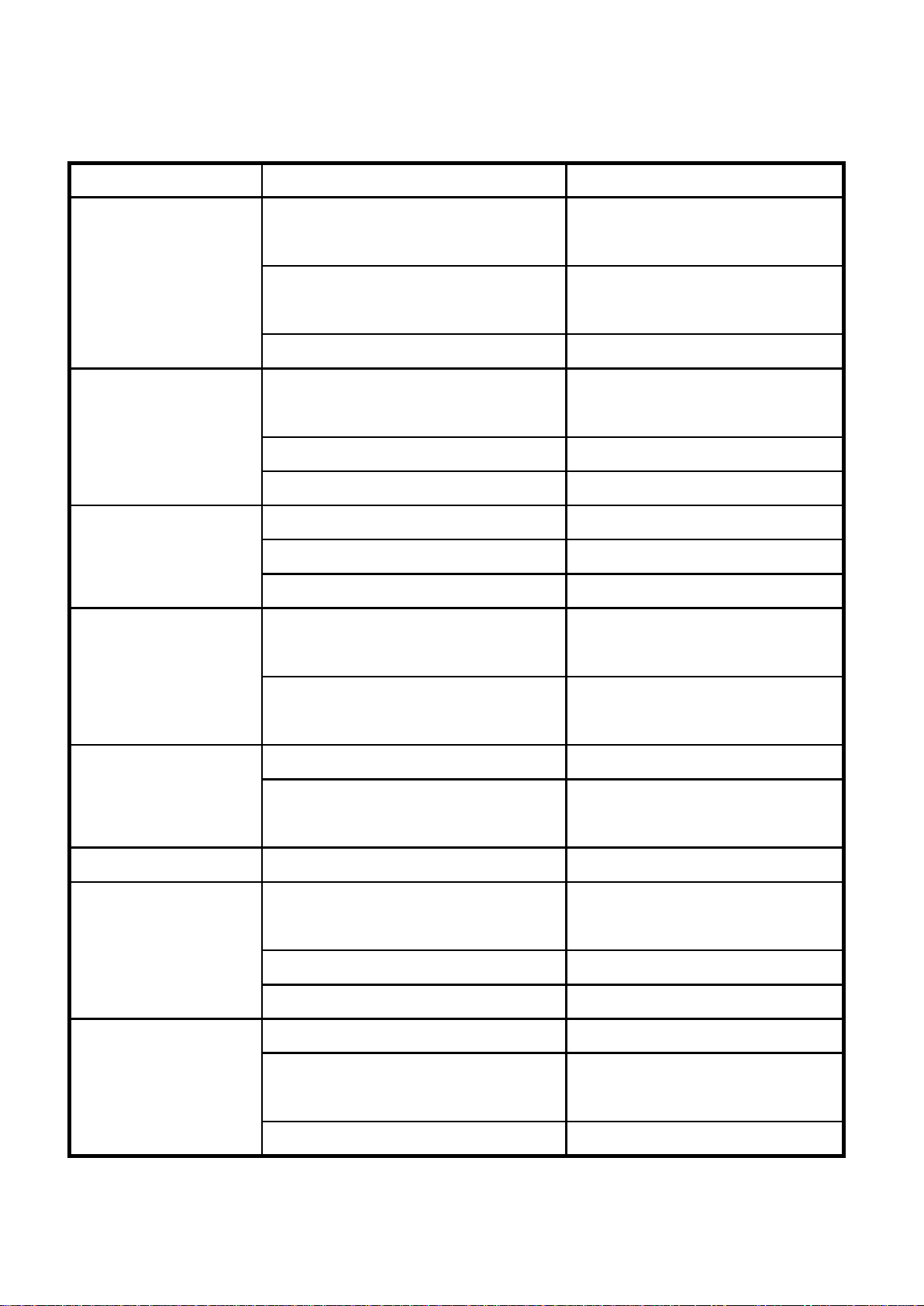

3.Specifications

①MotorSpecifications

●

Capacity

(

kW

)

Item

MotorType

RatedCurrent

(

A

)

AmbientTemperature(℃)

Protection

②BrakeSpecifications

Capacity

(

kW

)

Item

Voltage

(

±

10

%)(

V

)

Current

(

at

20

℃

)(

A

)

Power

(

at

20

℃

)(

W

)

4.MaintenanceandLifetime

4

-

1

.

MaintenanceandLifetime

●

●

4

-

2

.

MethodforBrakeGapAdjustment

1

2

3

30

(mm) 200

2.0

MaximumExtension

Distance

0.36

0.2kW

0.1kW 0.2kW 0.4kW

0.4kW

BlushlessDCMotor

0to40℃

0.6

0.9

0.1kW

0.75kW

3.8

24

0.58

Totallyenclosednon-ventilated(IP65)

0.57 0.95 1.76 3.43

13.9

0.58

13.9

1.05

20.6

0.75kW

8.6

(N・m)

■Attachingdirectionofthe

castellatednut.

Thelifeofoilsealmayvaryaccordingtotheconditionofuse.Thereforereplacement

maybeneededevenwithin10,000hoursuse.

TheRatedCurrentdescribedinthefollowingtableisareferencevaluewithoutthe

gearhead.(motorunitonly)

"Power-off,Brake-on"Type

(SpringClose)

(m)

Allmodelsusegreaselubricant,withoutneedingreplacementorreplenishment.The

gearmotorhasbeendesignedforanapproximateuselifeof10,000hours.

LengthofMotor

LeadWire

BrakeType

HoldingTorque

(atmotorshaft)

Danger

Afterinspectionandadjustmentofthegap,donot

operatethemotorwiththebrakecoveropen.Failureto

observethiswarningmaycausewind-inandphysical

injury.

Whenadjustingthegap,besuretodisconnectthemotor

fromthepowersource.Failuretoobservethiswarning

maycausephysicalinjury.Intheeventofthecastellated

nutremoved,besuretoattachitintherightdirection.

Attachinginthewrongdirectionmaycausedamages.For

therightattachingdirection,refertotheattaching

directionofthecastellatednutshownright.

Afterinspectionandadjustmentofthegap,besureto

confirmifthebrakefunctionsproperlybyturningthe

switchonandoff.Failuretoobservethiswarningmay

causeaccidentbyfallingorrunoutofcontrol.

11

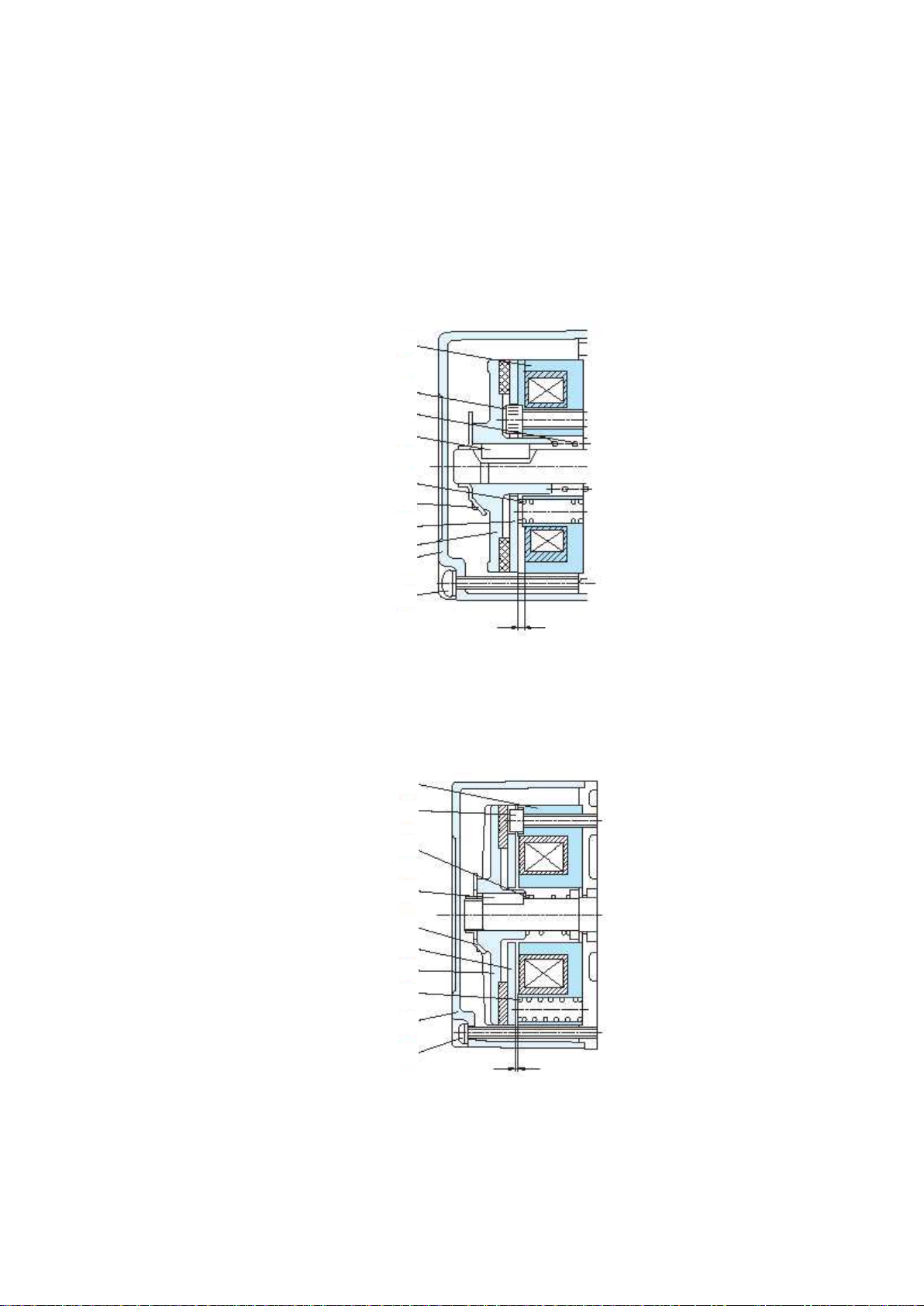

■QType(withBrake)

■Structureofbrake

0.1kW,0.2kWand0.4kW

①Field

②Armature

③OuterDisk

④Spring1

⑤Spring2

⑥CastellatedNut

⑦Key

⑧HexSocketHeadCapbolt

⑨BrakeCover

⑩Brakecoversettingbolt

※

ProperGap:0.4mm(±0.1mm)

GapforSuctionLimit:Lessthan0.7mm

0.75kW

①Field

②Armature

③OuterDisk

④Spring1

⑤Spring2

⑥CastellatedNut

⑦Key

⑧HexSocketHeadCapbolt

⑨BrakeCover

⑩Brakecoversettingbolt

※

ProperGap:0.2mm(±0.1mm)

GapforSuctionLimit:Lessthan0.5mm

Asaresultofusingbrakeforanextendedperiodoftime,naturallybrake

gapgrewandfinallybrakereleasingbecomeimpossible.Toavoidthis

trouble,besuretoadjustbrakegapperiodically.

Asaresultofusingbrakeforanextendedperiodoftime,naturallybrake

gapgrewandfinallybrakereleasingbecomeimpossible.Toavoidthis

trouble,besuretoadjustbrakegapperiodically.

Afteroperationforanextendedperiodoftime,thefrictiondiskofbrakebecomes

abradedandthegapincreases.Whenthegapclearancebecomesgreaterthanthelimitof

gaptoinhale,armatureinhalingbecomesdifficultbymagnet,makingitimpossibleto

releasethebrake.Whenusingthemotorcontinuouslywiththiscondition,theoperation

withbrake-oncausesoverloadandfinallyALARMLEDonthedriverlightsup,thenthe

motorwillstop.Inordertooperatethismachinesafely,itisrecommendedtocheckor

adjustthebrakegapperiodically(Every1yearorevery2to3millioncycles).

①

⑧

⑤

⑦

④

⑥

②

⑨

⑩

③

gap

③

①

⑧

⑤

⑦

⑥

②

④

⑨

⑩gap

12

5.Troubleshooting

Improperinstallationorslacked

bolts.

Foreignsubstancesoroilare

adheredtothefrictiondisk.

Disconnectionorshortcircuitof

brakecoil.

Whenthedefectiveoperationisfound,pleasecheckthecauseandtakemeasures

accordingtothefollowingpoints.

Disconnectionofmotorpower

cable.

Disconnectionorpoorcontactof

motorsignalcable.

Motorpowercableistoolong.

Continuednoise-defective

bearing,wornoutgear.

Damagedswitch.

Lifeofthefrictiondisk.

Brokengear,shaftorbearing.

Wornoutgear.

Repairorreplacetheswitch.

Repairatauthorizedfactory.

Removeforeignsubstances.

Excessivemomentofloadinertia.

Largerbrakegap.

Poorcontactofswitch.

Repairatauthorizedfactory.

Reducetheloadinertia.

Adjustthebrakegap.

Repairatauthorizedfactory.

Tightenthebolts.

Repairatauthorizedfactory.

Wornoutgearorbearing.

Reducethefrequency.

Repairatauthorizedfactory.

Repairatauthorizedfactory.

Repairatauthorizedfactory.

Reducetheload.

Reducetheload.

Checkthelengthanddiameter

ofpowercable.

Overloadoperation.

Overloadoperation.

TroubleshootingCause

Repairatauthorizedfactory.

Checktheconnection.

Checktheconnection.

Intermittentnoise-damagedgear

orforeignsubstancesinsidethe

motor.

Replaceorrepairtheswitch.

Abnormalnoise

Highfrequencyofstartandstop.

Damagetobearings.

Themotordoesnot

runeveninthe

unloadedcondition.

Themotordoesnot

runintheloaded

condition.

Abnormalrisein

temperature

Trouble

Excessivevibration

Brakedoesnotwork

Brakefunctionisnot

enough.

Motordoesnotrun.

(Rotatingspeeddoes

notincrease.)

Overheatedmotor.

Abnormalnoisein

braking.

13

6.Warranty

1.WarrantyTerm

2.ScopeofWarranty

1) Thescopeofourwarrantyislimitedtoourmanufacture.

2)

3.ExceptionforWarranty

1)

2)

3)

4)

5) secondaryfailurecausedbythedamageofcustomersequipment.

6)

7)

8)

9)

Incasethatanyfailuresontheproductbywhichproperfunctionsofthe

productcannotbeobtainedariseduringtheabovewarrantyterm,although

theproductisproperlyoperatedundertheconditionthattheproductis

properlyinstalledin,connectedtothemachine,treated(including

inspectionandmaintenance)inaccordancewiththisInstructionManual,we

willprovideappropriaterepairontheproductfreeofcharge,exceptas

stipulatedintheExceptionforWarrantyasdescribedbelow.

anyothertroubles,problemsordamagesontheproductwhicharenot

attributabletoourproductliability.

Wearenotresponsibleforthecompensationagainstthelossofshutdown

and/orforthedamagetotheequipmentswhicharenotproducedbyus,

causedbytheinterruptionofoperationofourproduct.

anyrepairstothelossesordamagescausedbythedisassemble,

modification,changeofpartsorthesubstitutedproductdeliveredwhich

arerenderedbycustomer.

anylossescausedbytheparts,drivingunits(examples:electricmotor,

servomotor,hydraulicmotor,etc.)whicharesuppliedbycustomer.

improperstorageandmaintenanceoftheproduct,orimproperhandlingof

theproduct.

disaster(earthquake,thunder,fire,flood,etc.)orhumanerrorsuchas

wrongoperationoftheproduct.

customer'simproperoperationoftheproductnotinconformitywiththe

rateddataspecifiedinourcataloguesorthespecificationsmutuallyagreed.

anyfailuresinthetransmissionparttocustomer'sequipment(alignmentof

theshaftwhencouplingwithothermachine,etc.)

Thiswarrantyshallnotbeappliedtotheproblems,troublesordamagesonthe

productwhicharecausedby:

Thewarrantytermfortheproductshallbe18monthsafterthedateof

deliveryor12monthfromtheproductstartingoperation,whetherbe

shorter.

14

NISSEICORPORATION

Sales,OverseasDivision

1-1Inoue,Izumi-cho,Anjo-shi,Aichi,444-1297JAPAN

TEL:+81-566-92-5312FAX:+81-566-92-7002

ver

1.0

2010/4

Ifyouhaveanyquestionsorconcernsabout

ourproduct,pleasecontactthedealeror

distributorfromwhompurchased,orcontact

thenearestsalesofficeorplantof

NisseiCorporation.

Acceptance

Certificate

This manual suits for next models

1

Table of contents

Other Nissei Engine manuals

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton 120000 Operating & maintenance instructions

Volvo

Volvo D11F Operator's manual and maintenance instructions

Chris-Craft

Chris-Craft 350-Q Operator's manual

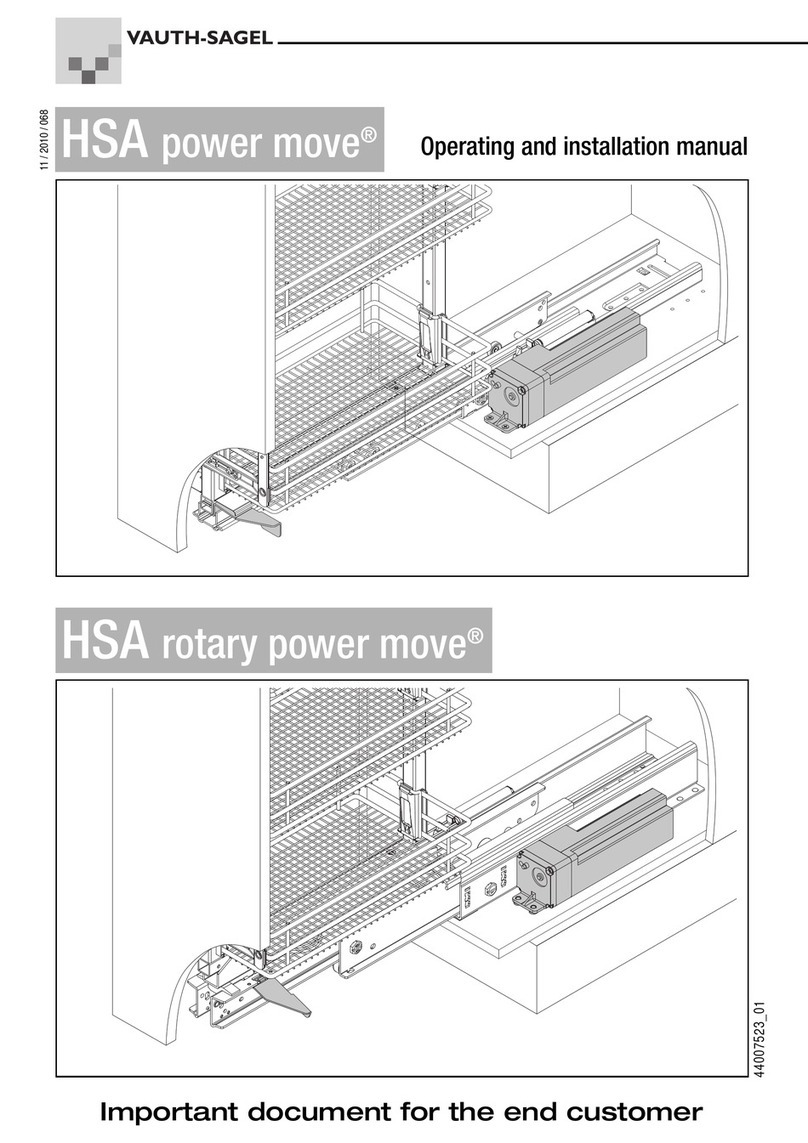

Vauth-Sagel

Vauth-Sagel HSA power move OPERATING AND INSTALLATION Manual

GAPOSA

GAPOSA XQ40 instructions

Suzuki

Suzuki DF 25 owner's manual

Briggs & Stratton

Briggs & Stratton 351700 Series Operating & maintenance instructions

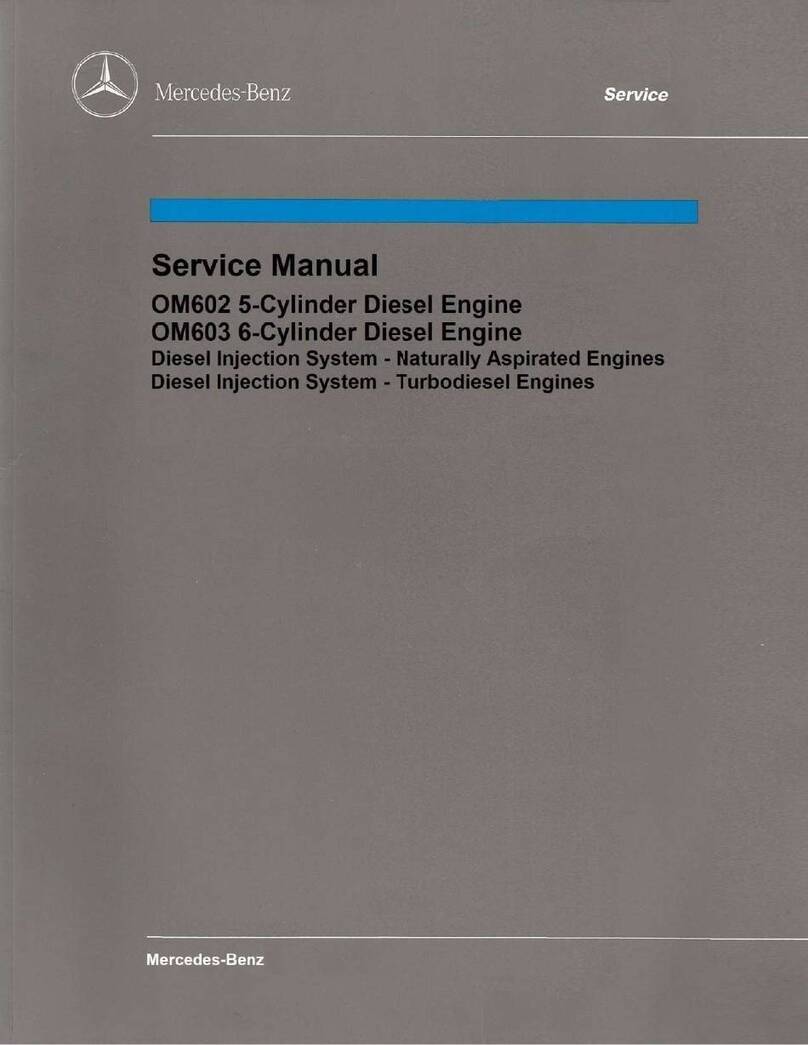

Mercedes-Benz

Mercedes-Benz OM602 Service manual

Leadshine

Leadshine iSV2-CAN Series user manual

Kohler

Kohler KDI 1903M owner's manual

Festo

Festo MTR-DCI series Brief overview

Westerbeke

Westerbeke 12B TWO Operator's manual