Nitronic ST730T User manual

www.nitronic.ch - 1 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Coax Stripping Machine

ST730T

Operating manual

Stand: V1.1 preliminary

Subject to change without notice!

Publisher:

Nitronic AG

Mattenstrasse 11

CH-2555 Brügg

Phone +41 32 373 7070

Fax: +41 32 373 7075

Web: www.nitronic.ch

Email:

info@nitronic.ch

www.nitronic.ch - 2 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Machine Description............................................................................................................ 6

Unpacking the ST730T....................................................................................................... 6

Touchscreen, Connections................................................................................................. 7

Touchscreen ...................................................................................................................... 7

Additional Functions ..................................................................................................... 8

Basic settings of the machine ....................................................................................... 9

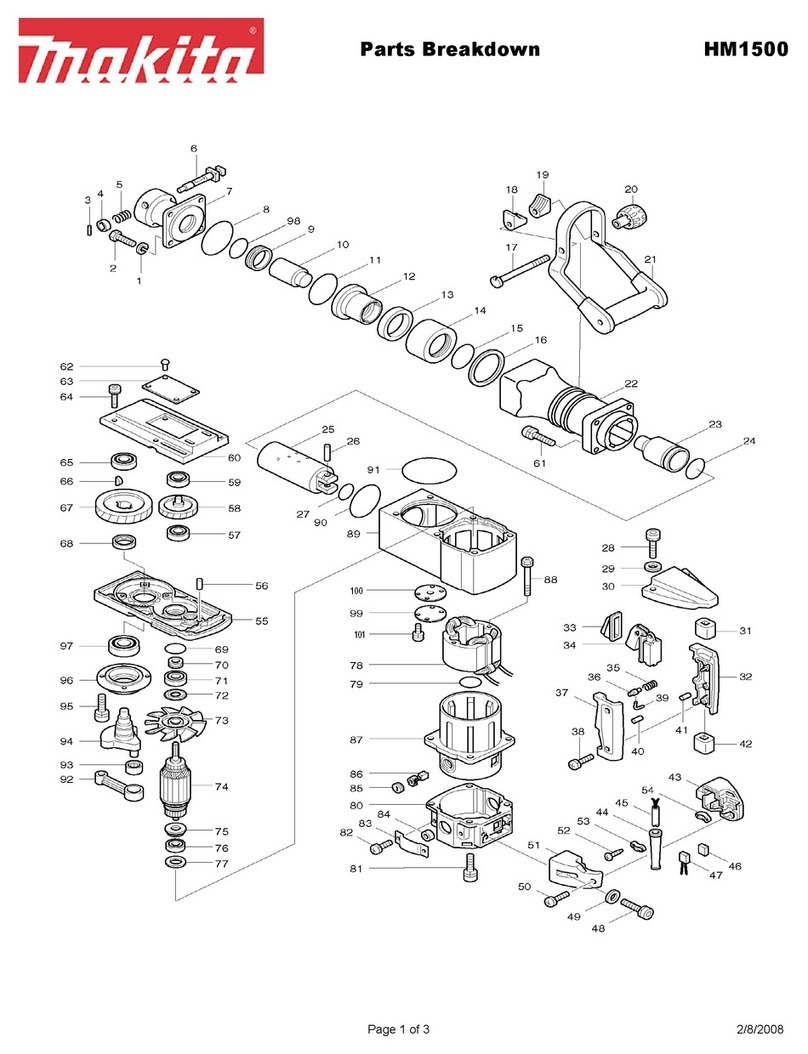

Fig. 1. Rear panel .................................................................................................. 10

Connections ..................................................................................................................... 10

Mains Connection ....................................................................................................... 10

Remote Control .......................................................................................................... 10

RS 232 C ............................................................................................................... 10

Switch .................................................................................................................... 10

Electromagnetic Immunity (EMI)................................................................................. 10

Set up.................................................................................................................................. 11

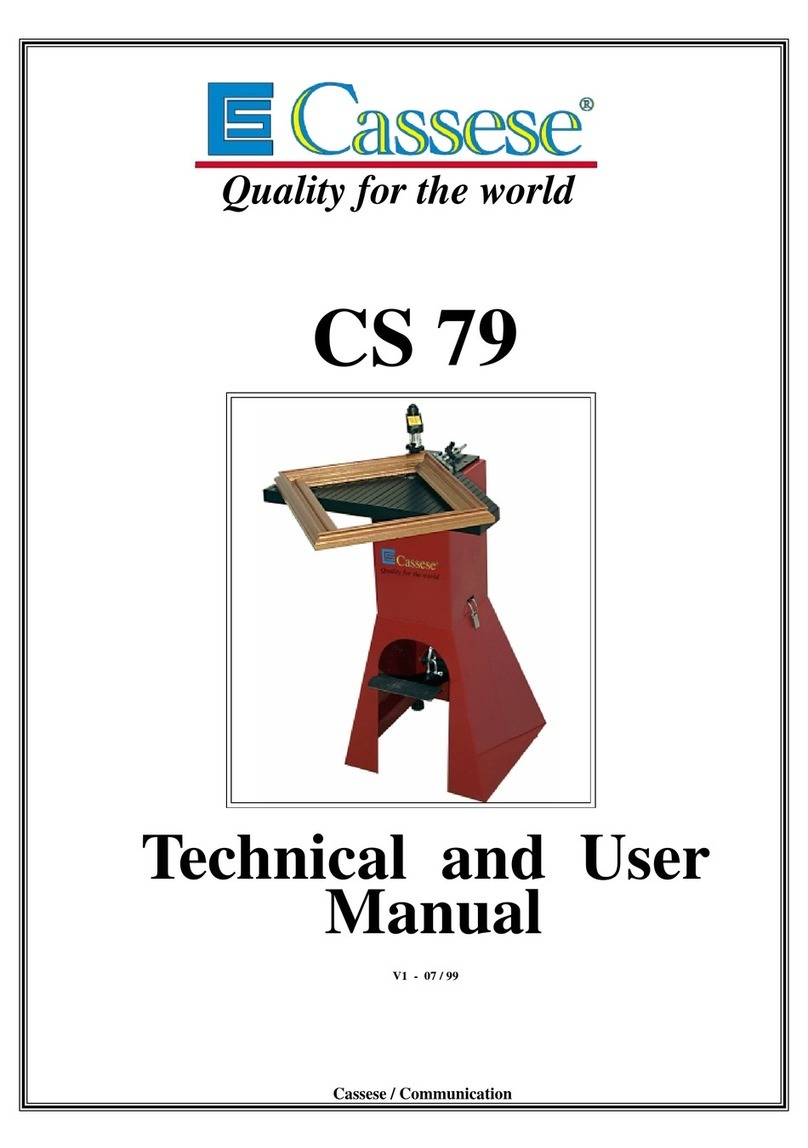

Fig. 2. Remove protective foam ............................................................................. 11

Fig. 3. Remove safety cover / place machine in position ....................................... 11

Fig. 4. Toggle main switch (A) to I ......................................................................... 11

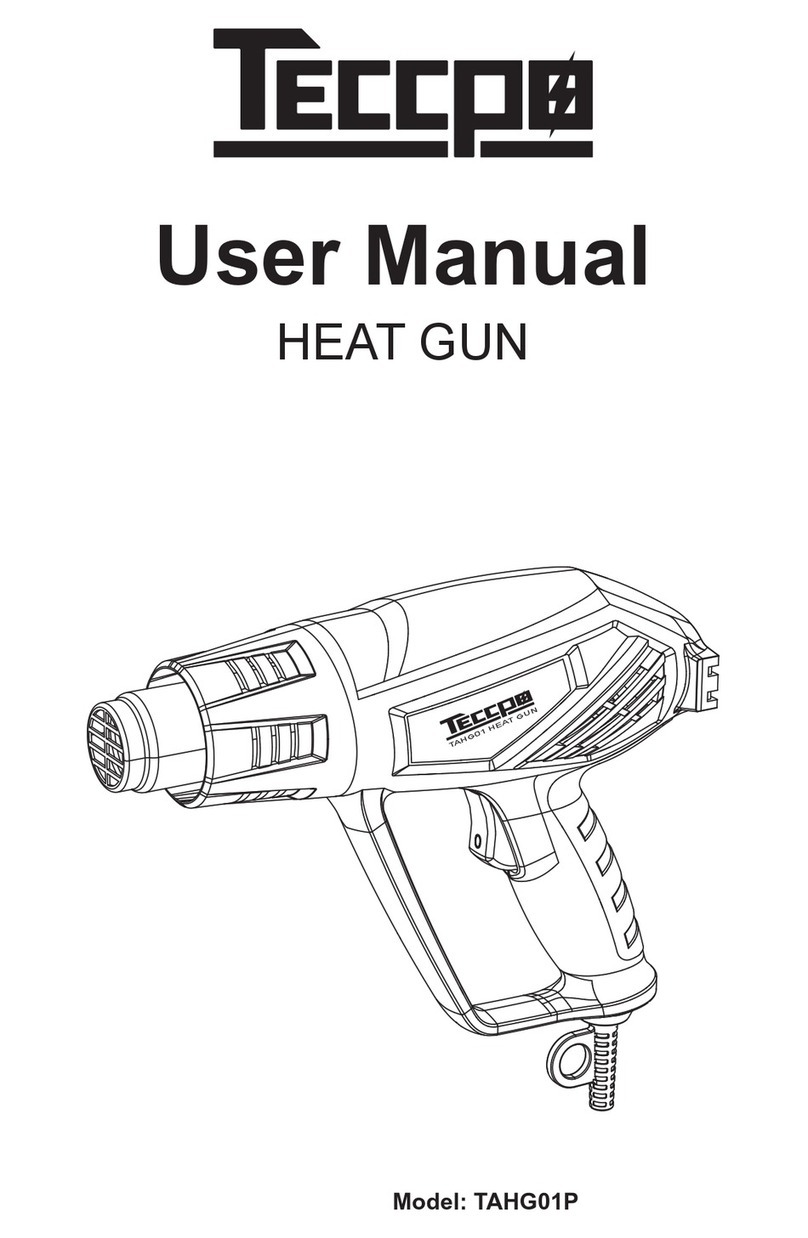

Setting the Mains Voltage ................................................................................................ 12

Fig. 5. Fuse holder................................................................................................. 12

Exchanging the Mains Fuses ........................................................................................... 12

Operation............................................................................................................................ 13

Testing of Functionality .................................................................................................... 13

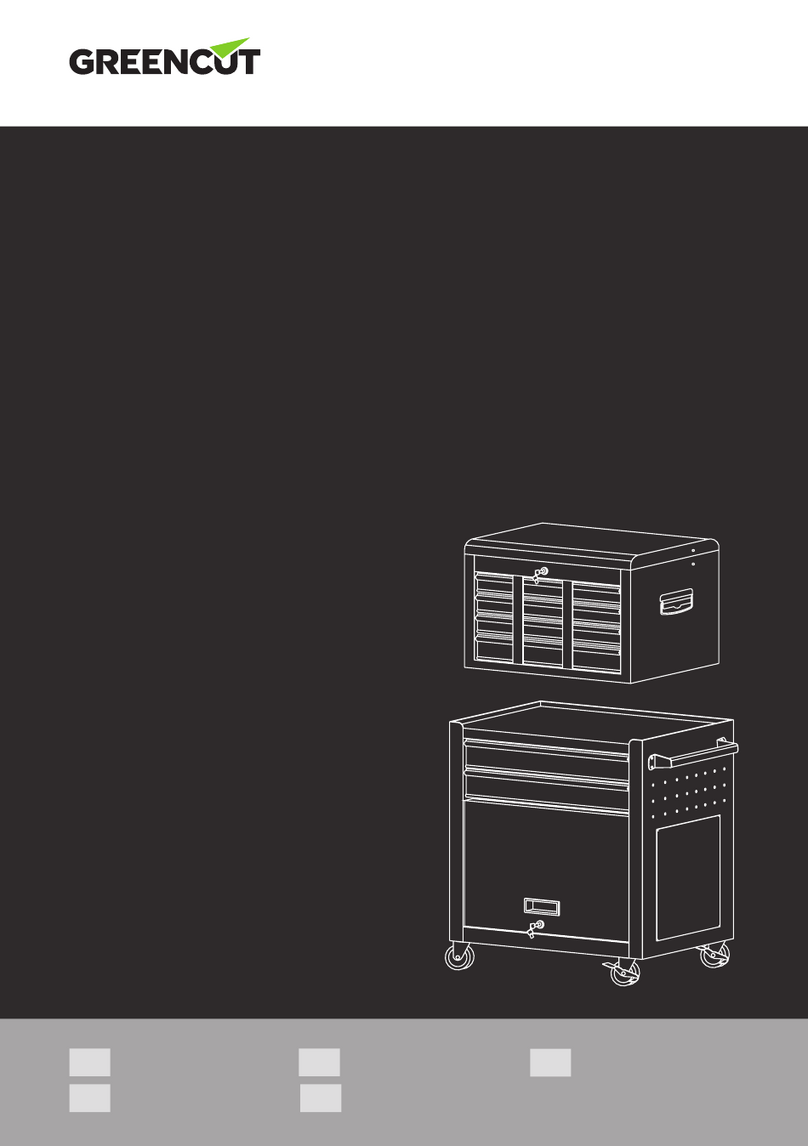

Fig. 6. Stripping of sample cable............................................................................ 13

Programming ................................................................................................................... 14

Processing Steps........................................................................................................ 14

Programming of (Step) in graphic mode........................................................................... 15

1. Turn the unit ON ................................................................................................ 15

2. Allocate a program memory position .................................................................. 15

3. Select graphic mode .......................................................................................... 15

4. Select 3 steps .................................................................................................... 15

5. Step 0 ................................................................................................................ 16

4. Step 1 ................................................................................................................ 16

5. Step 2 ................................................................................................................ 16

6. Step 3 ................................................................................................................ 17

7. Calling up the Program ...................................................................................... 17

8. Maintaining a List of Programs........................................................................... 17

9. Optimizing the Quality ........................................................................................ 17

www.nitronic.ch - 3 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

List of Programs..................................................................................................... 17

List of Programs (Example).................................................................................... 19

Auxiliary Functions ........................................................................................................... 20

1. Open blades prior to pull-off (Waybck).............................................................. 20

2. Partial Strip (Par Strip) ....................................................................................... 20

3. Feed rate and rotation time (Feed und RTime) .................................................. 21

Blade feed rate (Feed) ........................................................................................... 21

Rotating time (RTime) ............................................................................................ 21

4. Rotation during pull-off (Rot) ................................................................... 21

5. Counter .............................................................................................................. 21

6. Memory access locking code (Code)................................................................. 22

7. Joining of multiple programs (Sequence) .......................................................... 22

8. Exchange of an Steps with an other Step (Swap Step) ...................................... 23

9. Copying of memory contents (Copy Cable)........................................................ 23

10. Copying of Steps (Copy Step) ......................................................................... 24

Basic settings ................................................................................................................... 25

1.Toggle units Millimeter / Inch.............................................................................. 25

To toggle the units on the Nitronic ST730T from mm to inch, proceed as listed below 25

2. Micro Coax Mode ............................................................................................... 25

3. Autobaud OFF.................................................................................................... 25

4. RS232................................................................................................................ 26

5. Direction of rotation (Rotary Dir.)....................................................................... 26

6. Touchscreen calibration (Calib. Touch) 26

7. Deleting of memory contents (Del. Memory) .................................................... 27

8. Calibration of the blades (Calib. Blades) ............................................................ 27

Maintenance....................................................................................................................... 28

Service guidelines ............................................................................................................ 28

Replacing the stripping blades ......................................................................................... 28

Loosen wire catcher............................................................................................... 28

Fig. 7. Loosen set screws ...................................................................................... 28

Fig. 8. Centering guide lever.................................................................................. 29

Fig. 9. Remove stripping blades ........................................................................... 29

Fig. 10. Push both stripping blades ................................................................... 29

Fig. 11. Inserting the adjusting pin......................................................................... 30

Fig. 12. Centering of the stripping blades using the adjusting pin .......................... 31

Centering the centralizers ................................................................................................ 33

www.nitronic.ch - 4 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Fig. 13. Trigger contact.......................................................................................... 33

Fig. 14. Pull off protective ring ............................................................................... 33

Fig. 15. Positioning carriage .................................................................................. 34

Fig. 16. Shift stripping blades outwardly ................................................................ 34

Fig. 17. Adjusting the centralizers with the eccentric.............................................. 34

Fig. 18. Mount calibration kit onto the stripping head............................................. 35

Fig. 19. Threaded spindle ...................................................................................... 35

Fig. 20. Slightly secure the calibration kit............................................................... 35

Fig. 21. Open blade holders................................................................................... 36

Fig. 22. Centralizers............................................................................................... 36

Fig. 23. Centering the stripping blades using the brass sleeve .............................. 37

Centering the grippers with the calibration kit................................................................... 37

Fig. 24. Brass sleeve, 5.2 mm ............................................................................... 38

Fig. 25. Insert spacer............................................................................................. 38

Fig. 26. Centering the grippers .............................................................................. 38

Fig. 27. Adjust distance between grippers ............................................................. 39

Fig. 28. Gripper holder screws............................................................................... 39

Fig. 29. Final check................................................................................................ 39

Adjusting of the trigger contact......................................................................................... 40

Fig. 30. Loosen drive element................................................................................ 40

Fig. 31. Shift drive element .................................................................................... 40

Fig. 32. Adjust trigger contact ................................................................................ 41

Fig. 33. Moving contact element ............................................................................ 41

Fig. 34. Adjust trigger stroke.................................................................................. 41

Adjusting the clamping force ............................................................................................ 42

Fig. 35. Adjusting the clamping force..................................................................... 42

Replacing the toothed belt................................................................................................ 42

Fig. 36. Remove release rod.................................................................................. 42

Fig. 37. Remove locknut......................................................................................... 43

Fig. 38. Dismantle stripping shaft........................................................................... 43

Fig. 39. Axial bearing clearance............................................................................. 43

Cleaning and Inspection................................................................................................... 44

Cleaning of the work space......................................................................................... 44

Fig. 40. Move blade holders inwards...................................................................... 44

Cleaning the stripping blades and centralizers............................................................ 44

Cleaning of the grippers ......................................................................................... 44

Lubrication Schedule........................................................................................................ 45

Fig. 41. Points of lubrication .................................................................................. 45

Diagnostic, Troubleshooting............................................................................................. 46

General....................................................................................................................... 46

Troubleshooting checklist ................................................................................................ 47

Technical data.................................................................................................................... 51

Basic equipment, spares, options.................................................................................... 52

Basic equipment............................................................................................................... 52

www.nitronic.ch - 5 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Spare parts list ................................................................................................................. 52

Wear parts ....................................................................................................................... 52

Options............................................................................................................................. 52

Block diagram.................................................................................................................... 53

Index ................................................................................................................................... 54

www.nitronic.ch - 6 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Machine Description

The microprocessor controlled coaxial cable stripping machine ST730T is designed to

strip wires and coaxial cables up to 7 mm outer diameter and strip lengths up to 30 mm in

up to 9 steps. Even single insulated wires can be processed accurately. The ST730T is

capable of storing up to 999 programs. Cable parameters can easily be stored and re-

called at any time.

Following a brief summary of the machine features:

•The operations of the 9 stripping steps can be done in a single fixation. This increases the pro-

cessing speed and saves time.

•High reproducibility of the strip length when properly handled.

•Different wire diameters can be processed without any mechanical settings.

•Stripping and corrective values can be directly set and stored.

•Any stored stripping parameters can be selected and will remain in memory even in the event of

blade changes or power failures.

•The stripping diameters can be precisely adjusted with an accuracy of up to 1/1000 mm.

•The ST730Tis easy to operate and enables the user to be familiar with the process within a few

minutes.

•The precision of all components together with the microprocessor control assure the highest

process reproducibility.

•The RS 232 interface makes the ST730Tcompatible with various peripheral devices.

Unpacking the ST730T

•Take the ST730Tout of the package carefully and remove the packing material.

•The packaging should be kept for future handling purposes.

•In case the ST730Tis to be shipped by post than the transportation locks (foamed plastic (1)

between the stripping head

(

5

)

and the clamping jaws (4)) must be in place (Fig. 2, page 11).

www.nitronic.ch - 7 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Touchscreen, Connections

Touchscreen

Cable

Recalling data of an already programmed cable.

Step

Select individual processing steps.

Length

Programming of the current strip length.

ParStrip

Activating and setting of the partial strip.

Diameter

Programming of the respective diameters.

Waybck

Activating and setting of the wayback function.

Feed Programming the blade feed rate

RTime Programming the rotating time.

Rot

Activating the rotation during pull-off.

↑

↑↑

↑

↓

↓↓

↓

Scrolling in step.

www.nitronic.ch - 8 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Additional Functions

function key

F

-

Code

Activating and setting the password entry.

F

-

DelCounter

Reset the counter for produced cables.

F

-

Swap Step

Exchanging Step with another Step.

F

-

Sequence To connect several programs.

F

-

Copy Step Copying of freely selectable Step.

F

-

Copy Cable

Copying of freely selectable memory segments

Programming in graphic mode.

www.nitronic.ch - 9 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Basic settings of the machine

Inch

Toggling units “mm” / “Inches”

Micro Coax

Mode Resolution of the length until 0.01mm/0.00004inches

Resolution of diameter until 0.001mm/0.000004inches

Autobaud Automatically adapting the baud rate when transmission the data

RS232 Activation of the interface

Rotary Dir. Setting the direction of rotation

Calib. Touch Calibrate the touchscreen.

Del.Memory All programmed cable data is deleted

Calib. Blades

For calibration by the blade changing.

Sensor 4.8V Service information

www.nitronic.ch - 10 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Connections

I O

Main switch to turn the ST730TON or OFF.

Mains Connection

•Mains connection (6), single-phase with protective earth (2P + E) (Fig. 1).

•100, 115V, 230V / 50 - 60 Hz

•Maximum power consumption 100 VA

•Fuses:

100 VAC - 115 VAC = 2 x 0.630 A/T

230 VAC = 2 x 0.315 A/T

To set the mains voltage and to change the fuses, see page 12

Remote Control

RS 232 C

Port to connect the ST730Twith a PC.

Switch

Connection for a foot switch.

Electromagnetic Immunity (EMI)

Only specially designed cables must be used to make sure that the EMI require-

ments are fulfilled and thus ensuring the reduction of interference. In addition, the

interface connectors (D-Sub) have to be properly fastened.

Fig. 1. Rear panel

www.nitronic.ch - 11 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Set up

Check the set mains voltage on the unit and change if necessary following the

instructions on page 12.

•Place the ST730T onto a firm and level bench.

•Remove the safety cover (2) by removing screws (3)

(Fig. 2).

•Remove the foam (1) between the jaws (4) and the stripping head (5).

•Replace the safety cover (2) and fasten screws (3)

(Fig. 2).

•Place the ST730Ton a bench so that its front edge is

flush with the edge of the bench. This way the stripping

debris can fall into a waste basket.

•Plug in the power cord.

•Turn on the ST730Twith the main switch (A) (Fig.

4).

Fig. 2. Remove protective foam

Fig. 3. Remove safety cover / place

machine in position

Fig. 4. Toggle main switch (A) to I

www.nitronic.ch - 12 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Setting the Mains Voltage

Turn OFF the ST730Twith the main switch (A) and disconnect the power cord.

•Use a screwdriver to pull out the fuse holder (8).

•Remove the voltage selector (7) and place it in the de-

sired position of the fuse holder (8).

The selected voltage can now be seen in the small win-

dow of the fuse holder (8).

•Note the selected voltage on the nameplate.

•Exchange the fuses according to the selected voltage.

•Insert the fuse holder (8) in the ST730T.

•Connect the power cord.

Exchanging the Mains Fuses

Turn OFF the ST730Twith the main switch (A) and disconnect the power cord.

•Use a screwdriver to pull out the fuse holder (8).

•Exchange both fuses for the once listed below.

100 VAC - 115 VAC = 2 x 0.630 A/T

230 VAC = 2 x 0.315 A/T

•Insert the fuse holder (8) again.

•Connect the power cord.

Fig. 5. Fuse holder

www.nitronic.ch - 13 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Operation

Testing of Functionality

Provided with the ST730Tare two cable samples with different insulation thicknesses. One end of

each cable was stripped with the machine for testing at the factory. The respective stripping values

are stored in programs Cable 1, Cable 2, Cable 3 (for the thinner cable) and Cable 4 and Cable 5

(for the thicker cable). The stripping quality of the ST730Tcan be tested as follows:

Program Step

Selecting and Entering

Select cable No.1

Cable - 1- Enter

-

•Place the thinner sample cable with the non-stripped end through the jaws (4) until it touches

the trigger plate (9). As soon as the cable touches the plate the stripping process is initiated

based on the data set at the factory.

•The thin sample cable can be stripped applying

different stripping sequences; for this purpose press the button sequence Cable 2 or Cable 3.

•Proceed with processing of the thicker cable, by selecting Cable 4 and Cable 5 in the same

manner as described above.

Fig. 6. Stripping of sample cable

www.nitronic.ch - 14 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Programming

Processing Steps

The programmed steps (step 1, step 2 etc.) are processed in ascending order. The selection of

the process sequence is achieved by programming of the respective steps.

Standard process cycle Special process cycle

Ad-

van-

tages of the special process cycle

•The blade lifetime increases because the shielding is being cut only once.

•Clean cut because the short shield is supported by the dielectric and insulation.

•Clean cut edge of the dielectric because stripping is done as the last step; also partial strip can

be programmed to protect the conductor.

Disadvantage of the special process Cycle

•Soft dielectric may be distorted and bent by the centering jaws, at Step 3.

Only 3 of 9 possible steps are shown in this example.

www.nitronic.ch - 15 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Programming of (Step) in graphic mode

To ensure a quick and speedy 3-step processing cycle is to be programmed as follows:

1. Turn the unit ON

Toggle the main switch to I

2. Allocate a program memory position

Program Step

Selecting and Entering

Select an empty memory position, e.g. Cab

le No.

10

Cable - 10 - Enter

-

3. Select graphic mode

Program Step

Anwahl

Select the graphic mode

-

4. Select 3 steps

Program Step

Selecting

Select +Step three times.

www.nitronic.ch - 16 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

5. Step 0

Programming: To optimize the stripping time use Step 0 to enter the outside diameter of the wire.

After starting the stripping cycle, the stripping blades immediately close to the selected outside

diameter before they start cutting with the programmed feed rate.

Program Step

Selecting and Entering

Choose the preset diameter (∅

∅∅

∅3.00)

and enter the cable outside diameter

+0.5mm e.g. 6.50 mm.

3.00 – 6.5 - Enter

d

D

At missing entry of Step 0: In case Step 0 is not programmed the control uses the largest diam-

eter stored in the current program. In this example the diameter in Step 3 is the largest one stored

in the memory. This avoids the blades do not close with a high feed rate through the different lay-

ers.

Rule: The diameter in Step 0 can never be smaller than the largest diameter determined in the

current program.

4. Step 1

Program Step

Selecting and Entering

Choose the preset diameter (∅

∅∅

∅1.00)

and enter the cable diameter e.g. 0.90mm

Choose the preset stripping length (3.0)

and enter the stripping length e.g. 6.0mm.

1.00 – 0.9 – Enter

3

3.0 – 6– Enter

Avoid damaging of the cable: select during programming a slightly larger strip-

ping diameter and correct it downward after the stripping test.

5. Step 2

Program Step

Selecting and Entering

Choose the preset diameter (∅

∅∅

∅2.00)

and enter the cable diameter e.g. 3.65mm

Choose the preset stripping length (6.0) and

enter the stripping length e.g. 16.0mm.

1.90 – 3.65 – Enter

9.0 - 16 – Enter

www.nitronic.ch - 17 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

6. Step 3

Program Step

Selecting and Entering

Choose the preset diameter (∅

∅∅

∅3.00)

and enter the cable diameter e.g. 4.85 mm

Choose the preset stripping length (9.0) and

enter the stripping length e.g. 22.0mm.

3.00 – 4.65 – Enter

9.0 - 22 – Enter

To return to the table mode chosse Exit.

7. Calling up the Program

The entered processing cycle can now be activated as desired by selecting program 10.

8. Maintaining a List of Programs

To ensure the processing reproducibility, the stored parameters should be written down on paper

using the List of Programs (proposed layout is shown on page 18).

This list also provides info about the values stored in memory. In total are 999 storage locations

available for programs.

9. Optimizing the Quality

To optimize the stripping quality and processing time various auxiliary functions are available (refer

to Chapter „Auxiliary Functions“, page20).

List of Programs

Date : .....................

www.nitronic.ch - 18 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Wire : .............................................

Program : ........... mm Inch

Program - Lock : yes no

Step Length ParStrip Diameter Waybck Feed RTime

Rot

0

1

2

3

4

5

6

7

8

9

Notes :

www.nitronic.ch - 19 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

List of Programs (Example)

Date : ..27. Mai 2014...................

Wire : Sample wire RG59....................

Program : ..C04......... mm inch

Program lock : yes no

Step Length ParStrip Diameter Waybck Feed RTime

Rot

0

0.0

-

6.50

-

6

0

-

1 6.0

-

0.90

-

5

0

-

2

16.0

-

3.65

0.20

6

9

-

3

22.0

-

4.65

0.20

6

0

-

4

5

6

7

8

9

Notes :

X

X

www.nitronic.ch - 20 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg Tel. +41 32 373 7070

Switzerland Fax +41 32 373 70

75

Auxiliary Functions

The following auxiliary functions can be used to optimize stripping quality and processing time.

1. Open blades prior to pull-off (Waybck)

You can program the machine as such that the stripping blades open a little (in diameter) before

the pull-off is carried out.

Advantage:

•Better stripping quality because the blades will not scrape the conductor during the pull-off cy-

cle.

•Increased blade lifetime.

The opening of the blades (wayback) can be programmed for each step.

Program Step

Selecting and Entering

Select the wayback in the desired step, e.g. Step 2

and enter the blade opening value e.g. 0,20 mm.

0.2

-

Enter

The wayback can be deleted at anytime.

Select the Wayback 0.20 in Step 2 and delete the

selected wayback value.

0.20 - Del

2. Partial Strip (Par Strip)

To protect the exposed center conductor or shielding, the auxiliary function „Partial Strip“ can be

selected for every step. The partial strip can be programmed in increments between 1 mm and

30 mm.

Program Step

Selecting and Entering

Select the partial strip in the desired step e.g. Step 3

and enter the partial strip length, e.g. 5mm

5

-

Enter

The partial strip value can also be deleted. Select

The partial strip 5 mm in Step 3 and delete the

Selcted partial strip value.

5

-

Del

Table of contents