4

EN

General Pneumatic Tool Safety Warnings

WARNING

Use the tool with proper air pressure.

If the air pressure is high, the rotation speed and reciprocation frequency become faster, causing damage such

as damage or accelerated wear. Also, unexpected accidents could occur.

Connect the tool to air piping.

In some factories, other than air piping, there may be other piping such as oxygen, nitrogen, gas, etc. Before

connecting to piping, make sure it is the correct piping.

Do not start the tool carelessly.

Turn off the operation switch, then attach the Connecting Hose to the tool.

When attaching, removing, and maintaining accessories, make sure to detach the Connecting Hose from the

tool.

Be cautious about exhaust.

Pneumatic tool exhaust contains oil and drainage, etc. Be careful about the exhaust direction so that the exhaust

does not directly hit people nearby.

Do not allow sources of electricity to touch the tool.

The pneumatic tool is not insulated against contact by electric sources. Because there is a risk of electric shock,

do not allow sources of electricity to touch the tool.

CAUTION

Handle the tool with care.

Rough handling could cause accidents or malfunctions. Do not exert an impact on the tool by throwing or

dropping it.

Handle the Connecting Hose with care.

Do not carry the tool by holding the Connecting Hose, and do not pull the Connecting Hose to remove it.

Product Specific Safety Rules

WARNING

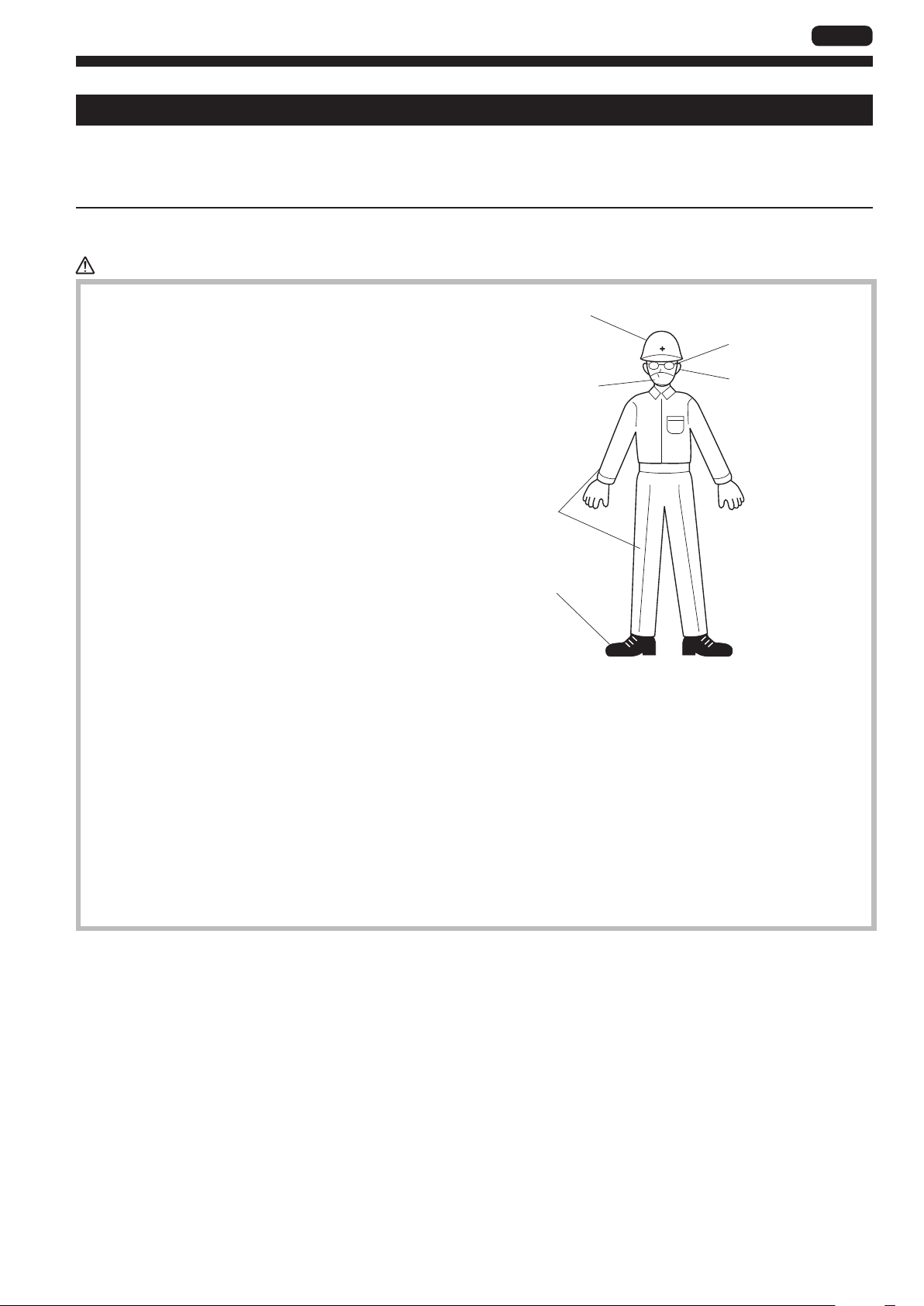

Protect your body from chips.

During grinding, hot chips scatter. Since it could cause blindness, respiratory disorders, burns or hearing

impairment, when working, to protect your body use protective eyewear, a dust mask, earplugs, gloves

(excluding knitted gloves), long-sleeved work clothes, etc. In addition, do not bring your face close to the tool.

Do not use a Grinding Wheel with an allowable rotational speed (indicated on the Grinding Wheel top label)

lower than the actual rotational speed of the machine. Also, please make sure that the specified dimensions of

the Grinding Wheel conform to the specifications of this machine.

(Article 119 of the Ordinance on Industrial Safety and Health)

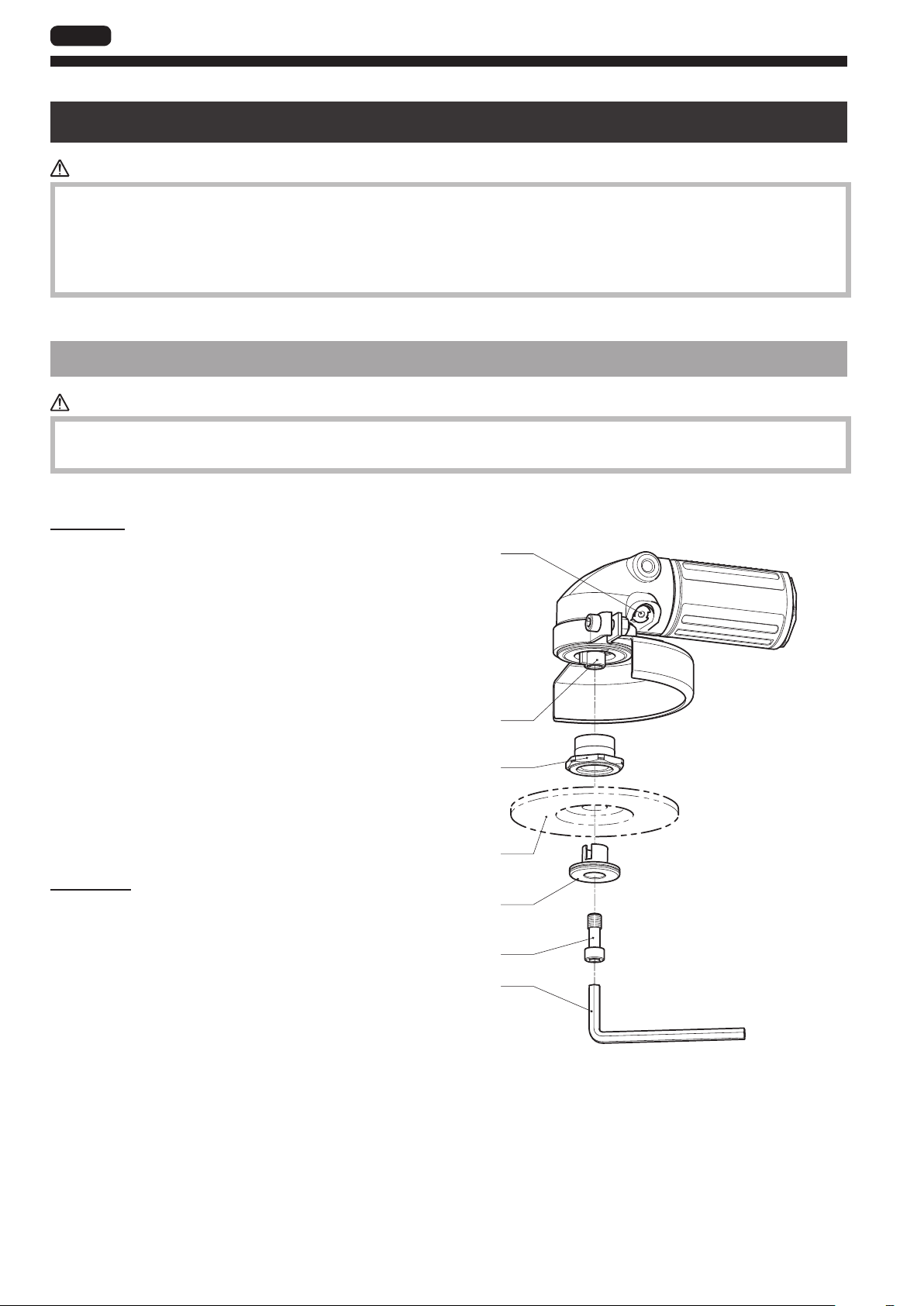

When attaching the Grinding Wheel, check that there are no abnormalities such as cracking, chipping, or

excessive wear.

Do not use the tool if there is a slight abnormality such as a Grinding Wheel containing moisture, damage, loss,

etc. of the display label.

Use our genuine Outer Flange.

Do not use Outer Flanges that are damaged, bent or severely worn out.

Also, do not use a substitute flange or flat washer.

Check that the Grinding Wheel is suitable for the Outer Flange.

Tighten the Grinding Wheel moderately.

When aligning the Grinding Wheel to the Outer Flange do not use a reduced bushing unless the bushing to be

used is supplied from the parts maker or is as specified.

When attaching the Grinding Wheel, make sure that the label on the top of the Grinding Wheel comes into

contact with the mounting surface of the Spindle.

For the label on top of the Grinding Wheel, use one with the same diameter as the outer diameter of the end face

of the Spindle, or larger.

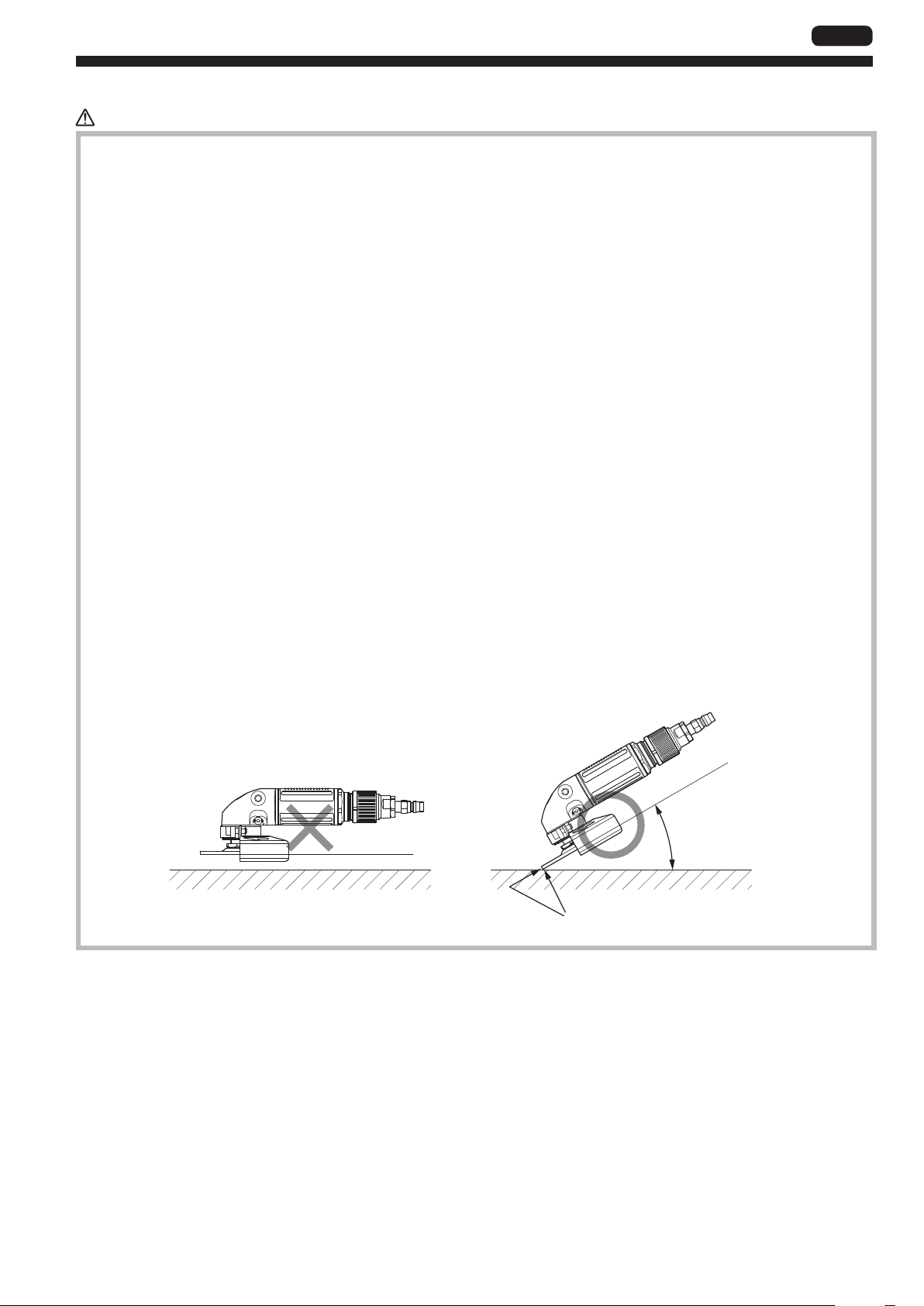

Precautions on use