Nitto DURAPrinter SR Programming manual

SR Troubleshooting

No problem page

1 Label LED is lit.

Label Error!! 1−5

2 Blurred Print!! 6−8

3 Ink Ribbon Comes Out

Stuck to the Label!! 9−12

4 Print Position Error!! 13−16

5 Head LED is lit.

Head Error!! 17−22

6 Can’t Print without any Error!! 23−25

7 Label and Vfr LEDs are Lit Together.

Verifier Hard Error!! 26−29

8 Frequent Voids!! 30−33

DURA Printer SR

Troubleshooting Manual

Doc. No.:HKT0002

This document provides you of remedies to the

problems about which we have got many inquiries.

Please refer to this troubleshooting manual first when

a similar problem occurs.

NITTO DENKO CORPORATION

SR Troubleshooting

Problem No.1

Label LED is lit.

Label Error!!

What shall

I do?

First, set the threshold value.

See “1. How to Set the Threshold Value”.

The printer

doesn’t work

y

et.

Clean the sensor.

See “2. How to Clean the Sensor”.

The trouble

still persists.

Check the label size.

See “3. Check of the Label Format”.

Check1

Check2

Check3

1

SR Troubleshooting

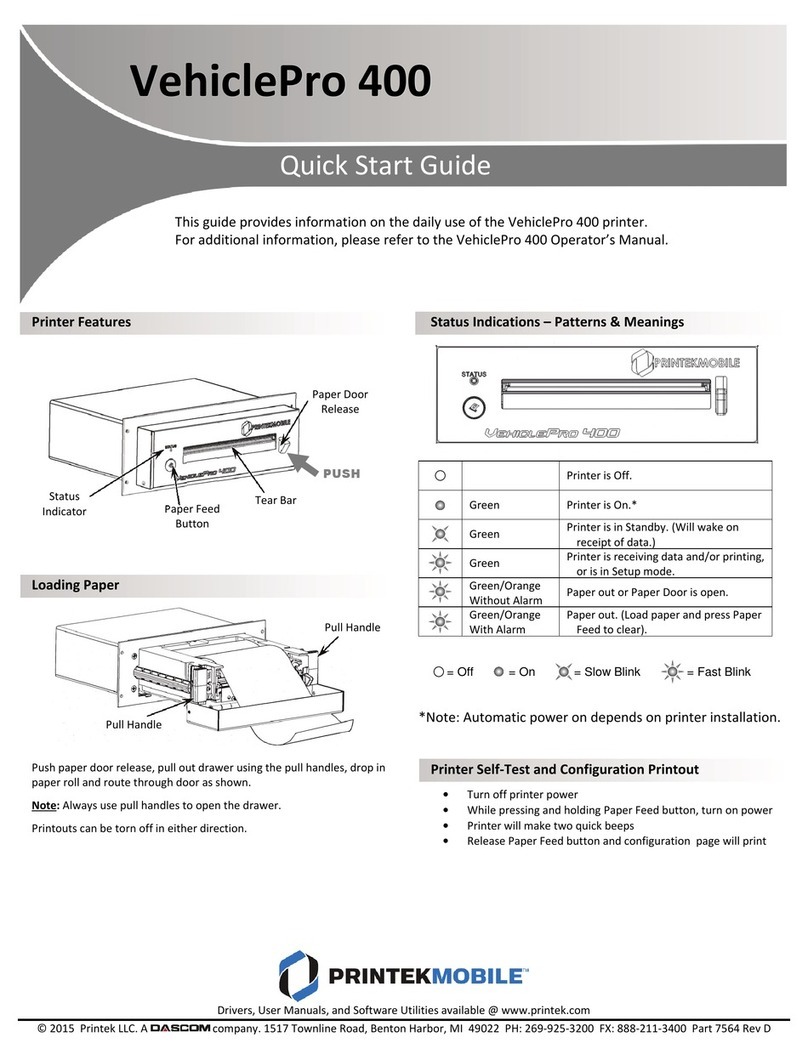

Turn on the power while pressing [Enter|Pause]. nds.Press and hold the switch until the buzzer sou

Y

ou can release the switch when the buzzer sounds.

(Be sure that the Buzzer is not OFF.)

1. How to Set the Threshold Value

Remedies for the Label Error

Please turn off the power first. on.Then set the labels and ink ribb

A

bout three labels are fed, the buzzer sounds at the intervals of one

second, and the Ready LED flashes to indicate that the threshold

value is set successfully.

Turn off the power.

The buzzer sounds continuously when the threshold value setting

fails. In this case, start over again from setting the labels and

the ribbon.

Check whether the printer works normally. Are labels printed correctly?

One Point Lesson

Note!!

Printer

Control Panel

What is the threshold value setting? label exists, the sensor measures the

st

To make a judgment whether the

amount of light that passes through label and that which passes through

the backing paper. The values are saved in the printer automatically.

Therefore, each time you change the label, the threshold value for it mu

be set.

We suggest you practice this operation each time you replace the labels.

2

SR Troubleshooting

2. How to Clean the Sensor Center Sensor (Fixed)

Necessary Tools

・ a minute flat-blade screwdriver

・ alcohol (methanol or ethanol)

・ cotton cloth

First, remove the center sensor.

Fig.1

center

sensor (fixed)

slotted head

screws

Loosen and remove the two slotted head screws shown in Fig.1

Next, clean the center sensor.

center sensor

Fig.2

Wipe the part behind the sensor with the attached cleaning cloth or a clean

cloth dampened with ethanol or isopropyl-alcohol. Wipe the light-emitting

part at the center carefully enough. (Note: Be sure not to damage the code

connected to the sensor!)

3

SR Troubleshooting

Wipe carefully the surrounding part of the light-receiving part (Fig.3).

Pass the cleaning cloth through the region where the labels pass and, lifting up

the cloth slightly, move it back and forth several times (You can clean the form

edge sensor without removing the center sensor.).

Mount the center sensor and tighten the two slotted head screws.

Set the labels and the ink ribbon and then set the threshold value,

following the steps in 1.1.

Form Edge Sensor (movable)

light-receiving

part

Fig.3

Fig.4

form edge

sensor (movable)

Clean the form edge sensor (movable),

Reassemble the sensor.

4

SR Troubleshooting

5

3. Check of the Label Format

label width

label height label pitch

(center)

Check whether the values of label height, width and pitch designated

he height or the pitch causes the label error.

If the values in program are different from the actual ones, correct the

label format.

in the program are identical with the actual values. Especially the

difference in t

Feeding direction

Label pitch:The label pitch means the sum of the label height and the gap

between labels.

When the value in the program is different from the actual

value, the label error occurs.

SR Troubleshooting

Problem No.2

Blurred Print!!

Check 1

A

blur occurs along

the length of the

label?

The ribbon is creased.

See “2. When the Ribbon is

Creased”.

Check 4

The final

check!

Check 3

Check the platen roller.

See “3. When the Platen Roller

Has a Scratch”.

A

blur occurs

in a slanting

direction?

Check the width of the backing paper of the labels and that of ink

ribbon. See “4. The Width of Backing Paper and that of the Ribbon”.

Clean the thermal head first.

See “1. How to Clean the Thermal Head”.

What shall

I do?

Check 2

6

SR Troubleshooting

1. How to Clean the Thermal Head

2. When the Ribbon is Creased

Turn the power off. →Open the

cover. →Remove the ribbon.

Clean the thermal head,

especially the brown part at

the center. (Use the cleaning

cloth or alcohol.)

When the positions of pay-off side

and take-up side of the ribbon are

not in a straight line, the ribbon is

creased and, as a result, a blur

occurs in a slanting direction.

Install the ribbon straightly (set

the both sides of the ribbon at the

center) and align the position o

f

the ribbon so as not to make a

wrinkle.

When no signs of improvement are shown,

replace the thermal head with a new one.

The thermal head may have reached the end

of its operational life.

Remedies for Blurred Print

7

SR Troubleshooting

8

. The Width of Backing

aper and that of the Ribbon

3. When the Platen Roller Has a Scratch

4

P

Pull the locking levers on both

sides of the platen roller toward

you and remove the platen roller

Wipe the platen roller with alcohol. When it has a scratch, replace it

with a new one.

(

A scratch or a hollow on the platen roller causes the blurred print at the

point on the label that runs over the scratch or the hollow. The platen

roller is a consumable component.)

The width of the ink ribbon should be

wider than that of the backing paper o

f

the labels by 5mm on both sides (See

ased ribbon may

figure on the right).

When the ribbon is as wide as, or much

wider than, the backing paper, a

blurred print or cre

occur.

SR Troubleshooting

Problem No.3

Ink Ribbon Comes Out

Stuck to the Label!!

Clean the thermal head and print labels with the

print density set to 0. See “1. How to Adjust

the Density”.

Check 1

One of the most common causes of this problem is that the ink ribbon is

fused into the thermal head because of a larger supply of energy than

necessary to the thermal head.

What shall

I do?

No

im

p

rovement?

Check 2

Check the setting of function No. 10.

See “2. How to Modify the Setting of Function No.10”.

9

SR Troubleshooting

1. How to Adjust the Density

1.1. How to Clean the Thermal Head

1.2. How to Adjust the Density

Rem n

Stuck on the Labels

edies for the Ink Ribbo

10

Control

Panel

Printer

Turn the power off. →Open the

cover. →Remove the ink ribbon.

Clean the thermal head,

especially the brown part at the

center (See the figure on the

right.). (Use the cleaning cloth

or alcohol.)

Set the ink ribbon, then set the density

switch to 0 and print labels.

If labels are printed lightly, turn the density

switch to the upper number gradually and

stop where you can get the best density.

If highly colored labels are printed with the

density switch set to 0, the setting of function

No. 10 (Supply Type) may not be suitable.

SR Troubleshooting

2. How to Modify the Setting of Function No.10

Check the ink ribbon you use. The type of the ink ribbon we produce and the

corresponding setting of function No. 10 are shown in the table below.

11

Ink Type G PN DLH

H(label PT)

PO

H(label PH)

DWH

Setting of function

NO.10 (Supply)

1 1 5 9 8

Buzzer switch

must be at L or H.

Turn the printer off and set the density switch C to

10. T on the power while pressing Furn

to see that

[Mode/Reset] (See the figure on the right.). Press

and hold the switch until the buzzer sounds

(Release the switch when the buzzer sounds.).

Check A [Ready] LED flashes (The

ows that the printer is in

What is the number o

flashing of [Ready] LED sh

the function setting mode.).

f

the lit LED in B? (If two LEDs are lit, the sum o

f

the numbers on the left of the LEDs is the value o

f

setting 10.)

number with

When the value for your ink and that

of function setting 10 is different, select the right

↑↓ in Eand press and hold D

[Enter/Pause] at least for two seconds (The buzzer

series of beeps.). Press and hold

F[Mode/Reset] at least for two seconds. Turn the

power off and reset the density switch.

makes a

Note: When the function setting is sent to the

printer by printing software you generated,

the sent setting is effective.

A

B

C

D

E

F

SR Troubleshooting

12

Turn the printer on and print labels.

Adjust the density. Set the density switch to the best position (8 is the

standard position.).

If the problem still persists, replace the

thermal head with a new one as yours ma

y

have reached its operating life.

Does the trouble

still persist?

SR Troubleshooting

Problem No.4

Print Position Error!!

Horizontal

deviation?

Check whether the labels

are set correctly.

See “1.1. Alignment o

f

Labels”.

See where the printed labels go.

See “1.2. The Influence of Ejected Paper”.

Check the width of the backing paper of the labels and that of ink

ribbon. See “1.3. The Width of Backing Paper and that of the Ribbon”.

Check 3

The final

k!chec

No improvement?

Check 2

Check 4

Check the Platen Roller

See “2.1. Platen Roller”.

Deviation in the

feeding direction?

Check 1

13

SR Troubleshooting

Remedies for Print Position Error

1. Horizontal Deviation

ls

1.1. Alignment of Labe

center sensor (fixed)

label guides

roll holders

14

SR Troubleshooting

1.3. The Width of the Backing Paper

and that of the Ink Ribbon

1.2. The Influence of Ejected Paper

15

Turn off the power. →Open the cover.

A

s is shown in the figure on the previous page, set the end o

f

the backing paper in parallel with the edge of the center

sensor and set the label guides. Adjust the position of the roll

holder so that the labels go straight in the feeding direction.

When the backing paper with a lot o

f

printed labels falls down slanting as

is shown in the upper figure on the

right, next label are likely to be

pulled leftward and as a result the

position of the printed data deviates

rightward.

Be sure that the backing paper falls

in a direction perpendicular to the

output slot.

The width of the ink ribbon should be

wider than that of the backing paper o

f

the labels by 5mm on both sides (See

figure on the right).

When the ribbon is as wide as, or far

wider than, the backing paper, a

blurred print or creased ribbon may

occur.

SR Troubleshooting

16

2. Deviation in the Feeding Direction

2.1. Platen Roller

Pull the locking levers on both sides o

f

the platen roller toward you and

remove the platen roller upward.

Wipe the platen roller with alcohol and remove the stains. If the platen

roller has a scratch or a hollow, replace the roller with a new one.

(When the diameter of the platen roller become smaller, the print position

may deviate in the feeding direction. The platen roller is a consumable

component.)

SR Troubleshooting

Replace the thermal head.

See “1. Thermal Head Breakdown”.

What shall I

do?

Problem No.5

Head LED is lit.

Head Error!!

Check 1

No

improvement?

Check the front cover limit switch.

See “2. Front Cover Limit Switch”.

Check 2

17

SR Troubleshooting

Remedies for Head Error

1. Thermal Head Breakdown

SR

Control Panel

Turn off the power. →Open the cover.

Replace the thermal head with a new one and print labels.

If the thermal head is broken, the replacement will solve the

problem. (See “How to Replace the Thermal Head”.)

If you do not have a spare thermal head and want

to continue printing labels even if the print

quality is deteriorated, follow the procedure

below. Head error is temporarily ignored. (Be

aware that the broken wiring in the thermal

head causes white vertical lines.)

Turn on the power while pressing [Mode/Reset]

and [↓/Set TOF] at the same time. Press and

hold the two switches until the buzzer beeps.

You can print labels until you turn off the power.

18

SR Troubleshooting

How to Replace the Thermal Head

①Turn the power off and open the top cover. Then Open the front cover and remove

the ribbon on the taking-up side.

front cover

notches

Put the removed ribbon on the notches behind.

②Press the release levers on both sides and lift the thermal head.

release levers

③Lift the electricity suppression brush and then you can see two connecters.

Remove the connecters.

connecters

electricity suppression brush

19

Table of contents