Technical Service Bulletin JANUARY 2019 TSB132.05

HYDRAcapModule Installation Instructions and Rack Design

This Technical Service Bulletin provides information required to install HYDRAcap

Ultrafiltration modules and to demonstrate a sample support rack assembly.

General Guidelines/Rack Design

HYDRAcapis a stand-alone module capable of withstanding a pressure of 73 psig (5bar)

at 20°C. The following rules are applicable to its installation:

1. The modules should be installed vertically with the filtrate connection at the top

(see figure 1). Vertical installation is highly recommended. If horizontal orientation

is the only choice, the modules should be placed with the feed and concentrate

ports facing upwards to avoid air entrapment.

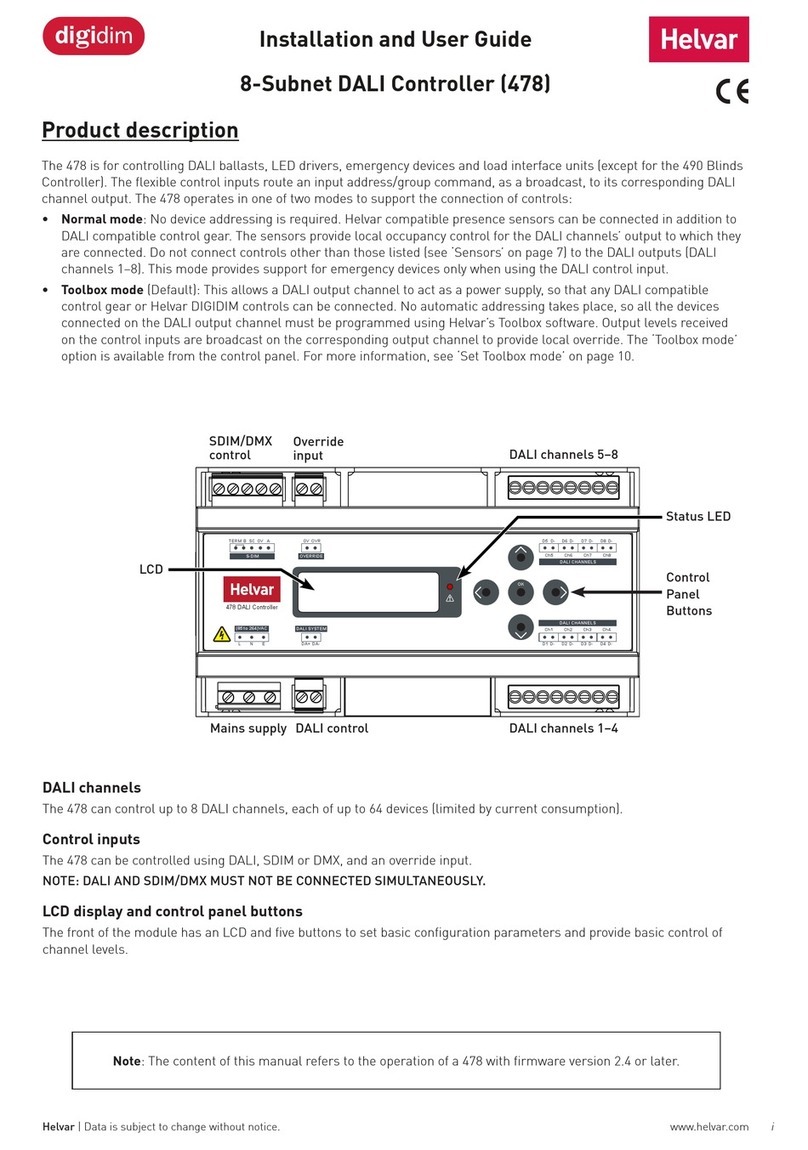

Figure 1: Flow Orientation

2. Feed water should enter the bottom of the module. Under certain conditions such

as high solid loading, it may be necessary to alternate the feed direction from

bottom-to-top to top-to-bottom.