10-2

WARNING: Keep hands, hair, clothing, etc.

away from the rotating disc and the seat when

operating the valve. Failure to do so could

cause serious injury.

CAUTION: Because of Valdisk’s self-centering

seat,thereisno reason to openthevalveatany

time during installation. Therefore, the valve

should remain closed until the valve is fully

installed.

4. Connect air supply and instrument signal. Throt-

tling valves are usually equipped with valve

positioners.Twoconnectionsaremarkedfortheair

supplyand forthe instrumentsignal. Both cylinder

andpositioneraresuitablefor150psiairsupply.An

air regulator is not required unless the supply

pressure exceeds 150 psi. An air filter is recom-

mended unless the supply air is unusually clean

and dry. All connections must be free of leaks.

CAUTION: On valves equipped with air filters,

the air filter bowl must point down; otherwise,

the air filter will not perform properly.

NOTE: In some rare cases, the air supply must be

limited to 100 psi rather than 150 psi. In this case,

a sticker found near the upper air port on the

cylinderwillindicatethisandanairregulatorshould

be installed to insure the supply pressure does not

exceed 100 psi.

5. Make sure proper clearance exists internally in the

mating piping to permit proper disc rotation.

6. Apply recommended torque values to line flange

bolting for proper sealing (see Table I).

Quick-check

Prior to start-up, check the control valve by following

these steps:

1. Check for full stroke by making the appropriate in-

strument signal change. Observe disc position

indicator plate mounted on the transfer case. The

disc should change position in a smooth, rotary

fashion.

2. Check all air connections for leaks. Tighten or

replace any leaky lines.

3. Evenly tighten the packing nuts to slightly over

finger-tight.

CAUTION: Do not overtighten packing. This

can cause excessive packing wear and high

shaftfriction, whichmayimpede shaftrotation.

After the valve has been in operation for a short

time,checkthe packingnutstomake suretheyare

just over finger-tight (readjust if necessary). If

packing box leaking occurs, tighten the packing

nuts only enough to stop leakage.

4. To observe the valve failure mode in case of air

failure,positionthevalvetomid-strokeandshutoff

Table I: Flange Bolting Torques

Valve Rating Torque

Size (inches) (ft./lbs.)

150 118

2 300 118

600 118

150 118

3 300 209

600 209

150 118

4 300 209

600 337

150 209

6 300 209

600 505

150 209

8 300 337

600 728

10 150 337

300 505

12 150 337

300 728

14 150 505

16 150 505

18 150 728

20 150 728

24 150 1009

30 150 1009

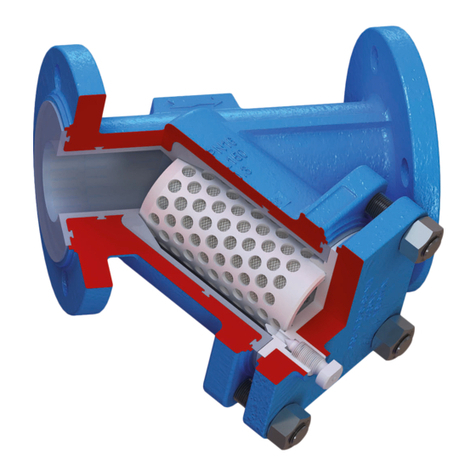

Installation

1. Before installing the valve, clean the line of dirt,

scale, welding chips, and other foreign material.

Clean the gasket surfaces thoroughly to insure

leak-proof joints.

2. Check flow direction to be sure valve is installed

correctly. Fail-closed valves should be installed

with the shaft upstream only on gas service. It

is preferred that liquid service valves must be

installed with the shaft downstream regardless of

air failure action. However, under certain flow

conditionsthevalvecanflowshaftupstream. Con-

sult factory if the valve must be mounted with the

shaft upstream in liquid service. Fail-open valves

should be installed with the shaft downstream.

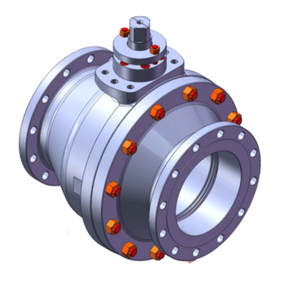

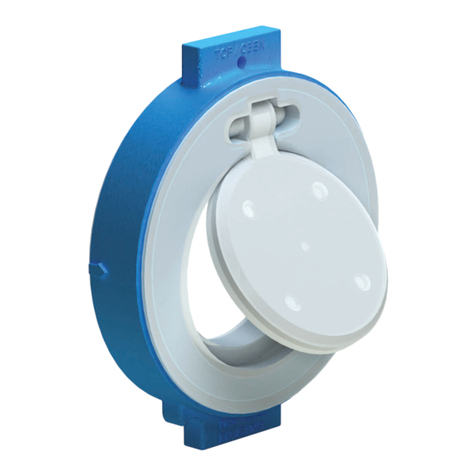

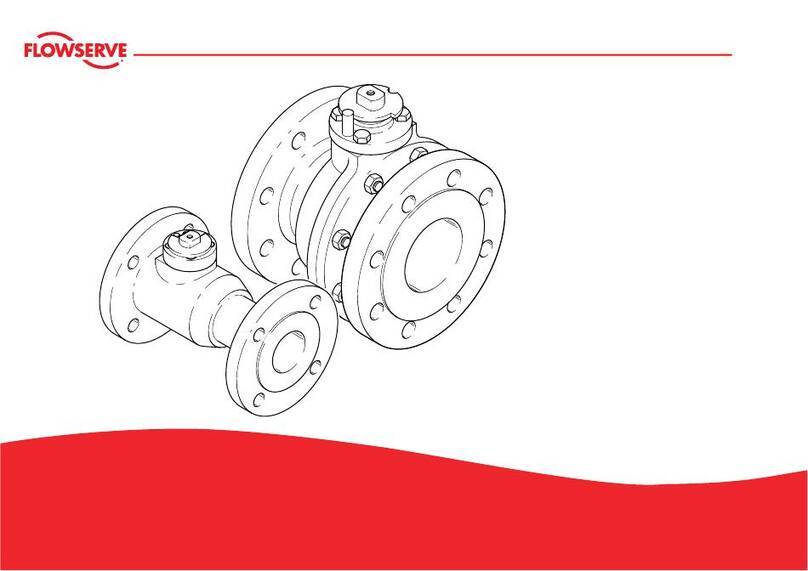

WARNING: When installing the valve in-line

between flanges, make certain the flange face

gasket covers both seat retainer and body and

surface. Failure to do so will cause excessive

leakagedownstream.Referto“SeatInsert/Snap-

ring Configuration” in Figure 1.

3. Fullyclosethevalvebeforeandduring the installa-

tion process.