708 BUS EXTENDER MODULES

Installation Guide

DESCRIPTION

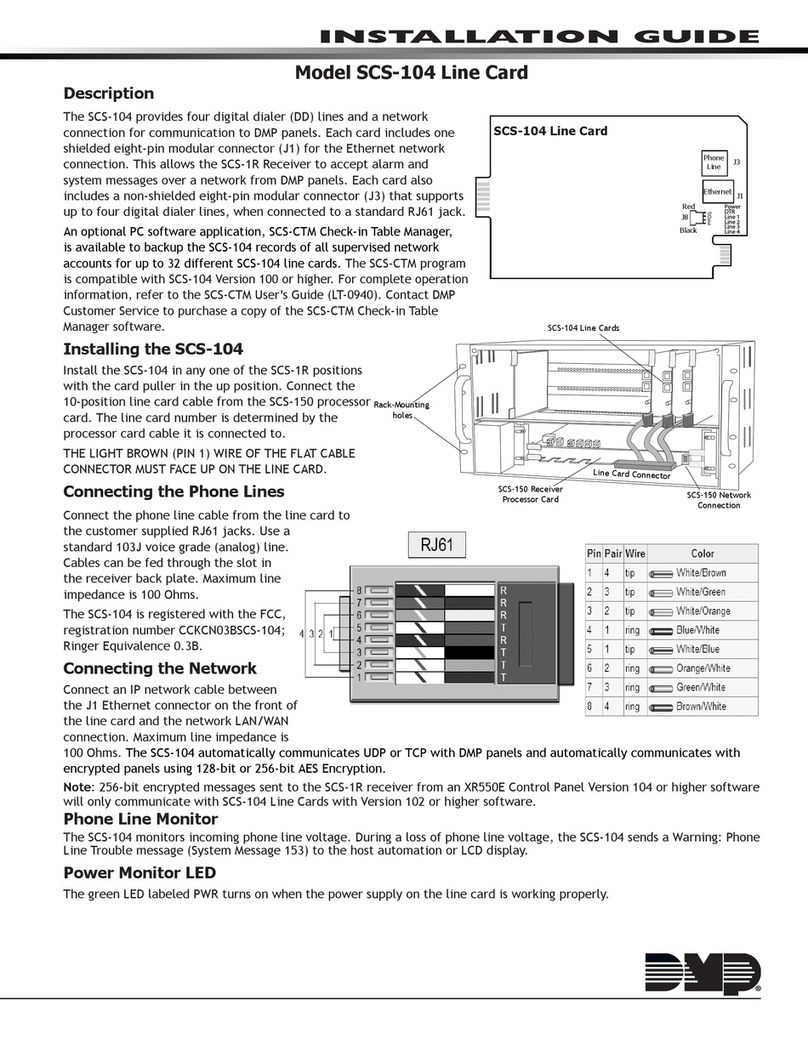

RED

1 2 3 4 5 6

YEL GRN BLK

CONNECT

TO PANEL

MODEL 708

RED

1 2 3 4 5 6

YEL GRN BLK

CONNECT

TO DEVICES

MODEL 708

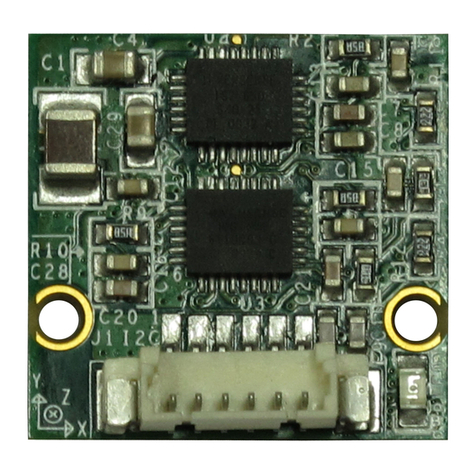

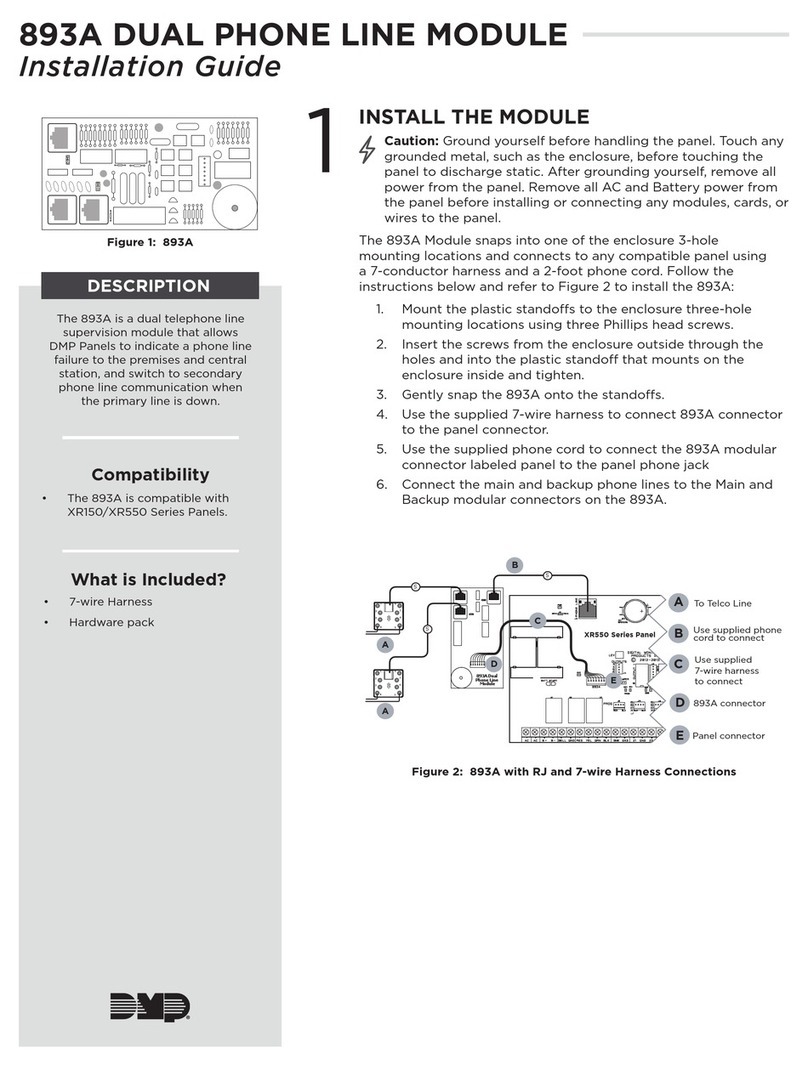

Model708Bus Extender Modules

allow you to increase the length

of LX‑Bus or Keypad Bus wiring

to a maximum of4,000ft while

providing immunity to wire noise.

Use708Modules in applications

such as long wire runs, noisy

environments, or where the bus run

is bundled with other wires, such as

telephone company wire.

The included pair of708modules

connect between the panel and

LX‑Bus or Keypad Bus devices.

These modules are referred

to as the Panel Moduleand

DevicesModulerespectively.

Compatibility

• All DMP XT and XR Series panels

• All DMP LX‑Bus and Keypad Bus

devices

What is Included?

• One pair of708Bus Extender

Modules in Universal Housings

• Hardware pack

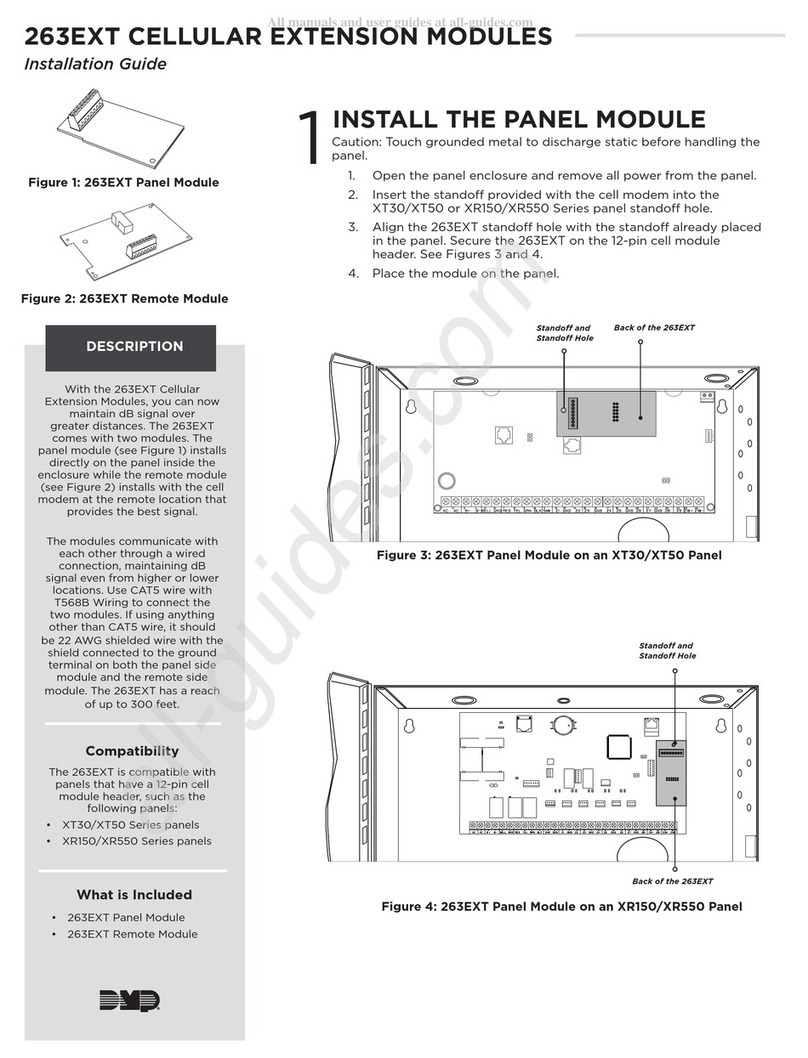

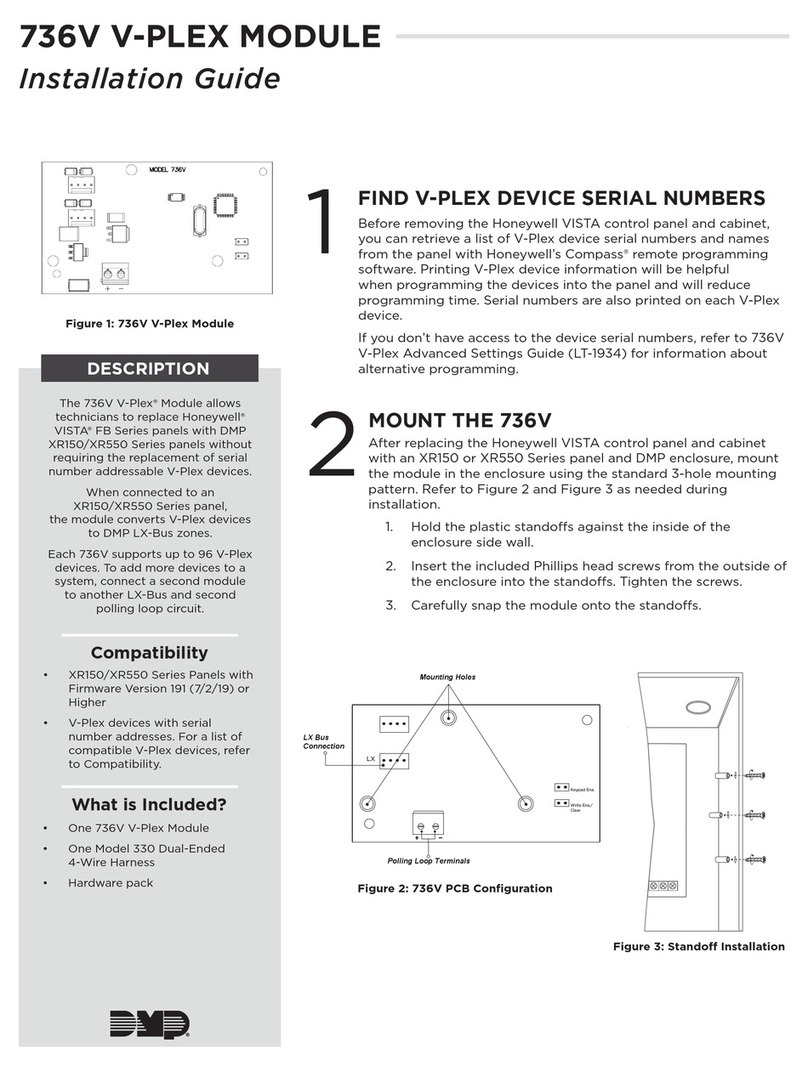

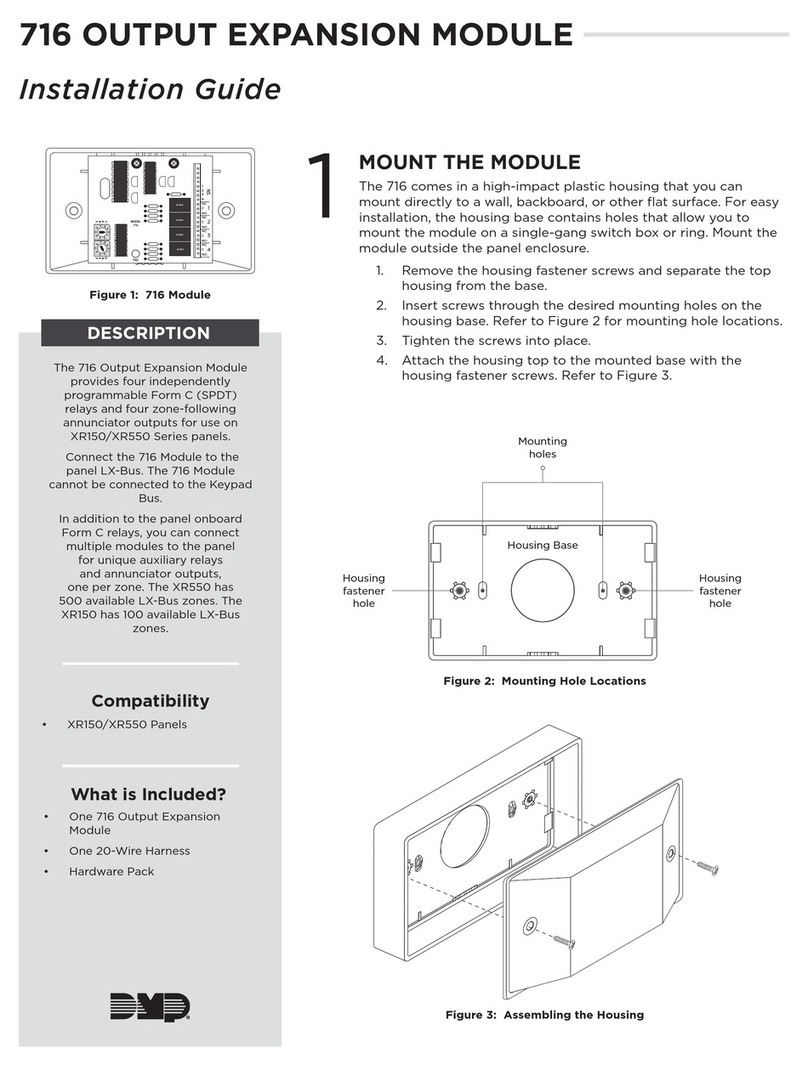

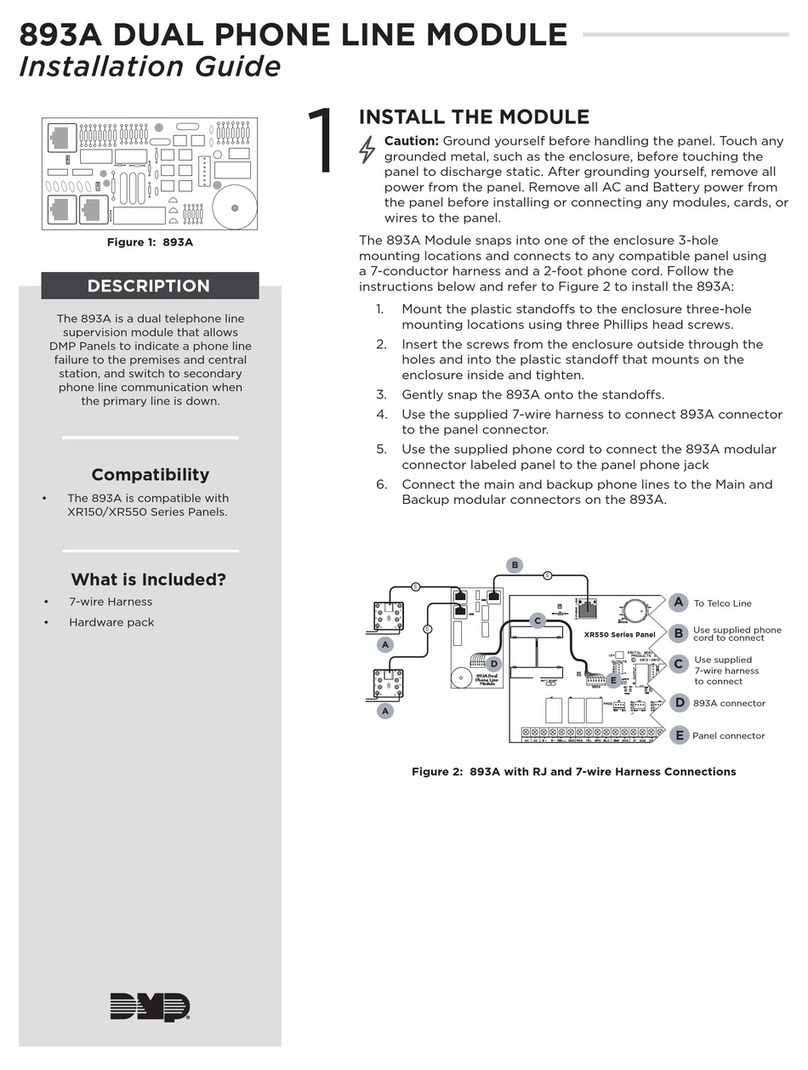

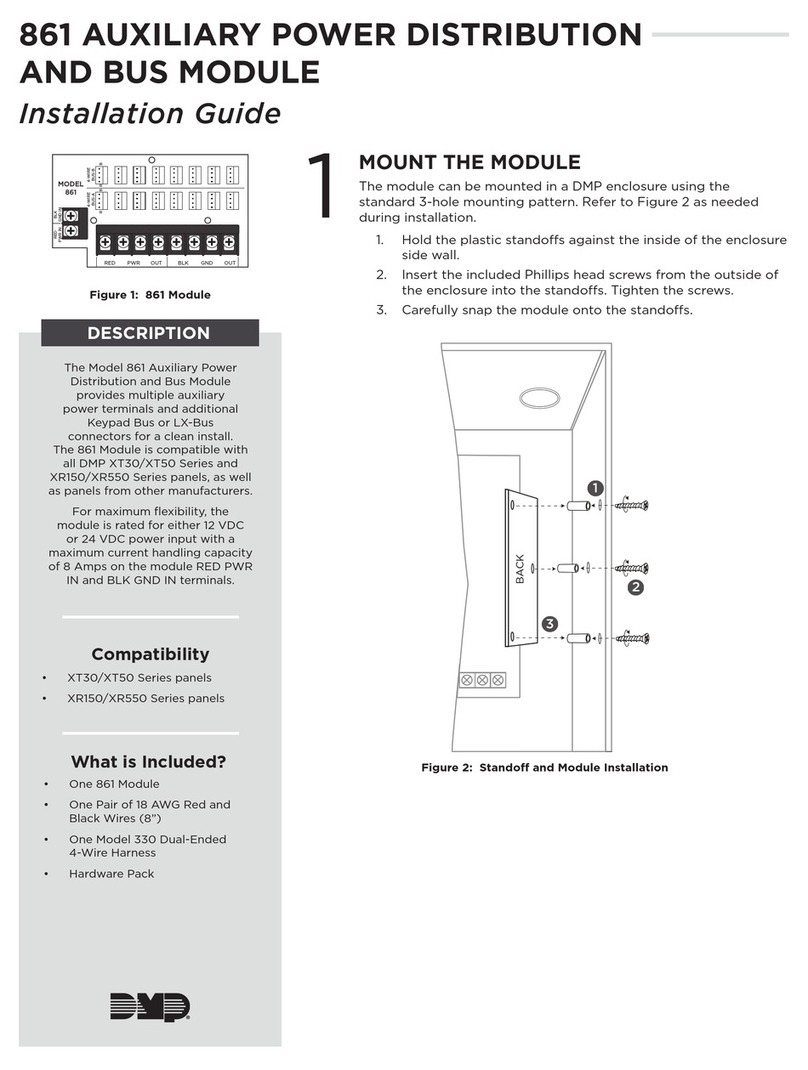

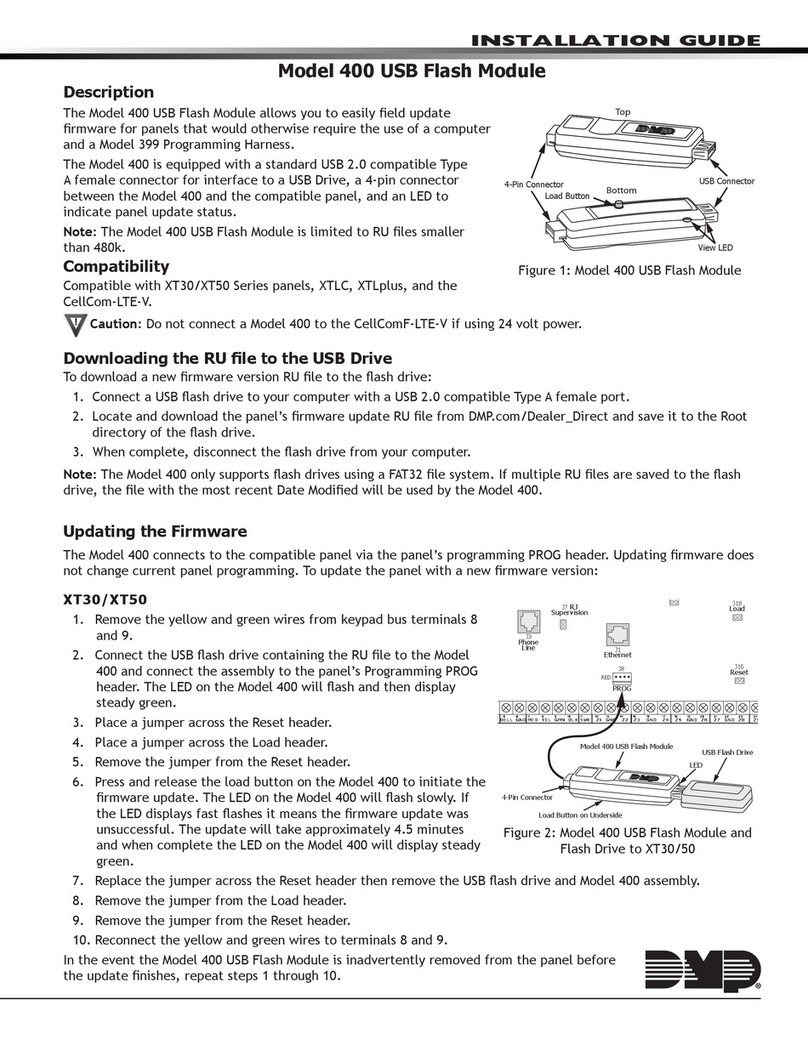

1MOUNT THE MODULES

The708comes in a high‑impact plastic housing that you can

mount directly to a wall, backboard, or other flat surface. For easy

installation, the back of the housing contains multiple holes that

allow you to mount themodule on a single‑gang switch box or

ring. Themodule can also be mounted in a DMP enclosure using

the standard3‑hole mounting pattern. Refer to Figure 2and

Figure 3as needed during installation.

1. Hold the plastic standos against the inside of the enclosure

side wall.

2. Insert the included Phillips head screws from the outside of

the enclosure into the standos. Tighten the screws.

3. Carefully snap the module onto the standos.

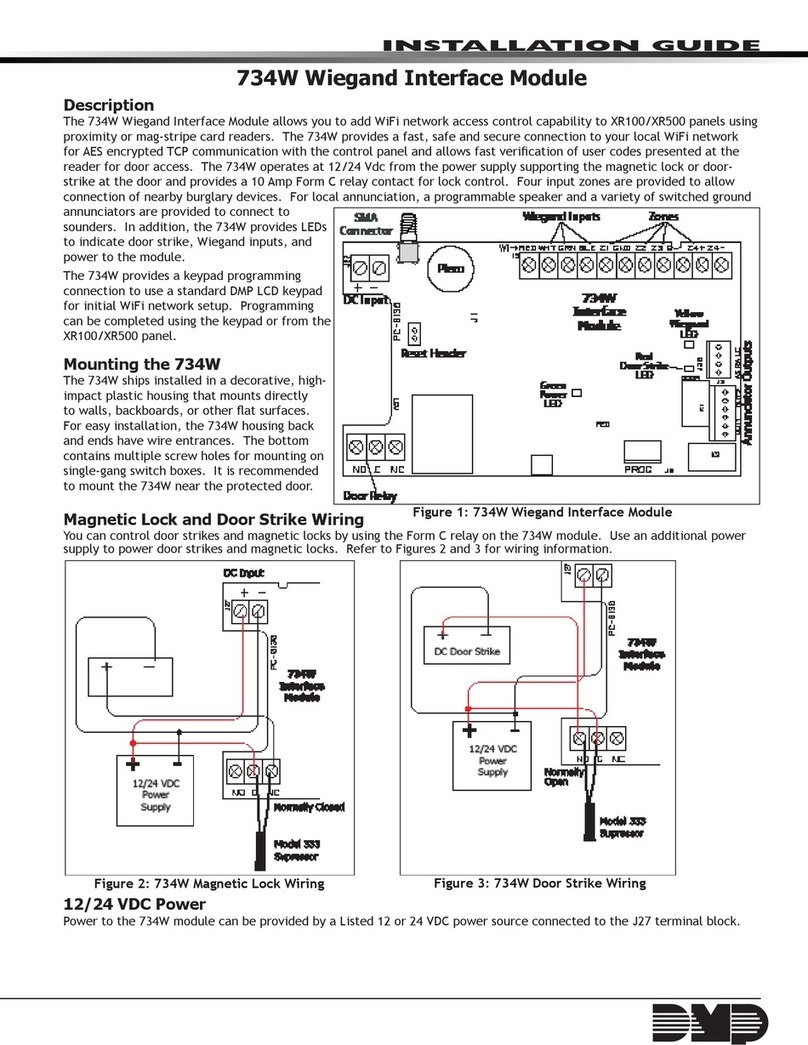

WIRE THE PANEL MODULE

2Use18to22AWG wire to connect thePanel Moduledirectly to

the Keypad Bus or use a dual‑ended4‑wire harness to connect

directly to the LX‑Bus. This connection allows the module to

communicate with the panel and receive12VDC power. For more

information about wiring, refer to Wiring Specifications. Refer to

Figure 4andFigure 5when wiring themodule.

Caution: To avoid potential equipment damage from lightning

strikes, do not run LX‑Bus, Keypad Bus, or708bus wires

underground.

Connect to the LX‑Bus

At the Panel Module, connect wires to the RED, YEL, GRN, and

BLK terminals. Connect the red, yellow, green, and black wires to

the corresponding4‑wire harness leads. Connect the other end of

the harness to the LX‑Bus header.

Connect to the Keypad Bus

At the Panel Module, connect wires to the RED, YEL, GRN, and

BLK terminals. Connect the red, yellow, green, and black wires to

panel Terminal7, 8, 9, and10respectively.

Figure 1: 708 Modules

Figure 2: Mounting Hole Locations Figure 3: Stando Installation