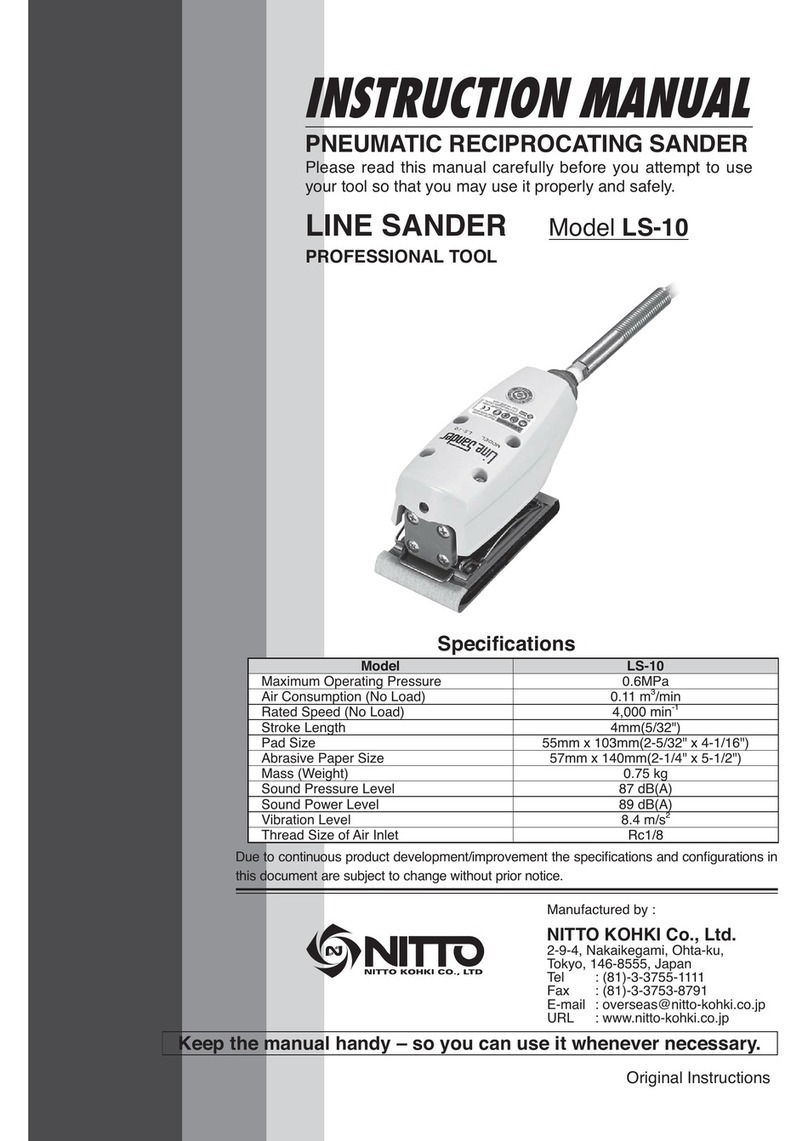

Nitto Free Sander FS-100C User manual

lJrFJrrrar励

嘔JИ

:R OSCILLATING SANDER

ALLiNSTRUCT:ONS BEFORE OPERAT:NG THIS T00L

REE SANDER

I FSⅢ

100C,FS‐ 50A

FESS10NAL T00L

ONlコ

驚Manufaclured by:

Nl■

TO KOHKICO"LTD

9‑4,Naka kegami

2‑chome,Ohta‐ ku,

Tokyo 146‑8555,」 apan

Tol:(03)3755‐ 1111

Fax:(03)3753‐ 8791

specifications

These specr calions and the prolle may be changed lorimp101 ement wlhOut pr or nOlice

SAVE THESE INSTRUCT10NS

△〇◎

CONTENTS

IMPORTANT SAFETY INSTRUCnONS FOR ALL ttR TOOLS

IMPORTANTINSTRUCl10NS FOR OSC LLATING SANDER

1 0SAGE …… 3

2 CHECK THE CONTENTS OF THC PACκAGE …

… 3

3 AIR SUPPLY…

…………………………………………… 4

4P… ■

ONS… …

…

…

……4

5 ATACH SANDPAPER…

…………………………

……… 4

6 HOW T0 0PERATE THE T00L… …

…

…

…

5

7 REPLACING RUBBEn SuPPoH[υ …

……

…

…

5

8 STORAGE ……

……

……

……

…

…

6

9 0PT ONAL ACCESSORIES ……

……

…

6

10 0RDERING SERViCE PARTS …

…

…

…

6

1l FS‐100C ASSEMBLY AND PARTS uST …

…

7

12 FS 50A ASSEMBLY AND PARTS LIST ……

…

8

PIC70GRAM

VVarningiit might be dangerous to opefate the powortool

if the instructions suppled are not fo‖

owod

Befofo operat ng the tool lead and undeletand a‖ in―

structions supplod Koop it for future'reforence

Personal pЮ tective equipment as eye and ear protec‐

tion and prOtective gloves must always be used when

oporating the tool

Operatois assigned to use the tools should be lnstructed in the

safe use of the tool

No person shOuld use this tool vythout frst having read and

understooO this instiuct on manual

ll)07038 PrOper!ソ Do not vvear loose clothing o7 αnaments

They can be caughtin moving parts Non― skid foomeaiis re

commended VVea子 protect ve ha r covei ng to contain 10n9

ha r

(2)Alway8 Wear eye p70teCtlon Everyday ey891asseS Only

have impactresistantlenses They Oo l10T protecl eyes Also

use Face or dust mask f operations creato Oust

(3)Alwaye w r protectlvo o87 0qul●mont

△ WARNING

VVhen using a r toois. basio safety precautions

should always be fo‖owed to reduce the risk of

personal iniury,including the fo‖

owing

(1)Be Sure ail external screws, nu峰 and bo13 are u9hlly

secured prior to each use

(2)Oo not use danaged frayed or deteriorated hoses and

fittings

(3)Remove adlu3ting k●ys and wrencho3 Fgm hab"of

checkin9 1o see that adlust ng keys and、 vrenches are remo―

ved from tool befoie turning lt on

14)use righi too: Do notforce a sma‖ tool or attachment to

do the Job of a heavy― duty tool Do not use too1lor a purpOse

not intended

15,Do notforco tool n wll● 。the,ob better and sarer at the

rate for、vhich it was designed

(6)Secure wo7k USe Clamp8 0r a Vise lo hold 、vork when

pract cal lt is saler than using your hand and t irees both

hands to operate tool

(7)Al,pro38ure atthe inlet mu3t not exceed O SO MPa(O k9r′

cm1 85 p3り ,5 9 bar)

(1)St070日 10 too 3 VVhen not in use,lools 8hOuld be stored

in d。

,and locked―

up places out of reach of ch‖

dlen

(2)Avold unin10ntbna1 3tartlng Do not ca子 ry ar po、 vered

tool w th fingo「on th子ottle VVhen car子 yin1 0o. be Sure the

connectinl hose to the oompre330 13 disoonnected

(3)Reduce the口 3k01 unintentiona1 3tarung Mako 3ure

throttte ls in oFF postlon before connect ng ol,ho30 10 tOol

(4)Do nol abu30 h030 Never carry tool 、″th a,r supply hose

connected or yank on hOse to disconnect

(5,Nev● 了

│●ave tool「unning unattended Always turn tt the

air supply and disconnect the a r supply い

ose Do not leave

tool unattended untl it comes to a completo stop

senge

Do not operate tool when you are tred

(6)Sone tOO13 1000rate 8ub31anual vlbratlon3 r dSCOm

foit o子

pain is encountered dur ng use, you should cease op‐

erations and check w th your physician pr o子 to fu"her use

17)Bo 8ure tO keep handB cloar of movinO part3

(1)Koop work area cloan Clutte(゛ work areas and ben

ches invite accldents and inlur,es

(2)Oon3 00r WOrk area onvlronmont Do not expose tЮ s

to rain Do not use tools in damp or、vet locatlons 卜鑽 p work

area wel lt

14)Do not overoocll

al times

(5)● いy al●

rt vVatch

(3)Do not operate n 7■8mmaue

eXp1031Ve abno3phere8

(4)Koop childtton away Also a'

away from work area Do not lot

compressor α conooct ng hoses

Keep proper footing and balance at

what you are dolng U30 COmmon

liquUs or in g8800u8 0r

visitors should be kept

vis tors contact the tool

(5)SOme t00 8 generate h19h no18e leVe18 CheCk to be sure

thatthe use of this tool conforms to aI Iocal noise requlations

││││││││1賢 団国=回目│■

■■■■■■■ ∠N WARNING

(1)Do■ot reconstruct or modily

(2)Check damaged paⅢ Before further use of the tool an

accessory Or other pan that is damaged shou10 be carefuly

checked to determine tha t wl1 0perate prOpery and perorm

is intended funct ons Check o( a19nment Of mOving parts

binding of moving patts breakage o(pans mOuntng and any

other cOnd tions that may areci ts Operat on An accessory

or other partthatis damaged or inoperable should be propery

repa red or replaced

(3)Repalrs by autho子 Zed Personne: Any repa rs on the tool

o「inSalat on oF replacement pans shOu10 be performed only

by the sales agent from 、vhom you purchased the tool or the

manulacturer use only genuine replacement parts Fa ure to

utilze the expertise oF an author zed sales aOent frOm 、

″

hom

you purchased the tool or the manuracturer or ialure to use

genuine replacement parts may resut in an increased risk of

iniury to the user and may inv81dab your、 varranty

(4)U8e reCOmmended accessorios Consu t this manual of

the sales agent from whom you purchasedthetoolorthe manu‐

facturerfor recommended accessor es The use of improper

accessoles may cause risk of iniury tO persons

(5)A[waysturn O the alr 8upply and disconnectthe a r supply

いose bo,ore instali ng,70mOVing Or adiusting any accessory on

the too[or before performing any maintenance oo lhe tool

(6)● o not removo any[abel placed on the tool ( the la

bels become damaged obegin to peel a、 ″ay contactthe sales

89ent from、 ●hom you purchased the tool orthe manじ (acttrer

for the r immediate replacement

(1)A[ways turn off the air supply and disconnect the air sup‐

ply hose leforehand whenever replacing abrasive papers

(2)Be sure to keep hands clear of moving parts

(3)Ai,pressure at the sander in10t with the Sander running

must not exc88● 0 59 MPa(6 kgf/cm′ ,85 psig,5 9 bar)

(4)Always rep18Ce damaged,bent or severe[y worn Pads Do

not use a Pad that has been subieCted to an AOrasive Paper

f810re

This tool is for sandingヽ vo「kpieces using an abrasive paper

Check the cOntents and make sure thatthe tool does not have

any damage due to an accident durng the transportaton if

any The contents should correspOndto the ist as iolo、 ″s Just

in case there are some damaqes or miss n9,arts contact the

sales agentirom whom yOu pJrclヽ iSed the tool or an autho‐

12ed dealer

FS 100C

PaCk890 COntent3

FREE SAllDER FS i00C

Hose E Assy

Bushlng PTl,4,NPTl,4

Sandρ8per 180

SandOaper r 240

Part Nb

TB02359

T P02236

T P04248

TP04249

TP15853

里

1

1

1

5

5

1

Check

INSTR∪ CT10N l.lANuAL

FS‑50A

繹 鍔1駄

1町 L

Hose E Assy TB02359

Bじshing PTl′

4× NPTl′4 TP02236

Sandpaper 1180 TP05713

SandOaper ■240 TP05714

INSTRUCT10N MANUAL i TP15858

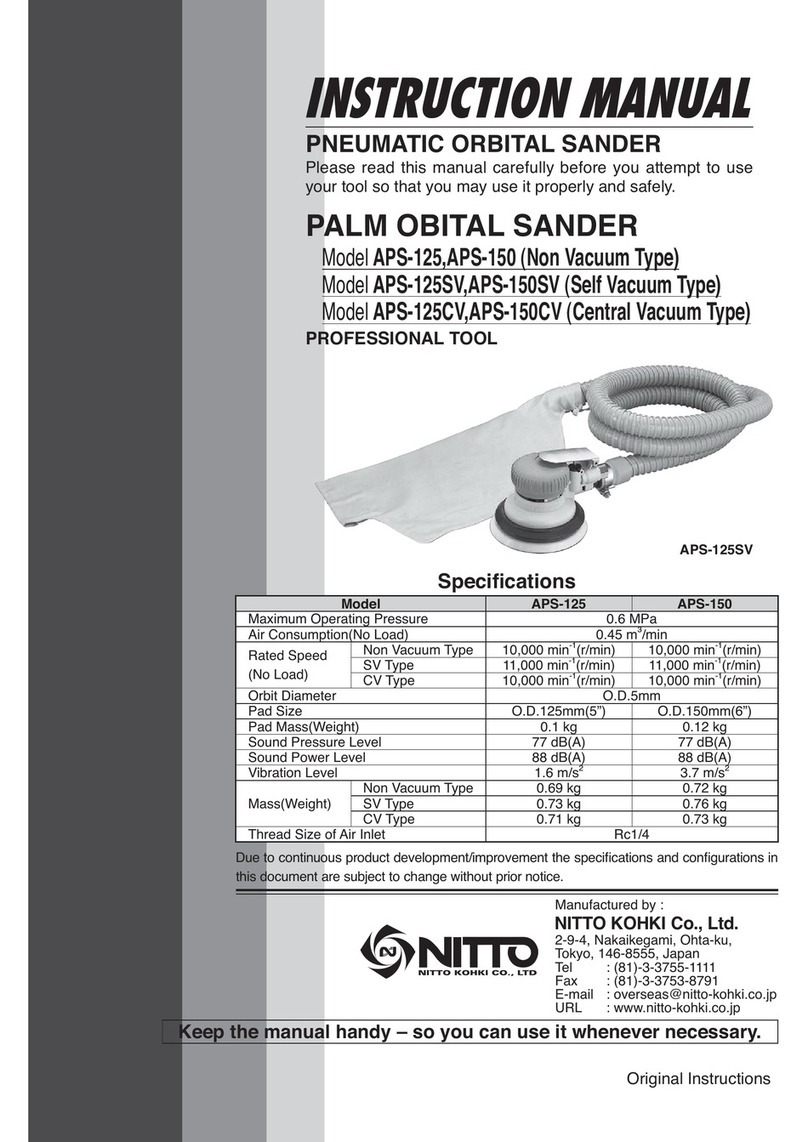

3‑l Alr Pre3Sure

Air pressure largely ddermines tool performance This tool is

des'9■od to be operated at a r pressure of 0 59 1.4Pa(6kgl cm2,

35 ps9,59 ban max mum

3‐2 Air llne{F191)

use a 95 mm (3/8)ar hoSe between the compressor and

the tool Compressed a ris cooled and its drain separat」 , as

soon as the a r leaves the compressor The drain hovvever is

condensed in the piping and can enter the tool mechanism

and may cause trouble So insta‖ an arf‖ ter an a r iegulator

and an o‖ er between the compressor and the tool

5‑l Sandpaper

Cut,andard s ze paper(9'× 11')nto 4,ieces for Mode FS

,00C and into 8 pieces for 卜Иodel FS‑50A as showo in F19 2

Fo′ diy sanding use an open coat type sandpaper、 v th silcon

carbide or aluminum oxide abrasive grains to口 event clo99in9,

improve gr nding tticiency and prolong the lfe of the paper

F92

5‐2 AttaCh Sand Paper

Raise the c rcular knob atthe end ofthe clamp spr n。 (2 pOints,

pu‖ tO the side and push t down The papei clamp、 vil then

open push in sandpaper at th,8 point iai30 the C'icular knob

anO insert the clamp spr n9 in3ide the clamp stopper This

completes fi"in9 the sandpaper RerertO日 13 3 and 4 (both

sides aie nOt clamped completely(800 Fi● 5, cutting and san‐

ding powe「 w l drop Compare F198 4 and 5 Nolce how in the

incorrect y clamped f Oure. the cutting surfaco ol the paper

does not come in contact vyth the rubber pad

3‑3 Lubrca」 on

lnstal an。│lo子

bOtwOon the compressor and the tool Use ■10

machine oil Ne91eci ng the o supply v.1l cause damage The

use ofthick ol、 vil lead to p00r pedormance Always use 1lo

mach ne ol

4‑l Thread s120 0f H030 Fitting

The pioduct comes w h a metalitting w th PT(metlC)thread

Connectthe Bushing PT l′ 4 thread× NPT,/4 thiead in the vinyl

bag containing standarO accessor es, f yOu would ike to have

Amelcan NPT i卜 read instead

△ WARN:NG

A vvays turn or the air supply and disconnect the

ai「

supply hose

Read and thoroughlソ understand lMPORTANT

INSTRUCT10NS FOR OSCILLATING SANDER be‐

fore carrying Out these operation

F93

F94

AIRe901ato「

96mm(ν 8)

AiSupply Ho3。

Fg 5

5‐3 1n C88e Of UЫ ng oOubb― Sided Adheslve Tape

Attach dOuble― sided adhesive tape to the sponge part then

arach the sandpaper to the tape

5‑4 1n Ca30 0f U31nO spray Adheslve

Spray the sandpaper with adhesive then attach itto the sponge

Since the 3andpaper must be removed ater t ha3 been used

Avoid using permanent adhesive Paper adhesives are ava

lable

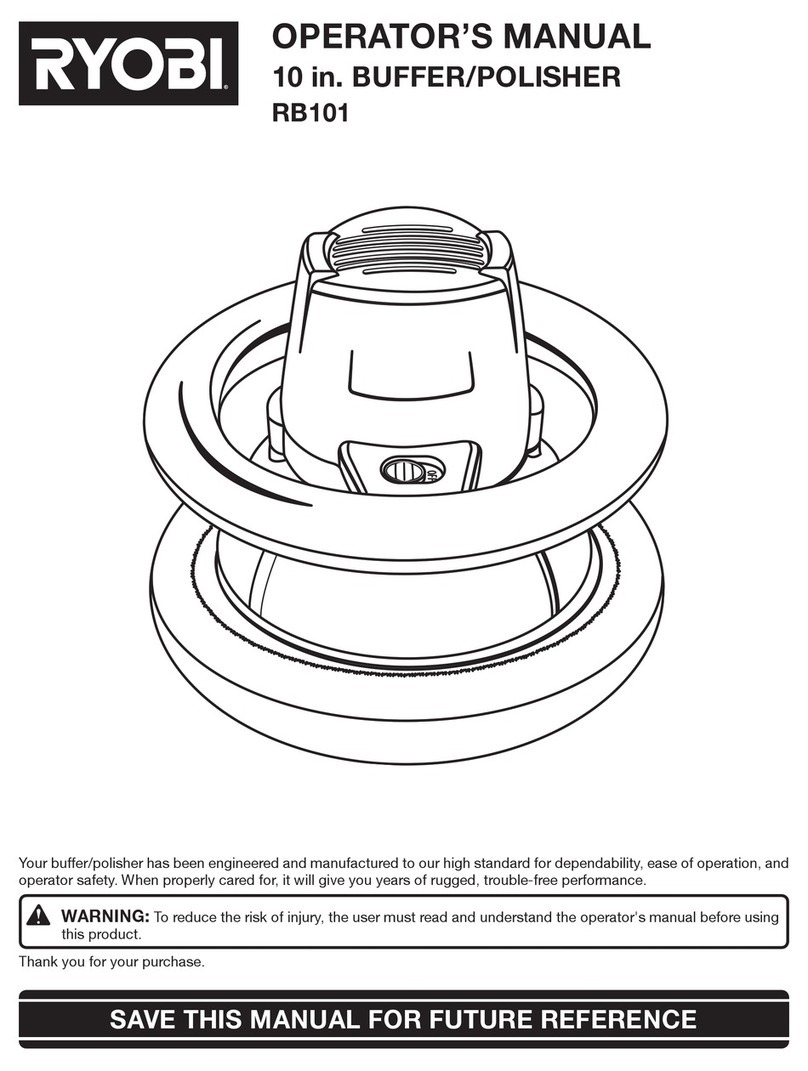

6‐l Start and stop

(1)FS‑100C

To stan press the tr 99er untl itis'ocked Hold the Tr ggerin

thi3つOSitiOn

To stop, pless the Cancei Switch and retuin the TrOger to it8

0子

ginal position

F96

(2)FS‐ 50A

To stan, push the tr 99or al the way to、 vards the body

To stop,pul the tri90or al the way out awayrom the body

F97

6‐2 Sanding Pre33ure

Sand ng pressure rOr FS■ CKCis2toSkg144tc ll bslandfOr

FS 50A l to O kO(2 2 to 6 6 1bo)Applying excessive rorce w‖ │

lower sanding efriclency

Fo子'lat work,ad,uSt pressure so iorce 18 appled evenly to the

entre surace Of the rubber pad uneven pressure wll resu t

in an iregular surace

△WARNING

Always turn off the air supply and disconnect the

al「supply hose

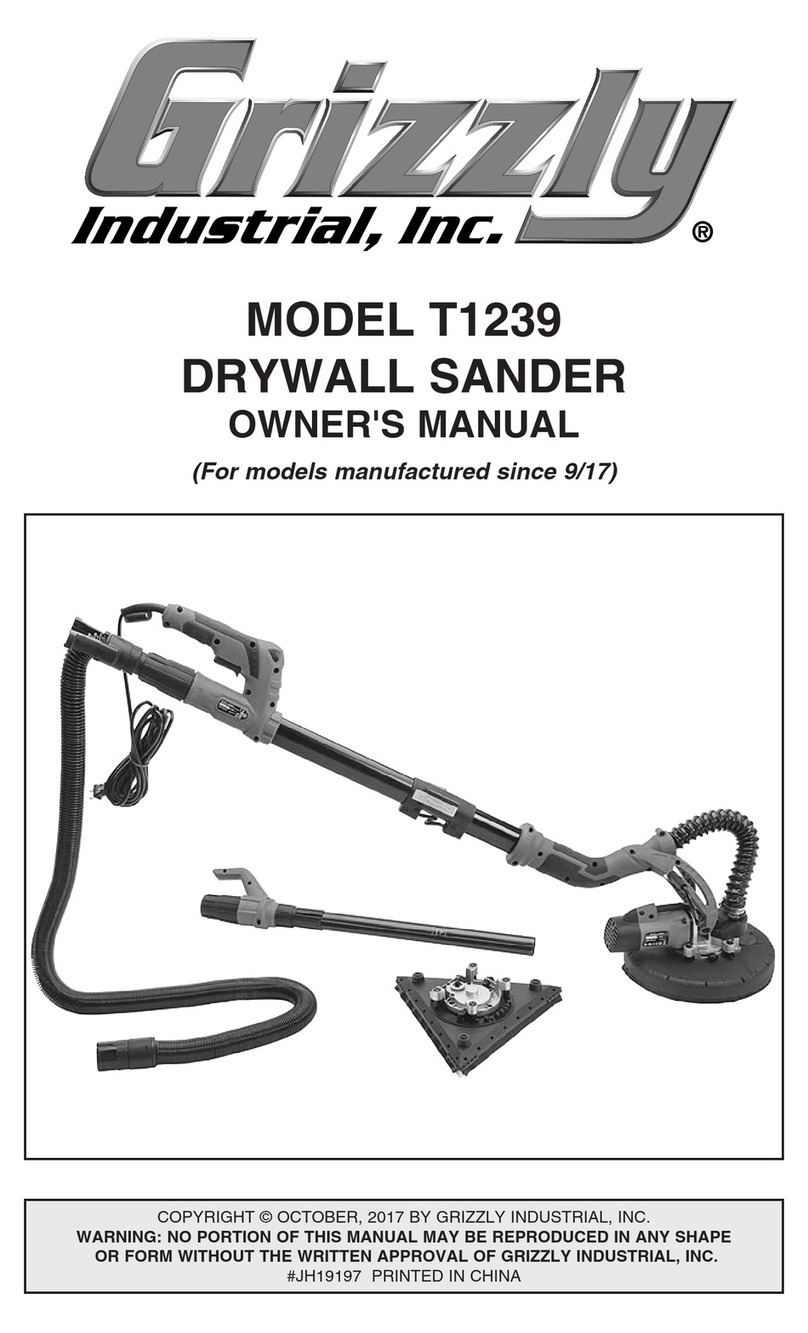

7 1 FS‑100C

Dlsa3Sembly sequelFe

l)PlaCe the t,99er at oFF loosen 4 screws(Crc SS Rece3sed

Pan HeaO Screw wth Sprng Lock Washg M 4× 101 and

iemove the rubber pao Loosen 4 nuls oi the rubber suppOrt

and remove the base plate

NOTE:Do nOt iemove the artube

2)Loosen 4 8CreWS(CiosS Recett Pao HeaO Tapping Sciew

M4× 20, and remove the housin9 cover(See F,9 8)The

t,99oi and the cancel sw,lch can be also taken Ofr at the

same time

0)Loosen 4 nuts of

supports,「 om the

od (Seo F19 9)

F98

the rubber suppOrt and tako out 4 rubbe子

housing Now the disassemblyis eompler

F99

A380muy sOquence

l)Flx 4 rubber supports to the housing with the nut Place the

tr 99er and the cancel s、vitch and sprng o 45× 31× 17 on

the housing and mount the housing cover on them and

t9hten 4 screws lcroSS Recessed Pan Head TappinO Screw

M4× 20)

2)Fix the base plate to the rubber 3uppOrts w th 4 nuts taking

care to prevent the rubber suppo蔵 frc m being Ⅲ isted

NOTE: lf the fubber support is instaled beinO lwi,ed, the

rubbe,support wll be quickly damaged (See F,9 9)

3)Thereafter re88Semble in the reverse of disassembly !f the

screws are not tightened securely they wil bcて xyne loose

doe to vibration leading to parts damage

Therefore t ghten them sufficiently

7‐2 FS‐

50A

D― bly Sequence

',Loosen 4 sc,o″ S(Cr∝ S ReCeSSed Pan Head Sciew with

Spang Lock Washer M 4× 8)and remove the rubber pad

〈

―Fig lo)

││

F,9 10

^ヒ "oぃ ooss R℃ o3sed Countersunk Flat Heed Screw MG

X● び " base plate and remove the ba30 plate iom

Ⅲ…plate(3oO Fi9 10)

●

,7E Don(■ ,帥 Ove the a r tube

3‑い e rr― at both sioes o(the rubber suppon and

…・e …S。

。。

。

" ThiS Completes di38880mbly

―F● ,1,

‐

…

…R― M PanH● nd Sor●●

一口th T・

・・

d tck

W hM4× 8

Robb●,Su…

0ぃ R― C●●l・

・

uほ 曰讚

Hd So智 M4×6

NOTE:The above sandpapercan notbe usedror● ust cb‖ector

Ass y use the Sandpaper exclusive For the Dust Ooloctor

Ass y

〔認 Plete

F911

… …

F・

=t

―

¨n… soppyttO the housing by screws(CrOss

―

Pan Head象 】ew wth Toothed Lock Washe子 M4

X8,

―

薇 ●■ end口 ate Oy scres lCrOSS Rece3801 COunter8unk

FIC― Sc■ew M4× 6 )0′ asping l19htly the bo"om of the

…・

X〕

〕蔵W th plo,s etc and takinO care tc prevent the

…alppOrt,。 m be n9ヽ ″sted

O For fulther operat onal and handi n● Informat on of ror iOp‐

!acement of pan3 and component8, COntact the sale a● 8nt

from whom yOu purchased the tool or an author zed dealel

●ln ordering palts and celmpOnents 91ve each part number

patt name and quantty 70quired

●U80 NITTO genuine parts

Aま"d藪 "o9the tool n a ocation sublectto h gh hun dity r

lヽ

et】 メis left as it is us3d,reSidual moisture on the insido can

ca

目en面 00 Before storing, and after operatlon o i the tool

at ar ntet wlh machine ol and run lor a short

ne

FS‐100C

T―Type Or center Pad Ass y

T Type Center Pad A3S y

Floxible Pad Ass y

Adhesive spray

Oouble Side AIい osive Tape

Sandpaper ■100(200 pc8/8etl

Sandpaper 1 120(200 pes′ set)

Sandpaper l 150(200 pc8′ 8et)

Sandpaper 1 100(200 pcs/set)

Sandpaper Ⅲ240(200 pc8/3et'

Sandpaper 1 230(200 pcs/set)

Sandpaper 1320(200 pcs′ setl

FS‑50A

Sandpaper ♯loo(200 pcs′ 3et)

Sandpap07 ■120(200 pcs′ 3et)

Sandpaper 1150(200 pcs′ 301)

SandpapOr 1180(200 pc8′ set,

Sandpaper 1240(200 0cs′ 30t)

Sandpaper 1280(200 pcs′ set)

Sandpaper 1320(200 oc313et)

Dust Collector A38 y

∠ゞ

CAUT10N

The llustration is fo「

info「

mation only users should never disassemble parts

Contact the sales agent from whom you purchased the tool o「autho「zed dealer should the tool need

service,repatr or replacement of parts

ノ

ヽ

3

iヾ

´

14‑―

――――――

24

ら

シ

│■´

The parte numbers w th( )are included in the Ass y part3 vvritten abore them

辣IT

WarninO Label CE M8rk 1 1

TP15374 1 Tr9987 1 1

Sping Lock Washer M4

Tapplng screw 4× 20

Splng 0 6× 31× 17

Cross RecesSed Pan Head

Tハ91647

B388 Plat Sub Assy

Throllle Valve Ass y

Cross Recessed Pan Hoad

Sc,ew 4× 8A3sy

日ubber Supporl Ass y

End Cap Assy

Screw 5× 12

Rubbe,Pad As y

∠ゝCAUT10N

The‖ lustration is for informat on only Users should never disassemble parts

Contact the sales agent from vvhom you purchased the tool or authorized dealer should the tool need

service,repa r or replacement of parts

ε目== u尋

6

7

8 9 Ю

The pans numbers w th( )are included in the Ass y pans written above them

Pa市 LI Patt N3me JO'

25

1

一

22

・23

24

T802338 1 Houslng Sub Assy

(TP05700) I HoUSing

稀誌性曇墨■i6― ││ │

(T02207)I Warttng Labd CE Mark

(TP05745)I Name f ate

¬505698 1 Va〜

o MoⅢ

e

TA― α AsSy

(TP12004, O Rin9 P 10

TA91647 Tube As y

TP05708 Clamp Stopper

TP05707 Clamp Splng

TQ1725 1 Hex SOCket

Screw 3 X 6

Countrsunk Flat Head

Scro″ 6× 14

RubOer Pad Ass

TA91575 Cross Recessed Pan

Screw 4× 8 Assy

Countersunk Head

Screw 4× 10

Rubber Suppo■ Ass y

End Plate

16 TP05712

Coootersunk Flat Head

Cylnder subハ ss y

Cyinder

Cross Recessed Pan Head

Screw w th Sprn9 Lock

VVぉ her 4× 8

4 setS

,

2

4s‐ts

JJSIttJrrroJJ‖

‖AI

AIR OSC‖:▲

¬NG SANDER

FREE SANDER ModelFS‑100C,FS‐ 50A

READ ALLINSTRuCl10NS BEFORE OPERA■ NG THIS TOOL

TP15858‑4‑60205A

This manual suits for next models

1

Other Nitto Sander manuals

Popular Sander manuals by other brands

Black & Decker

Black & Decker Powerfile KA902E Original instructions

Scheppach

Scheppach BTS900 Translation from the original instruction manual

Rupes

Rupes RX153A Original operating instructions

Casadei

Casadei LIBRA 10 Operation and maintenance manual

Makita

Makita BO6030 instruction manual

GMC

GMC GPDA manual

General International

General International 15-155 M1 Setup & operation manual

Struers

Struers LectroPol-5 instruction manual

Craftsman

Craftsman 320.39587 Operator's manual

EINHELL Bavaria

EINHELL Bavaria BSS 150/1 operating instructions

King Canada

King Canada KC-702CN instruction manual

Ryobi

Ryobi ERO240VK Owner's operating manual