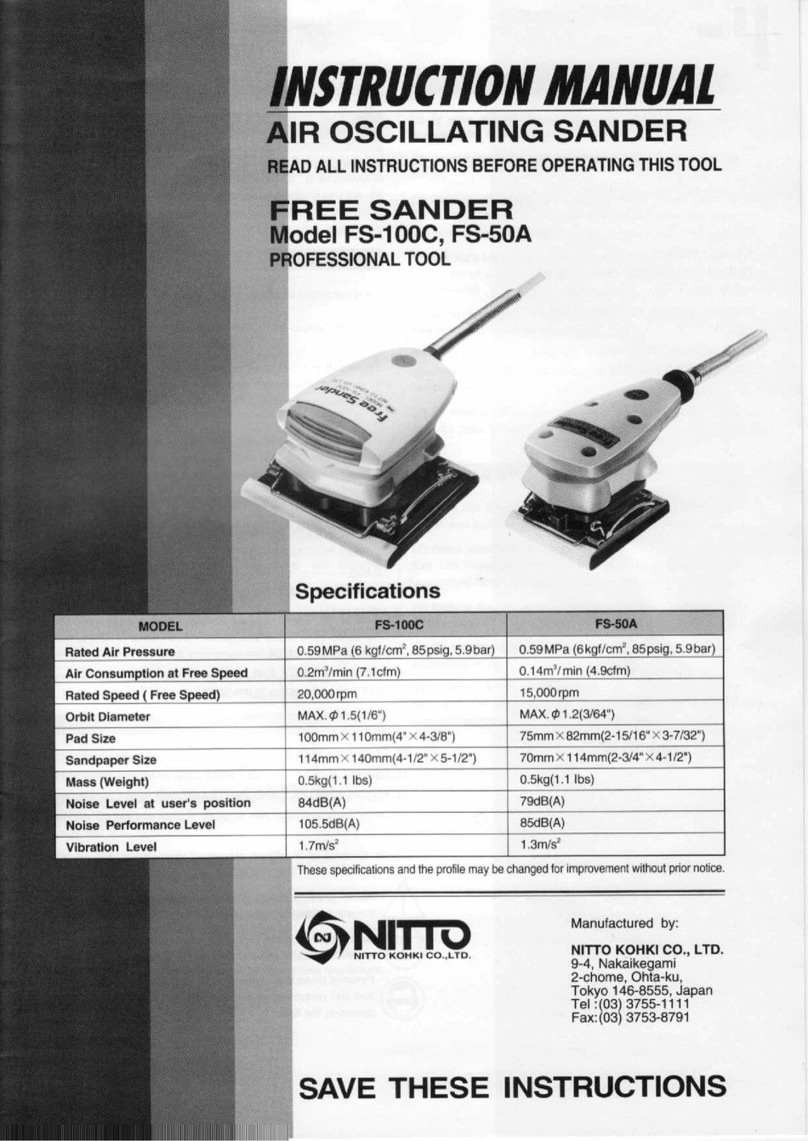

Nitto B-10N User manual

PNEUMATIC BELT SANDER

Please read this manual carefully before you attempt to use

your tool so that you may use it properly and safely.

BELTON

Model B-10N, B-20N, B-20NB, B-30N

PROFESSIONAL TOOL

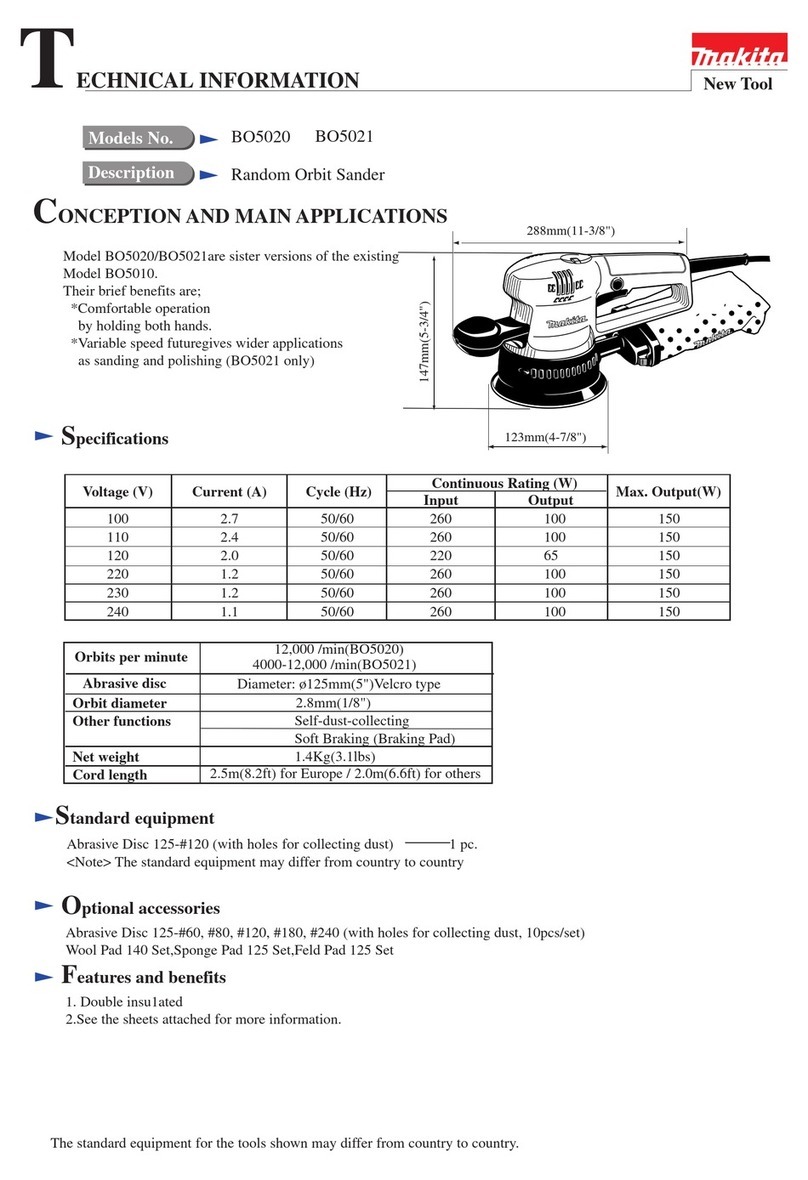

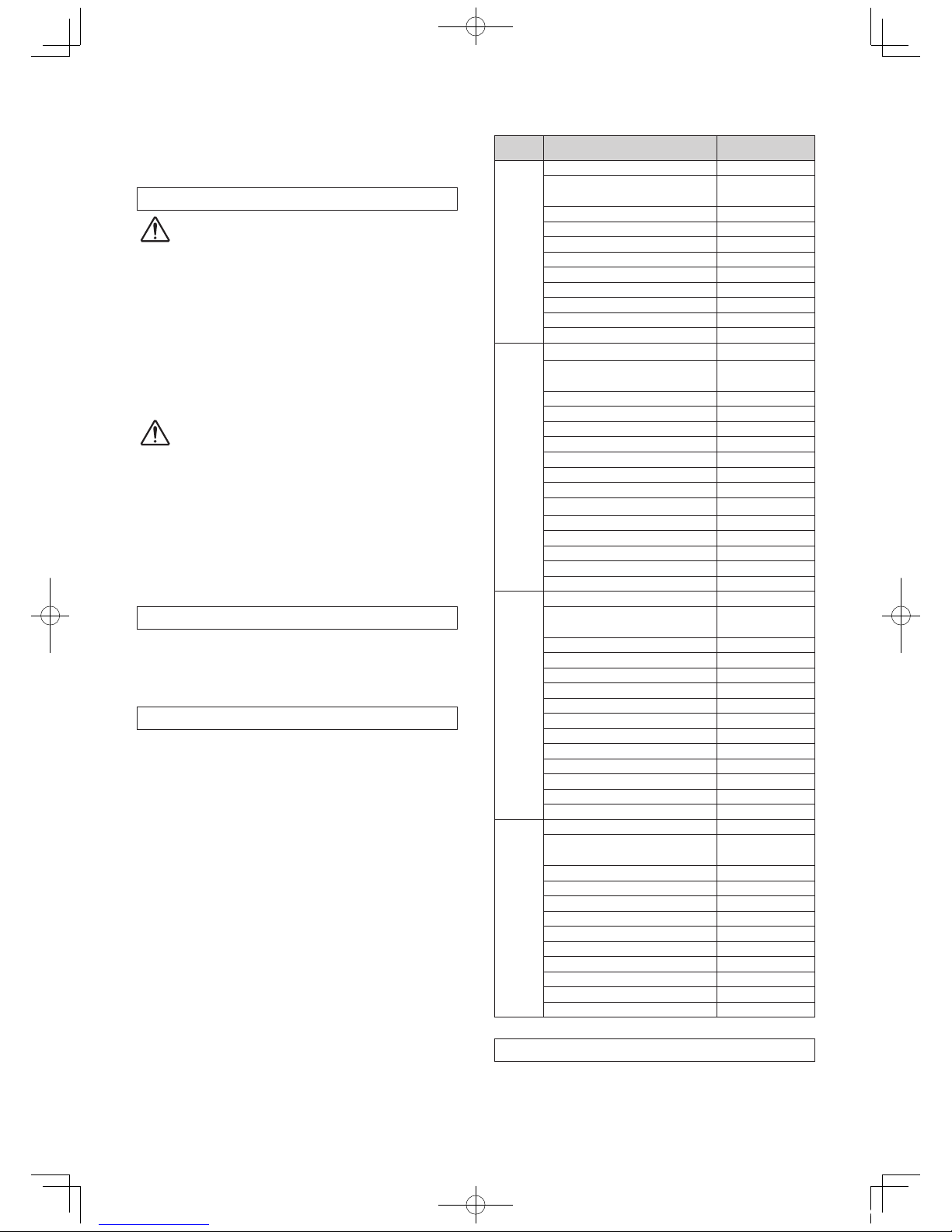

Specications

Model B-10N B-20N B-20NB B-30N

Maximum Operating Pressure 0.6 MPa

Air Consumption (No Load) 0.4 m3/min 0.52 m3/min 0.52 m3/min 0.68 m3/min

Rated Speed (No Load)

17000 r/min(min

−1

) 17000 r/min(min

−1

) 17000 r/min(min

−1

) 14000 r/min(min

−1

)

Standard Belt Size 10×330mm

(25/64″×13″)

20×520mm

(25/32″×20-15/32″)

30×540 mm

(1-3/16″×21-17/16″)

Mass (Weight) 0.7 kg 1.2 kg 1.2 kg 2.4 kg

Sound Pressure Level 78 dB (A) 83 dB (A) 85 dB (A) 82 dB (A)

Sound Power Level 89 dB (A) 94 dB (A) 96 dB (A) 93 dB (A)

Vibration Level 1.28 m/s20.80 m/s20.75 m/s2Handle : 1.53 m/s2

Grip : 0.45 m/s2

Thread Size of Air Inlet Rc 1/4

B-10N B-20N

B-20NB B-30N

Original Instructions

Thespecicationsandcongurationscontainedinthisdocumentaresubjectto

change without prior notice due to improvements we are making day in, day out.

Manufactured by :

NITTO KOHKI Co., Ltd.

2-9-4, Nakaikegami, Ohta-ku,

Tokyo, 146-8555, Japan

TEL : (81)-3-3755-1111

FAX : (81)-3-3753-8791

E-mail:[email protected]

URL :www.nitto-kohki.co.jp

Keep the manual handy – so you can use it whenever necessary.

B10N_B20N_B20NB_B30N_E.indd 1 10.7.9 9:30:22 PM

1

The following Safety notations are used throughout the manual to highlight safety precautions for the user and for

the tool.

Warning: Indicates a potentially hazardous situation which, if not avoided by following the

instructionsgiven,couldresultindeathorseriousinjury.

Caution: Indicates a potentially hazardous situation which, if not avoided by following the

instructionsgiven,couldresultininjuryormaterialdamage.

Please note, however, that failure to observe safety precautions under the “ Caution” category could result in a

serious occurrence depending on the situation: please observe all safety precautions in the manual.

Caution: Important precautions for tool setup, operation and maintenance.

Thank you very much for your purchase of this

Nitto Kohki product.

Before using your tool, please read this manual

carefully so that you may use it properly to get

the most out of it.

Please keep the manual handy - so you can

use it whenever necessary.

・English : Please ask your dealer or

distributor for instruction manual

in local language(s).

・German : Bitte fragen Sie lhren Händler

nach eine Betriebsanleitung in

Landessprache.

・French : S'il vous plait, veuillez demandez

á votre foumisseur de manuel

instruction en langue locale.

・Spanish : Por favor, cantacte con su

distribuidor para el manual de

instrucciones en español.

・Portuguese : Por favor pessa ao seo agente

ou distribuidor o manual de

instrucces ih linguagen local.

・Italian : Per Manuale Istruzioni in lingua

locale Vi preghiamo di rivolgervi

al rivenditore o distributore.

・Dutch : Vraag uw handelaar

om een nederladstalige

gebruiksaanwijzing.

・Swedish :BeerlokalaÅtreförsäljareeller

distributör om manualer pá

svenska.

・Danish : Venligst henvend Dem til den

danske distributør for instructions

manualer.

・Polish :Proszepytacswojegodealera

lubdystrybutoraoinstrukcje

obslugiwjezykulocalnym.

・中文 :請向當地供應商或経銷商詢問中

文使用説明書

CONTENTS page

IMPORTANT SAFETY INSTRUCTIONS …………………… 2

GENERAL: TOOLS …………………………………………… 2

GENERAL: PNEUMATIC TOOLS ………………………… 3

INSTRUCTIONS FOR THIS TOOL ………………………… 4

1. USAGE …………………………………………………… 4

2. CHECK THE CONTENTS OF THE PACKAGE ………4

3. AIR SUPPLY ……………………………………………… 4

4. PREPARATION …………………………………………… 5

5. HOW TO OPERATE THE TOOL ……………………… 6

6. THREAD SIZE OF HOSE FITTING …………………… 9

7. STORAGE ………………………………………………… 9

8. OPTIONAL PARTS ……………………………………… 9

9. ORDERING SERVICE PARTS ………………………… 9

10. EXPLODED DIAGRAM: B-10N ……………………… 10

11. EXPLODED DIAGRAM: B-20N ……………………… 11

12. EXPLODED DIAGRAM: B-20NB …………………… 12

13. EXPLODED DIAGRAM: B-30N ……………………… 13

PICTOGRAM

Warning: It might be dangerous to operate the tool if

the instructions supplied are not followed.

Usingthistoolimproperlycouldresultinseriousinjury.

Read the instruction manual before using.

Always wear suitable eye protection.

Always wear suitable hearing protection.

Always wear respiratory protective equipment (PPE).

IMPORTANT SAFETY

INSTRUCTIONS

When using the tool, please observe the safety

precautionsbelowtopreventpossibleaccidentorinjury.

GENERAL: TOOLS

Warning

TO OPERATORS

● Wear proper clothing for the type of work being

done.

Take care to avoid entanglement with the moving

parts of the tool with clothing, ties, hair etc. If items

become entangled it will cause the operator to be

pulled towards the tool and lead to possible cause of

accidentorinjury.

● Always wear suitable eye protection.

Remember, regular glasses are not safety glasses.

The lenses are only shock resistant, which will not

give you sufficient eye protection you may need in

your working environment.

● Always wear suitable hearing protection.

● Wear respiratory protective equipment (PPE).

Wear respiratory protective equipment (PPE) when

working in an environment where dust particles are

generated in operation.

● Avoid working posture that is too stressful.

Always ensure a firm footing and well balanced

posture.

● Do not operate the tool if you are too tired.

● Never touch any moving parts of the tool when

running.

ABOUT WORK AREA

● Keep the work area clean.

Cluttered work areas (e.g. workbench) invite

accidents.

● Carefully select the work area.

Do not expose tool to rain.

Do not use tool in a wet or soaked area.

See that the work area is adequately illuminated.

● Never work near inflammable liquid or in a

potentially explosive atmosphere.

● Keep children away from the work area.

Keep children and unauthorized people away from

theworkareatoavoidaccidentorinjury.

B10N_B20N_B20NB_B30N_E.indd 1 10.7.9 9:30:24 PM

2

The following Safety notations are used throughout the manual to highlight safety precautions for the user and for

the tool.

Warning: Indicates a potentially hazardous situation which, if not avoided by following the

instructionsgiven,couldresultindeathorseriousinjury.

Caution: Indicates a potentially hazardous situation which, if not avoided by following the

instructionsgiven,couldresultininjuryormaterialdamage.

Please note, however, that failure to observe safety precautions under the “ Caution” category could result in a

serious occurrence depending on the situation: please observe all safety precautions in the manual.

Caution: Important precautions for tool setup, operation and maintenance.

IMPORTANT SAFETY

INSTRUCTIONS

When using the tool, please observe the safety

precautionsbelowtopreventpossibleaccidentorinjury.

GENERAL: TOOLS

Warning

TO OPERATORS

● Wear proper clothing for the type of work being

done.

Take care to avoid entanglement with the moving

parts of the tool with clothing, ties, hair etc. If items

become entangled it will cause the operator to be

pulled towards the tool and lead to possible cause of

accidentorinjury.

● Always wear suitable eye protection.

Remember, regular glasses are not safety glasses.

The lenses are only shock resistant, which will not

give you sufficient eye protection you may need in

your working environment.

● Always wear suitable hearing protection.

● Wear respiratory protective equipment (PPE).

Wear respiratory protective equipment (PPE) when

working in an environment where dust particles are

generated in operation.

● Avoid working posture that is too stressful.

Always ensure a firm footing and well balanced

posture.

● Do not operate the tool if you are too tired.

● Never touch any moving parts of the tool when

running.

ABOUT WORK AREA

● Keep the work area clean.

Cluttered work areas (e.g. workbench) invite

accidents.

● Carefully select the work area.

Do not expose tool to rain.

Do not use tool in a wet or soaked area.

See that the work area is adequately illuminated.

● Never work near inflammable liquid or in a

potentially explosive atmosphere.

● Keep children away from the work area.

Keep children and unauthorized people away from

theworkareatoavoidaccidentorinjury.

BEFORE OPERATION

● Inspect tool before use.

Before using, check that screws are securely

tightened, that any protective cover or guard is

securely in place, other parts are free from damage

and that the tool runs as it should.

Checkthatmovingpartsareproperlyadjustedfor

positioning and tightened, that parts are free from

damage and properly mounted, and that all other

parts are in good condition for normal operation.

Should you find any damage to the protective

cover or other part, replace it in accordance with

the Operation Manual. If there are no instructions

in the Manual, please contact the sales agent

through which you have purchased your tool or an

authorized dealer near you for repair.

Likewise, if a switch failure occurs, contact sales

agent through which you have purchased your tool

or an authorized dealer near you for repair.

Do not use the tool if it does not start or stop with

the start/stop switch.

● Securely mount cutter

Animproperlymountedcuttermayyout,causing

possibledamagetothetoolorinjurytotheoperator.

● Always remove spanner, wrench, etc., once

adjustment has been made with them.

● Use a tool appropriate for the application.

Avoid heavy-duty application that is beyond the

capacity of tool.

● Do not use the tool for purposes other than what

it is designed for.

● Do not abuse tool.

Usetoolinaccordancewiththespecications:you’ll

get the most out of it while ensuring safety.

● Securely fasten workpiece in place.

Use a vice or clamp to securely fasten the workpiece

in place. It is much safer this way than holding it in

your hand, allowing you to operate the tool with both

hands.

ABOUT HANDLING

● How to store tool.

When the tool is not used, store it in a dry area and

out of reach of children.

● How to carry tool.

Do not touch the start switch while the tool is being

carried.

● Do not leave the tool unattended while it is

running.

Turn off the start switch and disconnect the tool from

power source. Do not leave the work area until the

tool comes to a complete stop.

B10N_B20N_B20NB_B30N_E.indd 2 10.7.9 9:30:25 PM

3

INSTRUCTIONS FOR

THIS TOOL

About Your Tool

Warning

● Wear protective glasses and a dustproof mask.

Operation generates dust and abrasive particles,

etc.whichmaycauseeyeand/orrespiratoryinjury:

Always use PPE (Personal Protective Equipment)

for eye and respiratory protection.

● When you change or adjust the tool or parts, be

sure to detach the tool from the air hose.

● Never touch the moving parts while in operation.

Caution

● Protect yourself from dust and abrasive particles.

Whensandinghotdustandabrasiveparticlesyoff

the workpiece: Always wear eye protection glasses,

long sleeve protective clothing, gloves (except

knitted gloves), foot and leg protection, etc. to

protect yourself. Always keep your face away from

the sanding surface.

1. USAGE

This is a handheld pneumatic belt sander designed

and built to perform sanding operation utilizing a

abrasive belt.

2. CHECK THE CONTENTS OF THE PACKAGE

Upon unpacking, check to see that the shipment is

complete without damage or oil leakage in transport.

Should you find any damage or short-shipment,

please contact sales agent through which you have

purchased your tool or authorized dealer near you for

corrective actions.

MAINTENANCE/SERVICE

● Do not take apart or modify tool.

Disassembly or modification carried out without

thesupervisionofaqualiedorauthorizedservice

engineercouldresultinanaccidentorinjury.

● Inspect cutting tool and accessories, etc.

Al wa ys c h ec k to s ee t ha t cu tt i ng t oo l an d

accessories, etc. are in good operating condition

without damage or deterioration before you mount

them on the tool. Should you find any damage to

an accessory or part, please contact sales agent

through which you have purchased your tool or an

authorized dealer near you for repair.

● Check parts for damage.

When you have found damage to accessory or other

part, carefully check the damaged part to determine

the extent of influence it has upon the functions

of the tool – that is, determine whether it can still

perform its normal functions.

Check to see that the linkage of the moving parts

is OK, that all parts are OK without damage,

that they are properly mounted, and that the tool

functions normally. Should you find any damage

to an accessory or part that may hamper proper

functioning of the tool, please contact sales agent

through which you have purchased your tool or an

authorized dealer near you for repair.

● Have your tool repaired at an authorized Nitto

Service Center.

For repair or parts replacement, please contact the

sales agent through which you have purchased your

tool or an authorized dealer near you.

● Use only Nitto genuine parts.

Use of improper part s may result in serious

occurrence.

To obtain a Nitto genuine part, consult this Manual

or contact the sales agent from which you have

purchased your tool directly.

● Do not detach label or nameplate from tool.

When a label/nameplate gets damaged, worn or

becomes missing, contact the sales agent through

which you have purchased your tool or Nitto Kohki

Co. Ltd, directly for a replacement.

DISPOSAL

When a tool is taken permanently out of service, it is

advised that the tool is disassembled, degreased and

parts separated by material and recycled locally in the

appropriate manner.

GENERAL: PNEUMATIC

TOOLS

Warning

● Use appropriate air pressure.

Excessively high air pressure will increase the

number of revolutions or strokes causing not only

potential premature failure/breakage but could also

leadtoanunexpectedaccidentorinjury.

● Connect tool to air supply line.

There are various types of pipes running in a factory

in addition to the pneumatic line (such as oxygen,

nitrogen, gas and water). For this reason, always

ensure that you are connecting to the pneumatic

line.

● Start tool properly.

Turn the start switch OFF before connecting to the

air supply line.

● Always disconnect the tool from the air supply

line before putting on/taking off any accessory

and prior to carrying out any maintenance work.

● Avoid exposure to exhaust air.

Pneumatic tool exhaust air contains oil and

contaminated moisture. Make sure the exhaust air is

not directed towards your face or anyone else within

the work area.

● Keep tool off electricity.

This pneumatic tool is not electrically insulated. To

avoid a potential electric shock do not use where

there is a possibility of coming into contact with live

electricity.

Caution

● Handle tool carefully.

Abusive use of tool could invite failure or accident.

Do not throw, drop or shock the tool.

● Handle air hose carefully.

Do not carry the tool by the air hose.

Do not pull the air hose to disconnect.

B10N_B20N_B20NB_B30N_E.indd 3 10.7.9 9:30:25 PM

4

INSTRUCTIONS FOR

THIS TOOL

About Your Tool

Warning

● Wear protective glasses and a dustproof mask.

Operation generates dust and abrasive particles,

etc.whichmaycauseeyeand/orrespiratoryinjury:

Always use PPE (Personal Protective Equipment)

for eye and respiratory protection.

● When you change or adjust the tool or parts, be

sure to detach the tool from the air hose.

● Never touch the moving parts while in operation.

Caution

● Protect yourself from dust and abrasive particles.

Whensandinghotdustandabrasiveparticlesyoff

the workpiece: Always wear eye protection glasses,

long sleeve protective clothing, gloves (except

knitted gloves), foot and leg protection, etc. to

protect yourself. Always keep your face away from

the sanding surface.

1. USAGE

This is a handheld pneumatic belt sander designed

and built to perform sanding operation utilizing a

abrasive belt.

2. CHECK THE CONTENTS OF THE PACKAGE

Upon unpacking, check to see that the shipment is

complete without damage or oil leakage in transport.

Should you find any damage or short-shipment,

please contact sales agent through which you have

purchased your tool or authorized dealer near you for

corrective actions.

Model Package Contents Qty

B-10N

B-10N 1 set

Abrasive Belts Z76#60×10 2 (one of them

mounted)

Abrasive Belts Z76#80×10 1

Abrasive Belts Z76#100×10 1

Abrasive Belts Z76#120×10 1

Hex. Socket Screw Key 2 1

Hex. Socket Screw Key 4 1

Bushing R1/4×NPT1/4 1

Instruction Manual 1

Declaration of Conformity 1

Caution for Use 1

B-20N

B-20N 1 set

Abrasive Belt Z76#60×20 2 (one of them

mounted)

Abrasive Belt Z76#80×20 1

Abrasive Belt Z76#100×20 1

Abrasive Belt Z76#120×20 1

Hex. Socket Screw Key 2.5 1

Hex. Socket Screw Key 4 1

Bushing R1/4×NPT1/4 1

FingerPadSubAss’y 1 set

Pan Head Screw 5×10 1

Pan Head Screw 6×10 1

Convex Shoe 1

Instruction Manual 1

Declaration of Conformity 1

Caution for Use 1

B-20NB

B-20NB 1 set

Abrasive Belt Z76#60×20 2 (one of them

mounted)

Abrasive Belt Z76#80×20 1

Abrasive Belt Z76#100×20 1

Abrasive Belt Z76#120×20 1

Hex. Socket Screw Key 4 1

Bushing R1/4×NPT1/4 1

FingerPadSubAss’y 1 set

Pan Head Screw 5×10 1

Pan Head Screw 6×10 1

Convex Shoe 1

Instruction Manual 1

Declaration of Conformity 1

Caution for Use 1

B-30N

B-30N 1 set

Abrasive Belt Z76#60×20 2 (one of them

mounted)

Abrasive Belt Z76#80×20 1

Abrasive Belt Z76#100×20 1

SilencerAss’y 1 set

HandleAss’y 1 set

Hex. Socket Screw Key 4 1

Hex. Socket Screw Key 5 1

Bushing R1/4×NPT1/4 1

Instruction Manual 1

Declaration of Conformity 1

Caution for Use 1

3. AIR SUPPLY

3-1. Air Pressure

AdjustairpressurewiththeAirRegulatortothelevel

appropriate for the pneumatic tool used.

B10N_B20N_B20NB_B30N_E.indd 4 10.7.9 9:30:26 PM

5

Air pressure that is too low fails the Tool to operate

at full capacity.

Air pressure that is too high may cause damage to

the Tool.

3-2. Air Line (Fig.1)

Use a 9.5 mm (3/8”) I.D. Connecting Hose between

the Compressor and the Tool.

Drained water, etc., if flown into the Tool, could

cause Tool failure. Install an Air Filter. between the

Compressor and the Tool.

Air Regulator Oiler

Air Filter

Compressor

Lubrication

Tool 9.5mm (3/8”) I.D.

Hose

Cupla

Fig. 1

3-3. Lubrication

Install an Oiler between the Compressor and the Tool.

Use the machine oil ISO VG-10. Failure to lubricate

as required may result in damage to the Tool. Use of

oil that is too thick will reduce the performance of Tool.

4. PREPARATION

4-1. Fastening The Guard

Caution

● No clearance should be allowed between the

Housing and the Guard. Any clearance, if there

is between them, can cause the Abrasive Belt to

come off, resulting in injury to the operator or

damage to the equipment or both.

YoucansettheGuardatanyangleyoumayndbest

suited for your working posture or the configuration

of workpiece. Once you have placed the Guard at

a desired angle, tighten the Hex. Socket Head Cap

Screw per “A” in Fig. 3 with a Hex. Socket Screw Key.

At that time, carefully fasten the Guard so that there is

no clearance between the Housing and the Guard.

Concava Spring

Convex Bushing

ExhaustCover Concave

Housing

B-30N

Fig.5

4-4.Attaching the Handle (B-30N) (Fig.6 )

Screw the Handle in the side of the Guard.

Handle

B-30N

Fig.6

5. HOW TO OPERATE THE TOOL

Warning

● When sanding, always wear protective glasses

and respiratory protection: Microscopic dust and

abrasive particles that y off the workpiece may

cause eye or respiratory injury or both.

● Before you change or adjust the tool or parts,

always disconnect the air supply hose.

● Never touch the moving parts in operation.

5-1. Start and Stop (Fig. 7)

(1) Check to see that the Throttle Lever is in the OFF

position.

Then connect the hose to the Belt Sander.

(2) B-10N, B-20N, B-20NB

Holding the Belt Sander:

a) Push the Lock Lever down and forward,

b) Grasp the Throttle Lever.

(3) B-30N

Holding the Belt Sander:

a) Push the Lock Lever down and behind,

b) Grasp the Throttle Lever.

The Belt Sander starts running.

(4) W h e n y o u r e l e a s e t h e T h r o t t l e L e v e r, i t

automatically returns to the OFF position.

Fig.2

A

Housing

Guard

Carefully fasten the Guard

sothatthereisnoclearance

between the Housing and

theGuard.

B-10N,B-20N,B-20NB

Fig.3

4-2. Installing The Finger Pad B-20N, B-20NB (Fig.4)

Caution

● Fasten the Finger Pad securely. Failure to do so

may result in injury to the operator or damage to

the equipment or both.

Securely fasten the supplied Finger Pad with two Pan

Head Screws, 5X10 and 6X10, clamping both sides of

the Guard. At that time, the Finger Pad locator should

be on the Guard surface.

PanHeadScrew5X10

PanHead

S

crew

6

x1

0

FingerPad

FingerPadlocator

Guardsurface

B-20N,B-20NB

Fig.4

4-3. How To Fix Silencer (B-30N) (Fig.5)

(a) Insert the Spring into the Exhaust Cover.

(b) Insert the Spring into the concave of the Bushing

PF3/8 of the Belt Sander.

(c) Insert the convex of the Exhaust Cover into the

groove of the Bushing PF3/8.

Guard

B-

30

N

Housing

A

Carefully fasten the

Guardso that there is

no clearance between

the Housing and the

Guard.

B10N_B20N_B20NB_B30N_E.indd 5 10.7.9 9:30:30 PM

6

Concava Spring

Convex Bushing

ExhaustCover Concave

Housing

B-30N

Fig.5

4-4.Attaching the Handle (B-30N) (Fig.6 )

Screw the Handle in the side of the Guard.

Handle

B-30N

Fig.6

5. HOW TO OPERATE THE TOOL

Warning

● When sanding, always wear protective glasses

and respiratory protection: Microscopic dust and

abrasive particles that y off the workpiece may

cause eye or respiratory injury or both.

● Before you change or adjust the tool or parts,

always disconnect the air supply hose.

● Never touch the moving parts in operation.

5-1. Start and Stop (Fig. 7)

(1) Check to see that the Throttle Lever is in the OFF

position.

Then connect the hose to the Belt Sander.

(2) B-10N, B-20N, B-20NB

Holding the Belt Sander:

a) Push the Lock Lever down and forward,

b) Grasp the Throttle Lever.

(3) B-30N

Holding the Belt Sander:

a) Push the Lock Lever down and behind,

b) Grasp the Throttle Lever.

The Belt Sander starts running.

(4) W h e n y o u r e l e a s e t h e T h r o t t l e L e v e r, i t

automatically returns to the OFF position.

Pushdownthelockleverto

unlockthethrottlelever.

LockLever

ThrottleLever

B-10N,B-20N,B-20NB

Fig.7

5-2. Adjusting the Rotation Speed (Fig. 8)

(1) B-10N, B-20N, B-20NB

ToadjusttheRotationSpeed,turntheAdjusting

Lever. It regulates the flow rate of air on which

sanding speed depends.

Turning the Lever upward increases the speed.

The highest speed is available with the Lever set

to the uppermost position.

(2) B-30N

The desired number of rotation between maximum

Rotation Speed and minimum Rotation Speed is

obtained by turning the groove of Valve clockwise

or counter clockwise with screwdriver.

Maximum Rotation Speed

PositionthegrooveofAdjustValvehorizontalto

main body.

Minimum Rotation Speed

Positionthe groove ofAdjust Valvevartical main

body.

Low

AdjustingLever

High

B-10N,B-20N,

B-20NB

AdjustValve

Minimum

Maximum

B-30N

Fig.8

5-3. Tracking Adjustment (Fig. 9)

(1) B-10N, B-20N, B-30N

LoosentheAdjustingScrew,AandB,perFig.9

with a Hex. Socket Screw Key.

ThenusingaHex.SocketScrewKey,Adjustthe

screws so that the Abrasive Belt runs right in the

middle of the Idle Pulley.

Oncetrackingadjustmentismadecorrectly,lock

theAdjustingScrews.

For B-10N, use a Hex. Socket Screw Key 2.

For B-20N, use a Hex. Socket Screw Key 2.5.

For B-20NB, B-30N, use a Hex. Socket Screw

Key 4.

Youneednotmakethistrackingadjustment

Guard

B-

30

N

Housing

A

Carefully fasten the

Guardso that there is

no clearance between

the Housing and the

Guard.

ThrottleLever

LockLever

B-30N

Pullthelocklevertoward

youtounlockthethrottle

lever.

B10N_B20N_B20NB_B30N_E.indd 6 10.7.9 9:30:33 PM

7

when you have an optional 6 mm wide Bracket 6

Assembly (applicable to B-10N only).

(2) B-20NB

Loosen the Hex. Cap Screw, Fig.9 with a Hex.

Socket Screw Key.

Turn the Hex. Socket Head Cap Screw clockwise

or counterclockwise with the accessory Hex.

Socket Screw Key in order to make the abrasive

belt run on the center of the idle pulley.

LoosenAdjusting

S

crewB

AdjustingScrewB

AdjustingScrewA

LoosenAdjustingScrewA

B-10N,B-20N,B-30N

Beltmovement

whenturned

clockwise

Hex.SocketHead

CapScrew

Beltmovement

whenturned

counterclockwise

Clockwise

turn

Counterclockwise

turn

B-20NB

Fig.9

5-4. Sanding Operation

Warning

● Do not press the Abrasive Belt too hard upon the

workpiece. If you do so, the Abrasive Belt may

break.

● When using a non-woven Belt, do not use the

Offset Bracket. If you do so, the Belt may come

Off , causing personal injury.

For deburring operation, an Offset Bracket (optional)

is to be used.

In this application, the Abrasive Belt will be brought

into light contact with the workpiece somewhere in

between the Idle Pulley and Offset Bracket.

For Sanding operation, the Offset Bracket will be

removed and a Shoe will be used.

The Abrasive Belt will be brought into light contact with

the workpiece where the Shoe extends.

5-5. Changing the Abrasive Belt

Caution

● Before servicing, turn the Throttle Lever OFF

and disconnect the hose from the Belt Sander.

● When the Abrasive Belt has an arrow marking on

its inner face, see to it that you set it to the same

direction in which the Belt Sander turns (there is

a marking on the Guard), as well. It is dangerous

to mount it wrong way for the Abrasive Belt may

break prematurely.

● Do not press the Push Button without a Abrasive

Belt mounted unless it is absolutely necessary

to do so, for it may cause equipment failure.

● When changing the Abrasive Belt, remove dust

and abrasive particles from the Drive Pulley area

by air blow, etc.

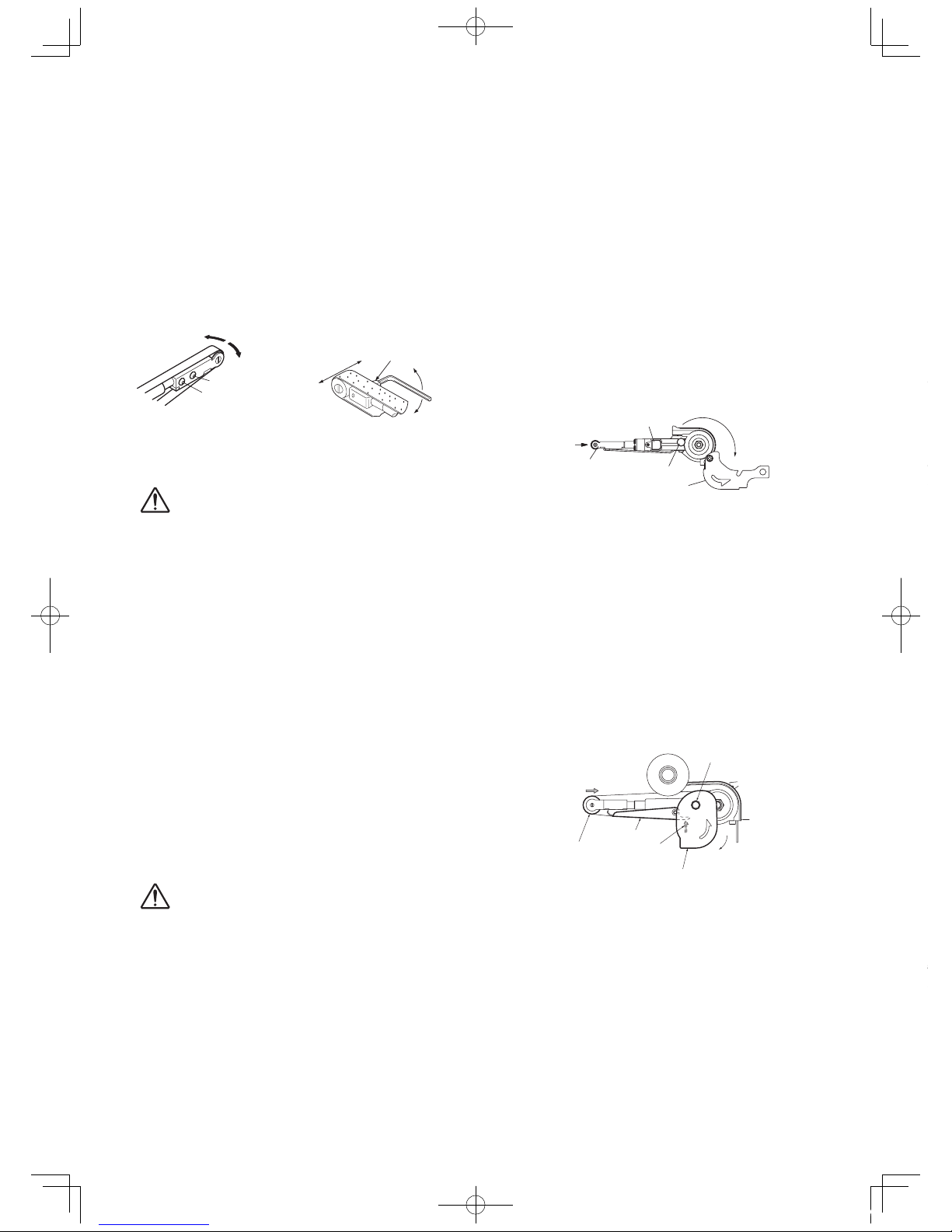

a) B-10N, B-20N, B-20NB (Fig.10)

1) Loosen the Decorative Screw and turn the Belt

Cover.

2) Keep pushing the Idle Pulley until the Tension

Bar locks.

3) Change the Abrasive Belt with a new one.

Press the Push Button to release Tension Bar

locking.

4) Turn the Belt Cover to get it back to where it

was. Tighten the Decorative Screw.

BeltCover

IdlePulley

PushtheIdlePulley

inthedirection

ofarrow

PushButton

DecorativeScrew

B-10N,B-20N,B-20NB

Fig.10

b) B-30N (Fig.11)

1) Loosen the Decorative Screw and turn the Belt

Cover.

2) Keep pushing the Idle Pulley until the Tension

Bar locks.

3) Change the Abrasive Belt with a new one.

Press the Shoe to release Tension Bar locking.

4) Turn the Belt Cover to get it back to where it

was. Tighten the Decorative Screw.

DecorativeScrew

Shoe

PushtheShoein

thedirection

ofarrow

PuttheIdlePulley

inthedirection

ofarrow

BeltCover

IdlePulley Rotation

B-30N

Fig.11

5-6. Offset Bracket (Optional)

The Offset Bracket is designed to utilize the spring

action of Abrasive Belt, facilitating light-duty sanding

applications, such as contoured surface sanding,

deburring, etc.

a) B-10N, B-20N, B-20NB (Fig.12)

You do not need tools for mounting or removal of

the Offset Bracket.

1) Following the same procedure as Abrasive Belt

replacement, remove the Abrasive Belt.

2) Insert the Offset Bracket into the lower part of

the Guard.

3) Install the Abrasive Belt and Belt Cover.

b) B-30N (Fig.13)

1) Following the same procedure as Abrasive Belt

replacement, remove the Abrasive Belt.

2) Remove the Shoe and mount the Offset Bracket

Ass'y. For removal, refer to 5-8 Replacing the

Shoe.

3) Install the Abrasive Belt and Belt Cover.

Insert

OffsetBracket

B-10N,B-20N,B-20NB

Fig.12 Fig.13

5-7. Replacing the Shoe

a) B-10N, B-20N, B-20NB (Fig.14)

Remove the Shoe by loosening Pan Head Screw

and replace the Shoe.

PanHeadScrew

Shoe

B-10N,B-20N,B-20NB

Fig.14

b) B-30N (Fig.15)

Remove the Belt Cover, Loosen 2pcs, of the M6

cross-recessed Pan Head Screws with a screwdriver

and replace the Shoe.

M6PanHeadScrew

Shoe

M6PanHeadScrew

B-30N

Fig.15

5-8. Replacing the Tension Bar

a) B-10N, B-20N, B-20NB (Figs.16 and 17)

1) Remove the Abrasive Belt.

Press the Push Button.

The Tension Bar will be unlocked.

2) Turn the Tension Bar 90° and pull it off in the

direction of arrow.

(See Fig.16 for B-10N)

B10N_B20N_B20NB_B30N_E.indd 7 10.7.9 9:30:37 PM

8

to do so, for it may cause equipment failure.

● When changing the Abrasive Belt, remove dust

and abrasive particles from the Drive Pulley area

by air blow, etc.

a) B-10N, B-20N, B-20NB (Fig.10)

1) Loosen the Decorative Screw and turn the Belt

Cover.

2) Keep pushing the Idle Pulley until the Tension

Bar locks.

3) Change the Abrasive Belt with a new one.

Press the Push Button to release Tension Bar

locking.

4) Turn the Belt Cover to get it back to where it

was. Tighten the Decorative Screw.

BeltCover

IdlePulley

PushtheIdlePulley

inthedirection

ofarrow

PushButton

DecorativeScrew

B-10N,B-20N,B-20NB

Fig.10

b) B-30N (Fig.11)

1) Loosen the Decorative Screw and turn the Belt

Cover.

2) Keep pushing the Idle Pulley until the Tension

Bar locks.

3) Change the Abrasive Belt with a new one.

Press the Shoe to release Tension Bar locking.

4) Turn the Belt Cover to get it back to where it

was. Tighten the Decorative Screw.

DecorativeScrew

Shoe

PushtheShoein

thedirection

ofarrow

PuttheIdlePulley

inthedirection

ofarrow

BeltCover

IdlePulley Rotation

B-30N

Fig.11

5-6. Offset Bracket (Optional)

The Offset Bracket is designed to utilize the spring

action of Abrasive Belt, facilitating light-duty sanding

applications, such as contoured surface sanding,

deburring, etc.

a) B-10N, B-20N, B-20NB (Fig.12)

You do not need tools for mounting or removal of

the Offset Bracket.

1) Following the same procedure as Abrasive Belt

replacement, remove the Abrasive Belt.

2) Insert the Offset Bracket into the lower part of

the Guard.

3) Install the Abrasive Belt and Belt Cover.

b) B-30N (Fig.13)

1) Following the same procedure as Abrasive Belt

replacement, remove the Abrasive Belt.

2) Remove the Shoe and mount the Offset Bracket

Ass'y. For removal, refer to 5-8 Replacing the

Shoe.

3) Install the Abrasive Belt and Belt Cover.

Insert

OffsetBracket

B-10N,B-20N,B-20NB

Fig.12 Fig.13

5-7. Replacing the Shoe

a) B-10N, B-20N, B-20NB (Fig.14)

Remove the Shoe by loosening Pan Head Screw

and replace the Shoe.

PanHeadScrew

Shoe

B-10N,B-20N,B-20NB

Fig.14

b) B-30N (Fig.15)

Remove the Belt Cover, Loosen 2pcs, of the M6

cross-recessed Pan Head Screws with a screwdriver

and replace the Shoe.

M6PanHeadScrew

Shoe

M6PanHeadScrew

B-30N

Fig.15

5-8. Replacing the Tension Bar

a) B-10N, B-20N, B-20NB (Figs.16 and 17)

1) Remove the Abrasive Belt.

Press the Push Button.

The Tension Bar will be unlocked.

2) Turn the Tension Bar 90° and pull it off in the

direction of arrow.

(See Fig.16 for B-10N)

3) Turn the Tension Bar 30° counter-clockwise and

pull it off in the direction of arrow.

(See Fig.17 for B-20N, B-20NB)

4) When reassembling the Tension Bar, assemble

in reverse order.

b) B-30N (Fig.18)

1) Remove the Abrasive Belt, the Belt Cover and

the Shoe.

2)SufcientlyloosentheKeyBoltandpulloffthe

Idle Pulley Bracket.

3)Formounting,adjustthegrooveontheIdle

Pulley Bracket to meet the Key Bolt, insert it

into the Guard, put the tip of Key Bolt into the

grooveandxitsoastheIdlePulleyBracket

not to be pulled off.

Pullitinthedirectionofarrow

Turn90°

TensionBar

PushButton

B-10N

Fig.16

Pullitinthedirectionofarrow

Turn30°

counter-

clockwise

TensionBar

PushButton

B-20N,B-20NB

Fig.17

Pullitinthedirectionofarrow

BracketAssy

KeyBolt

B-30N

Fig.18

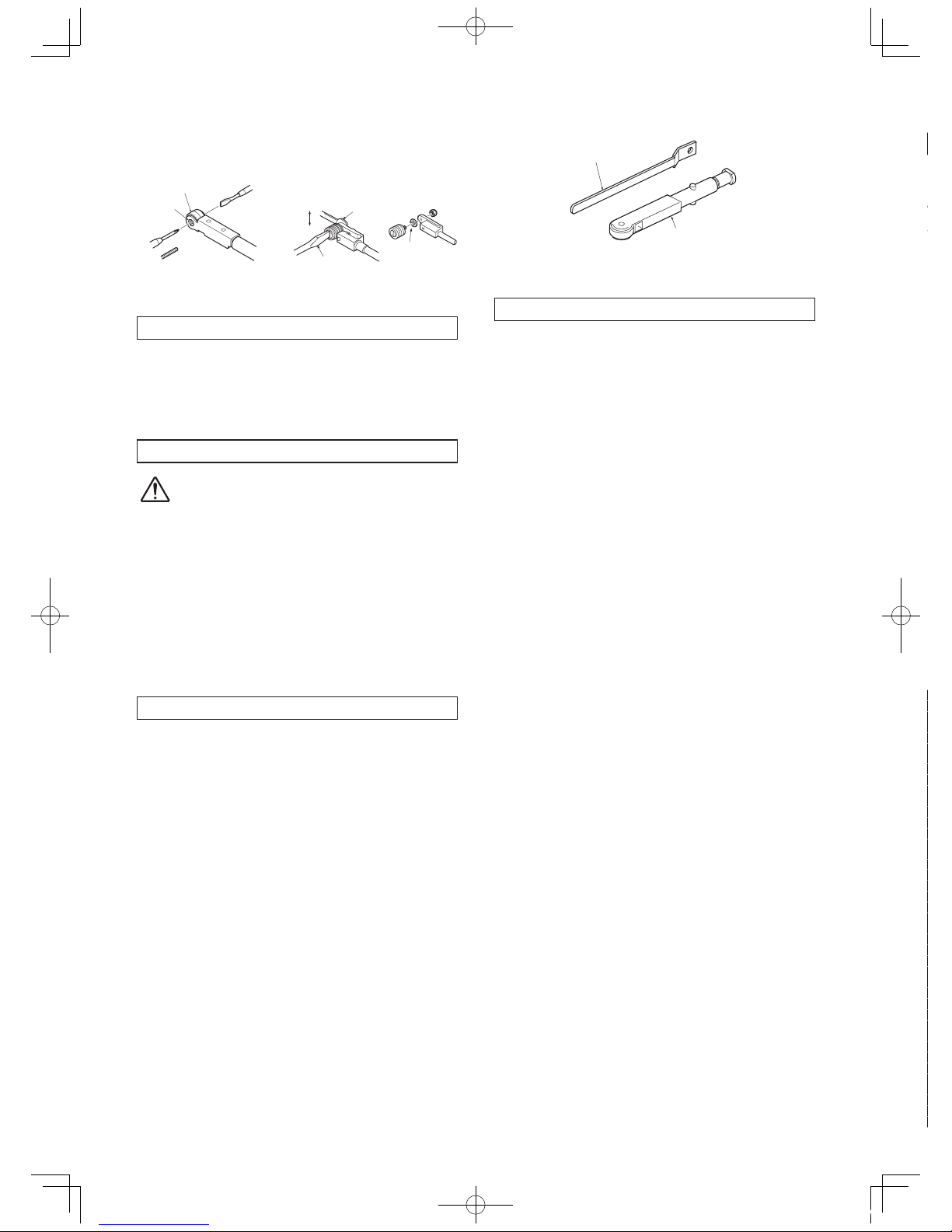

5-9. Replacing the Idle Pulley

(1) B-10N, B-20N, B-30N (Fig.19)

Using a flatblade screwdriver and a Phillips

Screwdriver (for B-10N) or Hex. Socket Screw

Key (for B-20N, B-30N), loosen the Flat Head

Screw and pull the Idle Pulley Shaft off.

(2) B-20NB (Fig.20)

Using a flatblade screwdriver and a Wrench 10,

loosen the Hex. Nut M6 and remove the Idle

B-30N

B10N_B20N_B20NB_B30N_E.indd 8 10.7.9 9:30:39 PM

9

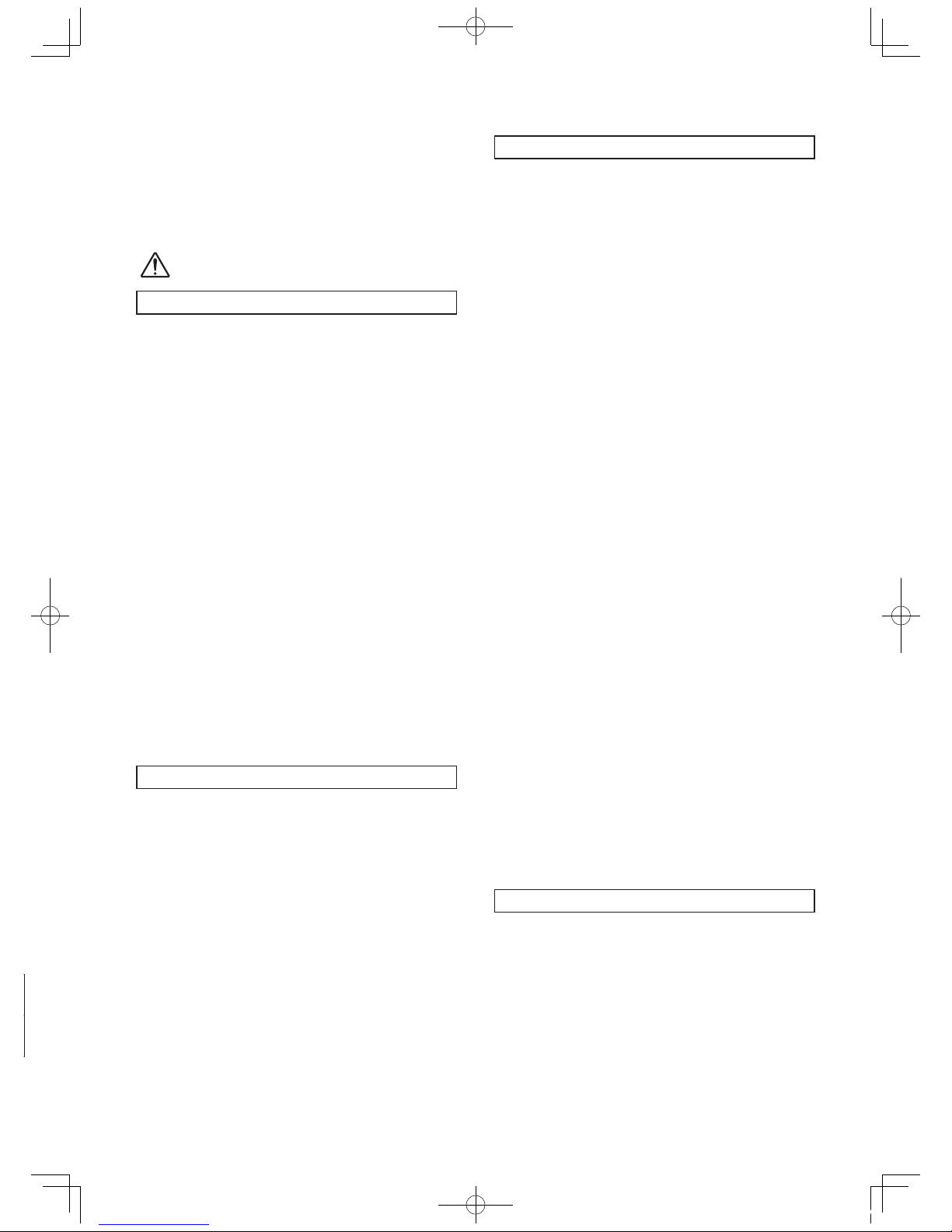

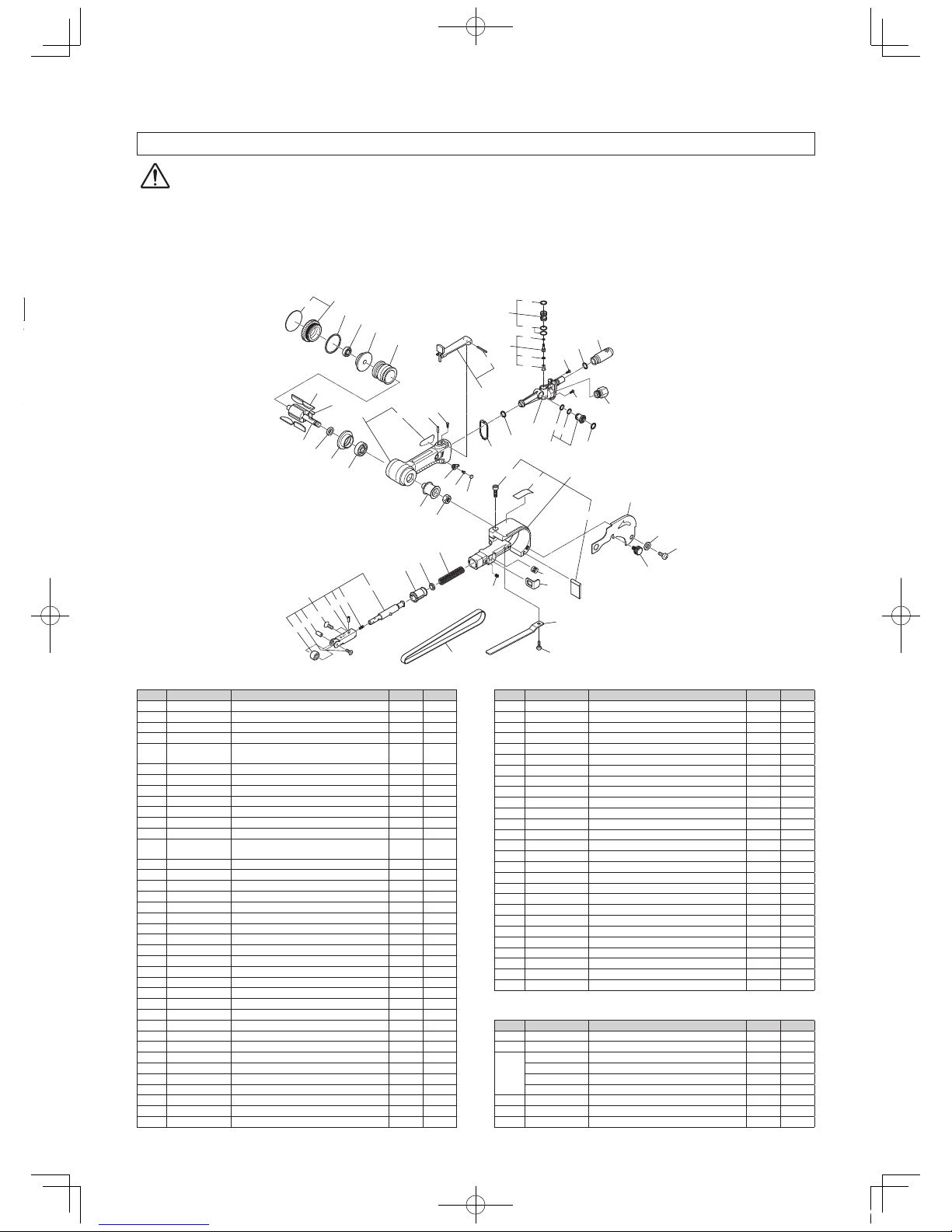

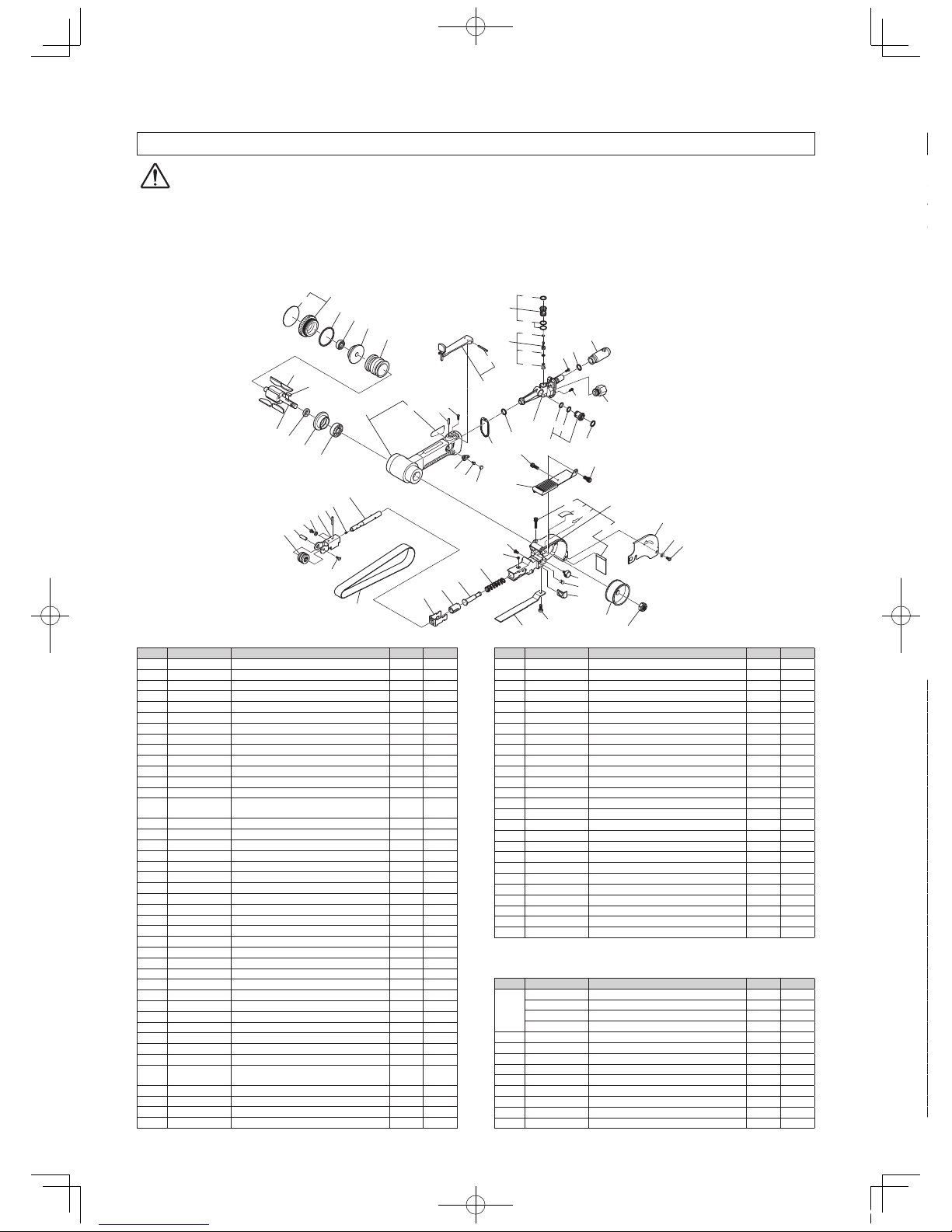

10. EXPLODED DIAGRAM: B-10N

Warning

This diagram is for your reference only. Do not attempt to service or repair the Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

No. Part No. Description Qty Price

1 TB08236 Bracket 10 Ass'y 1set

2 (TA99155) Idle Pulley10 Sub Ass'y 1set

3 (TQ12264) Idle Pulley Shaft10 1

4 (TP14455) Countersunk Head Screw 2X5 1

5 (TQ10725) Hex. Socket Countersunk Head Screw

3X6 2

6 (TB07898) Bracket 10 Sub Ass'y 1set

7 (TP14798) Spring Pin 3X10 AW 1

8 (TQ10526) Tension Bar Spring 1

9 (TB07236) Tension Bar Shaft Ass'y 1set

10 TQ07201 Guard Insert 1

11 TQ10934 Stopper 1

12 TQ10724 Spring 1.2X8.4X34 1

13 TP15643 Hex. Socket Set Screw 4X4 with Flat

Point 1

14 TQ07218 Spring 0.35X7.5X7 1

15 TQ10587 Push Button 1

16 TQ10709 Shoe 10 1

17 TP02618 Pan Head Screw 4X8 1

18 TB07294 Guard Sub Ass'y B 1set

19 (TP08646) Hex. Socket Head Cap Screw 5X14 1

20 (TP16361) Label Caution 1

21 (TQ10710) Dust Cover 1

22 TQ10711 Belt Cover 10 1

23 TQ10712 Decorative Screw 1

24 TP00144 Washer M4 1

25 TP12819 Pan Head Screw 4X6 1

26 TP14916 Drive Pulley 1

27 TP01924 Hex. Nut M6 1

28 TB08629 Cap Ass'y 1set

29 (TQ12644) Label Model B-10N 1

30 TP05531 O-ring S-36 1

31 TP06386 Ball Bearing 607ZZ 1

32 TP12414 End Plate A 1

33 TP12415 Cylinder 1

34 TA9A364 Blade Ass'y (4pcs/set) 1set

35 TP10130 Parallel Key Both Ends Round 3X3X10 1

36 TP12416 Rotor 1

37 TP06322 Spacer 8X11X3 1

38 TP12418 End Plate B 1

PulleyBAss’y.WhenmountingtheIdlePulleyB

Ass’y,assenbleinreverseorder.

FlatHeadScrew

or

IdlePulley

B-10N,B-20N,B-30N

Loosen Wrench

Screwdriver

Usea

spacerhere.

Tighten

B-20NB

Fig.19 Fig.20

6. THREAD SIZE OF HOSE FITTING

TheproductcomeswithametalttingwithR(metric)

thread. Connect the Bushing R thread × NPT thread in

the vinyl bag containing standard accessories, if you

would like to have American NPT thread instead.

7. STORAGE

Caution

● When tool is not used, store it out of reach of

children.

Avoidstoringthetoolinalocationsubjecttohigh

humidity. If the tool is left as it is used, residual

moisture on the inside can cause rusting. Before

storing, and after operation, oil the tool at the air inlet

with machine oil ISO VG-10 and run it for a short time.

8. OPTIONAL PARTS

In addition to various kinds or grain sizes of abrasive

materials and Sanding Belts, we have the following

optionalitemstomeetyourdiversiedneeds.

(1) Bracket6Ass’y(TB07283)forB-10N…..foruse

with our narrow belt 6 mm in width, best suited for

corner grinding or grinding in a narrow space. (Fig.

21)

For mounting and removal, see 5-9 Replacing the

Tension Bar.

(2) Offset Bracket Assembly

OffsetBracket10Ass’y(TB05539)forB-10N

OffsetBracket20Ass’y(TB07109)forB-20N,

B-20NB

OffsetBracket30Ass’y(TB08150)forB-30N

Shoe6(TQ10942)

Bracket6Assy(TB07283)

Fig.21

9. ORDERING SERVICE PARTS

For further operational and handling information or

for replacement of parts and components, contact the

company from whom you purchased the tool or an

authorized dealer.

In ordering parts and components give each part

number, part name and quantity required.

Use only NITTO genuine parts.

B10N_B20N_B20NB_B30N_E.indd 9 10.7.9 9:30:43 PM

10

10. EXPLODED DIAGRAM: B-10N

Warning

This diagram is for your reference only. Do not attempt to service or repair the Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

The parts numbers with ( ) are included in the Ass'y parts written above them.

No. Part No. Description Qty Price

1 TB08236 Bracket 10 Ass'y 1set

2 (TA99155) Idle Pulley10 Sub Ass'y 1set

3 (TQ12264) Idle Pulley Shaft10 1

4 (TP14455) Countersunk Head Screw 2X5 1

5 (TQ10725) Hex. Socket Countersunk Head Screw

3X6 2

6 (TB07898) Bracket 10 Sub Ass'y 1set

7 (TP14798) Spring Pin 3X10 AW 1

8 (TQ10526) Tension Bar Spring 1

9 (TB07236) Tension Bar Shaft Ass'y 1set

10 TQ07201 Guard Insert 1

11 TQ10934 Stopper 1

12 TQ10724 Spring 1.2X8.4X34 1

13 TP15643 Hex. Socket Set Screw 4X4 with Flat

Point 1

14 TQ07218 Spring 0.35X7.5X7 1

15 TQ10587 Push Button 1

16 TQ10709 Shoe 10 1

17 TP02618 Pan Head Screw 4X8 1

18 TB07294 Guard Sub Ass'y B 1set

19 (TP08646) Hex. Socket Head Cap Screw 5X14 1

20 (TP16361) Label Caution 1

21 (TQ10710) Dust Cover 1

22 TQ10711 Belt Cover 10 1

23 TQ10712 Decorative Screw 1

24 TP00144 Washer M4 1

25 TP12819 Pan Head Screw 4X6 1

26 TP14916 Drive Pulley 1

27 TP01924 Hex. Nut M6 1

28 TB08629 Cap Ass'y 1set

29 (TQ12644) Label Model B-10N 1

30 TP05531 O-ring S-36 1

31 TP06386 Ball Bearing 607ZZ 1

32 TP12414 End Plate A 1

33 TP12415 Cylinder 1

34 TA9A364 Blade Ass'y (4pcs/set) 1set

35 TP10130 Parallel Key Both Ends Round 3X3X10 1

36 TP12416 Rotor 1

37 TP06322 Spacer 8X11X3 1

38 TP12418 End Plate B 1

No. Part No. Description Qty Price

39 TP12419 Ball Bearing 628ZZ 1

40 TB08626 Housing Sub Ass'y 1set

41 (TQ12650) Label Warning 1

42 TQ11724 Parallel Pin 3X16 1

43 TQ11560 Tapping Screw 3X8 3

44 TB07709 Lever Ass'y 1set

45 (TP13893) Spring Pin 3X22AW 1

46 TQ11554 AdjustLever 1

47 TP08598 Pan Head Screw 3X5 1

48 TQ11626 Lever Cap 1

49 TQ11555 Packing 1

50 CQ14480 O-ring JASO-1010 1

51 TB08078 Air Inlet Sub Ass'y 1set

52 TB07938 Throttle Valve Ass'y 1set

53 (TP14604) O-ring S-10 1

54 (TP12569) O-ring S-11.2 2

55 TB07708 Valve Stem Ass'y 1set

56 (TQ10395) O-ringSS-2.5 1

57 (TP11994) O-ringP-4 1

58 (TP03769) Valve Spring 1

59 TB07937 AdjustValveAss'y 1set

60 (CQ25954) O-ring AS568-012 1

61 (CQ05860) O-ring AS568-013 1

62 (CP24969) O-ring JASO-1011 1

63 TP07031 O-ring S-8 1

64 TB08079 Silencer Ass'y 1set

65 TP00857 Bushing M16XRc1/4 1

Accessories

No. Part No. Description Qty Price

TP01939 Hex. Socket Screw Key 4 1

TP13892 Hex. Socket Screw Key 2 1

66

TP16597 Abrasive Belt Z76XN #60X10 2

TQ00109 Abrasive Belt Z76XN #80X10 1

TQ00110 Abrasive Belt Z76 #100X10 1

TQ00352 Abrasive Belt Z76 #120X10 1

TP02236 Bushing R1/4XNPT1/4 1

TQ12660 Instruction Manual 1

TQ12617 Declaration of Conformity 1

46

26

24

5

1

678

9

10

11

12

13

17

16

15

14

66

3

27

42 43

44

49

50

51 60

59

18

19

20

21

22

24

25

23

62

43

65

43

63

64

58

57

56

54

53

52

45

40 41

39

38

37

36

35

34

29 28

32

31

30

33

47

48

MODELB-10NASSY 2008/4/22

2008/8/18

61

55

Shoe6(TQ10942)

Bracket6Assy(TB07283)

Fig.21

9. ORDERING SERVICE PARTS

For further operational and handling information or

for replacement of parts and components, contact the

company from whom you purchased the tool or an

authorized dealer.

In ordering parts and components give each part

number, part name and quantity required.

Use only NITTO genuine parts.

B10N_B20N_B20NB_B30N_E.indd 10 10.7.9 9:30:45 PM

11

11. EXPLODED DIAGRAM: B-20N

Warning

This diagram is for your reference only. Do not attempt to service or repair the Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

No. Part No. Description Qty Price

43 TB08627 Housing Sub Ass'y 1set

44 (TQ12650) Label Warning 1

45 TQ11724 Parallel Pin 3X16 1

46 TQ11560 Tapping Screw 3X8 3

47 TB07709 Lever Ass'y 1set

48 (TP13893) Spring Pin 3X22AW 1

49 TQ11554 AdjustLever 1

50 TP08598 Pan Head Screw3X5 1

51 TQ11626 Lever Cap 1

52 TQ11555 Packing 1

53 CQ14480 O-ring JASO-1010 1

54 TQ11551 Air Inlet 1

55 TB07938 Throttle Valve Ass'y 1set

56 (TP14604) O-ring S-10 1

57 (TP12569) O-ring S-11.2 2

58 TB07708 Valve Stem Ass'y 1set

59 (TQ10395) O-ring SS-2.5 1

60 (TP11994) O-ring P-4 1

61 (TP03769) Valve Spring 1

62 TB07937 AdjustValveAss'y 1set

63 (CQ25954) O-ring AS568-012 1

64 (CQ05860) O-ring AS568-013 1

65 (CP24969) O-ring JASO-1011 1

66 TP07031 O-ring S-8 1

67 TQ11558 Silencer 1

68 TP00857 Bushing M16XRc1/4 1

Accessories

No. Part No. Description Qty Price

69

TP15867 Abrasive Belt Z76X #60X20 2

TP15868 Abrasive Belt Z76X #80X20 1

TP15869 Abrasive Belt Z76X #100X20 1

TP15870 Abrasive Belt Z76X #120X20 1

70 TB07908 Finger Pad Sub Ass'y 1set

71 (TP00051) Pan Head Screw 5X10 1

72 (TP02419) Pan Head Screw 6X10 1

TP04305 Hex. Socket Screw Key 2.5 1

TP01939 Hex. Socket Screw Key 4 1

TQ11686 Convex Shoe 1

TP02236 Bushing R1/4XNPT1/4 1

TQ12660 Instruction Manual 1

TQ12617 Declaration of Conformity 1

No. Part No. Description Qty Price

1 TA99885 Idle Pulley A Sub Ass'y 1set

2 TQ11616 Idle Pulley Shaft 1

3 TP16219 Hex. Countersunk Head Screw 4X10 1

4 TQ11400 Hex. Socket Button Head Screw4X8 2

5 TQ12197 Toothed Lock Washer AW-4 2

6 TB07747 Bracket Sub Ass'y A 1set

7 TP03544 Spring Pin3X16 AW 1

8 TQ10526 Tension Bar Spring 1

9 TB07777 Tension Bar Shaft Ass'y 1set

10 TQ11610 Stopper 1

11 TQ11609 Guard Insert 1

12 TQ11620 Push Rod 1

13 TQ11621 Spring1.6X11X45 1

14 TQ12196 Hex. Socket Set Screw 4X5 with Cup

Point 1

15 TQ11659 Hex. Socket Button Head Screw 3X6 1

16 TQ11611 Shoe 1

17 TQ11660 Pan Head Screw 5X6 1

18 TQ10712 Decorative Screw 1

19 TQ07218 Spring 0.35X7.5X7 1

20 TQ11622 Push Button 1

21 TB08068 Guard Sub Ass'y B 1set

22 (TP04532) Hex. Socket Head Cap Screw 5X30 1

23 (TP16361) Label Caution 1

24 (TP16360) Label Rotation 1

25 (TP16207) Dust Cover 1

26 TQ11618 Belt Cover 1

27 TP00144 Washer M4 1

28 TP12819 Pan Head Screw4X6 1

29 TQ11617 Drive Pulley 1

30 TP01918 Hex. Nut M10 1

31 TB08630 Cap Ass'y 1set

32 (TQ12645) Label Model B-20N 1

33 CQ04413 O-ring S-38 1

34 TP00468 Ball Bearing 608ZZ 1

35 TP01907 End Plate A 1

36 TP10000 Cylinder 1

37 TA9A212 Blade Ass'y(4pcs/set) 1set

38 TP00502 Parallel Key Both Ends Round

4X4X9.5 1

39 TP01909 Rotor 1

40 TP01912 Spacer 1

41 TP01911 End Plate B 1

42 TP01913 Ball Bearing 6000ZZ 1

9

8

7

6

45

2

69

10

11

12

1

3

13

MODELB-20NASSY 2008/4/22

2008/8/26

16 17

20

29

28

27

26

30

19

18

14

15

22 23 21

25

70

71

72

49

45 46

47

52

53

54 63

62 65

46

68

46 66

67

61

60

59

57

56

55

48

43 44

42

41

40

39

38

37

32

31

35

34

33

36

50

51

64

58

24

12. EXPLODED DIAGRAM: B-20NB

Warning

This diagram is for your reference only. Do not attempt to service or repair the Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

No. Part No. Description Qty Price

73 TB08336 Idle Pulley Bracket Sub Ass'y 1set

74 TA90514 Idle Pulley B Ass'y 1set

10 TQ11610 Stopper 1

11 TQ11609 Guard Insert 1

12 TQ11620 Push Rod 1

13 TQ11621 Spring1.6X11X45 1

14 TQ12196 Hex. Socket Set Screw 4X5 with Cup

Point 1

15 TQ11659 Hex. Socket Button Head Screw 3X6 1

16 TQ12411 Shoe 1

17 TQ11660 Pan Head Screw 5X6 1

18 TQ10712 Decorative Screw 1

19 TQ07218 Spring 0.35X7.5X7 1

20 TQ11622 Push Button 1

21 TB08068 Guard Sub Ass'y B 1set

22 (TP04532) Hex. Socket Head Cap Screw 5X30 1

23 (TP16361) Label Caution 1

24 (TP16360) Label Rotation 1

25 (TP16207) Dust Cover 1

26 TQ11618 Belt Cover 1

27 TP00144 Washer M4 1

28 TP12819 Pan Head Screw4X6 1

29 TQ11617 Drive Pulley 1

30 TP01918 Hex. Nut M10 1

31 TB08579 Cap Ass'y 1set

32 (TQ12604) Label Model B-20NB 1

33 CQ04413 O-ring S-38 1

34 TP00468 Ball Bearing 608ZZ 1

35 TP01907 End Plate A 1

36 TP10000 Cylinder 1

37 TA9A212 Blade Ass'y(4pcs/set) 1set

38 TP00502 Parallel Key Both Ends Round

4X4X9.5 1

39 TP01909 Rotor 1

40 TP01912 Spacer 1

41 TP01911 End Plate B 1

42 TP01913 Ball Bearing 6000ZZ 1

43 TB08627 Housing Sub Ass'y 1set

44 (TQ12650) Label Warning 1

45 TQ11724 Parallel Pin 3X16 1

The parts numbers with ( ) are included in the Ass'y parts written above them.

B10N_B20N_B20NB_B30N_E.indd 11 10.7.9 9:30:47 PM

12

11. EXPLODED DIAGRAM: B-20N

Warning

This diagram is for your reference only. Do not attempt to service or repair the Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

No. Part No. Description Qty Price

43 TB08627 Housing Sub Ass'y 1set

44 (TQ12650) Label Warning 1

45 TQ11724 Parallel Pin 3X16 1

46 TQ11560 Tapping Screw 3X8 3

47 TB07709 Lever Ass'y 1set

48 (TP13893) Spring Pin 3X22AW 1

49 TQ11554 AdjustLever 1

50 TP08598 Pan Head Screw3X5 1

51 TQ11626 Lever Cap 1

52 TQ11555 Packing 1

53 CQ14480 O-ring JASO-1010 1

54 TQ11551 Air Inlet 1

55 TB07938 Throttle Valve Ass'y 1set

56 (TP14604) O-ring S-10 1

57 (TP12569) O-ring S-11.2 2

58 TB07708 Valve Stem Ass'y 1set

59 (TQ10395) O-ring SS-2.5 1

60 (TP11994) O-ring P-4 1

61 (TP03769) Valve Spring 1

62 TB07937 AdjustValveAss'y 1set

63 (CQ25954) O-ring AS568-012 1

64 (CQ05860) O-ring AS568-013 1

65 (CP24969) O-ring JASO-1011 1

66 TP07031 O-ring S-8 1

67 TQ11558 Silencer 1

68 TP00857 Bushing M16XRc1/4 1

Accessories

No. Part No. Description Qty Price

69

TP15867 Abrasive Belt Z76X #60X20 2

TP15868 Abrasive Belt Z76X #80X20 1

TP15869 Abrasive Belt Z76X #100X20 1

TP15870 Abrasive Belt Z76X #120X20 1

70 TB07908 Finger Pad Sub Ass'y 1set

71 (TP00051) Pan Head Screw 5X10 1

72 (TP02419) Pan Head Screw 6X10 1

TP04305 Hex. Socket Screw Key 2.5 1

TP01939 Hex. Socket Screw Key 4 1

TQ11686 Convex Shoe 1

TP02236 Bushing R1/4XNPT1/4 1

TQ12660 Instruction Manual 1

TQ12617 Declaration of Conformity 1

12. EXPLODED DIAGRAM: B-20NB

Warning

This diagram is for your reference only. Do not attempt to service or repair the Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

No. Part No. Description Qty Price

46 TQ11560 Tapping Screw 3X8 3

47 TB07709 Lever Ass'y 1set

48 (TP13893) Spring Pin 3X22AW 1

49 TQ11554 AdjustLever 1

50 TP08598 Pan Head Screw3X5 1

51 TQ11626 Lever Cap 1

52 TQ11555 Packing 1

53 CQ14480 O-ring JASO-1010 1

54 TQ11551 Air Inlet 1

55 TB07938 Throttle Valve Ass'y 1set

56 (TP14604) O-ring S-10 1

57 (TP12569) O-ring S-11.2 2

58 TB07708 Valve Stem Ass'y 1set

59 (TQ10395) O-ring SS-2.5 1

60 (TP11994) O-ring P-4 1

61 (TP03769) Valve Spring 1

62 TB07937 AdjustValveAss'y 1set

63 (CQ25954) O-ring AS568-012 1

64 (CQ05860) O-ring AS568-013 1

65 (CP24969) O-ring JASO-1011 1

66 TP07031 O-ring S-8 1

67 TQ11558 Silencer 1

68 TP00857 Bushing M16XRc1/4 1

Accessories

No. Part No. Description Qty Price

69

TP15867 Abrasive Belt Z76X #60X20 2

TP15868 Abrasive Belt Z76X #80X20 1

TP15869 Abrasive Belt Z76X #100X20 1

TP15870 Abrasive Belt Z76X #120X20 1

70 TB07908 Finger Pad Sub Ass'y 1set

71 (TP00051) Pan Head Screw 5X10 1

72 (TP02419) Pan Head Screw 6X10 1

TP01939 Hex. Socket Screw Key 4 1

TQ11686 Convex Shoe 1

TP02236 Bushing R1/4XNPT1/4 1

TQ12660 Instruction Manual 1

TQ12617 Declaration of Conformity 1

No. Part No. Description Qty Price

73 TB08336 Idle Pulley Bracket Sub Ass'y 1set

74 TA90514 Idle Pulley B Ass'y 1set

10 TQ11610 Stopper 1

11 TQ11609 Guard Insert 1

12 TQ11620 Push Rod 1

13 TQ11621 Spring1.6X11X45 1

14 TQ12196 Hex. Socket Set Screw 4X5 with Cup

Point 1

15 TQ11659 Hex. Socket Button Head Screw 3X6 1

16 TQ12411 Shoe 1

17 TQ11660 Pan Head Screw 5X6 1

18 TQ10712 Decorative Screw 1

19 TQ07218 Spring 0.35X7.5X7 1

20 TQ11622 Push Button 1

21 TB08068 Guard Sub Ass'y B 1set

22 (TP04532) Hex. Socket Head Cap Screw 5X30 1

23 (TP16361) Label Caution 1

24 (TP16360) Label Rotation 1

25 (TP16207) Dust Cover 1

26 TQ11618 Belt Cover 1

27 TP00144 Washer M4 1

28 TP12819 Pan Head Screw4X6 1

29 TQ11617 Drive Pulley 1

30 TP01918 Hex. Nut M10 1

31 TB08579 Cap Ass'y 1set

32 (TQ12604) Label Model B-20NB 1

33 CQ04413 O-ring S-38 1

34 TP00468 Ball Bearing 608ZZ 1

35 TP01907 End Plate A 1

36 TP10000 Cylinder 1

37 TA9A212 Blade Ass'y(4pcs/set) 1set

38 TP00502 Parallel Key Both Ends Round

4X4X9.5 1

39 TP01909 Rotor 1

40 TP01912 Spacer 1

41 TP01911 End Plate B 1

42 TP01913 Ball Bearing 6000ZZ 1

43 TB08627 Housing Sub Ass'y 1set

44 (TQ12650) Label Warning 1

45 TQ11724 Parallel Pin 3X16 1

69

10

11

12

13

MODELB-20NASSY 2008/4/22

2008/8/26

16 17

20

29

28

27

26

30

19

18

14

15

2223 21

25

70

71

72

49

45

46

47

52

53

54 63

62 65

46

68

4666

67

61

60

59

57

56

55

48

43 44

42

41

40

39

38

37

32

31

35

34

33

36

50

51

64

58

24

73

74

The parts numbers with ( ) are included in the Ass'y parts written above them.

B10N_B20N_B20NB_B30N_E.indd 12 10.7.9 9:30:49 PM

13

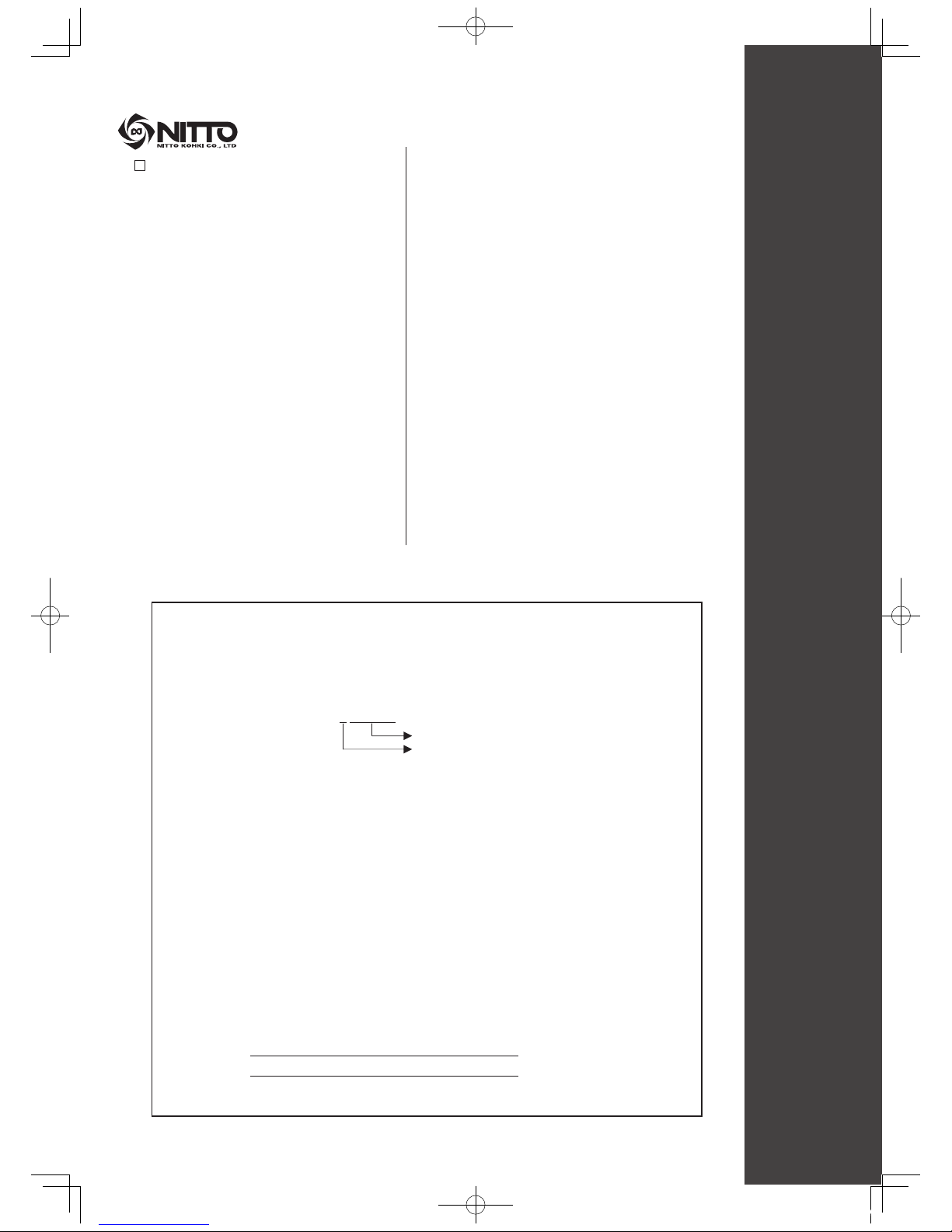

13. EXPLODED DIAGRAM: B-30N

Warning

This diagram is for your reference only. Do not attempt to service or repair the Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

MODELB-30NASSY 2008/8/18

2010/6/26

30

31

29

33

1

2

5

6

7

8

3

9

10

11

12

13

15

17

16

18 19 20

21

18

22

23

24

25

26

27

28

32

34

35 37

36 38

3940

41

42

43

46

44 45

47

48

49

50

51

52

53

54

55

57

34

4

14

No. Part No. Description Qty Price

1 TB08170 Idle Pulley A Ass'y 1set

2 TQ11792 Idle Pulley Shaft 1

3 TP16219 Hex. Countersunk Head Screw 4X10 1

4 TB08028 Bracket Sub Ass'y 1set

5 TP07577 Spring Pin 4X16 AW 1

6 TP08646 Hex.Cap Screw 5X14 2

7 TQ12215 Toothed Lock Washer AW-5 2

8 TQ10526 Tension Bar Spring 1

9 TQ11793 Tension Bar 1

10 TQ11881 Flat Shoe 1

11 TQ11794 Spring1.4X7.2X110 1

12 TQ11838 Spring Guide 1

13 TB08171 Guard Sub Ass'y B 1set

14 (TP16360) Label Rotation 1

15 (TP16361) Label Caution 1

16 (TP04060) Dust Cover 1

17 (TP04073) Hex.Cap Screw 6X35 1

18 TP08132 Pan Head Screw 6X8 2

19 TA92254 Key Bolt Ass'y 1set

20 TQ11810 Shoe Spring 1

21 TQ11997 Parallel Pin 5X16 1

22 TQ02418 Decorative Screw 5X10 1

23 TQ11797 Belt Cover 1

24 TQ04426 Nylon Washer 1

25 TP04077 Hex.Nut M12X1.5 1

26 TQ11807 Drive Pulley 1set

27 TP04058 Thrust Washer B 36.2X62X1 1

28 TP06290 Pan Head Screw 4X 8 1

29 TB01793 Throttle Lever Ass'y 1set

30 (TP00460) Spring Pin 3X22 AW 1

31 (TP05498) Spring Pin 2X16 AW 1

32 TB08628 Housing Sub Ass'y 1set

33 (TQ12656) Label Warning 1

34 TP00498 Ball Bearing 6001ZZ 2

No. Part No. Description Qty Price

35 TQ11986 Hex. Countersunk Head Screw 4X8 2

36 TP04061 SpringPin 3X 6 AW 1

37 TQ11801 Lower Bearing Case 1

38 TP04036 Spacer 1

39 TP04032 Rotor 1

40 TP00502 Parallel Key Both Ends Round 4X4X9.5 1

41 TA9A215 Blade Ass'y (5pcs/set) 1set

42 TP04031 Cylinder 1

43 TP04035 Upper Bearing Case 1

44 TB08631 Cap Ass'y 1set

45 (TQ12646) Label Model 1

46 TQ11806 O-Ring AS568A-034 1

47 TA93925 Valve Stem Ass'y 1set

48 TP12405 AdjustValve 1

49 TP12407 O-Ring S- 15 1

50 TP12406 Spacer 10.5X17.9X1.6 1

51 CP00987 Internal Retaining Ring C- 18 1

52 TP10005 Bushing PF 3/8 1

53 TA96323 Silencer Ass'y 1set

54 TP00857 Bushing M16XRc1/4 1

Accessories

No. Part No. Description Qty Price

55 TB08248 Handle Ass'y 1set

TP01939 Hex. Socket Screw Key 4 1

57

TQ00358 Abrasive Belt Z76X # 60X30 2

TQ00359 Abrasive Belt Z76X # 80X30 1

TQ00360 Abrasive Belt Z76X #100X30 1

TP02236 Bushing R1/4XNPT1/4 1

TP04004 Hex. Socket Screw Key 5 1

TQ12660 Instruction Manual 1

TQ12617 Declaration of Conformity 1

The parts numbers with ( ) are included in the Ass'y parts written above them.

B10N_B20N_B20NB_B30N_E.indd 13 10.7.9 9:30:51 PM

13. EXPLODED DIAGRAM: B-30N

Warning

This diagram is for your reference only. Do not attempt to service or repair the Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

MODELB-30NASSY 2008/8/18

2010/6/26

30

31

29

33

1

2

5

6

7

8

3

9

10

11

12

13

15

17

16

18 19 20

21

18

22

23

24

25

26

27

28

32

34

35 37

36 38

3940

41

42

43

46

44 45

47

48

49

50

51

52

53

54

55

57

34

4

14

No. Part No. Description Qty Price

35 TQ11986 Hex. Countersunk Head Screw 4X8 2

36 TP04061 SpringPin 3X 6 AW 1

37 TQ11801 Lower Bearing Case 1

38 TP04036 Spacer 1

39 TP04032 Rotor 1

40 TP00502 Parallel Key Both Ends Round 4X4X9.5 1

41 TA9A215 Blade Ass'y (5pcs/set) 1set

42 TP04031 Cylinder 1

43 TP04035 Upper Bearing Case 1

44 TB08631 Cap Ass'y 1set

45 (TQ12646) Label Model 1

46 TQ11806 O-Ring AS568A-034 1

47 TA93925 Valve Stem Ass'y 1set

48 TP12405 AdjustValve 1

49 TP12407 O-Ring S- 15 1

50 TP12406 Spacer 10.5X17.9X1.6 1

51 CP00987 Internal Retaining Ring C- 18 1

52 TP10005 Bushing PF 3/8 1

53 TA96323 Silencer Ass'y 1set

54 TP00857 Bushing M16XRc1/4 1

Accessories

No. Part No. Description Qty Price

55 TB08248 Handle Ass'y 1set

TP01939 Hex. Socket Screw Key 4 1

57

TQ00358 Abrasive Belt Z76X # 60X30 2

TQ00359 Abrasive Belt Z76X # 80X30 1

TQ00360 Abrasive Belt Z76X #100X30 1

TP02236 Bushing R1/4XNPT1/4 1

TP04004 Hex. Socket Screw Key 5 1

TQ12660 Instruction Manual 1

TQ12617 Declaration of Conformity 1

B10N_B20N_B20NB_B30N_E.indd 14 10.7.9 9:30:52 PM

■Overseas Affiliates / Offices

Nitto Kohki U.S.A ., Inc.

4525 Turnberry Drive, Hanover Park, IL 60133, U.S.A

Tel: (1)-630-924-9323 Fax:(1)-630-924-0303

http://www.nittokohki.com/index.html

Nitto Kohki Europe Co., Ltd.

Unit 21, Empire Centre, Imperial Way,

Watford Hertfordshire, WD24 4TS, United Kingdom

Tel: (44)-01923-239668 Fax:(44)-01923-248815

http://www.nitto.co.uk/

Nitto Kohki Deutschland GmbH

Lerchenstr. 47, D-71144 Steinenbronn, Germany

Tel: (49)-7157-22436 Fax:(49)-7157-22437

http://www.nitto-kohki.de/

Nitto Kohki Australia Pty. Ltd.

77 Brandl Street, Eight Mile Plains QLD 4113,

Australia

Tel: (61)-7-3340-4600 Fax:(61)-7-3340-4640

http://www.nitto-australia.com.au/

Nitto Kohki Co., Ltd. Singapore Branch

10 Ubi Crescent #01-62, Ubi Techpark Lobby D,

Singapore 408564

Tel: (65)-6227-5360 Fax:(65)-6227-0192

http://www.nitto-kohki.co.jp/e/nksb/

Nitto Kohki Co., Ltd. Shanghai Representative Office

#1117 Ruijing Building, Maoming South Road,

Shanghai 200020 China

Tel: (86)-21-6415-3935 Fax:(86)-21-6472-6957

http://www.nitto-kohki.cn/

Nitto Kohki Co., Ltd. Shenzhen Representative Office

#0726 International Culture Building, 3039, Shennan

Zhong Rd., FutianDistrict, Shenzhen, 518003 China

Tel: ( 86)-755-8375-2185 Fax:(86)-755-8375-2187

http://www.nitto-kohki.cn/

Nitto Kohki Co., Ltd. Bangkok Representative Office

38Q, House Convent Bldg, 7th Floor, Unit 7A,

Convent Rd, Silom, Bangkok,10500 Thailand

Tel: ( 6 6 ) - 2 -632-0307 Fax:(66)-2-632-0308

http://www.nittobkk.com/eng_index.htm

EC DECLARATION OF CONFORMITY

We hereby declare that the following our product conforms with the essential health and safety requirements of

EEC Directives.

Product:PNEUMATIC BELT SANDER

Model:BELTON:B-10N, B-20N, B-20NB and B-30N

Serial No:X X X X X X

Consecutive numbers (00001~99999)

Christian era’s last digit (0~9)

Manufacturer:NITTO KOHKI Co., Ltd.

2-9-4, Nakaikegami, Ohta-ku, Tokyo, 146-8555, Japan

Authorised Compiler In The Community:

NITTO KOHKI EUROPE Co., Ltd.

Unit21, Empire Centre, Imperial Way, Watford Hertfordshire, WD24 4TS, UK

Tel:(44)-01923-239668 Fax:(44)-01923-248815

Directive:98/37/EC and 2006/42/EC Machinery Directive

The above product has been evaluated for conformity with above directives using the following European standards.

The technical construction file (TCF) for this product is retained at the above manufacturer’s location.

Machinery Directive:EN ISO12100-1:2003, EN ISO12100-2:2003,

EN ISO14121-1:2007, EN792-8:2001+A1:2008, others

Sound Pressure/Power Level:EN ISO15744:2008, EN ISO4871:1996

Vibration Level:EN28662-1:1992, EN ISO8662-8:1997

Name:K.Kishi

Title: GENERAL MANAGER MACHINE TOOLS DIV.

Being the responsible person appointed and employed the manufacturer.

Printed in KOREA TQ12660-1

B10N_B20N_B20NB_B30N_E.indd 15 10.7.9 9:30:53 PM

This manual suits for next models

3

Table of contents

Other Nitto Sander manuals