Nittoh UP-65SV-8 Series User manual

ELECTRIC/HYDRAULIC PUMPS

UP-65SV(G)

-8

Series

Operation and maintenance manual

NITTOH ZOHKI CO.,LTD.

102,4-10,2-Chome,Kamezawa,Sumida-ku,

Tokyo 130,Japan

Telephone.03-3625-6551

Facsimile. 03-3625-6553

1

INDEX

1. Safety information ---------------------------- 2 page

2. Description of components ------------------ 4

3. Instructions before use ----------------------- 5

4. Operation --------------------------------------- 5

5. Maintenance ------------------------------------ 6

6. Circuits ------------------------------------------10

7. Construction drawings ------------------------11

8. Parts lists ----------------------------------------13

9. Trouble shooting guide ------------------------15

10. Warranty -----------------------------------------16

2

1Safety Information

Read and follow all WARNINGS,CAUTIONS and INSTRUCTIONS included with each

roduct to use the roducts correctly and to avoid ersonal injury or ro erty damage during

system o eration. NITTOH ZOHKI CANN NOT BE RESPONSIBLE FOR DAMAGE OR

INJYRY RESULTING FROM UNSAFE USE OF PRODUCTS, LACK OF MAINTENANSE

OR INCORRECT SYSTEM APPLICATION.

Cautions remarks used in this manual are classified as follows;

DANGER

In case as the r

esult of incorrect use in disregard of this remarks,

imminent danger may ha en, causing the risk of death or serious

injury.

WARNING

In case as the result of incorrect use in disregard of this remarks,

there will be s ossibility that an o erator will die or receive a

serious wound.

CAUTION

In case as the result of incorrect use in disregard of this remarks,

there will be a ossibility that and o erator will receive an injury or

material damage only will ha en.

Cautions when installed

WARNING

■Install a um unit for better balance.

Since the reservoirs of totally emclosed rubber structure are used in this series um s, the

um s can be laced for use in every direction (slant, inversion or er endicular).

However, the um s should be installed on stable laces. When a um is used aslant, fix

it firmly with. Otherwise, it slide down, causing an injury.

■Pre are good working environment.

Make sure all system com onents are rotected form external sources of damage such as

excessive heat, flame, moving machine arts, shar edges, corrosive chemicals.

CAUTION

■Do not use the um in the rain or on such wet or dusty laces.

■Do not ex ose hydraulic system to the direct rays of the summer’s sun.

Be careful with unacce table rise in hydraulic oil tem erature, causing trouble of

hydraulic equi ment.

■In case the um s are used outdoors in the extremely cold regions, exchange oil for

hydraulic oil of ro er viscosity.

Increased viscosity due to dro in oil tem erature, there is the ossibility that equi ment

gets out of order.

3

Caution when used

WARNING

■Take safety measures.

When hydraulic equi ment is o erated, rotect yourself with a ersonal safeguard,

working clothes and shoes, safety s ectacles, etc.

■Always check ressure limitations of hydraulic circuit.

Always confirm in advance that max. ermissible working ressure of a hydraulic um is

lower than the ressure rating of the lowest rated com onent connected in the system.

■Be careful to avoid electric shock.

Do not ull ower lug out with a wet hand. Use a grounded outlet or a lug ada ter with

a grounding attachment in order to rotect the o erator from electric shock. Do not o erate

the um by the side of electric welder or do not lace it on the earthed materials or

equi ment.

CAUTION

■Power su ly is AC220V 50/60Hz single hase.

Make sure your line voltage must be the same as the voltage your um is wired for.

Wrong voltage connection or voltage dro of your line shall cause burning or heating.

Be careful about voltage dro when used with an electric generator.

■When the ower su ly is disconnected, always gras the ower lug and ull it out.

Disconnection by gras ing the cord and ulling it out will cause breaking of a wire or a

short circuit.

■When a su lement cord is used, use only three-wire grounded cords of such sufficient

gauge as 1.25mm

2

or more, its length of max. 10M, in order to avoid voltage dro or

damage of the solenoid valves or electric motors.

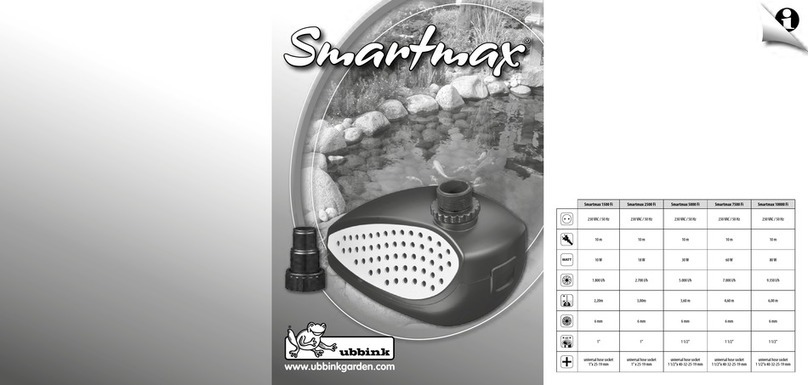

S ecifications

Model,No

Electric motor

Hydraulic um

Reservoir

UP-45SVG

-8H (L)

-8A(L)

-8SP(L)

-8WP(L)

-8R(L)

Commutator

and o en ty e,

0.65KW 220V

50/60Hz

single hase,

“E” insulation,

2000r m,

Max. 6A

Max,

Work ressure

MPa

Flow Rate

L/min(50Hz)

Ca acity

3.0L

(5.0L)

Usable

2.0L

(4.0L)

1

st

stage

2

nd

stage

1

st

stage 2

nd

stage

7 70 4 0.42

4

2 Descri tion of com onents

UP

-

6

5SVG

-

8H.8A

①

Erectric motor

②

Metal plug socket

③

Power supply plug

④

HP relief valve

⑤

Oil feeding plug

⑥

Reservoir

⑦

Oil gauge

⑧

Delivery port block

⑨

Pressure gauge

⑩

Pendant switch 2.5m

⑪

Power cable 2.5m

⑫

4-way solenoid valve

UP

-

6

5SVG

-

8SP.8WP

①

Erectric motor

②

Metal plug socket

③

Power supply plug

④

HP relief valve

⑤

Oil feeding plug

⑥

Reservoir

⑦

Oil gauge

⑧

Delivery port block

⑨

Pressure gauge

⑩

Pendant switch 2.5m

⑪

Power cable 2.5m

⑫

4-way solenoid valve

⑬

Pilot valve

UP

-

6

5SVG

-

8R

①

Erectric motor

②

Metal plug socket

③

Power supply plug

④

HP relief valve

⑤

Oil feeding plug

⑥

Reservoir

⑦

Oil gauge

⑧

Delivery port block

⑨

Pressure gauge

⑩

Pendant switch 2.5m

⑪

Power cable 2.5m

⑫

4-way solenoid valve

⑬

Double relief valve

5

3Instructions before use

3-1 Confirmation of all com onents for shi ing damage or oil leakage. If any shi ing

damage is found, notify carrier at once. Shi ing damage is not covered by warranty.

The carrier is res onsible for all re air or re lacement costs resulting from damage in

shi ment.

3-2 Oil feeding lug CAUTION

Use it after 2~3 turns loosens a lug.

3-3 Confirmation of your ower su ly WARNING

Power su ly is 220V 50/60Hz single hase. Make sure that a grounded outlet or a lug

ada ter with a grounding attachment must be used.

3-4 Confirmation of hydraulic oil WARNING

Always check oil level before o eration, with the connected cylinders fully retracted

(extended if ull cylinders). In case oil is added with cylinders fully extended and then

cylinders are retracted, the returned oil will overflow in the reservoirs, causing

generation of high ressure in the reservoirs, confirm required oil volume in a reservoir

as follows;

①Retract the connected cylinder fully.

②Check the oil gauge and confirm if oil is feeded u to half of the gauge. If oil is short,

not reaching the half of the level gauge, re lenish oil. (See 5-1 kind of hydraulic

working oil).

4O eration

“UP-65SVG-8H/8A”

with SVS-4A or SVS-4H 4-way 3- osition solenoid valve.

Advance/Retract.

1Plug in the um .

2De ress “A” switch to run the motor and to advance the cylinder (flow to ort “A” , ort

“B” returns flow to the reservoir). The motor sto s with “A” switch released.

3De ress “B” switch to retract the cylinder. UP-45SVG-8A um allows sto ing of the

cylinder, but can not hold ressure. UP-45SVG-8H has all orts o en solenoid valve.

“UP-65SVG-8SP/8WP”

with SVS-4H 4-way 3- osition solenoid valve and VPCS-10 or

VPCW-10 ilot-o erated check valve. Advance/Hold/Retract.

1Plug in the um .

2De ress “A” switch to run the motor and to advance the cylinder (flow to ort “A” ort

“B” returns flow to the reservoir). The motor sto s with “A” switch released.

3De ress “B” switch to run the motor and to retract the cylinder (flow to ort “B”, ort

“A” returns flow to the reservoir). UP-45SVG-8SP um allows ressure holding of

ort “A” by means of single ilot-o erated check valve, while UP-45SVG-8WP can hold

ressure on both orts “A” and “B” by ilot-o erated check valves.

6

“UP-65SVG-8R”

with SVS-4H 4-way 3- osition solenoid valve and WDRL-10 relief valve.

Advance/Hold/Retract.

1Plug in the um .

2De ress “A” switch to run the motor and to advance the cylinder (flow to ort “A” ort

“B” returns flow to the reservoir). The motor sto s with “A” switch released.

3De ress “B” switch to run the motor and to retract the cylinder (flow to ort “B”, ort

“A” returns flow to the reservoir).

4Pressure of both orts “A” and “B” can be adjusted by means of relief valves. They can

not hold ressure, but it is ossible to convert into ressure holding ty e um s by

adding ilot-o erated check valves.

5 Maintenance

5-1 Hydraulic working oil

①Kind of oil

Use only Nittoh NHO-32 hydraulic oil or an a roved, high-grade oil (ISO #32, viscosity :

32 cSt @40°C) with these um s to romote long um life.

②Oil tem erature

A titude tem erature for use of hydraulic oil is max. 55 °C. In case it ha ens

unacce table rise in oil tem erature, sto working so as to decrease oil tem erature or

take such a measure as installation of an oil cooler.

③ Oil exchange CAUTION

The frequency of oil change will de end u on general working conditions, severity of use

and overall cleanliness. 300 hours (working time) of use or about 3 months is considered

as a standard change interval. Periodically com are sam les oh the reservoir oil with new

oil and ins ects oil color for contaminants or differences.

Remove oil feeding lug and tilt the um to drain out old oil. Be careful that such

im urities as dusts do not enter info the reservoir and new oil is filled u to the gauge

level mark shown on um . Precautions when oil changed are;

●Retract all cylinders fully to the return osition.

●Do not fill with even a small quantity of re lenishment of different kinds of oil.

●Be careful that im urities or foreign matter do not enter info new oil.

④ Others WARNING

When oil enters into a eye, wash it away fully with clean water and consult a doctor

immediately. In case oil enters into the skin of such a wound, wash it away with soa y

water and consult a doctor without delay.

7

5-2 Pressure and i ing

① Com osition of hydraulic equi ment system WARNING

When a um , high- ressure hose(s), cylinder, valve, cou lings are connected together,

always check roduct limitations regarding ressure ratings and load ca acities. The

system o erating ressure must not exceed the ressure rating of the lowest rated

com onent in the system.

②Pressure gauges

Always install or re are a ressure gauge in-line form the um in order to check

ressure develo ed.

③ Pi ing CAUTION

Use wra ing of Teflon ta e on hoses fittings, valves and cou lers. Make sure all hose

connections are tight-use ro er tools to tighten connections with reference to the

following table. Do not over tighten the connections.

NPT,PT sizes

Tightening torque N

-

m(kgf

-

m)

1/8

”

13

-

14 (1.3

-

1.4)

1/4

”

30

-

40 (3.0

-

4.0)

3/8

”

60

-

70 (6.0

-

7.0)

1/2

”

100

-

110 (10.0

-

11.0)

Make sure that ta e not shed into hydraulic system, causing damage. Trim loose ends.

5-3 High ressure hoses

① Hose installation WARNING

Install hoses, leaving something in reserve, because high- ressure hoses ex and and

contract more or less when full ressure is a lied. Be careful that the hoses do not rub

against other solid materials.

Never allow the hoses to kink, twist, curl or bend so tightly that oil flow within hoses are

blocked or restricted. Do not clam the hoses, causing troubles.

② Hose handling DANGER

Never dro heavy things against the hoses, causing bursting of hoses or serious accident.

Do not subject the hoses to any otential hazard (fire, extreme heat or cold, heavy im act

or shar surfaces), which might ru ture or weeken the hoses. Never ull hoses to move or

lift equi ment connected with hoses.

Should a hose ever burst or ru tured, immediately sto o erating the um before

attem ting to remedy the situation. Never attem t to gras a leaking hose under

ressure with your hands. The force of the esca ing hydraulic fluid could cause serious

and ermanent injury.

8

5-4 Quick cou lers

① Connections

Make sure that all cou lers are connected ro erly. Incom lete cou ling connections

might cause artial or com lete blockage of oil flow, resulting in trouble of hydraulic

system.

② Handling WARNING

Sto o erating of the um with a hose and cou ler, but without a cylinder. The damaged

cou ler will cause accident. Do not disconnect the cou ler sets, which are under ressure.

5-5 Bleeding air from the system CAUTION

In case a new cylinder and/or a hose is connected with the um or hydraulic oil is

exchanged, air may accumulate in the hydraulic system. This air will cause the um not

deliver oil or the cylinder to res ond in an unstable or slow manner. To remove this air;

(a) The cylinder(s) must be ositioned on their side with the cou lers located u ward.

(b) Remove any load from the cylinder(s) and cycle the hydraulic system through several

cycles (fully extend and retract the cylinders) or intermittently 2 to 3 minutes.

5-6 Carbon brushes

① Cautions when in use WARNING

Always check the wearing condition of the carbon brushes. When the carbon brushes have

been worn down and exchanging time has come, the motor will sto automatically.

Re lace when a carbon brush has been worn down to 6mm in length as shown below or

working time of the motor is 150 hours or more subject to the conditions of their uses. Use

only NITTOH carbon brushes with these um s to romote long um life. When they

have been worn down, the s ring exerts insufficient ressure to hold brush against the

commutator.

② How to change

Firstly disconnect the ower su ly. Remove rubber ca s on two laces and loosen and

remove fitting screws inside with a screw driver, so the carbon brushes can be taken out.

Re lace with new ones and fix the screws and rubber ca s.

9

5-7 Relief valve adjustment

Range of standard ressure adjustment available is form 58.8 to 68.6MPa. different kind

of a s ring is needed to adjust and set at lower ressure than the standard. Contact

NITTOH authorized distributor.

Loosen lock screw on the relief valve and turn the adjusting screw a few turns

counter-clockwise to decrease ressure setting to a lower desired ressure. Clockwise

rotation of the adjusting screw will increase ressure.

10

6Circuits

UP-65SVG-8A/8H

Hydraulic Circuit

Electric Circuit

UP-65SVG-8SP/8WP

Hydraulic Circuit

Electric Circuit

UP

-

6

5SVG

-

8R

Hydraulic Circuit

Electric Circuit

11

7Construction drawings

The um art is an attached sheet (Drawing attachment).

The valve art mentions it according to a model as follows.

UP-65SVG-8H/8A

12

VPCW-10 (UP-65SVG-8WP/8SP) Pilot he k valve

VDRL-10 (UP-65SVG-8R) Double relief valve

13

8 Parts list

No. Part No. Descri tion

Driving ortion

1-1 1P50155 Pum body

1-2 TLA1616Z

Bearing

1-3 AC0687A0

Oil seal

1-4 4P53051 Low res, iston

1-5 4P53052 High res, iston

1-6 UF-8.5-20

S ring

1-7 4P50636 Co er acking

1-8 4P52942 Blind lug

1-9 MSWA12 Screw lug

1-10 4P52943 Eccentric collar

1-11 RNAF253517

Bearing

1-12 NTB1629 Thrust bearing

1-13 AS1629 Thrust washer

1-14 φ4×30 S ring in

1-15 4P52944 Driving shaft

1-16 G-16 G ty e ring

1-17 Key

1-18 2 Gear

1-19

MUM-S8-2

Electric motor

1-20 Carbon brush

1-21 Screw ca

1-22 4P52995 Rubber lug

1-23 M6 S ring washer

1-24 M6×15 Fitting bolt

1-25

SCK2003R

Metal lug socket

1-26 M3×10 Screw

1-27 OA-05 Ca cone

1-28 M4 S ring washer

1-29 M4×10 Fitting bolt

1-30

MB700-040

Ex ander

1-31

MB700-050

Ex ander

1-32 PT1/16 Blind lug

1-33 P-8 O ring

1-34 4P53053 Return i e

1-35 UHP-16 Hole lug

1-36 4P53055 Guide late

1-37 M5×10 Fitting bolt

HL valve ortion

2-1 φ5.55 Ceramic ball

2-2 S ring

2-3 4P53854 Co er acking

2-4 Valve seat

2-5 Screw lug

2-6 φ7 Steel ball

2-7 S ring

2-8 Co er acking

2-9 Retainer

2-10 Screw lug

2-11 φ5 Steel ball

2-12 WY5-10 S ring

2-13 4P53854 Retainer

2-14 PT1/8×PS1/4

L fitting

2-15 Filter

2-16 Filter block

2-17 Fitting bolt

Unloader ortion

3-1 φ1/4 Steel ball

3-2 TB8-15 S ring

3-3 4P52949 Adjusting screw

3-4 M10 Lock nut

3-5 SL-M5 Air filter

3-6 4P53050 Push in

3-7 φ4×15.8 Needle roller

3-8 P-4 O ring

3-9 P-4 Back-u ring

3-10 4P50636 Co er acking

3-11 4P52951 Blind lug

3-12 MSWA12 Blind screw

3-13 USA-4-10 S ring

Relief valve ortion

4-1 φ2.5 Steel ball

4-2 4P51889 Ball receiver

4-3 TB8-15 S ring

4-4 4P51980 S ring usher

4-5 P-6 O ring

4-6 MSWA12 Pushing screw

4-7 M4×10 Lock screw

14

Tank ortion

5-1 1P50156 Reservoir 3L

5-2 KCM-20 Oil gauge

5-3 G-140 O ring

5-4 M6 S ring washer

5-5 M6×15 Fitting bolt

5-6 PN-3/8 Feeding lug

5-7 P-16 O ring

5-8 PT3/8 Blind screw

5-9 1P50165 Reservoir 5L

Electrical arts ortion

6-1 Power cord

6-2 SCK2003P

Plug socket

6-3 COB61 Pendant control switch

6-4 Fan

6-5 Fan cover

UP-65SVG-8H/8A Valve ortion

7-1 2P50484 Manifold

7-2 7-1 Gauge ada tor

7-3 φ63-100MPa

Pressure gauge

7-4 PT1/16 Blind lug

7-5 PT1/8 Blind lug

7-6 PT3/8 Blind lug

7-7 M6×45 Fitting bolt

7-8 M5×45 Fitting bolt

7-9 P-8 O ring

7-10 3P50502 Valve body

7-11-1

4P52049 S ool shaft (8H)

7-11-2

4P52050 S ool shaft (8A)

7-12 W-22B Solenoid

7-13 4P52053 Push in

7-14 4P51083 S ring

7-15 4P52051 S ring receiver

7-16 φ4×10 S ring in

7-17 P-15 O ring

7-18 PT1/16 Blind lug

7-19 P-7B O ring

7-20 4P52908 Back-u ring

7-21 M8×35 Fitting bolt

VPCW-10(UP-65SVG-8WP/8SP)

8-1 3P50563 Check valve body

8-2 4P54491 Piston

8-3 P-10A O ring

8-4 P-10A Back-u ring

8-5

φ3×17.8F

Push in

8-6 4P53489 Valve seat

8-7 P-14 O ring

8-8 P-14 Back-u ring

8-9 4P53492 Valve seat retainer

8-10 φ1/4 Steel ball

8-11 WL5-10 S ring

8-12 P-14 O ring

8-13 P-14 Back-u ring

8-14 4P52249 Retaining late

8-15 M8×15 Fitting bolt

8-16 M8 S ring washer

8-17 PT1/16 Blind lug

8-18 P-7B O ring

8-19 4P53488 S ring

8-20 MS3-10 Parallel in

8-21 MS3-10 Parallel in

8-22 4P52908 Back-u ring

8-23 M8×75 Fitting bolt

VDRL-10(UP-65SVG-8R)

9-1 3P50555 Relief valve body

9-2 4P52258 Relief case

9-3 S-18 O ring

9-4 4P52259 Valve seat

9-5 4P50434 Co er acking

9-6 4P50624 Needle valve

9-7 SWB8-35 S ring

9-8 4P52260 S ring ushing iece

9-9 P-9 O ring

9-10 4P52261 Adjusting screw 1

9-11 M16P2 Lock nut 2

9-12 4P52262 Adjusting screw 2

9-13 EK63 Handle

9-14 φ3×20 S ring in

9-15 4P52263 Lock nut 1

9-16 P-7B O ring

9-17 4P52908 Back-u ring

9-18 PT1/16 Blind lug

9-19 M8×75 Fitting bolt

Dam er ortion

8

-

1

Dam er body

8-2 Piston

8-3 SWH10-15

S ring

8-4 Blind lug

8-5 P-12 O ring

8-6 P-12 Back-u ring

Number of the drawing

15

9 Trouble shooting guide

WARNING

●To revent injuries, any re air work or trouble-shooting must be done by qualified ersonel

familiar with this kind of equi ment. Use the ro er gauges and device.

Problems

Possible Causes

Remedies

Motor does not run

WARNING

Disconnect ower

su ly before

disassembly or re air.

(1)

No su ly voltage.

(2) Broken lead wire or defective

ower cord lug.

(3) Defective switches.

(4) Worn carbon brushes.

(5) Defective motor.

(6) Defective remote switch.

(7) Unit is not lugged in.

(1)

Check line voltage.

(2)Re lace defective artd.

(3)Check switches.

(4)Re lace carbon brushes.

(5)Re air or re lace motor.

(6)Re air or re lace switch.

(7)Plug in unit.

Abnormal noise of

motor.

(1)

Damage or um or motor.

(2)

Damage of ball bearings, etc.

(1)

Re air or re lace unit.

(2)

Re lace ball bearings.

Motor runs, but

cylinders do not

advance or retract.

(1)

Damage of release valve.

(2)Oil level is too low.

(3)Air in system.

(4)Filter lugged or dirt in um .

(5)Damage of um body.

(6)Damage or out of adjustment

of relief valve.

(1)

Re air or re lace it.

(2) Fill reservoir to 1/2 of level

gauge with all cylinders

retracted.

(3) Bleed the system.

(4) Pum filter should be

cleaned and if necessary,

um should be dismantled

and cleaned.

(5) Re air um .

(6) Re air or readjust as needed.

Cylinders works, but

full ressure is not

built u .

(1)

Damage of release valve.

(2) Air in system.

(3) Damage of um body.

(4) Lowering of set ressure or

damage of relief valve.

(1)

Re air or r

e lace.

(2)Bleed the system.

(3)Re air um .

(4)Readjustment of set ressure

or re air of relief valve.

Cylinders works, but

their s eed too slow,

artially or erratically.

(1)

Damage of release valve.

(2) Air in system.

(3) Unacce table rise in oil

tem erature.

(4) Damage of um body.

(1)

Re air or re lace.

(2)Bleed the system.

(3)Sto o eration or install oil

cooler. (max. 55℃)

(4)

Re air um .

Cylinders do not

retract.

(1)

Damage of release valve.

(2) Damage of return s rings of

cylinders or quick cou lers.

(1)

Re air or re lace.

(2) Re air or re lace s rings or

cou lers.

Oil leaks.

Damage seals, s

eats or steel

balls.

Re lace them.

Short circuit.

(1)

Damage cords.

(2)Bad insulation of electric

arts.

(1)

Re lace.

(2)Re lace.

16

10 Warranty

9-1 Warranty eriod

It is for one year from urchase.

9-2 Warranty

All NITTOH roducts and arts, with the exce tion mentioned below, are warranted

against defects in materials and workmanshi , which results in damage to roducts and

arts. This warranty shall cover re air and/or re lacement of the roducts or

com onents/ arts free of charge. To qualify for warranty consideration, return the

NITTOH roduct, freight re aid, to a NITTOH factory. Refer to the NITTOH

STANDARD EXPRESS WARRANTY for the details.

9-3 Warranty exce tions

No warranty claim will be acce ted for damage or breakdown arising for any of the

following reasons.

“Abuse or im ro er use, fair wear and tear, faulty or negligent o eration, im ro er

storage, chemical/ electrical influences or climatic or other effects which can not be

related s ecially to faults in manufacture”

No liability is acce ted for acking seals, s rings, and/ or the like, and the following:

◎Alterations or remodeling on the roducts undertaken by the urchasers without any

rior notice and agreement to NITTOH.

◎Severe and very highly frequent use, deviating from roduct s ecifications.

◎Damage due to faulty installation or assembly by urchasers or third arties.

◎Damage from natural disaster.

◎Damage from such accidents as fire, submersion, dro ing, etc.

This manual suits for next models

8

Table of contents

Other Nittoh Water Pump manuals

Popular Water Pump manuals by other brands

Stenner Pumps

Stenner Pumps SVP4L1 Installation and maintenance manual

SFA

SFA SANICOM 2 installation instructions

UDOR

UDOR VY Series Use and maintenance manual

fluid-o-tech

fluid-o-tech DGD Series instruction manual

Clarke

Clarke PSV7A Operation & maintenance instructions

Bosch

Bosch Rexroth A10VGT instruction manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 811/4A3-B Installation, operation, and maintenance manual with parts list

Dover

Dover PSG WILDEN PR870 Engineering, operation & maintenance

Pfeiffer Vacuum

Pfeiffer Vacuum HIPACE 350 operating instructions

Gilson

Gilson Minipuls 3 user guide

Stubbe

Stubbe SHB Series Original operating manual

Teral

Teral MSU instruction manual