OPERATING CONDITIONS

Make sure the pumped fluid is compatible with the materials of the

pump. Fluid-o-Tech’s gear pumps are designed to work only with

clean fluids and are tested with water at ambient temperature.

Any other fluid and/or operating condition must be verified and

approved by the end customer under the actual conditions of

use. Make sure the maximum temperature of the liquid and the

environment are compatible with the model used. It is necessary

to use – especially on the pump’s intake duct – pipes with an inner

diameter adequately sized in relation to the pump’s flow rate. This

precaution prevents the risk of cavitation and resulting damage on

the pump.

The sum of the inlet and outlet pressure must not exceed the

maximum system pressure indicated in the catalogue.

We recommend you adapt the size of the pipe in relation to the

delivery duct for pressure values at least 1.5 times the maximum

pressure of the system.

The pumped fluids must not contain solid suspended particles.

Before mounting the pump, we recommend installing a 10 µm

filter with a surface area large enough in order to prevent excessive

pressure drops in the circuit. Although occasional, particles larger

than 10 µm cause premature wear of internal components. It is

also important to periodically check the state of the cartridge and

the filter. To monitor the filter we recommend installing a pressure-

vacuum gauge after the filter. If the vacuum increases by more than

0.1 bar, the cartridge must be cleaned or replaced.

Although DGD and DGM gear pumps are self-priming pumps, they

should operate with a positive suction head. Indeed dry running

causes premature wear of the internal components of the pump.

If the water supply system operates with low pressure or no flow

rate, it is necessary to install a pressure switch before the pump to

turn off the motor. It is also necessary also protect the system from

accidental excessive pressure with safety devices such as a bypass

valve or a pressure switch connected to the motor.

The solenoid valves must not be installed in the circuit but, if

necessary, must only be installed on the delivery section of the

pump. We strongly recommend against installing the solenoid valves

before the pump. To avoid pressure peaks it is necessary to close

the solenoid valve only after the pump has stopped, then wait a

few seconds after the motor has been turned off to allow it stop

completely. The size of the inner diameter of the solenoid valve’s

duct must be adequate to the pump’s flow rate. The maximum

pressure depends on the unit model used.

Outside the values specified in the charts on page 4 the unit could

stop or the coupling could fail (DGM only). To re-fit the coupling it

is necessary to disconnect the motor’s power supply and wait till it

stops before restarting it.

STANDARD MAINTENANCE

Maintenance and replacement of parts subject to wear of

Fluid-o-Tech’s DGD and DGM units must be performed

by qualified technical staff. We recommend cleaning

the circuit and filters periodically to prevent cavitation

and wear of the internal components of the pump.

WARRANTY TERMS AND CONDITIONS

Every pump comes with a 12-month warranty valid from the date

of manufacture indicated on the label, plus a period of 3 months to

cover transport and storage. This period shall not exceed 15 months

from the date of the original invoice under any circumstances.

Fluid-o-Tech can only for held liable for the repair or replacement of

faulty parts returned on a DDP base, provided that our inspection

reveals that the part(s) in question was faulty at the time of sale.

The warranty is voided if:

• Themounting/useinstructionshavebeendisregarded.

• The pump was removed by a technician not authorized by

Fluid-o-Tech and/or repaired with non-original parts.

• Thepumpoperatedwithnowaterorundercavitationconditions.

• Solidforeignparticlesarefoundinthepump.

• Clearsignsofexcessivepressurearedetected.

• Thepumphasbeenusedforanapplicationitwasnotintended

for, where the operating conditions and/or the pumped liquid are

incompatible with the pump itself and therefore such application

had not been approved by Fluid-o-Tech.

• Thewarrantydoesnotcoverthenormalwearofthepump.

The repair or replacement of faulty parts during the warranty period

will not extend the original period of the warranty.

CERTIFICATIONS

Some gear pump models of the DGD and DGM series are NSF

certified for use with food-grade fluids. The CE label can be applied

only on motor-pump units. The label cannot be applied on the pump

alone in accordance with the applicable EC standard.

In this case the group meets the requirements of the following

directives: 89/366/EEC concerning Electromagnetic Compatibility

– EMC, 73/23/EEC concerning electrical equipment for use in

potentially explosive atmospheres – DTB and 94/9/EC on

Equipment and Safety devices intended for use in potentially

explosive atmospheres – ATEX. Fluid-o-Tech is able to provide

a declaration of conformity to certify compliance with the above

mentioned Directives.

We recommend a minimum safety factor of 1.5. Protect the

DGM and DGD units from frost. Freezing could permanently

damage the pump and pipes.

7The DGD and DGM units are low voltage devices, though it is

still necessary to comply with the relevant safety standards.

The installer is responsible for making sure current regulations,

closely associated with the final application, are complied with.

8Insert a filter of a suitable size upstream of the pump to prevent

solid particles with a diameter greater than 10μm from entering

inside. The surface of the filter must be sized in relation to the

flow rate and type of circuit in order to prevent excessive drops

in pressure. This filter must be cleaned periodically.

9If the units are connected in circuits fitted with solenoid valves,

make sure these always act with a certain delay after the motor

shuts down. Solenoid valves with early or simultaneous closure

can cause excessive pressure or cavitation and damage the

unit and/or the hydraulic circuit.

10 We recommend inserting a fuse of a suitable size in the unit’s

power supply circuit to avoid damage to the unit and/or

electrical circuit.

11 Make sure the electrical connections can ensure the necessary

seal and insulation. Inadequate connections could cause damage.

12 Choose your DGD or DGM unit model in relation to the

application cycle and performance required.

Using the units in harsher conditions than the ones they were

designed for could cause damage. Use the unit only for the

time required for the application.

PLAN THE INSTALLATION

1Make sure the size of the electrical circuit and hydraulic circuit

is suited to the electrical and hydraulic features of the DGD and

DGM units. Provide adequate identification for the sections of

the hydraulic and electric circuit.

2The installation must be conducted in a well ventilated, dry

area protected from splashes, away from heat sources and

flammable fluids. Install the pump in an accessible place to

make subsequent maintenance work easier. Place the unit in a

horizontal position or with the pump facing downwards.

3Make sure the unit is not subjected to vibration induced by the

mechanical or hydraulic connection. If such a condition occurs,

insulate the unit with adequate anti-vibration mounts.

4Provide for requirements related to the pre-assembly/mounting

of the unit’s accessories, such as the installation of the motor

unit of the DGM pump (see relevant paragraph)

5Provide for the cabling requirements of any additional electronic

boards. If the boards are fitted with heat sinks, install them

adequately to favour dissipation through natural convection.

INSTALLATION

1Secure the unit from a mechanical point of view. We

recommend installing it horizontally (with the motor axis parallel

to the ground) or, in the event of vertical installation, with the

pump facing downwards. Secure the pump to the motor using

the designated adapter (only for DGM units).

2Remove any IN/OUT protective plugs on the ducts.

3Connect the unit to the hydraulic and electrical circuit.

Make sure it does not cause mechanical stress and pay special

attention to the fluid there may be in the pipes, as this must

not come into contact with electrical parts. In case of negative

suction head, prime the unit. The electrical, hydraulic and

mechanical connections must be able to ensure the necessary

seal during operation of the unit.

4Make sure the polarity and voltage in the electric circuit near

the connection to the motor matches the data reported on the

unit’s plate. Identify the positive pole, which should preferably

be protected by a fuse. Please remember that reversing the

polarity may cause permanent damage to the unit. With the

electrical circuit not powered on, connect the motor.

5Make sure the unit is able to prime the fluid. If this does not

happen after 15 seconds, check the efficiency of the intake

circuit’s seal. Make sure there are no leaks in the hydraulic

circuit in both the delivery and in the intake section.

6Check the operation of the valves, which must be fully open

when the unit is installed. Gradually close the delivery valve until

the required performance is achieved. Finally, make sure the

hydraulic performance and absorption values are consistent

with the ones the machine was designed for.

7Once the pump has been primed, check if it is operating

correctly. The parameters to verify this are: the rotation speed

of the motor, the flow rate and pressure in relation to the power

absorbed. Make sure there are no air bubbles in the delivery/

intake duct. Air bubbles could be caused by cavitation or poor

seal of the pipe connected to the intake duct.

CONNECTING THE MOTOR TO THE MAINS

The electrical features of the mains must be compatible with the

electrical data on the motor’s plate, particularly the supply voltage

and frequency. The motor must not be connected to the mains

during installation.

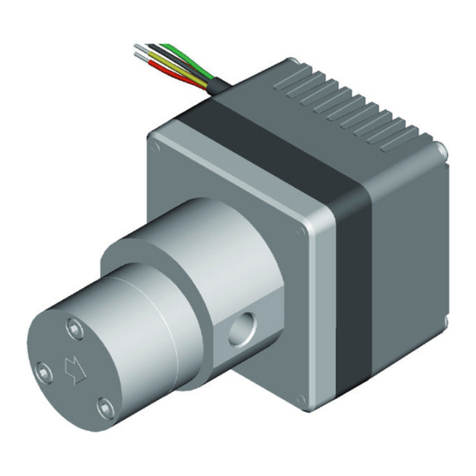

CHOOSING THE MOTOR (DGM ONLY)

If the motor is not supplied with the pump, make sure the coupling

dimensions and relative tolerances are those recommended by

Fluid-o-Tech. The flow rate is proportional to the speed of the

motor. The maximum continuous torque must be less than 0.1 Nm

with an external and internal magnetic joint made of ferrite

ASSEMBLY OF THE DRIVE SHAFTS’

MAGNET (DGM ONLY)

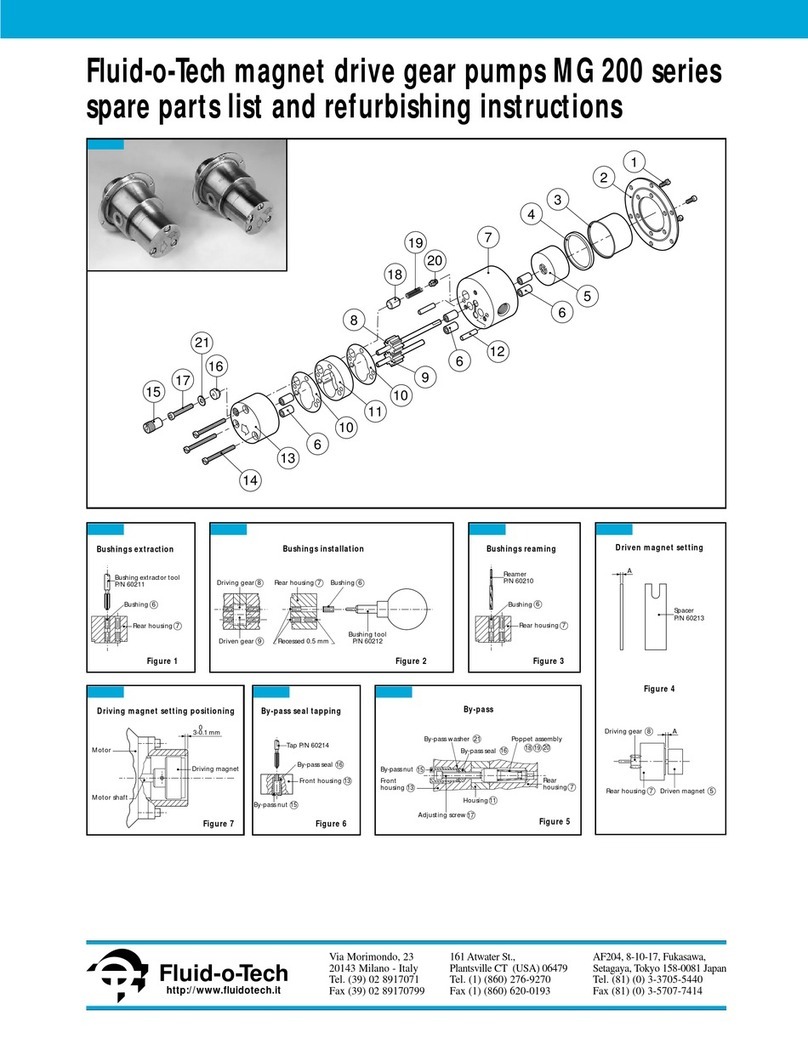

Motors with smooth shafts (“D” type)

1. To make sure there are no imperfections in the thread which

might prevent the dowel from blocking the magnet on the drive

shaft, screw the dowel on the threaded hole of the magnet

holder until it protrudes from the hole of the metal insert.

2. Unscrew the dowel until the hole where the shaft will be placed

is completely clear.

3. Place the magnet on the AT152 device with the fixing dowel

placed on the reference surface of the “D” pin (fig. 1).

4. Screw in the dowel until it touches the surface of the pin to

allow for an easy extraction of the magnet. The surface of the

equipment’s pin must not be scratched by the dowel when the

shaft is removed.

5. Remove the magnet and place it on the drive shaft. In these

conditions, the magnet’s dowel protrudes by a few tenths beyond

the inner diameter of the hole of the brass bushing and prevents

the magnet from being positioned incorrectly on the drive shaft.

6. Place the motor vertically on the AT152/1 device with the

magnet facing downwards in order to place the magnet in the

correct position (fig. 2). Tighten the dowel to the maximum

torque of 1.5 Nm. MGAF series external magnets with “D” shaft.

Fig. 2 -MGAF series external magnets with “D” shaft

AT 152/1

Tool pin reference plane

Fig. 1 - Reference surface for the pin device