Nivetec BULLETIN 824A Guide

BUL L E T I N

824A

INSTALLATION & OPE ATION

SFD-2 Microwave

Solids Flow Detector

separate components are connect-

ed via a low-voltage 3-wire system.

The SFD-2 consists of a split archi-

tecture design incorporating a sensor

head and a separate power

supply/conditioner. The SFD-2 sen-

sor head is a microwave transceiver

(combination transmitter/receiver)

encased in a watertight aluminum

housing with a screw-on cover. A

process seal (Teflon®or Ryton®-equiv.)

acts as a transparent window through

which the microwave signal is trans-

mitted and the reflected return signal

is received. The transceiver module

generates and transmits a microwave

signal into the area where the flow is

being monitored. The reflected signal

is analyzed whereby a frequency

shift in the reflected signal caused by

material movement is decoded as a

flow condition. The resultant output is

carried back to the power

supply/conditioner PCB where the

signal is indicated by an output relay and LEDs. This PCB also provides

the power to drive the sensor head and is the location for control settings

such as sensitivity, hold-off delay, hold-on delay and fail-safe selection.

Thank you for purchasing a

quality product manufactured by

Monitor Technologies LLC. We

realize that you do have a choice

of vendors when procuring flow

sensors and we sincerely

appreciate your business.

This manual contains the

information necessary to ensure

a safe and successful installa-

tion. Please read and comply with

the section on pages 7 & 8 of this

manual pertaining to SAFETY.

Doing so will ensure proper

operation of the equipment and

the safety of all personnel.

In the event that information con-

tained herein does not complete-

ly satisfy your requirements or

answer your questions, you may

contact Technical Support on our

website www.monitortech.com,

by telephone at 800-766-6486

(630-365-9403), or by fax at

630-365-5646. If your SFD-2 ever requires service either in or out

of warranty, please contact us and obtain an RMA number prior to

shipping the unit to us.

Monitor's SFD-2 Microwave Solids Flow Detector is a high qual-

ity, industrial grade instrument capable of providing a signal indi-

cating flow/no-flow conditions of solids and powders in pneumat-

ic pipelines, gravity chutes and feeders. This non-contact detec-

tor contains no moving parts or probes that can wear out or

break off in the material flow, thus ensuring process integrity.

The SFD-2 uses low power microwaves to sense motion within

the vessel or channel being monitored. Microwave technology is

used in the SFD-2 because the microwaves are virtually unaf-

fected by heat, humidity, ambient light, pressure, vacuum, high

or low temperatures, or dust, thus providing maximum effective-

ness in industrial applications.

Every SFD-2 assembly consists of a sensor head and a remote

power supply/conditioner board. The remote board can be pur-

chased with or without a NEMA 4X fiberglass enclosure. The two

Model SFD-2

tNo maintenance

tNon-contact operation

tNon-intrusive flush mounting

tImmune to environmental conditions

tDust-ignition proof design

RINCI LE OF O ERATION

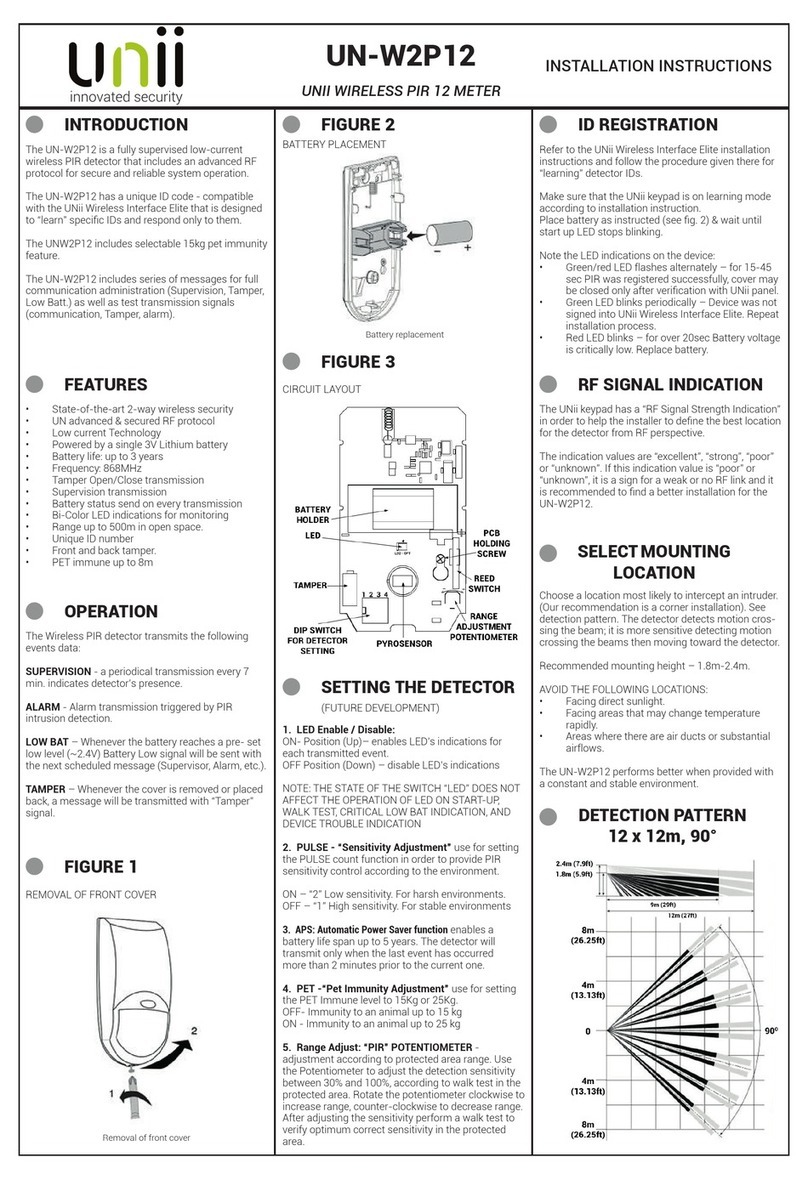

CHOOSING THE SYSTEM LOCATION (See Figure 1)

1) Hazardous/Non-hazardous - The sensor portion of the split

architecture is designed for use in Hazardous Locations associ-

ated with combustible dusts. The location chosen must comply

with the classification listed in the specifications. The power sup-

ply/conditioner is to be used in non-hazardous environments

unless the user chooses to house the PCB in a customer sup-

plied enclosure which has the appropriate hazardous location

classifications.

2) Temperature Limits - The operational temperature limits for

the sensor and power supply/conditioner must be satisfied.

3) Accessibility - Since the sensor head usually does not need

adjustment after installation, it can be located at a remote loca-

tion not as accessible to personnel. The power supply/condi-

tioner should be located where personnel can easily access the

RE-INSTALLATION CONSIDERATIONS

GDR JSC APR 18 2014 DOC-001-824A 8

2

CHOOSING THE SENSO LOCATION (See Figure 2)

1) Pipe/Chute Material - Microwave energy is contained and

channeled by metallic pipes or chutes. Internal reflections with-

in the line enhance the sensitivity of sensor. As the diameter of

the pipe/chute increases, the sensitivity of the sensor decreases.

When possible it is desirable to mount the sensor to a metallic

line to take advantage of the enhanced sensitivity. For non-

metallic pipes such as glass, plastics and concrete, material is

not as easily sensed so increased sensitivity must be set on the

electronics. However, since microwave energy can propagate

through non-metallic material, the sensor can be mounted to be

truly non-contact.

2) Material Flow Tendencies - Select a mounting location

where the process seal will be exposed to the full motion of the

process material under normal flow conditions. The SFD-2 has

the greatest sensitivity when the material being detected is either

coming toward or going away from the process seal. When pos-

sible, mount the sensor to take advantage of this phenomena.

Many applications will be satisfied without this type of mounting.

However, if the application poses sensitivity concerns, mounting

the sensor less than 90 degrees to material flow is recommend-

ed; refer to the Calibration section which describes sensitivity.

Avoid locations where substantial product buildup can occur. In

applications where material coating occurs, position the sensor

to take advantage of any cleaning action provided by normal

flow.

3) System Movements - The electronic circuitry has been

designed to be relatively insensitive to slow movements com-

monly associated with augers/conveyors. However, for best

operation, position sensor away from such mechanical move-

ments. When sensing through non-metallic materials, the ener-

gy can travel through the pipe/chute to the backside of the instal-

lation. The sensor must be positioned to avoid having motion of

nearby equipment or personnel interpreted as a flow condition.

Backing the non-metallic pipe/chute with a metallic shield will

greatly reduce the possibility of false signals.

Figure 1

Figure 2

SENSO MOUNTING

Coupling Mount - (See Figure 3) The SFD-2 sensor housing

incorporates an aluminum 1 1/4" NPT connection. The connec-

tion is specially machined to provide flush mount installation

when installed into a standard 1 1/4" half coupling. After select-

ing the appropriate location, cut a 1 1/2" diameter hole within the

pipe/chute. Position/center a 1 1/4" half coupling over the hole

and weld into place. Prior to sensor installation, prepare the

mounting threads with Teflon®tape or pipe dope to insure seal-

ing. Tighten the sensor into place insuring the conduit connection

is facing downward.

ME C HANI CAL IN STAL LATI O N

internal controls and where indicators can be clearly seen. The

sensor and power supply/conditioner can be separated up to

2500 feet (See Electrical Installation section).

3

Stainless Steel Adapter - (See Figure 5) In some cases, the

standard aluminum 1 1/4" NPT threads are not suitable for the

application primarily due to poor abrasion or corrosion resist-

ance. A stainless steel adapter with 1 1/2" NPT process con-

nection threads can be installed to the standard sensor. Using

a suitable mating 1 1/2" NPT half coupling will achieve flush

mounting to the pipe/chute. Teflon®or Ryton®-equivalent)

process seals can be used with this adapter.

Saddle Coupling - (See Figure 4) In cases where the SFD-2

sensor is to be installed on small pipes/chutes, Monitor’s saddle

coupling can be used to overcome the difficulty of welding to the

curvature of the material handling line. The aluminum saddle

coupling is threaded to permit engagement of the 1 1/4" NPT

connection on the SFD-2. Using the supplied gasket, acceptable

mounting can be achieved for diameters ranging from 4" to 10".

After selecting the appropriate location, cut a 1 1/2" diameter

hole in the pipe/chute. Position/center the saddle coupling over

the hole while placing the gasket in between. Fasten the saddle

coupling to the pipe/chute using industrial grade hose clamps.

Prior to sensor installation, prepare the mounting threads with

Teflon®tape or pipe dope to insure sealing. Tighten the sensor

into the saddle coupling insuring the conduit connection is facing

downward. The saddle coupling can also be fastened to a

pipe/chute with standard screw/nut fasteners by simply creating

mounting holes in the saddle coupling’s “ears” and fastening to

the pipe/chute. It is also feasible to flatten the profile of the sad-

dle coupling (via belt sander, mill, etc.) and use it as a standard

half coupling.

Figure 3

Figure 5

Figure 6

Figure 4

Food Grade Adapter - (See Figure 6) In applications where

mounting threads are not permitted, a food grade adapter with

an 2" industry standard TRI-CLOVER®or Cherry Burrell type

connection can be installed to the standard sensor. A 2" mating

ferrule must be used for mounting to the line.

Locknut - (See Figure 7) A chrome-plated 1 1/4" NPSM locknut

is available in cases where particular positioning of the sensor in

the mounting apparatus is desired. Some mounting couplings

(straight thread types) may require a locknut to achieve flush

mounting. Using the locknut with other mounting couplings

(tapered thread types) may prohibit flush mounting. Therefore,

careful consideration should be made to insure the mounting

technique does not create a void where material could accumu-

late in front of the sensor’s process seal.

Figure 7

L2/N

EL E CTRI CAL IN STAL LATI O N

Figure 8

Figure 9

Enclosure - (See Figure 9) Locate the SFD-2 power supply/con-

ditioner where the controls are accessible and the indicators can

be seen. Position the enclosure for convenient conduit/cord con-

nector access. Use the four mounting ears to mount the enclo-

sure. Before altering the enclosure in any way, remove the inter-

nal PCB by removing the four mounting screws Carefully handle

the PCB to avoid component damage or generating an electro-

static discharge (ESD). Cut the necessary conduit/cord connec-

tor holes in enclosure wall with punch or hole saw. Use proper

fittings to preserve the NEMA 4X integrity of the enclosure.

1) Sensor to Power Supply/Conditioner - (See Figure 10)

Insure the sensor and power supply/conditioner are positioned

closer than 2500 feet from each other. Interconnect the sensor

to the power supply/conditioner via a 3-conductor cable. A

shielded cable should be used when the cable is in close prox-

imity to high voltage or heavy current switching wires.

Recommended cable types are as follows:

- Shielded, 22 AW , 3-conductor, (Belden 8771 or similar)

- Unshielded, 22 AW , 3-conductor, (Belden 8443 or similar)

On the sensor route the wires through the 1/2" NPT entrance.

Match up the terminal block designations “+, -, SI ” found on

both the sensor and power supply/conditioner. Improper inter-

connection may result in circuit damage. If a shielded cable is

used, connect the shield to the power supply/conditioner at the

terminal designated “SHLD”. (Note: The “SHLD” terminal is con-

nected to the “E ND” terminal on the power supply/conditioner

as explained below. The shield will perform its function only if the

“E ND” terminal is connected properly.) The earth ground post

should be used in hazardous location applications as directed by

the National Electrical Code.

2) Line Power - The SFD-2 power supply/conditioner is

designed to accept 100 – 240VAC line voltages. The “E ND”

terminal should be used for safety and “SHLD” drain purposes.

A disconnection box containing a switch and over current pro-

tection (fuse or circuit breaker) is recommended to be mounted

within 9ft of the power supply. Check with your local electrical

code requirements. See specifications at the end of this

document for sizing.

3) Power Supply/Conditioner Outputs - The power

supply/conditioner provides DPDT (two Form C) dry contacts for

customer connection. They are capable of switching high

voltage/high current loads as listed in the specifications.

The terminal block designations represent the condition of the

relay contacts as if all power was off (See Figure 13).

Figure 10

POWE SUPPLY/CONDITIONE MOUNTING

PCB Only - (See Figure 8) Carefully handle the PCB so as not

to damage components or to create an electrostatic discharge

(ESD). Leave PCB in shielded bag until ready to install. Mount

the PCB in an enclosure suitable for the particular application

(i.e. water-tight, dust-tight, non-hazardous location). Select a

location free from heavy electrical switching caused by heavy

motors, actuators, etc. Position PCB so all connectors and con-

trol adjustments can be accessed. Use the four corner holes to

mount the PCB. Hardware (standoffs, nuts, screws, washers) is

provided for installation convenience.

4

5

SENSO (See Figure 11)

Coarse Sensitivity - The coarse sensitivity is a slide switch

which permits selection of “HI” or “LO” settings. This selection

operates in tandem with the main sensitivity adjustment found in

the power supply/conditioner. The sensor is provided with the

coarse sensitivity switch placed in the “LO” setting which will sat-

isfy most applications. The status of the coarse sensitivity can

be changed to “HI” if the adjustability range found on the power

supply/conditioner is inadequate. (See Calibration of Power

Supply/Conditioner.)

SENSO INDICATO S

1) Green LED - Illumination of the reen LED indicates that

power is properly connected to the sensor. Lack of illumination

could be from lack of supplied power or reversing the polarity of

the input connections.

2) Yellow LED - Any illumination of the Yellow LED indicates that

the “SI ” connection loop is correctly installed. Lack of illumi-

nation could be from improper connection between the sensor

and power supply/conditioner. Detected motion will cause the

Yellow LED to more intensely illuminate.

CA L IBRA TION

Figure 11

Figure 12

2) Material Density in the Pipe/Chute - As more product is

placed in motion, the amount of disturbance which is analyzed

as motion also increases. Thus, applications which have signif-

icant material flow can tolerate a lower sensitivity setting then

those applications with minimal material flow.

3) Material Dielectric Constant - Microwave propagation is

affected by the dielectric constant of the material being sensed.

Typically, low dielectric materials tend to absorb/pass the energy

while high dielectrics tend to reflect the energy. The SFD-2 will

sense material better when energy is reflected. Therefore, low

dielectric materials (i.e. plastics, soap, cement) will require a

greater sensitivity setting than high dielectric materials (i.e.

grains, feed, ores)

4) Material Particle Size - Microwaves have a particular wave-

length and therefore are more easily reflected when hitting larg-

er particle sizes. Thus, applications with small particle sizes (i.e.

powders) will require a greater sensitivity setting than large par-

ticle sizes (i.e. granulars).

5) Mounting Environment - When microwave energy is

entrapped within metal containers, internal reflections are pro-

duced therefore creating a increased probability to see material

motion. Thus applications utilizing metallic pipes/chutes require

a lower sensitivity setting than applications utilizing non-metallic

pipes/chutes. Also, since microwave energy losses its power

density with respect to traveled distance, applications utilizing

small diameter pipes/chutes require a lower sensitivity setting

than applications utilizing large diameter pipes/chutes.

2-STEP CALIB ATION

1) While the system is operating (conveyors, augers, etc.) but no

material is flowing, rotate the sensitivity adjustment clockwise

until the “sense” (Yellow) LED illuminates. Note the adjustment

position. (On most applications, this will occur near the 4 o’clock

position).

2) With the material flowing, rotate the adjustment counter-clock-

wise until the “sense” (Yellow) LED turns off. Note the adjust-

ment position. Reposition the sensitivity adjustment at the

halfway point between the LED “on” and LED “off” settings.

(NOTE: If the difference between the two conditions is very

small, thereby making final calibration difficult, reposition the

sensor’s coarse sensitivity setting to the “HI” position and repeat

the 2-Step Calibration procedure. (See Calibration of the

Sensor.) In general, applications which are difficult to sense will

require a greater clockwise setting.

POWE SUPPLY/CONDITIONE (See Figure 12)

Sensitivity - A single-turn potentiometer is used to adjust how

sensitive the SFD-2 will be to objects in motion. The poten-

tiometer permits adjustment between the 7 o’clock and 5 o’clock

positions (300 degrees of rotation). Physical stops exist at both

extremes of the adjustment. A fully counter-clockwise adjust-

ment (7 o’clock) creates a very insensitive setting where nearly

all motion is ignored. A fully clockwise adjustment (5 o’clock)

creates the greatest sensitivity. In addition, this setting forces the

power supply/conditioner into the “sense” condition regardless of

motion presence. Ideal adjustment can be achieved via a sim-

ple “2-Step Calibration” procedure. The setting and the ability of

the SFD-2 to sense material is influenced by the mechanical

mounting (See Pre-Installation Considerations) as well as mate-

rial characteristics such as velocity, flow density, dielectric con-

stant, and particle size.

1) Material velocity - Electronic signal conditioning enables

the sensor to see faster moving material easier than slow mov-

ing material. This is particularly important when distinguishing

between typical material movement and extraneous influences

such as augers, conveyors, etc. enerally, the slower the mate-

rial movement, the greater the sensitivity setting must be.

6

Hold-off Time Delay - The single-turn adjustment controls the

amount of time that motion must be sensed before the SFD-2 will

change from its “no-motion/no-flow” condition to its “motion/flow”

condition. Clockwise rotation of the potentiometer will increase

the time required for such activity from .25 to 15 seconds. The

delay permits the user to adjust the sensor to ignore unwanted

sensing caused by equipment vibration or short durations of

material flow.

Hold-on Time Delay - The single-turn adjustment controls the

amount of time that no-motion must be seen before the SFD-2

will change from its “motion/flow” condition to its “no-motion/ no-

flow” condition. Clockwise rotation of the potentiometer will

increase the time required for such activity from .25 to 15 sec-

onds. The delay permits the user to adjust the sensor to ignore

momentary material stoppages induced by shifting or settling of

material.

Fail-safe (See Figure 13) Selection of the fail-safe mode will per-

mit the output contacts to be signaled in a manner which assures

proper control of loads in the event of SFD-2 sensor/power fail-

ure. Depending on which condition is most critical to signal (flow

or no-flow), the selection can be made by positioning the slide

switch to the desired state.

FLOW - When no-motion/no-flow is sensed, the relay will be

energized. The relay will de-energize when motion/flow occurs,

or if sensor/power failure occurs.

NO-FLOW - When motion/flow is sensed, the relay will be

energized. The relay will de-energize when no-motion/no-flow

occurs, or if sensor/power failure occurs.

All SFD-2 units are set to the NO-FLOW fail-safe configuration

prior to shipping. The terminal block designations represent the

condition of the relay contacts as if all power was off.

POWE SUPPLY/CONDITIONE INDICATO S

1) Green LED - Illumination of the reen LED indicates power

is properly connected to the power supply/conditioner PCB.

Failure to illuminate indicates that the input AC voltage is improp-

erly connected, the fuse is blown, or that the power supply/con-

ditioner is damaged.

2) Yellow LED (and external indicator) - The Yellow LED indi-

cates whether the motion detected by the sensor is above the

threshold established by the sensitivity adjustment. Illumination

of the Yellow LED indicates the threshold has been reached. Its

state is not affected by the time delay settings.

P OBLEM: The SFD-2 does not provide relay activation

upon material flow.

CAUSE/SOLUTION:

1) Verify electrical power is connected to proper

terminations and that the sensor is properly

interconnected to the power supply conditioner.

2) Verify sensitivity settings and increase if necessary.

3) Verify hold-off delay setting and decrease if necessary.

4) Verify material flow at sensor face. Eliminate any

conductive buildup. Reevaluate sensor position and

move if increased disturbance can be detected

elsewhere.

P OBLEM: The SFD-2 provides relay activation without

material flow.

CAUSE/SOLUTION:

1) Verify interconnection between sensor and power

supply/conditioner.

2) Verify sensitivity settings and decrease if necessary.

3) Verify hold-on delay and decrease if necessary.

4) Verify movement at sensor face. Reevaluate sensor

position if motion from augers, conveyors or other

material movement causes sensing.

WARNIN : The SFD-2 is a maintenance free product and shall

be serviced by Monitor Technologies LLC only. No cleaning is

required. Changes or modifications to the SFD-2 not expressly

approved by Monitor Technologies LLC could void the user’s

authority to operate the product.

NOTE: This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential and

industrial installations. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interfer-

ence in radio communications.

However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be deter-

mined by turning the equipment off and on, the user is encour-

aged to try to correct the interference by one or more of the fol-

lowing measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between SFD-2 and receiver.

- Connect the SFD-2 to a different circuit different

from which the receiver is connected.

- Consult the dealer or a radio/TV technician for help.

Figure 13

TRO UBLE SHOO TING

MAINTENANCE

3) ed LED (and external indicator) - The Red LED indicates the

condition of the output relay. Illumination of the red LED indi-

cates the output status of the relay is in the “motion/flow” condi-

tion. Its state is influenced by the time delay settings.

This device complies with RSS-210 of Industry Canada.

Operation is subject to the following two conditions:

- This device may not cause interference.

- This device must accept any interference, including

interference that may cause undesired operation of

the device.

7

Sensor

Power Supply/Conditioner PC Board

Enclosure

Stainless Steel Adapter

Locknut

Half Coupling

Saddle Coupling

Food Grade Adapter

MECHANICALS

SAF ETY

Electrical Shock Caution:

The SFD-2 power supply/conditioner is powered with HI H

VOLTA E. Care shall be taken whenever the main terminal

block connections are exposed. To avoid electrical shock, do

not contact any exposed electrical connections.

All servicing is

to be performed by qualified personnel.

NOTE: If this equipment is used in a manner not

specified by Monitor Technologies LLC, the protection

provided by this equipment may be impaired.

Monitor Technologies LLC warrants each SFD-2 it manufactures to be free from

defects in material and workmanship under normal use and service within two (2)

years from the date of purchase. The purchaser must give notice of any defect to

Monitor Technologies LLC within the warranty period, return the product intact and

prepay transportation charges. The obligation of Monitor Technologies LLC under

this warranty is limited to repair or replacement at its factory. This warranty shall

not apply to any product which is repaired or altered outside of the Monitor

Technologies LLC factory, or which has been subject to misuse, negligence, acci-

dent, incorrect wiring by others or improper installation. Monitor Technologies LLC

reserves the right to change the design and/or specifications without prior notice.

BULLETIN

824

Each SFD-2 is provided with a "protective conductor terminal"

which shall be terminated to earth ground potential (see

Electrical Installation). This product's design complies with

EN61010-1 installation category II and pollution degree 4.

Hazardous Location Caution:

The SFD-2 sensor is “approved” for use in certain Hazardous

Locations (see specifications). The products shall only be used

in applications covered by these ratings or those considered

non-hazardous. Failure to comply could result in catastrophe

damage to personnel and property. The following must be main-

tained to assure safe operation:

1) Housing integrity - the dimensions of the housing,

cover or process seal shall not be altered.

2) Maintenance - Removal of the sensor cover to conduct

maintenance while power is yet supplied does not meet

hazardous location requirements. If done, it is at the

risk of the customer only.

adiated Energy

OSHA has adopted regulations designed to prevent possible

harmful effects in human being from exposure to electromagnet-

ic fields in the frequency range of 300 KHz to 100 Hz. The

SFD-2 generates energy within this band. OSHA permits human

exposure to power densities up to 10mW/cm2 for 1/10 hour or

greater continuous duration. The SFD-2 produces a power den-

sity less than 1mW/cm2 at the sensor face and therefore poses

no health danger to operators or the general public.

Electromagnetic Compatibly (EMC)

The SFD-2 was tested and found to comply with the standards listed

below. The SFD-2 should not be used in residential or commercial envi-

ronments. Compliance to the EMC standards was demonstrated by

means of a test setup using the following installation methods.

1) SFD-2 sensor was connected to earth ground (protective earth).

2) Shielded cable was used to interconnect the sensor and power sup-

ply/conditioner connections (+, and -). The shield drain was connected to

earth ground (SHLD terminal) at the power supply/conditioner end.

EMC Emissions:

Meets EN 61326-1 Electrical Equipment for Control Use, EMC

EN 55011 Radiated and conducted emissions

(Class A - industrial)

EN 61000-3 Fluctuation/Flicker

Meets FCC Part 15B RF Devices, Unintentional Radiators

CISPR 11 Radiated and conducted emissions

(Class A- industrial)

EMC Immunity:

Meets EN 61326-1 Electrical Equipment for Control Use, EMC

IEC 1000-4-2 Electrostatic discharge (industrial)

IEC 1000-4-3 RF radiated EM fields (industrial)

IEC 1000-4-4 Electrical fast transients (industrial)

IEC 1000-4-5 Electrical surges (industrial)

IEC 1000-4-6 RF conducted EM energy (industrial)

IEC 1000-4-8 Power frequency magnetic fields (industrial)

IEC 1000-4-11 Source voltage deviation

Ryton®- Trademark of Phillips Chemical Co.

Teflon®- Trademark of Dupont Chemical Co.

TRI-CLOVER® - Trademark of Tri-Clover Inc.

WARRANTY

SENSO

Enclosure cast aluminum, polyester coated (beige)

Enclosure protection NEMA 4, IP66

Operational temp. range -40 to +185 degrees F (-40 to +85 degrees C)

Process temp. max +250 degrees F (+121 C) if ambient air

temp. below +150 degrees F (+65 C)

Process seals TFE Teflon®, Ryton®-equivalent

Pressure ratings TFE Teflon®(75 PSI intm.), Ryton®-equiv. (300 PSI)

Process connection 1 1/4" NPT (flush mount with half coupling)

Conduit connection (2) 1/2" NPT

Detection range 0 to 10’ free air, environment and target

dependent

Sensitivity switch selectable HI/LOW

Minimum Velocity: 2.5 ft/sec (7.62mm/sec)

Power requirement provided by power supply/conditioner PCB

Output none, signal delivered to and processed by

power supply/conditioner

Indicators reen LED- power

Yellow LED- loop, intensifies with motion

Emission 24.125 Hz, FCC and IC certified, less than

1mW/cm2(OSHA limit at 10mW/cm2)

Approvals Class II, Div. 1, roups E, F &

(CSAUS/C)

CE Mark

POWE SUPPLY/CONDITIONE (PS/COND)

Installation Category II

Pollution Degree 4

Altitude 6562ft (2000M) max

Enclosure (if applicable) PBT/Polycarbonate

Enclosure protection NEMA 4X, IP66, Suitable for outdoor use

Operational temp. range -40 to +158 degrees F (-40 to +70 degrees C)

Interconnection distance 2500ft max (minimum wire size 22 AW )

Power 100-240VAC(+10%) 50/60 HZ

Power consumption 5 VA max

Output DPDT dry contact, 5A @ 250VAC or 30VDC

External lights (if applicable) solid state LED clusters; Yellow- material sense,

Red- output operate

Sensitivity adjustment single-turn adjustment 0~100% of sensor

range

Time delay hold-off, single-turn adjustment,

.25~15 seconds

hold-on, single-turn adjustment,

.25~15 seconds

Fail-safe switch selectable, (FLOW/NO-FLOW)

Indicators reen LED- power, Yellow LED- sense,

Red LED-output

Approvals ordinary locations, industrial control

equipment (CSAUS/C)

CE Mark

Fuse 250VAC, 315mA, TR-5, FAST

S ECIFICATIONS

GDR JSC APR 18 2014 DOC-001-824A 8

Table of contents