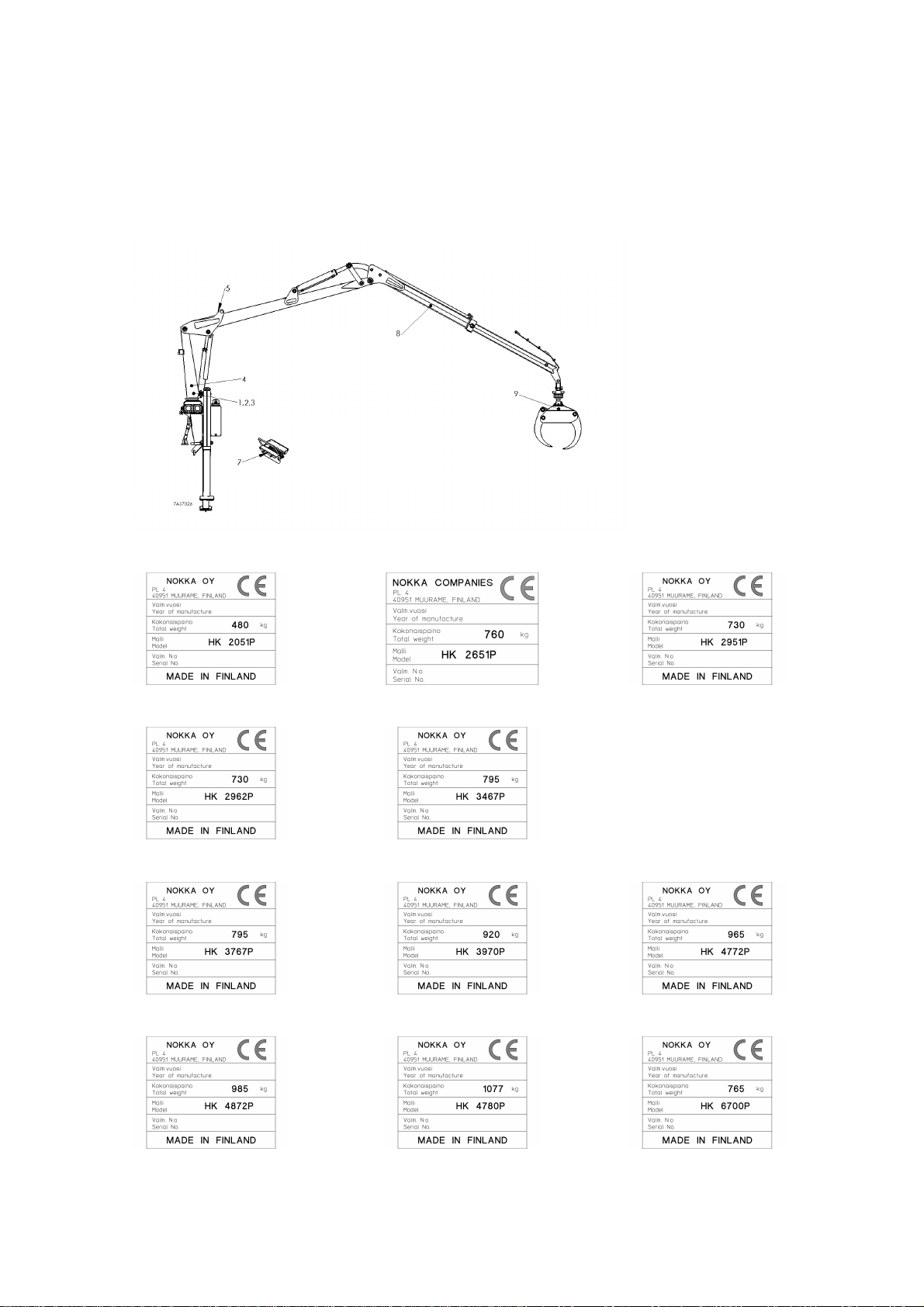

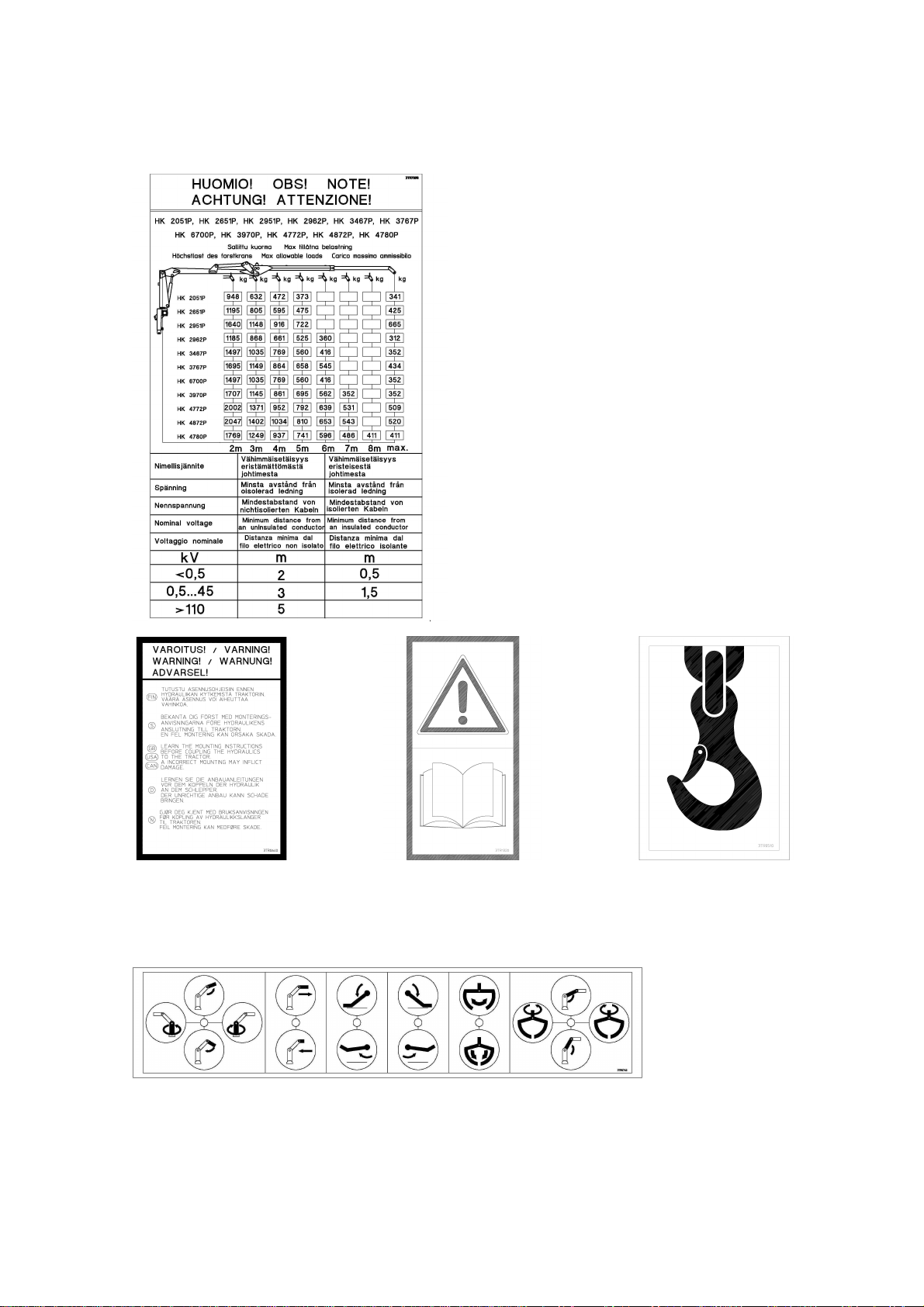

NOKKA 2962 P

Weight of the loader ready for work with log grab.............................730 kg

Net lifting torque............................................................................23,5 kNm

Gross lifting torque...........................................................................29 kNm

Swing torque ......................................................................................7 kNm

Boom turning angle...............................................................................400o

Maximum reach...................................................................................6,2 m

Extension stroke....................................................................................1,38

Maximum working pressure...........................................................18,2 MPa

Minimum hydraulic pump capacity ................................................. 40 l/min

NOKKA 3467 P

Weight of the loader ready for work with log grab.............................795 kg

Net lifting torque............................................................................27,5 kNm

Gross lifting torque...........................................................................34 kNm

Swing torque ...................................................................................7,5 kNm

Boom turning angle...............................................................................400o

Maximum reach...................................................................................6,7 m

Extension stroke................................................................................1,38 m

Maximum working pressure..............................................................17 MPa

Minimum hydraulic pump capacity ................................................. 40 l/min

NOKKA 3767 P

Weight of the loader ready for work with log grab.............................795 kg

Net lifting torque...............................................................................30 kNm

Gross lifting torque...........................................................................37 kNm

Swing torque ...................................................................................8,7 kNm

Boom turning angle...............................................................................400o

Maximum reach with extension...........................................................6,7 m

Extension stroke................................................................................1.38 m

Maximum working pressure...........................................................18,4 MPa

Minimum hydraulic pump capacity ................................................. 50 l/min

NOKKA 3970

Weight of the loader ready for work with log grab.............................910 kg

Net lifting torque...............................................................................32 kNm

Gross lifting torque...........................................................................39 kNm

Swing torque ...................................................................................7,1 kNm

Boom turning angle...............................................................................400o

Maximum reach...................................................................................7,0 m

Extension stroke................................................................................1,38 m

Maximum working pressure..............................................................15 MPa

Minimum hydraulic pump capacity ................................................. 50 l/min