NorAM 65E Turbo Motor Grader User manual

65E Turbo Motor Grader

Service Manual

IService 2.00_2013.02

65E

TURBO

|

Motor Grader

Service Manual

Part # 22145

Serial #

Tier III 65ET9500 -65ET9899

Tier IVi 65ET9900 -UP

This page intentionally left blank.

65E Turbo Motor Grader

Service Manual

IService 2.00_2013.03

PROPRIETARY NOTICE

The contents of this manual are proprietary data of the manufacturer. Reproduction or use of any part for

other than the operation and maintenance of this equipment is permissible only if expressly authorized in

writing by the manufacturer. Additional copies may be obtained from your dealer.

COMPANY POLICY

Company policy, which is one of continuous improvement, reserves the right to change prices and to make

changes in design and specification at any time without notice and without obligation to modify units previ-

ously built.

All data given in this book is subject to production variations. Dimensions and weights are approximate only

and the illustrations do not necessarily show machines in standard condition. For exact information about

any particular machine please consult your dealer.

PARTS AND ACCESSORIES

Genuine parts and accessories have been specifically designed for these machines. We would like to point

out that "non-genuine" parts and accessories have NOT been examined and released by Weiler. The instal-

lation and or use of such products could have negative effects upon the design characteristics of your

machine and thereby affect its safety. Weiler is not liable for any damage caused by the use of "non-genu-

ine" parts and accessories.

MODEL CODES

The range of machines listed may not be available in all countries or markets therefore, for the latest infor-

mation consult your local dealer.

SPARE PARTS

To maintain operating efficiency, use OEM original spare parts. When ordering parts, give the following

information:

• Machine model

• Machine and engine serial numbers

• Part number from the Parts Catalog

Model 65ET Tier III 65ET Tier III

Engine Type / HP Cummins / 110 HP CAT / 114 HP

Model 65ET Tier IVi 65ET Tier IVi

Engine Type / HP Cummins / 110 HP CAT / 115 HP

65E Turbo Motor Grader

Service Manual

Service 2.00_2013.03II

TOTHE OWNER

The machine was designed to power and propel itself. It is intended to move material in the

normal and customary applications.

Do not modify or alter or permit anyone else to modify or alter this machine or any of its

components mechanical function without first consulting your dealer.

Your safety and the safety of those around you depend upon the care and good judgment

you use while operating this equipment. Read the safety precautions carefully.

After you have operated the machine for 50 hours, take your machine and this manual to

your selling dealer. They will perform the factory recommended 50-hour service. You will be

responsible for the cost of lubricants, fluids, filters and other items replaced as part of

normal maintenance. Prior to taking the machine to your selling dealer for service, it is

recommended that you contact them to determine any other charges for which you may be

responsible.

IMPROVEMENTS

The manufacturer is continually striving to improve its products. We reserve the right to make improvements

or changes when it becomes practical and possible to do so, without incurring any obligation to make

changes or additions to the equipment sold previously.

All data given in this book is subject to product variations. Dimensions and weights are approximate only

and the illustrations do not necessarily show machines in standard condition. For exact information about

any particular machine, please consult your dealer.

65E Turbo Motor Grader

Service Manual

IIIService 2.00_2013.03

The symbol above is used throughout this book whenever personal

safety is involved. Take time to read and follow the instructions. Be

careful!

Pictures in this manual may show protective shielding open or

removed to better illustrate a particular feature or adjustment.

Be certain, however, to close or replace all shielding before operating the

machine.

!

65E Turbo Motor Grader

Service Manual

Service 2.00_2013.03IV

CONTENTS OVERVIEW

Electronic Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 1

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 2

Operator’s Platform and Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 3

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 4

Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 5

Rear Axle and Tandem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 6

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 7

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 8

Moldboard and Implement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 9

Service Manual

Section 1: Electronic Display

Service 2.00_2013.03

65E Turbo Motor Grader

Service Manual

Service 2.00_2013.03ii

Section 1

Electronic Display

SAFETY PRECAUTION INFORMATION

UNSAFE OPERATING PRACTICES AND IMPROPER USE OF THE MACHINE AND ITS

ATTACHMENTS ON THE PART OF THE OPERATOR OR SERVICE TECHNICIAN CAN

RESULT IN INJURIES. OBSERVE THE FOLLOWING SAFETY PRECAUTIONS AT ALL TIMES:

1. Read the Operator's Manual carefully before using the machine. Lack of operating

knowledge can lead to accidents.

2. OSHA requires that all operators be instructed on the proper operation of the machine

before they operate the unit.

3. Only allow properly trained and qualified persons to operate and service the motor

grader.

4. Wear proper safety equipment as required by the job, such as hard hats, safety glasses,

ear protection, heavy gloves, reflective vests, etc. Consult your employer, site

supervisor or OSHA for specific requirements.

5. To prevent falls, use assist rails and steps when getting on and off the machine. Keep

steps and platform clear of mud, oil, grease, snow, tools, and debris.

6. Do not use controls or hoses as hand-holds when climbing on or off machine. Controls

may move and inadvertently cause machine travel or implement movement.

7. Do not permit anyone but the operator to ride on the motor grader. There is no safe

place for extra riders.

8. Do not allow children to operate the machine or ride on the machine at anytime.

9. Never use moldboard or implements as a personnel lift.

10. Do not use the machine as scaffolding or a work platform.

11. Replace all missing, illegible or damaged safety decals.

12. Keep safety decals free of dirt and grime.

13. Do not modify or alter or permit anyone to modify or alter machine or any of its

components or machine functions without first consulting an authorized dealer.

14. Do not operate machine without ROPS or FOPS in place and in good condition.

!

65E Turbo Motor Grader

Service Manual

iiiService 2.00_2013.03

Section 1

Electronic Display

15. Install all shields before starting or operating machine.

16. Do not operate an unsafe machine. If items are found during inspection that render a

machine unsafe, be sure any malfunctions are remedied before accepting

responsibility for operation.

17. Always properly tie down the machine to a truck or trailer before transport.

18. Do not start engine or operate controls while standing beside the vehicle. Always sit in

the seat when starting engine or operating controls.

19. Do not operate an unsafe machine. Be sure that any reported problems have been

repaired and all shielding is in place before accepting responsibility for machine

operation.

20. Do not bypass transmission neutral start switch. Consult an authorized dealer if the

neutral start controls malfunction. Use jumper cables only in the recommended

manner. Improper use can result in a runaway vehicle.

21. Check brakes, steering and implement controls before moving. Advise maintenance

personnel of malfunctions before operating. Be sure malfunctions are remedied before

accepting responsibility for operation.

22. Avoid accidental contact with the transmission control lever while the engine is

running. Unexpected movement may result from such contact.

23. Do not get off or on the vehicle while it is moving.

24. Lower unlocked implements to the ground, apply parking brake and shut off the engine

before getting off the machine.

25. Do not use machine to carry loose objects or attach implements in ways other than

intended.

26. Before starting the engine, be sure that all operating controls are in neutral and the

parking brake is engaged.

27. Install lock pins in front and rear mounted implements before transporting machine

between job sites.

28. Do not park on a steep incline.

29. Do not operate the vehicle in an enclosed building without adequate ventilation.

Exhaust fumes can cause death.

30. If the power steering or engine ceases to operate, stop the vehicle immediately.

31. Stop the engine and relieve pressure before connecting or disconnecting hydraulic,

steering or fuel lines.

32. Tighten all connections before starting engine or pressurizing lines.

65E Turbo Motor Grader

Service Manual

Service 2.00_2013.03iv

Section 1

Electronic Display

33. Remember that the vehicle, if abused or incorrectly used, can be dangerous and

become a hazard to the operator and bystanders.

34. Noise levels can exceed recommended levels when working between buildings or in

confined areas on canopy equipped machines or cab equipped machines with doors

and windows open. Use ear protection when warranted.

35. Always look in the direction of travel when moving machine. Be sure personnel in the

area are clear before moving machine or implements. If someone arrives in operating

area, stop machine immediately.

36. When transporting or traveling on roads, position moldboard within width of machine.

37. When driving on roads have consideration for other road users. Pull to the side of the

road so following traffic may pass. Maintain a safe distance from other vehicles. Yield

right of way to loaded machines.

38. Obey federal, state and local laws concerning slow-moving emblems, flashers, rotating

beacons and licensing requirements.

39. Obey flagmen, safety signals and signs.

40. Dim vehicle lights when meeting a vehicle at night. Make sure lights are adjusted to

prevent blinding oncoming drivers.

41. Reduce speed before turning or applying brakes.

42. Always check overhead clearance, especially when transporting. Be aware of low,

overhanging obstacles, such as trees and bridges.

43. Know the exact location of gas lines, utility lines, sewers, overhead and buried power

lines and other obstructions before operating in an area.

44. Use a signal person in congested areas or when people are around.

45. Use extreme caution when operating on slopes. Avoid traveling across slopes. Drive up

and down slopes whenever possible.

46. If slopes cannot be avoided, keep moldboard low and close to the machine. If machine

starts to slip, lower moldboard to the ground.

47. To avoid overturns, drive the vehicle with care and at speeds compatible with safety,

especially when operating over rough ground, when crossing ditches or slopes and

when turning.

48. Select the same gear when going downhill as you would going uphill. Select the gear

before starting down the slope.

49. Do not coast or freewheel machine down hills or slopes.

65E Turbo Motor Grader

Service Manual

vService 2.00_2013.03

Section 1

Electronic Display

50. After operating the engine, never touch the muffler, exhaust pipe, engine or radiator

until they have had time to cool.

51. Dress appropriately -wear relatively tight-fitting clothing when operating or servicing

the machine. Loose or torn clothing can catch in moving parts or controls.

52. Wear an approved safety hat when operating the machine and while in any work area.

53. When driving the machine on a road or highway, use warning lights or warning devices

as may be required by local or state government regulations. head lights, warning

lights and SMV signs are available through your dealer.

54. Keep the machine clean. Do not allow trash, debris or other articles to accumulate in

the cab, floor or foot control pedal area that may hinder safe machine operation.

55. Do not allow unauthorized personnel to service or maintain this machine. Do not

perform any work that is not authorized.

56. Machine should not be serviced with anyone in the operator's seat unless that person

is qualified and is assisting in the service procedure. Be sure operator can see

mechanic.

57. Always use external supports when working under any linkage or raised part of the

machine. Lower implements to ground whenever possible.

58. Do not service the grader with the engine running unless the grader is properly and

securely supported with all six wheels off the ground.

59. Use caution when servicing the unit around moving parts.

60. The cooling system operates under pressure that is controlled by the radiator cap. It is

dangerous to remove the cap while the system is hot. Always turn cap slowly to the

first stop and allow pressure to escape before removing the cap entirely.

61. The hydraulic system operates under pressure that is controlled by the reservoir cap.

Always turn cap slowly to relieve pressure before removing cap entirely or

disconnecting any hydraulic lines.

62. Do not smoke while refueling the vehicle. Keep any type of open flame away. Wait for

the engine to cool before refueling.

63. Keep vehicle, particularly brakes and steering, maintained in a reliable and satisfactory

condition to ensure your safety and comply with legal requirements.

64. To prevent fire or explosion, keep open flames away from battery or cold weather

staring aids. To prevent sparks which could cause explosion, use jumper cables

according to instructions.

65E Turbo Motor Grader

Service Manual

Service 2.00_2013.03vi

Section 1

Electronic Display

65. Do not attempt to service air conditioning system, if equipped. It is possible to be

severely frostbitten or injured by escaping refrigerant. Special equipment and

instruments are required to service air conditioning system. See an authorized dealer

for service.

66. Stop the engine before performing any service on the vehicle.

67. Always turn master switch to the "OFF" position when maintaining or servicing

machine.

68. When using compressed air for cleaning parts, use safety glasses with side-shields or

goggles. Limit pressure to 30 psi.

69. Escaping diesel/hydraulic fluid under pressure can penetrate skin causing serious

injury.

70. DO NOT use your hand to check for leaks. Use a piece of cardboard to search for leaks.

• Stop engine and relieve pressure before connecting or disconnecting lines.

• Tighten all connections before starting engine or pressurizing lines.

• If fluid is injected into skin, obtain medical attention immediately or gangrene may

result.

71. Fuel oil in the injection system is under high pressure and can penetrate the skin.

Unqualified persons should not remove or attempt to adjust a pump, injector nozzle or

any other part of the fuel injector system. Failure to follow these instructions can result

in serious injury.

72. Continuous long-term contact with used engine oil may cause skin cancer. Avoid

prolonged contact with used engine oil. Wash skin promptly with soap and water.

73. Wheels can be very heavy. Handle with care and ensure, when stored, that they cannot

fall and cause injury.

74. When checking tire inflation pressure, stand to the side in case of explosion.

75. Never use reconditioned tire rims.

76. If brakes are to be serviced, the machine must be secured to prevent movement.

77. Dispose of all drained fluids and removed filters properly.

78. If any servicing or adjustments require the battery to be disconnected, disconnect the

negative (-) ground cable.

79. When servicing electrical components, disconnect the negative (-) ground cable.

80. If welding is required on the machine, disconnect the negative (-) ground cable. Failure

to disconnect the battery may result in damage to the electrical components.

65E Turbo Motor Grader

Service Manual

viiService 2.00_2013.03

Section 1

Electronic Display

81. If welding is required on an attachment, remove the attachment from the machine.

82. Give complete and undivided attention to the job at hand so that complete control of

the machine is maintained at all times.

83. Under no circumstances should gasoline, alcohol or blended fuels be added to diesel

fuel. These combinations can create an increased fire or explosive hazard. In a closed

container, such as a fuel tank, these blends are more explosive than pure gasoline.

84. Refuel the machine outdoors with the engine shut off. Replace the fuel cap securely.

Use an approved fuel container. Do not smoke when handling fuel. Avoid spilling fuel.

85. Never remove the fuel cap or refuel with the engine running.

86. Do not smoke while refueling the machine or when standing near fuel. Keep any type of

open flame away.

87. Maintain control of the fuel filler nozzle when filling the tank.

88. Do not fill the fuel tank to capacity. Allow room for expansion.

89. Wipe up spilled fuel immediately.

90. Always tighten the fuel tank cap securely.

91. If the original fuel tank cap is lost, replace it with a genuine replacement cap. A non

approved cap may not be safe.

92. Keep equipment clean and properly maintained.

93. Do not drive equipment near open fires.

94. Never use fuel for cleaning purposes.

95. The motor grader is equipped with Roll Over Protection System (ROPS) and a Falling

Object Protection System (FOPS) which must be maintained in a serviceable condition.

96. Do not modify, drill, weld or alter the ROPS or FOPS in anyway. Doing so could render

you liable to legal prosecution in some countries.

97. Never attempt to straighten or weld any part of the main frame or retaining brackets

that have suffered damage. By doing so the structure may be weakened and safety

compromised. Replace all damaged parts.

98. Be careful when driving under bridges or working in confined spaces with low

headroom.

99. Never attach chains or ropes to the ROPS or FOPS for pulling purposes.

100. Never take unnecessary risks even though the ROPS and FOPS provide protection.

65E Turbo Motor Grader

Service Manual

Service 2.00_2013.03viii

Section 1

Electronic Display

OSHA REQUIREMENTS NOW MAKE IT THE EMPLOYER'S RESPONSIBILITY TO FULLY

INSTRUCT EACH OPERATOR IN THE PROPER AND SAFE OPERATION OF ALL OPERATIVE

EQUIPMENT. BOTH EMPLOYER AND EMPLOYEE SHOULD THOROUGHLY FAMILIARIZE

THEMSELVES WITH THE MACHINE OPERATION.

Some pictures in this manual show safety shields removed or open to

show parts being serviced or for clarity. all shields should be closed or

replaced prior to operating the machine.

Fasten seat belt before starting engine!

65E Turbo Motor Grader

Service Manual

IService 2.00_2013.03

Section 1

Electronic Display

CONTENTS

ELECTRONIC DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Screen Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Start-Up Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Main Operating Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

View Engine Diagnostics 1 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

View Engine Diagnostics 2 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

View Transmission Diagnostics Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

View CAN Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

System Settings Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

– Inching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

– Contrast Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

– Reset All . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

– AEB Mode Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

– AEB Calibration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

– Top Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

– Top Right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

– Bottom Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

– Bottom Right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

View Errors Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Active Error Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Electronic Display Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

65E Turbo Motor Grader

Service Manual

Section 1

Electronic Display

Service 2.00_2013.031-II

This page intentionally left blank.

65E Turbo Motor Grader

Service Manual

1-1Service 2.00_2013.03

Section 1

Electronic Display

Section 1: Electronic Display

SCREEN DESCRIPTIONS

The system incorporates gauges and diagnostics with a LCD (Liquid Crystal Display) of current readings

through which the operator may scroll.

Start-Up Screen

This screen appears for 2 seconds after engine is started.

Control Keys, 1, - Functions change, depending on screen being

displayed. Key functions will be displayed with each screen.

Main Operating Screen

1. Active Gear - Displays what gear is currently active.

2. Engine RPM - Displays engine rpm.

3. Fuel Level - Displays current fuel level.

4. Menu - Main Menu Control key option. Press control key

associated with icon to enter Menu Screen.

5. Top Left - Displays operator chosen system setting. For

example, the current system setting is fuel level.

6. Top Right - Displays operator chosen system setting. For

example, the current system setting is oil pressure.

7. Bottom Left - Displays operator chosen system setting. For

example, the current system setting is coolant temperature.

8. Bottom Right - Displays operator chosen system setting.

For example, the current system setting is fuel rate.

1

1

2

3

4

5

6

78

65E Turbo Motor Grader

Service Manual

Service 2.00_2013.031-2

Section 1

Electronic Display

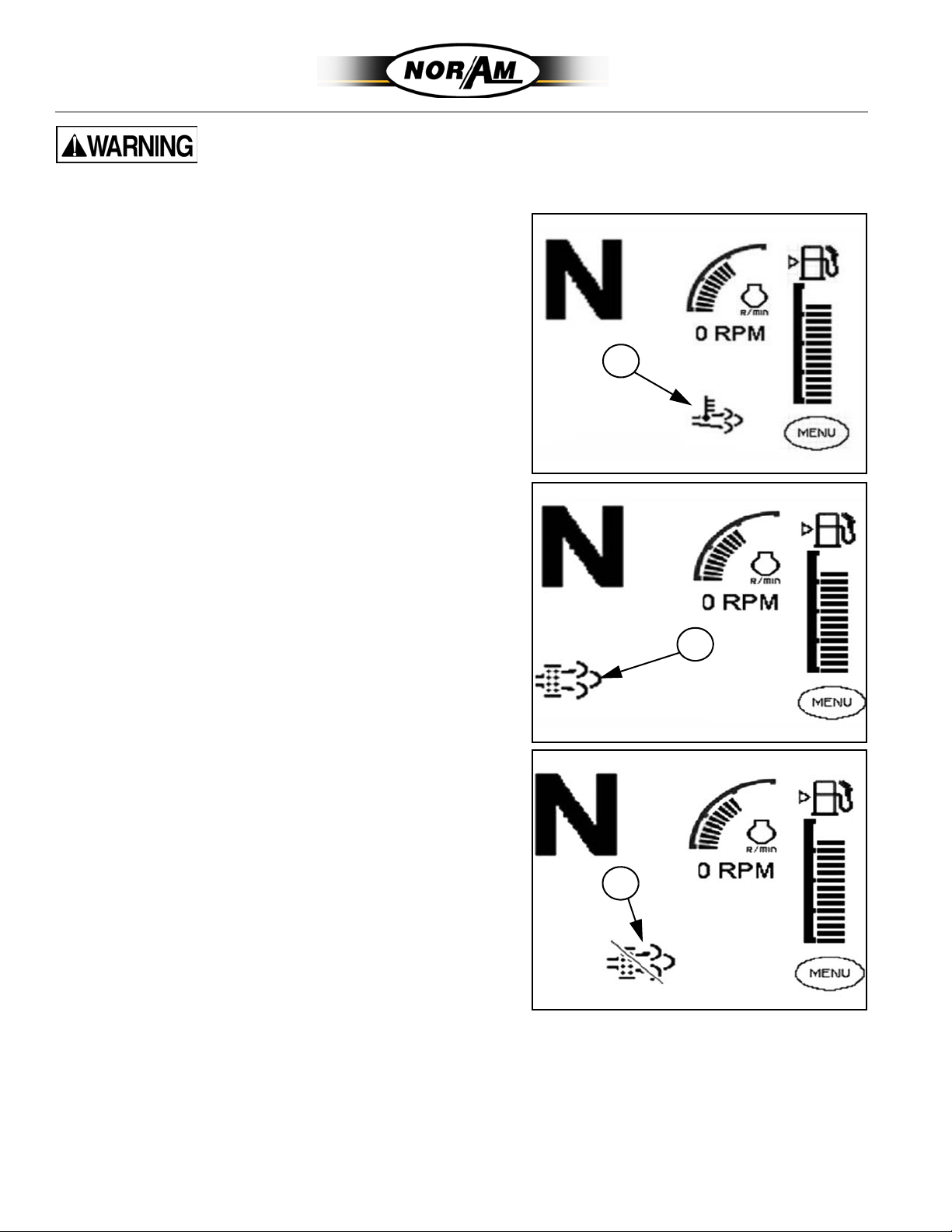

High exhaust temperatures during a regeneration cycle.

9. Regeneration In-Progress - Displays icon when a

regeneration in-progress cycle is active.

NOTE: Regeneration In-Progress is only available on the CAT

C3.4 Tier IVi engine.

The CAT C3.4 Tier IVi engine will automatically enter a

regeneration cycle at 90% soot load. The operator will be

able to operate the machine as normal during a

regeneration cycle.

10. Regeneration Force Option - Displays icon when a forced

regeneration cycle is active.

NOTE: Regeneration Force Option is only available on the

CAT C3.4 Tier IVi engine. This option is best used immediately

following deactivation of the Regeneration Inhibit Option.

When the Regeneration Force function is active, the engine

will enter a regeneration cycle when the ECM recognizes a

high soot load. The CAT C3.4 Tier IVi engine will not

regenerate on command at any soot load, the ECM will

control the regeneration cycle.

11. Regeneration Inhibit Option - Displays icon when inhibit

regeneration is active.

NOTE: Regeneration Inhibit Option is only available on the

CAT C3.4 Tier IVi engine.

The Regeneration Inhibit Option prevents the engine from

entering a regeneration cycle. It is not recommended to

leave the inhibit function active.

NOTICE: Do not leave Regeneration Inhibit Option active at

all times, only use as needed. Preventing a regeneration cycle

past the soot load limit can cause damage to the after-

treatment system.

9

10

11

65E Turbo Motor Grader

Service Manual

1-3Service 2.00_2013.03

Section 1

Electronic Display

Menu Screen

Down arrow, 1, moves selection box down.

Up arrow, 2, moves selection box up.

Right arrow, 3, enters selected screen.

ESC, 4, exits to previous screen.

Highlight screen name and select with the right arrow key.

View Engine Diagnostics 1 Screen

View Engine Diagnostics 1 Screen displays the following:

– Engine Speed

– Percent Load (Engine)

– Coolant Temperature

– Fuel Level

– Oil Pressure

– Boost Pressure

– Throttle Command

NOTE: View Engine Diagnostics 1 Screen is a read only screen. The up, down, and enter control keys do

not function in View Engine Diagnostics 1 Screen.

123

4

65E Turbo Motor Grader

Service Manual

Service 2.00_2013.031-4

Section 1

Electronic Display

View Engine Diagnostics 2 Screen

View Engine Diagnostics 2 Screen displays the following:

– Battery

– Manifold Temperature

– Fuel Temperature

– Hest Lamp

– DPF Inhibit Lamp (Only available on the CAT C3.4 TIVi engine option)

– DPF Force Lamp (Only available on the CAT C3.4 TIVi engine option)

– Regeneration Force Icon (Only available on the CAT C3.4 TIVi engine option)

– Regeneration Inhibit Icon (Only available on the CAT C3.4 TIVi engine option)

To activate Regeneration Force or Regeneration Inhibit, press the control keys associated with the desired

arrows. Press the control key associated with the “ESC” icon to return to the Menu Screen.

View Transmission Diagnostics Screen

View Transmission Diagnostics Screen displays the following:

– Transmission Oil Temperature

– Torque Converter Temperature

– Current Gear

– Input Shaft Speed

– Output Shaft Speed

– Ratio

– Inching

– Brake

NOTE: View Transmission Diagnostics Screen is a read only screen. The up, down, and enter control keys

do not function in View Transmission Diagnostics Screen.

This manual suits for next models

2

Table of contents