Nord Drivesystems B 1050 Series Product guide

B 1050 – en

Industrial gear units

Operating and Assembly Instructions

Industrial gear units – Operating and Assembly Instructions

2 B 1050 en-1819

Pos: 2/ A nl eit ung en /G et ri e be/ 0. Prol og /Sic her hei ts - un d Anwe nd ung s hi nw ei s e f ür Getri eb e [B105 0.. .B 2 05 0] @ 27 \mod_1550741709815_388.docx@ 2489430@ @ 1

General safety and operating instructions

1. General

Depending on its

protection class, the device may have live, bare,

moving or rotating parts or hot surfaces during operation,.

Unauthorised removal of covers, improper use, incorrect installation or

operation causes a risk of serious personal injury or material damage.

All transport, installation, commissioning and maintenance work must be

carried out by qualified specialist personnel (national accident

prevention regulations must be observed).

Within the meaning of this basic safety information, qualified specialist

person

nel are persons who are familiar with the installation, assembly,

commissioning and operation of the product and who have the training

and experience to recognise and avoid any hazards and risks.

2. Intended use

NORD products may only be used according to

the information in the

catalogue and the associated technical documentation.

Compliance

with the operating and installation instructions is a

prerequisite for fault-free operation

and for the fulfilment of any

warranty claims. These operating and installation instructions must

be read and understood before working with the device!

These operating and installation instructions contain important

information about servicing. They must therefore be kept

in close

proximity to the device.

All details regarding te

chnical data and permissible conditions at the

installation site must be complied with.

3. Transport, storage

Information regarding transport, storage and correct handling must be

complied with.

4. Installation

The device must be protected against impermissible loads. In particular,

during transport and handling, components must not be deformed or

changed.

Touching of electronic components and contacts must be

avoided.

5. Electrical connection

When working on live three-

phase motors, the applicable

national accident prevention regulations must be complied with

(e.g. BGV A3, formerly VBG 4).

The electrical installation must be implemented according to the

applicable regulations (e.g. cable cross-

section, fuses, earth

lead connections).

Information regarding EMC-compliant installation –

such as

shielding, earthing and installation of cables –

can be found in

the three-

phase motor documentation. Compliance with the limit

values specified in the EMC regulations is the responsibility of

the manufacturer of the system or machine.

6. Operation

Appropriate safety measures must be taken for applications

where failure of the device may result in injury.

Where necessary, systems in which NORD devices are installed

must be equipped with additional monitoring and protective

equipment according to the applicable safety requirements, e.g.

legislation concerning technical equipment, accident prevention

regulations, etc.

All covers and guards must be kept closed during operation.

7. Maintenance and repairs

After the de

vice has been disconnected from the power supply,

live equipment components and power connections should not

be touched immediately, because of possible charged

capacitors.

Further information can be found in this documentation.

These safety instructions must be kept in a safe place!

Documentation

B 1050 en-1819 3

Pos: 3/ A nl eit ung en /G et ri e be/ 0. Prol og /D o ku men tat i o n - Versionsliste[B 1050]@ 27\mod_1550672159365_388.docx@ 2489190 @ @ 1

Documentation

Designation:

B 1050

Material No.:

6052902

Series: Gear units and geared motors

Type series:

SK 5207 – SK 15507 and SK 5217 – SK 11217

Gear unit types: Industrial gear units

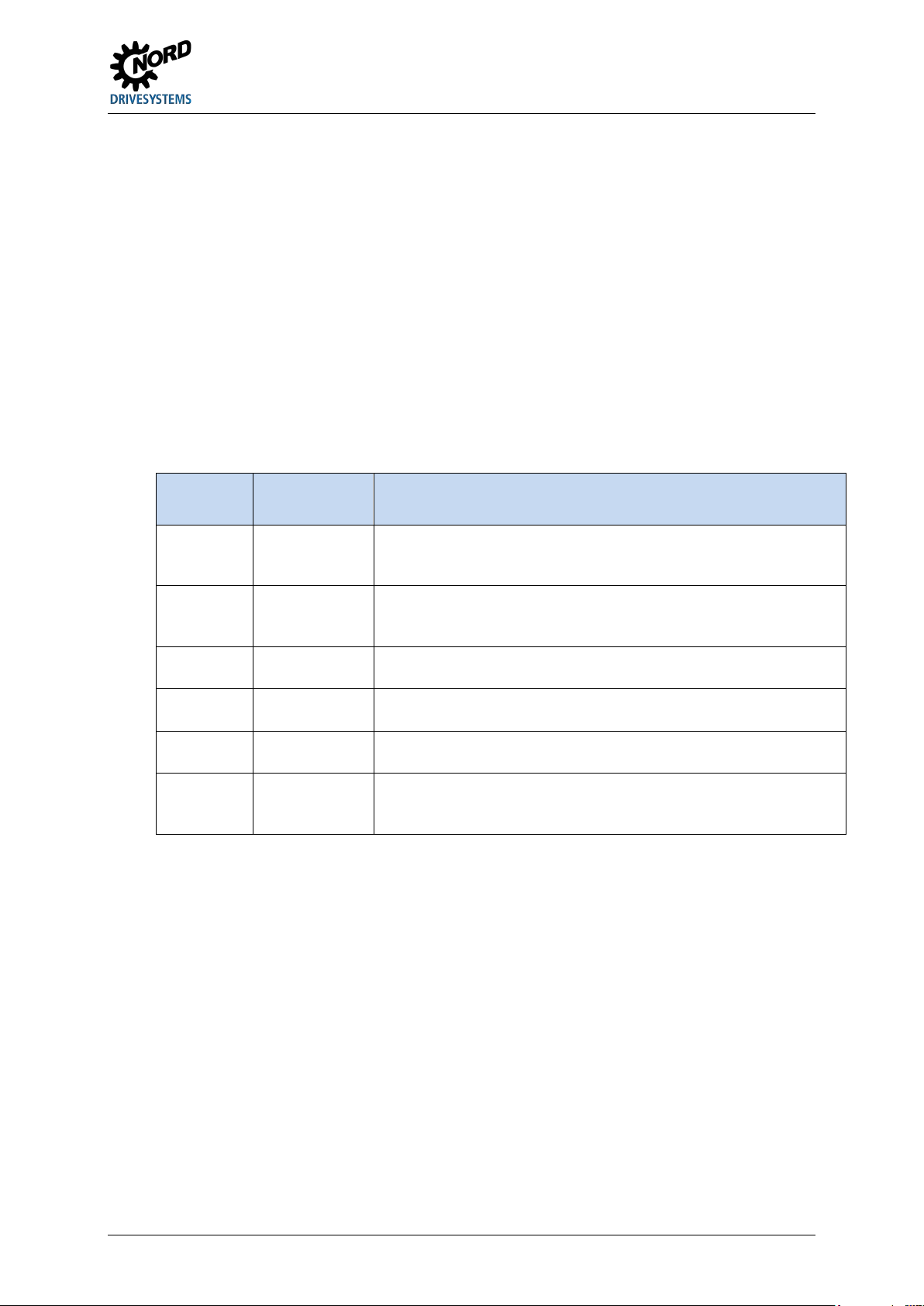

Version list

Title,

Date

Order number Remarks

B 1050,

January

2013

6052902 / 0213

-

B 1050,

September

2014

6052902 / 3814

General corrections

B 1050,

April 2015

6052902 / 1915

General corrections

B 1050,

March 2016

6052902 / 0916

General corrections

B 1050,

May 2017

6052902 / 1817

Revised

B 1050,

May 2019

6052902 / 1819

Extension of the series MAXXDRIVE®XT

General corrections

Table 1: Version list B 1050

Pos: 4/ Al lg emei n/ All ge mei ngül tig e M o dul e/---------Seitenumbruch kompakt---------@ 13\mod_1476369695906_0.docx@ 2265495@ @ 1

Industrial gear units – Operating and Assembly Instructions

4 B 1050 en-1819

Pos: 5/ Al lg e mei n/ All ge mei ng ülti ge Modul e/U r he ber rec ht s ver mer k @ 5\mod_1410955083459_388.docx@ 150427@ @ 1

Copyright notice

As an integral component of the device described here, this document must be provided to all

users in a suitable form.

Any editing or amendment or other utilisation of the document is prohibited.

Pos: 6/ Al lg emei n/ All ge mei ngül tig e M o dul e/H era usg eb er @ 0\mod_1325779078002_388.docx@ 5270@ @ 1

Publisher

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 1 • 22941 Bargteheide, Germany • http://www.nord.com/

Fon +49 (0) 45 32 / 289-0 • Fax +49 (0) 45 32 / 289-2253

Member of the NORD DRIVESYSTEMS Group

===Endeder ListefürT extmarkeCopyright ===

Publisher

B 1050 en-1819 5

Industrial gear units – Operating and Assembly Instructions

6 B 1050 en-1819

Pos: 8/ A ll ge mei n/ S t euer mo d ule/ In h al ts ver zei c h nis @ 0 \mod_1317978518480_388.docx@ 4078@ @ 1

Table of Contents

=== Ende d er List e f ür Text m ar ke I nh al ts ver z ei ch ni s = ==

1Notes ..........................................................................................................................................................10

1.1 General information..........................................................................................................................10

1.2 Safety and information symbols .......................................................................................................10

1.3 Explanation of markings...................................................................................................................10

1.4 Intended use ....................................................................................................................................11

1.5 Safety information ............................................................................................................................12

1.6 Other documents..............................................................................................................................13

2Description of gear units ..........................................................................................................................14

2.1 Type designations and gear unit types.............................................................................................14

3Assembly instructions, storage, preparation, installation ....................................................................17

3.1 Transporting the gear unit................................................................................................................17

3.1.1 Standard gear units ............................................................................................................18

3.1.2 with motor adapter..............................................................................................................19

3.1.3 with V-belt drives ................................................................................................................20

3.1.4 with V-belt drive..................................................................................................................21

3.1.5 on motor swing base or base frame ...................................................................................22

3.2 Storage ............................................................................................................................................23

3.3 Long-term storage............................................................................................................................23

3.4 Inspecting the drive unit ...................................................................................................................24

3.5 Checking the type plate data............................................................................................................25

3.6 Checking the version........................................................................................................................26

3.7 Preparing for installation ..................................................................................................................27

3.8 Installing the gear unit......................................................................................................................29

3.9 Motor (Option: IEC, NEMA)..............................................................................................................31

3.10 Gear unit with hollow shaft (Option: A, EA)......................................................................................34

3.10.1 Hollow shaft with fastening element (Option: B) .................................................................35

3.10.2 Hollow shaft with shrink disc element (Option: S)...............................................................36

3.11 Flange version gear units (Option: F, FK, VL2/3/4/5, KL2/3/4).........................................................39

3.12 Motor base frame and motor swing base (Option: MS, MF).............................................................39

3.13 Motor mount (Option: MT)................................................................................................................40

3.14 Belt drives ........................................................................................................................................40

3.15 Internal cooling system (Option: CC) ...............................................................................................43

3.16 External cooling system (Option: CS1-X, CS2-X) ............................................................................44

3.17 Lubricant circulation (Option: LC, LCX)............................................................................................46

3.18 Torque supports (Option: D, ED, MS) ..............................................................................................47

3.19 Oil heater (Option: OH) ....................................................................................................................48

3.20 Brake................................................................................................................................................48

3.21 Covering cap (Option: H, H66, FAN, MF.., MS…)............................................................................48

3.22 Hubs on gear unit shafts ..................................................................................................................49

3.22.1 Drive coupling.....................................................................................................................51

3.22.1.1 Dog coupling 51

3.22.1.2 Turbo coupling 51

3.22.1.3 Dog coupling 52

3.22.2 Output coupling ..................................................................................................................53

3.23 Gear unit monitoring sensors ...........................................................................................................53

3.24 Subsequent paintwork......................................................................................................................53

4Commissioning .........................................................................................................................................54

4.1 Oil level and venting.........................................................................................................................54

4.2 Taconite seal....................................................................................................................................55

4.3 Lubricant circulation (Option: LC, LCX)............................................................................................56

4.4 Gear unit cooling with fan( Option: FAN)..........................................................................................57

4.5 Internal cooling system (Option: CC) ...............................................................................................58

4.6 External cooling system (Option: CS1-X, CS2-X) ............................................................................59

4.7 Oil heater (Option: OH) ....................................................................................................................60

Table of Contents

B 1050 en-1819 7

4.8 Temperature monitoring (Option: PT100) ........................................................................................60

4.9 Backstop / freewheeling coupling (Option: R, WX) ..........................................................................61

4.10 Checking the gear unit .....................................................................................................................65

4.11 Checklist ..........................................................................................................................................66

4.11.1 Obligatory ...........................................................................................................................66

4.11.2 Optional ..............................................................................................................................67

5Service and maintenance .........................................................................................................................68

5.1 Service and Maintenance Intervals ..................................................................................................68

5.2 Service and maintenance work ........................................................................................................70

5.2.1 Visual inspection.................................................................................................................71

5.2.2 Running noises...................................................................................................................71

5.2.3 Gear unit cooling with fan (Option: FAN)............................................................................71

5.2.4 Heat exchanger (Option CS2) ............................................................................................71

5.2.5 Shaft sealing rings..............................................................................................................72

5.2.6 Oil level...............................................................................................................................73

5.2.6.1 Oil level screw 73

5.2.6.2 Oil inspection glass/oil level glass (Option: OSG), Oil level indicator (Option: OST) 74

5.2.6.3 Oil dipstick (Option: PS) 74

5.2.6.4 Oil level tanks (Option: OT) 74

5.2.7 Venting ...............................................................................................................................75

5.2.7.1 Vent filter (Option: FV) 75

5.2.7.2Cellulose filter (Option: EF) 75

5.2.7.3 Drying agent filter (Option: DB) 76

5.2.8 Rubber buffer (Option: ED).................................................................................................76

5.2.9 Piping .................................................................................................................................76

5.2.9.1 Piping (Option: LC, LCX, OT) 76

5.2.9.2 Hose lines (Option: LC, LCX, CS1, CS2, OT) 76

5.2.10 Oil filter (Option: CS1-X, CS2-X, LC/LCX) ..........................................................................77

5.2.11 Bearings is the output flange (Option: VL2/3/4/6, KL2/3/4/6)..............................................77

5.2.12 Taconite seal ......................................................................................................................78

5.2.13 Changing the oil..................................................................................................................79

5.2.14 Internal cooling system (Option: CC)..................................................................................80

5.2.15 Bearings in the gear unit.....................................................................................................80

5.2.16 V-belts (belt drives).............................................................................................................81

5.2.17 General overhaul................................................................................................................81

6Disposal .....................................................................................................................................................82

7Appendix....................................................................................................................................................83

7.1 Standard positions of the oil drain, vent and oil level .......................................................................83

7.2 Installation orientation ......................................................................................................................97

7.2.1 Helical gear unit..................................................................................................................97

7.2.2 Bevel helical gear unit ........................................................................................................97

7.3 Lubricants ........................................................................................................................................98

7.3.1 Roller bearing greases .......................................................................................................98

7.3.2 Types of lubricant oil...........................................................................................................99

7.3.3 Lubricant quantities ..........................................................................................................101

7.3.3.1 Helical gear units 101

7.3.3.2 Helical bevel gear units 102

7.3.3.3 MAXXDRIVE®XT industrial helical bevel gear unit 102

7.4 Torque values ................................................................................................................................103

7.5 Tolerances for bolting surfaces ......................................................................................................103

7.6 Troubleshooting .............................................................................................................................104

7.7 Leakage and leak-tightness ...........................................................................................................106

7.8 Repair information..........................................................................................................................108

7.8.1 Repairs .............................................................................................................................108

7.8.2 Internet information...........................................................................................................108

7.9 Abbreviations .................................................................................................................................109

Industrial gear units – Operating and Assembly Instructions

8 B 1050 en-1819

Pos: 10 /Al lg e mei n/ Ste u erm o dul e/ Abbi ld ung s ver z eich nis @ 0\mod_1317978515699_388.docx@ 3917 @ @ 1

List of illustrations

=== Ende d er List e f ür Text m ar ke A b bi ldu ng s ver zei c h ni s == =

Figure 1: MAXXDRIVE®XT 2-stage helical bevel gear unit .................................................................................. 16

Figure 2: Transport of standard gear unit .............................................................................................................. 18

Figure 3: Transport of gear unit with motor adapter............................................................................................... 19

Figure 4: Transport of agitator version gear unit.................................................................................................... 20

Figure 5: Transport of agitator version gear units.................................................................................................. 21

Figure 6: Transport of gear unit with motor swing base or base frame.................................................................. 22

Figure 7: Name plate (example) ............................................................................................................................ 25

Figure 8: Centre of gravity of motor....................................................................................................................... 32

Figure 9: Fitting the coupling to the motor shaft..................................................................................................... 33

Figure 10: Applying lubricant to the shaft and the hub........................................................................................... 34

Figure 11: Assembly and disassembly of the fastening element (schematic diagram).......................................... 35

Figure 12: Machine shaft assembly for special hollow shafts with shrink discs ..................................................... 37

Figure 13: Fitted shrink disc................................................................................................................................... 38

Figure 14: V-belt pulley (disassembled/assembled) .............................................................................................. 42

Figure 15: Axle alignment (belt drives) .................................................................................................................. 42

Figure 16: Cooling cover with cooling coil fitted (schematic diagram) ................................................................... 43

Figure 17: Industrial gear unit with CS1-X and CS2-X cooling systems ................................................................ 44

Figure 18: Hydraulic plan of industrial gear units with CS1-X and CS2-X cooling systems ................................... 45

Figure 19: Permissible installation tolerances of the torque support (Option D and ED) (schematic diagram)...... 47

Figure 20: Correct assembly of drive elements ..................................................................................................... 49

Figure 21: Example of a simple pulling device....................................................................................................... 50

Figure 22: Switching pin with separate mechanical switch.................................................................................... 52

Figure 23: Activation of the pressure vent ............................................................................................................. 55

Figure 24: Testing a Taconite seal ........................................................................................................................ 55

Figure 25: Industrial gear unit with backstop (schematic diagram)........................................................................ 61

Figure 26: MSS7 seal ............................................................................................................................................ 72

Figure 27: Checking the oil level with a dipstick .................................................................................................... 73

Figure 28: Checking the oil level with an oil dip-stick............................................................................................. 74

Figure 29: Vent filter (Option FV)........................................................................................................................... 75

Figure 30: Cellulose filter (Option EF) ................................................................................................................... 75

Figure 31: Re-greasing Taconite seals.................................................................................................................. 78

Figure 32: Numbering of oil screw holes on SK 5207 – SK 10507 ........................................................................ 90

Figure 33: Numbering of oil screw holes on SK 11207 – SK 15507 ...................................................................... 96

Figure 34: Helical gear unit installation positions with standard mounting surface................................................ 97

Figure 35: Bevel gear unit installation positions with standard mounting surface.................................................. 97

List of tables

B 1050 en-1819 9

Pos: 12 /Al lg e mei n/ Ste u erm o dul e/T ab ell en ver zei c hni s @ 0\mod_1317978519199_388.docx@ 4124@ @ 1

List of tables

=== Ende d er List e f ür Text m ar ke T a bel l en verz eic hnis == =

Table 1: Version list B 1050..................................................................................................................................... 3

Table 2: Type designations and gear unit types .................................................................................................... 14

Table 3: Versions and options ............................................................................................................................... 15

Table 4: Explanation of type plate ......................................................................................................................... 26

Table 5: IEC and NEMA motor weights ................................................................................................................. 31

Table 2: Transnorm motor weights........................................................................................................................ 32

Table 6: Oil spaces as delivered............................................................................................................................ 54

Table 7: Backstop lift-off speeds SK 5..07 – SK 10..07 ......................................................................................... 62

Table 8: Backstop lift-off speeds SK 11..07 – SK 15..07 ....................................................................................... 63

Table 9: Backstop lift-off speeds SK 5..17 – SK 11..17 ......................................................................................... 64

Table 10: Obligatory checklist for commissioning.................................................................................................. 66

Table 11: Optional checklist for commissioning..................................................................................................... 67

Table 12: Service and Maintenance Intervals........................................................................................................ 69

Table 13: Disposal of materials ............................................................................................................................. 82

Table 14: Position of housing options on oil screw holes (standard installation positions) .................................... 84

Table 15: Roller bearing greases........................................................................................................................... 98

Table 16: Lubricant oil table................................................................................................................................. 100

Table 17: Lubricant quantities for helical gear units............................................................................................. 101

Table 18: Lubricant quantities for bevel helical gear units ................................................................................... 102

Table 19: Lubricant quantities MAXXDRIVE®XT bevel gear unit........................................................................ 102

Table 20: Torque values...................................................................................................................................... 103

Table 22: Overview of malfunctions..................................................................................................................... 105

Table 23: Definition of leakage according to DIN 3761........................................................................................ 107

Pos: 15 /A nl ei tu nge n/ Ge tri ebe /1. Hin wei s e/ 1. H i n weis e @ 3\mod_1368690405560_388.docx @ 65212@ 1@ 1

Industrial gear units – Operating and Assembly Instructions

10 B 1050 en-1819

1 Notes

Pos:16/Anleitungen/Getriebe/1.Hinweise/AllgemeineHinweise@ 27\mod_1550742220897_388.docx@ 2489 466 @ 2 @ 1

1.1 General information

Read the Operating Manual carefully prior to performing any work on or putting the gear unit into

operation. Strict compliance with the instructions in this operating manual is essential. This Operating

Manual and all associated special documentation must be kept in the immediate vicinity of the gear

unit.

Getriebebau NORD accepts no liability for personal injuries or damage to material or assets which

result from failure to observe the operating instructions, incorrect operation, deployment of

inadequately qualified personnel, improper use or modifications to the gear unit, including installed or

attached components.

General wearing parts, e.g. radial seals are excluded from the warranty.

If additional components are attached to or installed on or in the gear unit (e.g. motor, cooling system,

pressure sensor etc.) or components (e.g. cooling system) are supplied with the order, the operating

instructions for these components must be observed.

If geared motors are used, compliance with the Motor Operating Manual is also necessary.

If you do not understand the contents of this Operating Manual or additional operating instructions,

please consult Getriebebau NORD!

Pos: 17 /A nl ei tu nge n/ Ge tri ebe /1. Hin wei s e/Si c her hei ts- un d H i n wei sz eic h en [_Ti t el] @ 3\mod_1370591783249_388.docx@ 76351@ 2 @ 1

1.2 Safety and information symbols

Pos: 18 /A nl ei tu nge n/ El e ktr o ni k/FU und Star t er/ 1. Allg e mei n es/ Si ch er hei ts- u nd Inst allati onshi nweis e und War n- Gef ahr en hi nw eis e/ Er lä uter u ng d er ver we nd et e n A usz ei c hnu ng e n @ 22\mod_1530603439595_388.docx@ 2429680@ 2 @ 1

1.3 Explanation of markings

DANGER

Indicates an immediate danger, which may result in death or very serious injury if it is not avoided.

WARNING

Indicates a dangerous situation, which may result in death or serious injury if it is not avoided.

CAUTION

Indicates a dangerous situation, which may result in minor injuries if it is not avoided.

NOTICE

Indicates a situation, which may result in damage to the product or its environment if it is not avoided.

Information

Indicates hints for use and especially important information to ensure reliability of operation.

Pos: 19 /Allgemein/AllgemeingültigeM odul e/ ---------Seite num br uc h ko m pak t --------- @ 13 \mod_1476369695906_0.docx@ 2265495@ @ 1

1 Notes

B 1050 en-1819 11

Pos: 20 / A nl ei tu ng e n/ Ge tr ie be /1. Hin w eis e/B es ti m mu ng s ge mäß e V er w e nd ung [B1 05 0] @ 17 \mod_1492069354889_388.docx@ 2340259@ 2@ 1

1.4 Intended use

These gear units generate a rotational movement and are intended for use in commercial systems.

The gear unit must only be used according to the information in the technical documentation from

Getriebebau NORD.

Commissioning (start of proper operation) is prohibited until it has been established that the machine

complies with the local laws and directives. The EMC Directive 2004/108/EC and the Machinery

Directive 2006/42/EC in their currently valid scope of application must be complied with in particular.

DANGER Explosion hazard

Serious injury and material damage due to explosion are possible.

• Use in explosion hazard areas is prohibited.

WARNING Injury to persons

Appropriate safety measures must be taken in the case of applications in which failure of a gear unit or geared

motor may cause a hazard to persons.

• Safeguard a wide area around the hazard zone.

WARNING

Material damage and personal injury

If the gear unit is not used as designed, this may cause damage to the gear unit or the premature failure of

components. Personal injury as a result of this cannot be ruled out.

• Strict compliance with the technical data on the type plate is essential. The documentation must be observed.

Pos: 21 /Al lg emei n/Al lg em eing ülti ge M od ule/ ---------Seite num bruc h kom pak t --------- @ 13 \mod_1476369695906_0.docx@ 2265495@ @ 1

Industrial gear units – Operating and Assembly Instructions

12 B 1050 en-1819

Pos: 22 /A nl ei tu nge n/ Ge tri ebe /1. Hin wei s e/Si c her hei ts hi nw eis e [ B1 050 ] @ 3\mod_1368692826860_388.docx@ 65841@ 2 @ 1

1.5 Safety information

Observe all safety information, including that provided in the individual sections of this Operating

Manual. All national and other regulations on safety and accident prevention must also be observed.

DANGER Severe personal injury

Serious physical and property damage may result from inappropriate installation, non-designated use, incorrect

operation, non-compliance with safety information, unauthorised removal of housing components or safety covers

and structural modifications to the gear unit.

Work, e.g. transportation, storage, installation, electrical connection, commissioning, servicing, maintenance and

repair must only be performed by qualified specialist personnel

• Observe the Operating Manual

• Observe the safety information

• Observe the safety and accident prevention regulations

• Tighten the driven elements or secure the parallel keys before switching on

• Do not make any structural modifications

• Do not remove any safety devices

• If necessary, wear hearing protection when working in the immediate vicinity of the gear unit

• All rotating components must be provided with guards. As standard, covers are fitted by NORD. The covers

must always be used if contact protection is not provided by other methods.

DANGER Injury to persons

The surfaces of gear units or geared motors may become hot during or shortly after operation. Danger of burns!

• Installation and maintenance work must only be performed when gear unit is at a standstill and has cooled

down. The drive must be isolated and secured to prevent accidental start-up.

• Wear protective gloves.

• Shield hot surfaces with contact guards.

• Do not store inflammable objects or substances in the immediate vicinity of the gear unit.

WARNING

Injury to persons

Serious injury and material damage due to improper transport are possible.

• No additional loads may be attached.

• Transportation aids and lifting gear must have an adequate load-bearing capacity.

• Pipes and hoses must be protected from damage.

1 Notes

B 1050 en-1819 13

CAUTION Injury to persons

Danger of cuts from exterior edges of attachment adapters, flanges and covers.

Contact freezing with metallic components in case of low temperatures.

• In addition to personal protective equipment, wear suitable protective gloves and suitable goggles during

assembly, commissioning, inspection and maintenance, in order to prevent injuries.

It is recommended that repairs to NORD products are carried out by the NORD Service department.

Pos: 23 /A nl ei tu nge n/ Ge tr i ebe /1. Hin w eis e/ Wei ter e U nt er lag e n @ 3\mod_1368693112418_388.docx@ 65889@ 2 @ 1

1.6 Other documents

Further information may be obtained from the following documents:

• Gear unit catalogues (G1000, G1012, G1014, G1035, G1050, G2000),

• Operating and maintenance instructions for the electric motor,

• if applicable, the Operating Manuals for attached or supplied options

Pos: 25 /A nl ei tu nge n/ Ge tr i ebe /2. Getr i eb eb esc hrei b ung / 2. Getri e be bes c hr eib u ng [ Ti t el] @ 3\mod_1368691027023_388.docx@ 65591@ 1 @ 1

Industrial gear units – Operating and Assembly Instructions

14 B 1050 en-1819

2 Description of gear units

Pos: 26 /A nlei tunge n/Ge triebe /2. Getr ieb ebeschr eib ung/T ypenb ezeic hnung en und Ge trie beart en_01 [B 1050, B 2050] @ 29 \mod_1551802372814_388.docx@ 2498172@ 2 @ 1

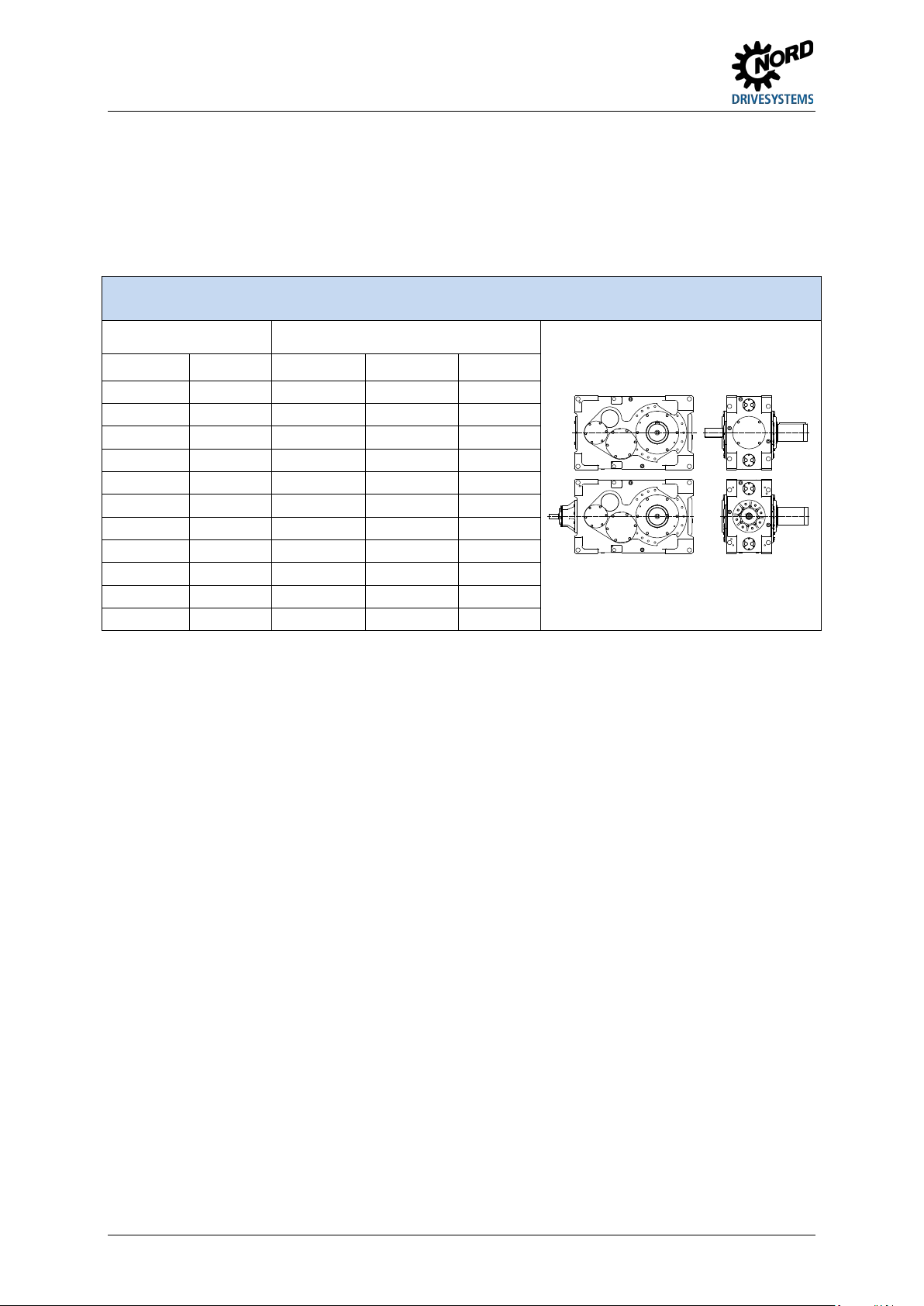

2.1 Type designations and gear unit types

Gear unit types / Type designations

Helical gear units

Helical bevel gear units

2-stage 3-stage 2-stage 3-stage 4-stage

SK 5207 SK 5307 SK 5217 SK 5407 SK 5507

SK 6207

SK 6307

SK 6217

SK 6407

SK 6507

SK 7207

SK 7307

SK 7217

SK 7407

SK 7507

SK 8207

SK 8307

SK 8217

SK 8407

SK 8507

SK 9207

SK 9307

SK 9217

SK 9407

SK 9507

SK 10207

SK 10307

SK 10217

SK 10407

SK 10507

SK 11207 SK 11307 SK 11217 SK 11407 SK 11507

SK 12207

SK 12307

SK 12407

SK 12507

SK 13207

SK 13307

SK 13407

SK 13507

SK 14207 SK 14307

SK 14407 SK 14507

SK 15207

SK 15307

SK 15407

SK 15507

Table 2: Type designations and gear unit types

Double gear units consist of two single gear units.

SK 5207 - SK 15507 and SK 5217 – SK 11217 gear units should be treated according to these

instructions. The operating and assembly manual B 1000 should be used for attached gear units.

Type designation for double gear units: e. g. SK 13307 /7282 (consisting of single gear units

SK 13307 and SK 7282).

Pos: 27 /All ge mei n/Al lge mei ng ültig e M odul e/---------Sei te num bruc h kom pak t --------- @ 13 \mod_1476369695906_0.docx@ 2265495@ @ 1

2 Description of gear units

B 1050 en-1819 15

Pos: 28 /A nl ei tu nge n/ Ge tri ebe /2. Getr ie b ebes c hrei b ung /T yp en bez eic h nu nge n undGetriebearten_02[B1050]@ 30\mod_1552914025076_388.docx@ 2510772@ @ 1

Versions / Options

Abbreviation

Description

Details on type plate

See Section 3

See Section 4

Abbreviation

Description

Details on type plate

See Section 3

See Section 4

A

Hollow shaft version

X

X

…K

with elastic coupling

X

B

Fastening element

X

X

…T

with hydrodynamic coupling

X

CC

Cooling coil

X

X

X

MS…

Motor swing base

X

X

CS1-X

Cooling system oil / water

X

X

X

…B

with brake

X

CS2-X

Cooling system oil / air

X

X

X

…K

with elastic coupling

X

D

Torque support

X

X

…T

with hydrodynamic coupling

X

EA

Splined hollow output shaft

X

X

MT

Motor mount

X

X

ED2) Elastic torque support X NEMA

Standard NEMA motor

attachment

X

EV

Splined solid output shaft

X

OH

Oil heater

X X

EW

Splined drive shaft

OT

Oil level tank

X

F

Block flange

X

X

PT100

Temperature sensor

X

FAN

Fan

X

R

Backstop

X

X

FK

Collar flange

X

S

Shrink disc

X

X

F1

Drive flange

X

V

Solid output shaft

X

H/H66

Covering cap as contact guard

X

X

VL

Reinforced bearings

X

IEC Standard IEC motor mounting X VL2

Agitator version

- Reinforced bearings

X X

KL2 Agitator version

- Standard bearings X X VL3

Agitator version

- Reinforced bearings

- Drywell

X X

KL3

Agitator version

- Standard bearings

- Drywell

X X VL4

Agitator version

- Reinforced bearings

- True Drywell

X X

KL4

Agitator version

- Standard bearings

- True Drywell

X X VL6

Agitator version

- Reinforced bearings

- True Drywell

- Foot mounting

X X

KL6

Agitator version

- Standard bearings

- True Drywell

- Foot mounting

X X X VL5 Extruder flange version X X

L

Solid output shaft on both sides

X

W

One free drive shaft journal

LC(X)1

)

Lubricant circulation X X X W2 Two free drive shaft journals

MC

Motor bracket

X

W3

Three free drive shaft journals

MF...

Motor base frame

X

X

WX

Auxiliary drive unit

X

…B

with brake

X

1)

with pressure switch

2)

Also only stated with D on the type plate

Table 3: Versions and options

Pos: 29 /All ge mei n/Al lge mei ng ültig e M odul e/---------Sei te num bruc h kom pak t --------- @ 13 \mod_1476369695906_0.docx@ 2265495@ @ 1

Industrial gear units – Operating and Assembly Instructions

16 B 1050 en-1819

Pos: 30 /A nleitu ngen/ Getri ebe/2. G etrie bebesc hrei bung/ Typ enbezei chnu ngen un d Getri ebear ten_ 03 [B105 0, B20 50] @ 30\mod_1552914035630_388.docx@ 2510809@ @ 1

Certain versions / options can only be used for particular gear unit sizes or configurations.

Figure 1: MAXXDRIVE®XT 2-stage helical bevel gear unit

Pos: 32 /A nleitu ngen/ Getri ebe/3. M ontag e, Lager ung, Vor berei tung, Au fstel lung/3 .M ontag eanl eitung, L ager ung, Vor bereit ung, Aufstellung@ 23\mod_1531915085387_388.docx@ 2434207@ 1 @ 1

3 Assembly instructions, storage, preparation, installation

B 1050 en-1819 17

3 Assembly instructions, storage, preparation, installation

Please note all safety information 1.5 "Safety information"and warning information in the relevant

sections.

Pos: 33 /A nleitu ngen/ Getri ebe/3. M ontag e, Lager ung, Vor berei tung, Au fstel lung/T rans port des Ge trie bes -Allgemein[B1050_B2050]@ 17\mod_1492760671058_388.docx@ 2341179@ 2@ 1

3.1 Transporting the gear unit

WARNING Hazard due to heavy loads

Severe injuries and material damage due to falling, swinging or tipping heavy loads are possible.

• To prevent injury, the danger area must be generously cordoned off.

• Standing under the gear unit during transport is extremely dangerous.

• Use adequately dimensioned and suitable means of transportation. Lifting tackle must be designed for the

weight of the gear unit. The weight of the gear unit can be obtained from the dispatch documents.

• If geared motors have an additional eyebolt attached to the motor, this must not be used.

• Only the four ring bolts provided may be used for transporting the gear unit.

CAUTION

Slipping hazard

Transport damage to the gear unit or gear unit components may result from the leakage of lubricants. There is a

slipping hazard due to leaked lubricants.

• The drive unit must be inspected and may only be installed if no transportation damage or leaks are visible. In

particular the radial seals and the sealing caps must be inspected for damage.

NOTICE Gear unit damage

Damage to the gear unit due to improper use is possible.

• Prevent damage to the gear unit. Impacts to the free ends of the shafts may cause internal damage to the

gear unit.

• The ends of the shafts must not be used for transportation, as this may seriously damage the gear unit.

An additional lashing point may be required for versions which deviate greatly from the following

illustrations, or in the case of additional drive units and components.

In this case, please contact NORD Service.

Pos: 34 /All ge mei n/Al lge mei ng ültig e M odul e/---------Sei te num bruc h kom pak t --------- @ 13 \mod_1476369695906_0. docx@ 2265495@ @ 1

Industrial gear units – Operating and Assembly Instructions

18 B 1050 en-1819

Pos: 35 /A nleit ungen/ Getr iebe/3. M ontag e, Lager ung, V orberei tung , Aufstel lung /Trans port des Ge trie bes -Standardgetriebe[B1050_B2050]@ 28\mod_1551451615952_388. docx@ 2494466 @ 3@ 1

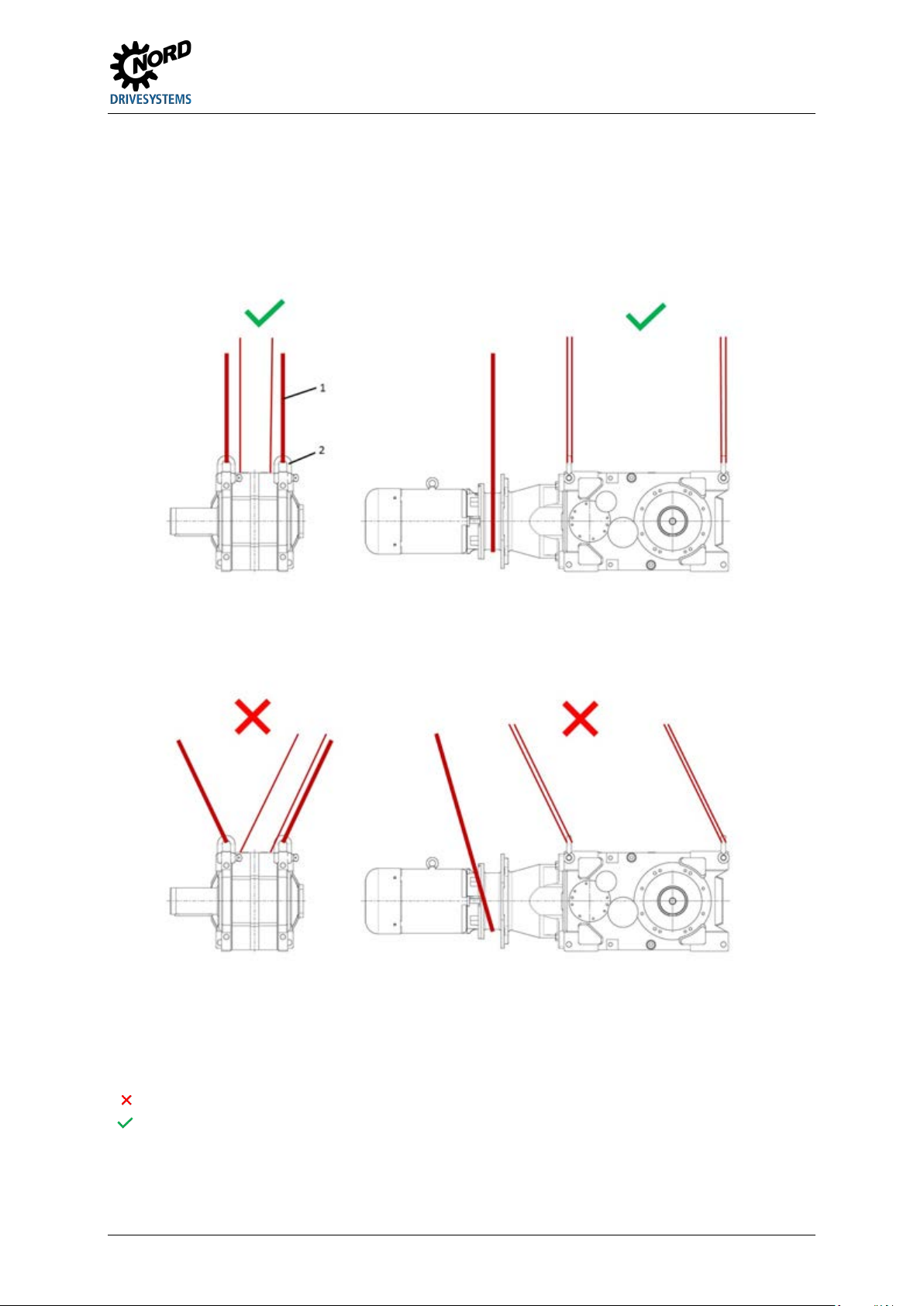

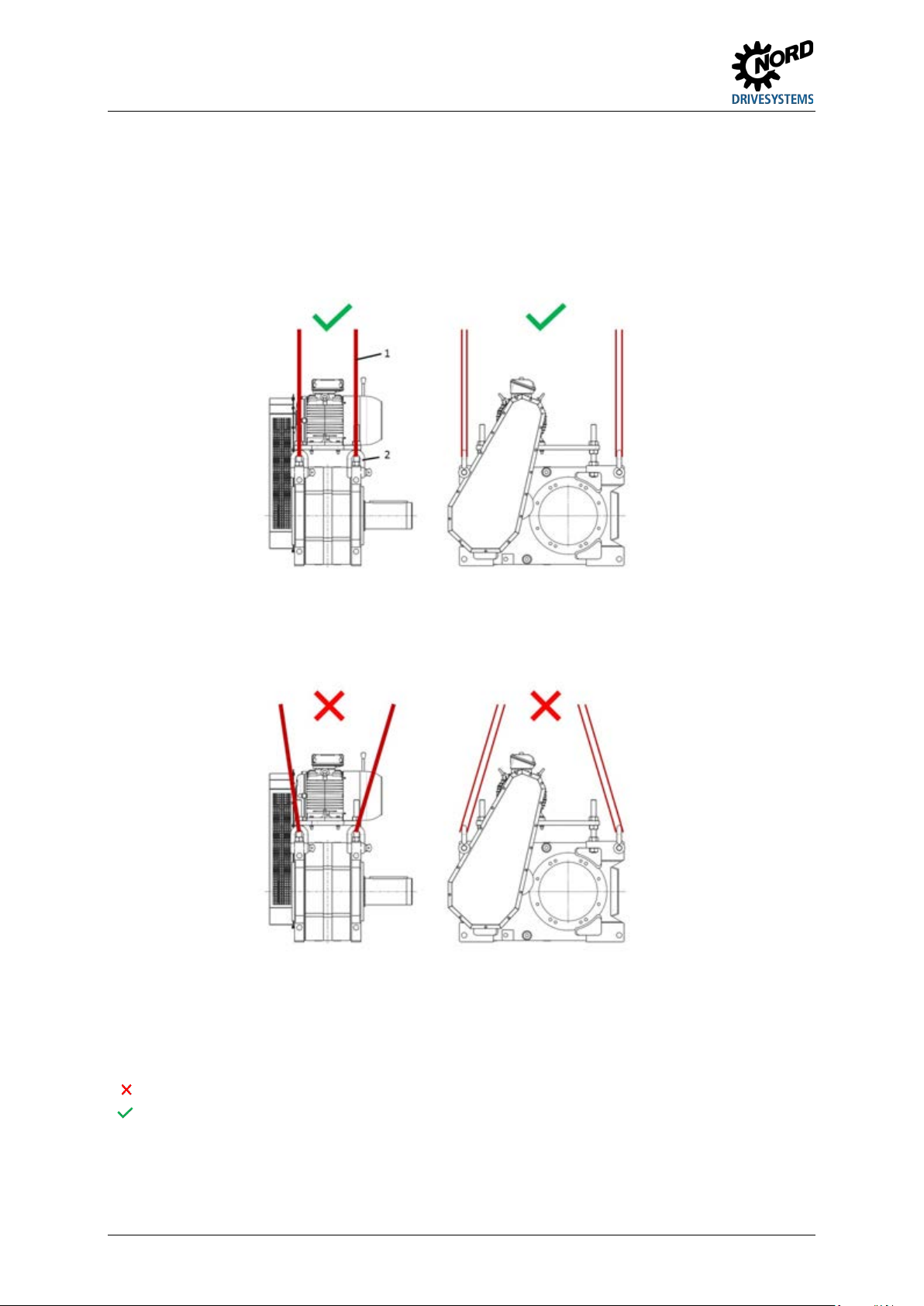

3.1.1 Standard gear units

Gear units may only be transported with lifting ropes and chains or lifting straps at an angle of 90° to

70° to the horizontal.

Legend

1:

Lifting strap

2:

Shackle

:

Not permissible

:

Permissible

Figure 2: Transport of standard gear unit

Pos: 36 /All ge mei n/Al lge mei ng ültig e M odul e/---------Sei te num bruc h kom pak t --------- @ 13 \mod_1476369695906_0.docx@ 2265495@ @ 1

3 Assembly instructions, storage, preparation, installation

B 1050 en-1819 19

Pos: 37 /A nleitu ngen/ Getri ebe/3. M ontag e, Lager ung, Vor berei tung, Au fstel lung/T rans port des Ge trie bes -Motoradapter[B1050_B2050]@ 29\mod_1552033260962_388.docx@ 2499916@ 3@ 1

3.1.2 with motor adapter

Gear units with motor adapters may only be transported with lifting ropes and chains or lifting straps at

an angle of 90° to 70° to the horizontal.

The ring bolts on the motor must not be used for transportation.

Legend

1:

Lifting strap

2:

Shackle

:

Not permissible

:

Permissible

Figure 3: Transport of gear unit with motor adapter

Pos: 38 /All ge mei n/Al lge mei ng ültig e M odul e/---------Sei te num bruc h kom pak t --------- @ 13 \mod_1476369695906_0. docx@ 2265495@ @ 1

Industrial gear units – Operating and Assembly Instructions

20 B 1050 en-1819

Pos: 39 /A nleit ungen/ Getr iebe/3. M ontag e, Lager ung, V orberei tung , Aufstel lung /Trans port des Ge trie bes -Keilriemenantrieb[B1050] @ 27\mod_1551104882121_388. docx@ 2490614@ 3@ 1

3.1.3 with V-belt drives

Gear units with V-belt drives may only be transported with lifting ropes and chains or lifting straps at

an angle of 90° to 70° to the horizontal.

The ring bolts on the motor and the motor bracket must not be used for transportation.

Legend

1:

Lifting strap

2:

Shackle

:

Not permissible

: Permissible

Figure 4: Transport of agitator version gear unit

Pos: 40 /All ge mei n/Al lge mei ng ültig e M odul e/---------Sei te num bruc h kom pak t --------- @ 13 \mod_1476369695906_0. docx@ 2265495@ @ 1

This manual suits for next models

51

Table of contents

Other Nord Drivesystems Engine manuals