Nord Drivesystems B1091 Specification sheet

B 1091 –en

Motors

Manual with installation instructions

Motors – Manual with installation instructions

2 B 1091 en-1221

Pos: 2 /Anleitungen/M otoren/B1091 Drehstrommotor en/1. Allgemeines/0. Prolog /Sicherheits- und Anwendungs hinweise für Elek tromotoren @ 66\mod_16130480906 52_388.docx @ 2735079 @ @ 1

Safety and operating instructions for electric motors

(according to: Low Voltage Directive 2014/35/EU)

1 General

During operation, devices may, depending on their protection class,

have live, bare, moving or rotating parts or hot surfaces.

Unauthorised removal of covers, improper use, incorrect installation or

operation causes a risk of serious personal injury or material damage.

Further information can be found in this documentation.

All transportation, inst

allation commissioning and maintenance work

must be carried out by qualified personnel (compliant with IEC

364 or.

CENELEC HD 384 or DIN VDE 0100 and IEC 664 or DIN VDE 0110

and national accident prevention regulations).

For the purposes of these basic safety instructions, qualified personnel

are persons who are familiar with the assembly, installation,

commissioning and operation of this product and who have the relevant

qualifications for their work.

2. Proper use in Europe

The devices are components inte

nded for installation in electrical

systems or machines.

When installed in machines, the devices must not be commissioned (i.e.

commencement of the proper use) until it has been ensured that the

machine meets the provisions of the EC Directive 2006/42/EEC

(Machinery Directive); EN 60204 must also be complied with.

Commissioning (i.e. implementation of proper use) is only permitted if

the EMC directive (2014/30/EU) is complied with.

Devices with a CE label meet the requirements of the Low Voltage

Directive 2014/35/EU. The stated harmonized standards for the devices

are used in the declaration of conformity.

Technical data and information for connection conditions can be found

on the r

ating plate and in the documentation, and must be complied

with.

The devices may only be used for safety functions which are described

and explicitly approved.

3. Transport, storage

Information regarding transport, storage and correct handling must be

complied with.

4. Installation

The installation and cooling of the equipment must be implemented

according to the regulations in the corresponding documentation.

The devices must be protected against impermissible loads.

Especially during transport and handling, components must not

be deformed and/or insulation distances must not be changed.

Electrical components must not be mechanically damaged or

destroyed (this may cause a health hazard!).

5. Electrical Connection

When working on live devices, the applicable national accident

prevention regulations must be complied with.

The electrical installation must be implemented according to the

applicable regulations (e.g. cable cross-

section, fuses, earth

lead connections). Furth

er instructions can be found in the

documentation.

Information regarding EMC-compliant installation –

such as

shielding, earthing, location of filters and installation of cables –

can be found in the documentation for the devices. These

instructions must b

e complied with even with CE marked

devices. Compliance with the limiting values specified in the

EMC legal regulations is the responsibility of the manufacturer

of the system or machine.

6. Operation

Where necessary, systems in which the devices are installed

must be equipped with additional monitoring and protective

equipment according to the applicable safety requirements, e.g.

legislation concerning technical equipment, accident prevention

regulations, etc.

The parameterisation and configuration of the devices must be

selected so that no hazards can occur.

All covers must be kept closed during operation.

7. Maintenance and repairs

The following applies in particular for operation with frequency

inverters:

After the devices are disconnected from the power supply, live

equipment components and power connections should not be

touched immediately, because of possible charged capacitors.

Observe the applicable information signs located on the device.

Further information can be found in this documentation.

These safety instructions must be kept in a safe place!

Documentation

B 1091 en-1221 3

Pos: 3 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/0. Prol og/Dokumentation - Versi onsliste [ BU 1091] @ 67\mod_161 3484756730_388. docx @ 2738515 @ @ 1

Documentation

Title:

B 1091

Order no.:

6051302

Series:

Asynchronous motors / synchronous motors

1)

2)

3)

• Single and three-phase asynchronous motors

SK 63*1)/*2) *3) to SK 315*1)/*2) *3)

Power labelling: S, SA, SX, M, MA, MB, MX, L, LA, LB, LX, R, X, Y, A, W

- optionally supplemented with: H, P

Pole number labelling: 2, 4, 6, 8, …

Further options

1)

2)

3)

4)

• Three-phase synchronous motors

SK 63*1)*2)/*3) *4) to SK 132*1)*2)/*3) *4)

Winding version: T, F, …

Power number: 1 to 9

Pole number labelling: 4, 6, 8, …

Further options

1)

2)

3)

• Three-phase asynchronous motors

SK 63*1)/*2) 2D *3) to SK 250*1)/*2) 2D *3)

Power labelling: S, SA, SX, M, MA, MB, MX, L, LA, LB, LX, R, X, Y, A, W

- optionally supplemented with: H, P

Pole number labelling: 4, 6

Options

with ATEX labelling II 2D Ex tb IIIC T . . . °C Db

1)

2)

3)

SK 63*1)/*2) 3D *3) to SK 250*1)/*2) 3D *3)

Power labelling: S, SA, SX, M, MA, MB, MX, L, LA, LB, LX, R, X, Y, A, W

- optionally supplemented with: H, P

Pole number labelling: 4, 6

Options

with ATEX labelling II 3D Ex tc IIIB T . . . °C Dc

1)

2)

3)

SK 63*1)/*2) 2G *3) to SK 200*1)/*2) 2G *3)

Power labelling: S, SA, SX, M, MA, MB, MX, L, LA, LB, LX, R, X, Y, A, W

- optionally supplemented with: H, P

Pole number labelling: 4, 6

Further options

with ATEX labelling II 2G Ex eb IIC T3 Gb

1)

2)

3)

SK 63*1)/*2) 3G *3) bis SK 200*1)/*2) 3G *3)

Power labelling: S, SA, SX, M, MA, MB, MX, L, LA, LB, LX, R, X, Y, A, W

- optionally supplemented with: H, P

Pole number labelling: 4, 6

Further options

with ATEX labelling II 3G Ex ec IIC T3 Gc

Motors – Manual with installation instructions

4 B 1091 en-1221

Version list

Title,

Date

Order number Remarks

B 1091,

January

2015

6051302 / 0215

-

B 1091,

March 2016

6051302 / 1016

• General corrections

• Structural modifications to the document

B 1091

,

December

2016

6051302

/ 4816 • General corrections

B 1091,

June 2017

6051302 / 2417

• Technical supplements

B 1091,

August 2017

6051302 / 3517

• Technical supplements

B 1091,

June 2018

6051302 / 2318

• General corrections

• Update of EU Declaration of Conformity 2D / 3D

B 1091,

August 2018

6051302 / 3118

• General corrections

• Section for operation with frequency inverter removed

• Section for special operating conditions, permissible surrounding

area supplemented

• Ignition protection type labelling and name plates updated

• Update of EU Declaration of Conformity 2G / 3G

B 1091

,

June 2019

6051302

/ 2319 • General corrections

• Update of EU Declaration of Conformity 3D

B 1091,

October

2020

6051302 / 4020

• General corrections

• Supplement with new chapter for use of explosion-protected electric

motors in the People's Republic of China

B

1091March

2021

6051302 / 1221

• General corrections

Pos: 4 /Allgemein/ Allgemeingültig e Module/Urheberrec htsvermerk @ 5\mod_141095508345 9_388.docx @ 150427 @ @ 1

Copyright notice

As an integral component of the device described here, this document must be provided to all

users in a suitable form.

Any editing or amendment or other utilisation of the document is prohibited.

Pos: 5 /Allgemein/ Allgemeingültig e Module/Herausgeber @ 67\m od_1613484928402_388.doc x @ 2738552 @ @ 1

Publisher

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 1 •22941 Bargteheide, Germany •http://www.nord.com

Fon +49 (0) 45 32 / 289-0 •Fax +49 (0) 45 32 / 289-2253

Member of the NORD DRIVESYSTEMS Group

=== Ende der Liste f ürT extmarke Copyright == =

Publisher

B 1091 en-1221 5

Motors – Manual with installation instructions

6 B 1091 en-1221

Pos: 7 /Allg emein/Steuermodul e/Inhaltsv erzeichnis @ 0\mod_13179 78518480_388.doc x @ 4078 @ @ 1

Table of Contents

=== Ende der Liste f ürT extmarke Inhaltsv erzeichnis ===

1General.........................................................................................................................................................8

1.1 Safety and installation notes..............................................................................................................9

1.1.1 Explanation of labels used....................................................................................................9

1.1.2 List of safety and installation notes.....................................................................................10

1.2 Field of use ......................................................................................................................................11

1.3 Correct handling of electric motors ..................................................................................................12

1.3.1 Transport, storage ..............................................................................................................12

1.3.2 Installation ..........................................................................................................................13

1.3.3 Balancing, drive elements ..................................................................................................13

1.3.4 Alignment ...........................................................................................................................14

1.3.5 Output shafts......................................................................................................................14

1.3.6 Electrical connection...........................................................................................................15

1.3.7 Operation with frequency inverter.......................................................................................16

1.3.8 Checking the insulation resistance .....................................................................................17

1.3.9 Commissioning...................................................................................................................17

1.3.10 Disposal..............................................................................................................................18

2Maintenance and servicing ......................................................................................................................19

2.1 Safety measures..............................................................................................................................19

2.2 Bearing replacement periods...........................................................................................................20

2.3Maintenance intervals......................................................................................................................21

2.4 General overhaul .............................................................................................................................21

3ATEX Explosion hazard areas..................................................................................................................22

3.1 Motors with increased ignition protection, type Ex eb ......................................................................22

3.1.1 Cable glands.......................................................................................................................23

3.1.2 Cable connections..............................................................................................................24

3.1.3 Terminal box cover seals....................................................................................................25

3.1.4 Motor position – special features for IM V3, IM V6.............................................................25

3.1.5 Further operating conditions...............................................................................................26

3.1.6 Protective devices ..............................................................................................................26

3.1.7 Operation with frequency inverter.......................................................................................27

3.1.8 Repairs...............................................................................................................................28

3.1.9 Painting ..............................................................................................................................28

3.1.10 Name plate of NORD Ex eb motors according to EN 60079 ..............................................29

3.1.11 Applied standards...............................................................................................................29

3.2 Motors with ignition protection class Non Sparking Ex ec................................................................30

3.2.1 Cable glands.......................................................................................................................31

3.2.2 Cable connections..............................................................................................................31

3.2.3 Terminal box cover seals....................................................................................................32

3.2.4 Motor position – special features for IM V3, IM V6.............................................................32

3.2.5 Further operating conditions...............................................................................................33

3.2.6 Protective devices ..............................................................................................................33

3.2.7 Repairs...............................................................................................................................33

3.2.8 Painting ..............................................................................................................................34

3.2.9 Type plate for NORD Ex ec motors according to EN 60079...............................................35

3.2.10 Applied standards...............................................................................................................35

3.3 Motors for use in Zone 21 and Zone 22 according to EN 60079 and IEC 60079.............................36

3.3.1 Commissioning information / Application area....................................................................37

3.3.2 Terminal box cover seals....................................................................................................38

3.3.3 Electrical Connection..........................................................................................................38

3.3.4 Cable glands.......................................................................................................................38

3.3.5 Permissible ambient temperature range.............................................................................39

3.3.6 Painting ..............................................................................................................................40

3.3.7 IEC-B14 motors..................................................................................................................40

3.3.8 Motor position – special features for IM V3, IM V6.............................................................40

3.3.9 Further operating conditions...............................................................................................41

3.3.10 Design and operating principle...........................................................................................41

3.3.11 Minimum cross section of bonding conductors...................................................................41

3.3.12 Maintenance.......................................................................................................................42

3.4 Options for motors for use in Zone 21 and Zone 22.........................................................................43

Table of Contents

B 1091 en-1221 7

3.4.1 Operation with frequency inverters.....................................................................................43

3.4.2 External fan ........................................................................................................................44

3.4.3 Second temperature sensor 2TF........................................................................................45

3.4.4 Back stop............................................................................................................................45

3.4.5 Brake..................................................................................................................................45

3.4.6 Overview of brake attachment for NORD ATEX motors.....................................................46

3.4.7 Name plate of motors (Ex tb, Ex tc) according to EN 60079 for FI operation .....................47

3.5 Motors according to TP TC012/2011 for the Eurasian Economic Union..........................................48

3.5.1 Type plates / Labelling........................................................................................................48

3.5.2 Standards...........................................................................................................................49

3.5.3 Service life..........................................................................................................................49

3.5.4 Special operating conditions (X-labelling)...........................................................................49

3.6 Motors according to GB 12476.1-2013 / GB 12476.5-2013 for the People's Republic of China ......50

3.6.1 Type plates / Labelling........................................................................................................50

3.6.2 Standards to be observed during operation and maintenance ...........................................51

4Synchronous motors – special information ...........................................................................................52

4.1 Type designation..............................................................................................................................52

4.2 Connection.......................................................................................................................................52

4.3 Encoders..........................................................................................................................................53

4.4 Commissioning ................................................................................................................................53

4.5 Maintenance and servicing ..............................................................................................................53

5Replacement parts....................................................................................................................................54

6Declarations of Conformity ......................................................................................................................55

Pos: 10 /Anleitungen/M otoren/B1091 Drehstromm otoren/1. Allgemeines/!1! Allg emeines @ 7\mod_1431347018514_388.doc x @ 217366 @ 1 @ 1

Motors – Manual with installation instructions

8 B 1091 en-1221

1 General

Pos: 11 /Anleitungen/M otoren/B1091 Drehstromm otoren/1. Allgemeines/!1! Allg emeines_Inhalt @ 7\mod_14313301125 64_388.docx @ 217304 @ @ 1

These operating instructions must be read before NORD motors are transported, installed,

commissioned, serviced or repaired. All persons who are involved in these tasks must observe these

operating instructions. In order to prevent injury or damage, all of the safety information in these

operating instructions must be strictly observed.

The information and instructions in the instructions, safety and commissioning information which is

supplied, as well as all other instructions must be observed.

This is essential to prevent injury and damage.

The applicable national, local and plant-specific regulations and requirements and regulations must be

observed.

Technical details may vary for special designs and constructions. In case of doubt, we urgently

recommend that the manufacturer is contacted, giving details of the type designation and the

motor number.

Qualified personnel are persons who due to their training, experience and instruction, and their

knowledge of the relevant standards, accident prevention regulations and operating conditions are

authorised to carry out the necessary activities.

This also includes knowledge of first aid measures and the local emergency services.

It is assumed that the work for transport, assembly, installation, commissioning, maintenance and

repair will be performed by qualified staff.

In particular, the following must be observed:

• Technical data and information regarding permissible use, installation, connection, ambient and

operating conditions, which are contained in the catalogue, the order documents and other

documentation for the product.

• Local and plant-specific regulations and requirements

• Correct use of tools, lifting and transportation equipment

• Use of personal protective equipment

For reasons of clarity, the operating instructions do not contain detailed information about possible

versions and therefore do not consider all possible cases of installation, operation or servicing.

Because of this, these operating instruction essentially only contain the information which is necessary

for proper use by qualified personnel.

In order to prevent faults it is necessary that the prescribed service and inspection work is carried out

by appropriately qualified personnel.

• For the operation on an inverter, the planning guideline B1091-1 forms a part of these operating

instructions.

• The supplementary operating instructions must be observed if an external fan is present.

• For braking motors, the supplementary brake operating instructions must be observed..

If the operating instructions or the planning guide are lost for any reason, these documents must be

obtained from NORD.

Pos: 12 / Allgemein/Allg emeingültig e Module/----------Seit enumbruch ----------@ 1 \mod_1329145698658_0.doc x @ 15891 @ @ 1

1 General

B 1091 en-1221 9

Pos: 13 /Anleitung en/Elektronik/ FU und Starter/1. Allgemei nes/Sicherheit s- und Installationshi nweise und Warn- Gefahrenhinwei se/Sicherheits - und Installati onshinweise (inkl. Ei nleitung) @ 0\mod_1325780428207_ 388.docx @ 5385 @ 2 @ 1

1.1 Safety and installation notes

The devices are operating materials intended for use in industrial high voltage systems, and are

operated at voltages that could lead to severe injuries or death if they are touched.

The device and its accessories must only be used for the purpose which is intended by the

manufacturer. Unauthorised modifications and the use of spare parts and additional equipment which

has not been purchased from or recommended by the manufacturer of the device may cause fire,

electric shock and injury.

All of the associated covers and protective devices must be used.

Installation and other work may only be carried out by qualified electricians with strict adherence to the

operating instructions. Therefore keep these Operating Instructions at hand, together with all

supplementary instructions for any options which are used, and give them to each user.

Local regulations for the installation of electrical equipment and accident prevention must be complied

with.

Pos: 14 /Anleitung en/Elektronik/ FU und Starter/1. Allgemei nes/Sicherheit s- und Installationshi nweise und Warn- Gefahrenhinwei se/Erläuterung der verwendeten Kennzeic hnungen [B1091] ### ausl aufend ### @ 33\mod_15580763425 33_388.docx @ 2535760 @ 3 @ 1

1.1.1 Explanation of labels used

DANGER Indicates an immediate danger, which may result in death or serious injury.

WARNING Indicates a possibly dangerous situation, which may result in death or

serious injury.

CAUTION Indicates a possibly dangerous situation, which may result in slight or

minor injuries.

NOTICE Indicates a possibly harmful situation, which may cause damage to the

product or the environment.

Note Indicates hints for use and useful information.

Pos: 15 / Allgemein/Allg emeingültig e Module/----------Seit enumbruch ----------@ 1 \mod_1329145698658_0.doc x @ 15891 @ @ 1

Motors – Manual with installation instructions

10 B 1091 en-1221

Pos: 16 /Anleitung en/Elektronik/ FU und Starter/1. Allgemei nes/Sicherheit s- und Installationshi nweise und Warn- Gefahrenhinwei se/Auflistung der Sicher heits- und Installations hinweise @ 1\m od_1341560303401_388.docx @ 30325 @ 3 @ 1

1.1.2 List of safety and installation notes

Pos: 17 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/Si cherheitshinweis e/Gefahr - Elektrisc her Schlag - Motoren [B1091] @ 11\mod_145995 2302755_388.docx @ 316085 @ @ 1

DANGER! Electric shock

The motor is operated with a dangerous voltage. Touching certain conducting components (connection terminals

and supply cables) will cause electric shock with possibly fatal consequences.

Even when the motor is at a standstill (e.g. due to the electronic block of a connected frequency inverter or a

jammed drive unit) the connection terminals and supply cables may carry a dangerous voltage. A motor standstill

is not identical to electrical isolation from the mains.

Even if the drive unit has been disconnected from the mains, a connected motor may rotate and possibly

generate a dangerous voltage.

Installation and work must only be carried out when the motor is at a standstill and is disconnected (all phases

disconnected from the mains).

Follow the 5 Safety Rules (1. Switch off the power, 2. Secure against switching on, 3. Check for no voltage, 4.

Earthing and short circuiting, 5. Cover or fence off neighbouring live components).

Pos: 18 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/Si cherheitshinweis e/Warnung - schwere Last en - Motoren [B1091] @ 11\mod_1460533 620869_388.docx @ 317935 @ @1

WARNING

Hazard due to heavy loads

The large weight of the motor must be taken into account during any transportation or installation work.

Incorrect handling may cause the motor to fall or swing without control and therefore cause severe, and possibly

fatal injuries due to impact, crushing and other physical injuries. In addition, severe damage to the motor and its

surroundings are possible.

Therefore:

– Do not stand under suspended loads

– Only use the attachment points provided

– Check that lifting equipment and lashings have and adequate load capacity and are undamaged

– Avoid hectic movements

– Use personal protective equipment

Pos: 19 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/Si cherheitshinweis e/Warnung - Bewegung - Motor en [B1091] @ 11\mod_1459953068537_3 88.docx @ 316120 @ @ 1

WARNING Injury due to movement

Under certain conditions (e.g. switching on the power supply, releasing a holding brake) the motor may start to

move. The machinery which it drives (press / chain hoist / roller / fan etc.) may then make an unexpected

movement. This may cause various injuries, including to third parties.

Before switching on, secure the danger area by warning and removing all persons from the danger area.

Pos: 20 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/Si cherheitshinweis e/Warnung - lose Teil e - Motoren [B1091] @ 11\mod_1459954601199_38 8.docx @ 316155 @ @ 1

WARNING Hazard due to loose parts

Care must be taken that there are no loose parts on the motor. Otherwise, these may cause injury during

transportation and installation work, or when the motor in in operation.

Loose carrying or lifting eyes may cause the motor to fall during transportation.

Parallel keys on the motor shaft may be thrown out when the motor shaft rotates.

Fasten or remove loose parts and carrying or lifting eyes; secure or remove free parallel shaft keys on the motor

shaft(s).

1 General

B 1091 en-1221 11

Pos: 21 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/Si cherheitshinweis e/Vorsicht - Verbrennungsg efahr @ 11\mod_1460532707435_388. docx @ 317900 @ @ 1

CAUTION

Danger of burns

The surface of the motor may heat up to temperatures in excess of 70°C.

Touching the motor may cause local burns to the affected parts of the body (hands, fingers, etc.).

To prevent such injuries, allow sufficient time for cooling down before starting work - the surface temperature

should be checked with suitable measuring equipment. In addition, keep sufficient distance from adjacent

components during installation, or install protection against contact.

Pos: 22 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Anwendungsbereich @ 7\mod_14313307 65571_388.docx @ 217335 @ 2 @ 1

1.2 Field of use

Use of the motors:

The motors may only be used for their intended purpose (to drive machinery).

The motors are constructed with at least protection class IP55 (for the protection class: see rating

plate). They may be installed in dusty or damp environments.

In principle the conditions of use and the ambient conditions determine the necessary protection class

and any other additional measures. For outdoor installation and vertical versions, e.g. V1 or V5 with

the shaft pointing downwards, Getriebebau NORD recommends the use of the double fan cover option

[RDD].

Motors must be protected against intensive sunlight, e.g. by the use of a protective cover. The

insulation is tropicalised.

Installation altitude: ≤ 1000 m

Ambient temperature: -20°C...+40°C

For standard motors an extended ambient temperature range from -20°C...+60°C is permissible.. In

this case, the rated power must be reduced to 82% of the value stated in the catalogue. If the

maximum ambient temperature is between +40°C and +60°C, the power output should be inversely

linearly interpolated between 100% and 82%.

The motor connection cables and the cable glands must be suitable for temperatures ≥ 90°C.

Motors – Manual with installation instructions

12 B 1091 en-1221

Pos: 23 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Bestimmungsgemäßer Umgang m it Elektromotoren @ 7\mod_14 31347154915_388.docx @ 217398 @ 2 @ 1

1.3 Correct handling of electric motors

All work must only be carried out with the power to the system switched off.

Pos: 24 /Anleitungen/M otoren/B1091 Drehstromm otoren/1. Allgemeines/Trans port, Einlagerung @ 67\mod_1613401505511_38 8.docx @ 2737482 @ 35 @ 1

1.3.1 Transport, storage

WARNING

Fall hazard

Incorrect handling during transport may result in the motor falling down or swivelling uncontrolledly, and thus

possibly causing serious or fatal injuries such as bruises, contusions and other physical injuries. It may also result

in serious damage to the motor and its environment.

That is why:

– Use the existing threads for ring bolts during transport (see following illustration).

– Do not attach additional loads! The lifting eyes are designed for the motor weight only.

– For transporting the machine units (e.g. gear unit attachments), only use the lifting eyes and pins provided

for this purpose!

– Machine units must not be lifted by attaching them to the individual machines!

To avoid any damage to the motor, the motor must always be lifted via suitable lifting equipment. If the

period between delivery and motor commissioning is more than four years under favourable conditions

(storage in dry and dust-free spaces protected from vibrations), the roller bearings should be replaced.

Unfavourable conditions significantly reduce the period. If necessary, unprotected and finished

surfaces (flange surface, shaft end, ...) may be treated with corrosion protection agents. If necessary,

the winding’s insulation resistance must be checked (1.3.8 "Checking the insulation resistance").

Changes compared to normal operation (increased power consumption, higher temperatures or

vibrations, unusual noises or odours, response of monitoring systems, etc.) may indicate that the

function is impaired. To avoid personal injury or material damage, the maintenance staff responsible

must be informed of these changes without delay.

In case of doubt, switch off the motor immediately as soon as this is allowed by the system’s state.

Mounting of ring bolts for transport

The number, position and thread size of the ring bolts provided for transport varies depending on the

motor size.

Size Threads Position

63

…

…

71

…

…

80

M6

2, 4

90

M8

1, 2, 3, 4

100

M8

1, 2, 3, 4

100 APAB

M8

2, 4

112

M8

1, 2, 3, 4

132 M10 1, 2, 3, 4

160

M12

1, 2, 3, 4

180

M12

1, 2, 3, 4

200X

M12

1, 2, 3, 4

Pos: 25 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Aufstellung @ 7\mod_1431348785190 _388.docx @ 217460 @ 3 @ 1

1 General

B 1091 en-1221 13

1.3.2 Installation

• After installation, screwed-on lifting lugs must be tightened or removed.

• Smooth running: Precise alignment of the clutch and a well-balanced drive element (clutch, pulleys,

fan, etc.) are prerequisites for smooth vibration-free running.

• Complete balancing of the motor and the drive elements may be necessary.

• The top section of the terminal box and the position of the terminal box can be rotated by 4 x 90

degrees.

• Even if not required, on IEC B14 motors all four fixing screws, must be screwed into the flanged

bearing plate! The fixing screw threads must be inserted with a sealant, e.g. Loctite 242.

WARNING

Electric shock

The maximum depth for screwing into the type plate is 2x d. There is a danger that the motor windings may be

damaged if longer screws are used. This creates a danger of potential transfer to the housing and danger of

electric shock if touched.

• The motor must be inspected for damage before installation and commissioning. A damaged motor

must not be commissioned.

• Rotating shaft ends and unused shaft ends must be protected against contact. Unused parallel

shaft keys must be secured against being thrown out.

• The motor must be suitable for the installation location. (requirements prescribed by standards,

ambient conditions, installation altitude)

• Motor surfaces may become very hot during operation. Suitable protective measures must be

taken if there is a danger of contact or a hazard to the vicinity of the installation.

Pos: 26 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/Wuc htung, Abtriebselem ente @ 7\mod_1431349031782_3 88.docx @ 217491 @ 3 @ 1

1.3.3 Balancing, drive elements

The fitting and removal of drive elements (clutch, pulley, gear wheel,…) must be performed with

suitable equipment. As standard the rotors are balanced with half key balancing. The appropriate

form of balancing must be observed if drive elements are installed on the motor shaft. Drive

elements must be balanced according to ISO 1940.

The generally required measures for protection against touching the drive elements must be observed.

If a motor is started without a drive element, the parallel key must be secured against being thrown

out. This also applies for any second shaft end. Alternatively, the parallel shaft key must be removed.

Motors – Manual with installation instructions

14 B 1091 en-1221

Pos: 27 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Ausrichten @ 7\mod_1431349204216_38 8.docx @ 217522 @ 3 @ 1

1.3.4 Alignment

In particular with direct coupling, the motor shafts and the driven machine must be axially and radially

aligned to each other. Incorrect alignment may result in damage to the bearings, excessive vibration

and breakage of the shaft.

Pos: 28 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Abtriebswellen @ 64\mod_161192260 5855_388.docx @ 2726037 @ 3 @ 1

1.3.5 Output shafts

The maximum permissible axial (FA) and radial forces (FR) for the A side end of the motor shaft can be

obtained from the table below. Getriebebau NORD should be consulted if the radial force (FR) is

applied at a distance which is greater than the length E/2.

Type

F

R

[N]

F

A

[N]

63

530

480

71

530

480

80

860

760

90

910

810

100

1300

1100

112

1950

1640

132

2790

2360

160

3500

3000

180 .X

3500

3000

180

5500

4000

200 .X

5500

4000

225

8000

5000

250

8000

5000

No axial (FA) and radial forces (FR) are permissible for the B side shaft end.

NOTICE! Attachments must not cause rubbing (danger of excessive temperatures and sparking) or

impair the necessary flow of cooling air.

Pos: 29 / Allgemein/Allg emeingültig e Module/----------Seit enumbruch ----------@ 1\mod_13291 45698658_0.docx @ 15891 @ @1

1 General

B 1091 en-1221 15

Pos: 30 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Elektrischer Anschluss @ 10\mod_1455530538031_388. docx @ 299682 @ 3 @ 1

1.3.6 Electrical connection

The connection cables must be passed through the cable glands in the terminal box. The terminal box

must be sealed against dust and water. The mains voltage and frequency must conform to the data on

the rating plate. ±5 % voltage or ±2 % frequency deviations are permissible without reduction of the

power. The connection and configuration of the jumpers must be made according to the circuit

diagram in the terminal box.

Please refer to the following table for the labelling of the auxiliary terminals

Auxiliary terminal designation

Additional equipment

Labelling of auxiliary terminals

Comments

New: EN 60034-8

Thermistor

TP1 – TP2

1TP1 – 1TP2

2TP1 – 2TP2

3TP1 – 3TP2

4TP1 – 4TP2

Switch-off

Warning Winding 1

Switch-off Winding 1

Warning Winding 2

Switch-off Winding 2

Option: TF 5TP1 – 5TP2 Brake

Bi-metal temperature sensor

Normally closed

Option: TW

1TB1 –1TB2

2TB1 –2TB2

3TB1 –3TB2

4TB1 –4TB2

Warning Winding 1

Switch-off Winding 1

Warning Winding 2

Switch-off Winding 2

Bi-metal temperature sensor,

normally open

1TM1 – 1TM2

2TM1 – 2TM2

3TM1 – 3TM2

4TM1 – 4TM2

Warning Winding 1

Switch-off Winding 1

Warning Winding 2

Switch-off Winding 2

PT100

1R1 – 1R2

2R1 – 2R2

3R1 – 3R2

Winding 1 (Phase U)

Winding 1 (Phase V)

Winding 1 (Phase W)

KTY

Silicon temperature sensor (+) 4R1 – 4R2 (-)

(+) 5R1 – 5R2 (-) Winding 1

Winding 2

Standstill heating

Option: SH

1HE1 – 1HE2

2HE1 – 2HE2

Motor heater

Brake heater

Capacitor

Motor version:

EAR/EHB/EST

1CA1 – 1CA2

2CA1 – 2CA2

3CA1 – 3CA2

4CA1 – 4CA2

with operating capacitor 1

with operating capacitor 2

with starting capacitor 1

with starting capacitor 2

Direct current brake

Option: BRE...

BD1 – BD2

Option: DBR… Brake1: BD1-BD2

Break2: BD3-BD4

Pos: 31 /Allgem ein/Allgemeing ültige Module/ ----------Seitenumbruc h ----------@ 1\mod_132914569 8658_0.docx @ 15891 @ @ 1

Motors – Manual with installation instructions

16 B 1091 en-1221

Pos: 32 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Betrieb am Frequenzumric hter @ 64\mod_1612254091330_388. docx @ 2727030 @ 3 @ 1

1.3.7 Operation with frequency inverter

Type SK 63 ./. – SK 250 ./. three phase asynchronous motors are qualified for operation with link

circuit inverters according to DIN EN 60034-18-41 (2014).

Please also observe the operating instructions for the frequency inverter which is used.

The insulation system used by NORD consists of suitable varnished copper wire, phase insulation,

homogeneous impregnation and groove lining as insulation against earth, and in the standard version

is designed for the increased requirements for link circuit inverters.

The maximum permissible FI input voltage is 500 V +10%. Link circuit voltages in excess of 750 V DC

are not permissible. When the motor is warm due to operation, the peak voltages due to the system,

the inverter, the cable or the motor must not exceed the following values.

If the values are outside of the permissible range, du/dt or sine wave filters may be used (not the

additional voltage drop).

The cable lengths shown in the diagram are for guidance only and may deviate according to the

specific conditions.

For additional information for operation with a frequency inverter, especially with regard to information

about the maximum speed, thermal design and possible torques, please refer to the current NORD

motor catalogue M7000.

Permissible impulse voltages depending on voltage rise-time

Impulse voltage [V]

Voltage rise time [µs]

1 General

B 1091 en-1221 17

Pos: 33 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Überprüfung des Isolat ionswiderstandes @ 7\mod_143135 3806825_388.doc x @ 217716 @ 3555 @ 1

1.3.8 Checking the insulation resistance

Prior to initial commissioning of the motor after a long period of storage or standstill (approx. 6

months) the insulation resistance of the windings must be checked. During and immediately after the

measurements, the terminals have voltages which can be dangerous, and must not be touched.

Insulation resistance

The insulation resistance of new, cleaned, repaired windings against the housing and against each

other is > 200 MΩ.

Measurement

The insulation of the windings against the housing for operation voltages up to 400 V must be

measured with 500 V DC. For operating voltages up to 725 V the measurement must be made with

1000 V DC. The temperature of the windings should be 25°C ± 15°C.

Testing

If the minimum insulation resistance of the winding against earth is less than 50 MΩ, this may be due

to moisture. The windings must then be dried.

The insulation resistance may reduce after long periods of operation. As long as the measured value

does not fall below the calculated value for the critical insulation resistance of < 50 MΩ, operation of

the motor may continue. If the value is less than this, the cause must be established and if necessary

the windings or parts of the windings must be repaired, cleaned or dried.

Pos: 34 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/Inbet riebnahme @ 7\mod_143135407379 5_388.docx @ 217747 @ 3 @ 1

1.3.9 Commissioning

Information

Electromagnetic compatibility

NORD motors comply with the EU-Directive 2014/30/EU. Assembly or installation work must not cause

impermissible interference. Immunity from interference must still exist.

Production of interference: In cases of large differences of torque (e.g. when driving a piston

compressor) a non-sine wave motor current is induced, whose harmonics can cause an impermissible

effect on the mains and therefore impermissible production of interference.

With supply by frequency inverters, various strengths of interference are produced according to the

design of the frequency inverter (type, interference suppression, manufacturer). The EMC information

of the inverter manufacturer must be observed. If a shielded motor supply cable is recommended, the

shielding is most effective if a large area is electrically connected to the metal terminal box of the

motor (with metal EMC cable gland). With motors with integrated sensors (e.g. thermistors)

interference voltages due to the inverter may be produced in the sensor cables.

Motors – Manual with installation instructions

18 B 1091 en-1221

Interference immunity: For motors with integrated sensors (e.g. thermistors) the operator must

ensure adequate immunity to interference by the selection of a suitable sensor cable (possibly with

screening, with connection as for the motor supply cable) and evaluation device. The information and

instructions in the operating instructions for the inverter and all other instructions must be observed

before commissioning. After installation of the motor, it must be checked for correct functioning. In the

case of brake motors, the correct function of the brake must also be checked.

Pos: 35 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/1. Allgemeines/ Entsorgung @ 7\mod_1431354230589_ 388.docx @ 217778 @ 3 @ 1

1.3.10 Disposal

NOTICE Environmental damage

Incorrect disposal of the product may cause damage to the environment.

• Ensure correct disposal

• Comply with current local regulations

Content: aluminium, iron, electronic components, copper

Please observe the additional documentation for the attachments

Pos: 37 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/2. Instandhaltung, War tung/!1! Instandhal tung und Wartung @ 7\mod_143135 4436983_388.docx @ 217809 @ 1 @ 1

2 Maintenance and servicing

B 1091 en-1221 19

2 Maintenance and servicing

Pos: 38 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/Si cherheitshinweis e/Gefahr - Elektrisc her Schlag - Motoren [B1091] @ 11\mod_145995 2302755_388.docx @ 316085 @ @1

DANGER!

Electric shock

The motor is operated with a dangerous voltage. Touching certain conducting components (connection terminals

and supply cables) will cause electric shock with possibly fatal consequences.

Even when the motor is at a standstill (e.g. due to the electronic block of a connected frequency inverter or a

jammed drive unit) the connection terminals and supply cables may carry a dangerous voltage. A motor standstill

is not identical to electrical isolation from the mains.

Even if the drive unit has been disconnected from the mains, a connected motor may rotate and possibly

generate a dangerous voltage.

Installation and work must only be carried out when the motor is at a standstill and is disconnected (all phases

disconnected from the mains).

Follow the 5 Safety Rules (1. Switch off the power, 2. Secure against switching on, 3. Check for no voltage, 4.

Earthing and short circuiting, 5. Cover or fence off neighbouring live components).

Pos: 39 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/Si cherheitshinweis e/Warnung - Bewegung - Motoren [ B1091] @ 11\mod_1459953068537_388. docx @ 316120 @ @ 1

WARNING Injury due to movement

Under certain conditions (e.g. switching on the power supply, releasing a holding brake) the motor may start to

move. The machinery which it drives (press / chain hoist / roller / fan etc.) may then make an unexpected

movement. This may cause various injuries, including to third parties.

Before switching on, secure the danger area by warning and removing all persons from the danger area.

Pos: 40 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/2. Instandhaltung, War tung/Sicherheit smaßnahmen @ 7\mod_143135450019 8_388.docx @ 217840 @ 2 @ 1

2.1 Safety measures

Before starting any work on the motor or the device, but especially before opening the covers of active

components, the motor must be isolated according to regulations. In addition to the main power

circuits, any additional or auxiliary circuits must be taken into account.

The usual "5 Safety Rules" e.g. according to DIN VDE 0105 are:

• Disconnect

• Secure to prevent reactivation

• Check for no voltage on all poles

• Earth and short circuit

• Cover or cordon off adjacent live components

These measures may only be removed when the maintenance work is complete.

Motors – Manual with installation instructions

20 B 1091 en-1221

Motors must be properly inspected at regular intervals; current national standards and regulations

must be complied with. In particular, special attention must be paid to any mechanical damage, free

path of the cooling air, abnormal noises and correct electrical connection.

Only original parts may be used as spare parts with the exception of standardised, commercially

available and equivalent parts.

Swapping parts between motors of the same type is not permissible.

Information

Condensation outlets

If the motors are designed with closed condensation outlets, these must be opened occasionally in order to allow

any accumulated condensation to drain off. Condensation outlets must always be located at the lowest point of

the motor. During installation of the motor care must be taken that the condensation outlets point downwards and

are closed. Open condensation outlets cause a reduction of the protection class.

Pos: 41 /Anleitung en/Motoren/B1091 Dr ehstrommotoren/2. Instandhaltung, War tung/Lagerwec hselfristen @ 67\mod_1613485099 782_388.docx @ 2738589 @ 2 @ 1

2.2 Bearing replacement periods

Under normal operating conditions, with horizontal motor installation, the bearing replacement period

in operating hours [h] for IEC motors is the following depending on the listed coolant temperature and

motor speeds:

25°C 40°C 60°C

to 1,800 min-1

approx. 40,000 h

approx. 20,000 h

approx. 8,000 h

to 3,600 min-1

approx. 20,000 h

approx. 10,000 h

approx. 4,000 h

In case of direct mounting of the gear units or special operating conditions, for example vertical motor

installation, high vibration and impact loads, frequent reversing operation, etc., the above-mentioned

operating hours can be significantly reduced.

Pos: 42 / Allgemein/Allg emeingültig e Module/----------Seit enumbruch ----------@ 1 \mod_1329145698658_0.doc x @ 15891 @ @ 1

Other manuals for B1091

1

Table of contents

Other Nord Drivesystems Engine manuals

Popular Engine manuals by other brands

YANGDONG

YANGDONG Y90 Series Operation & maintenance manual

Subaru

Subaru EH025 Instructions for use

Mercury

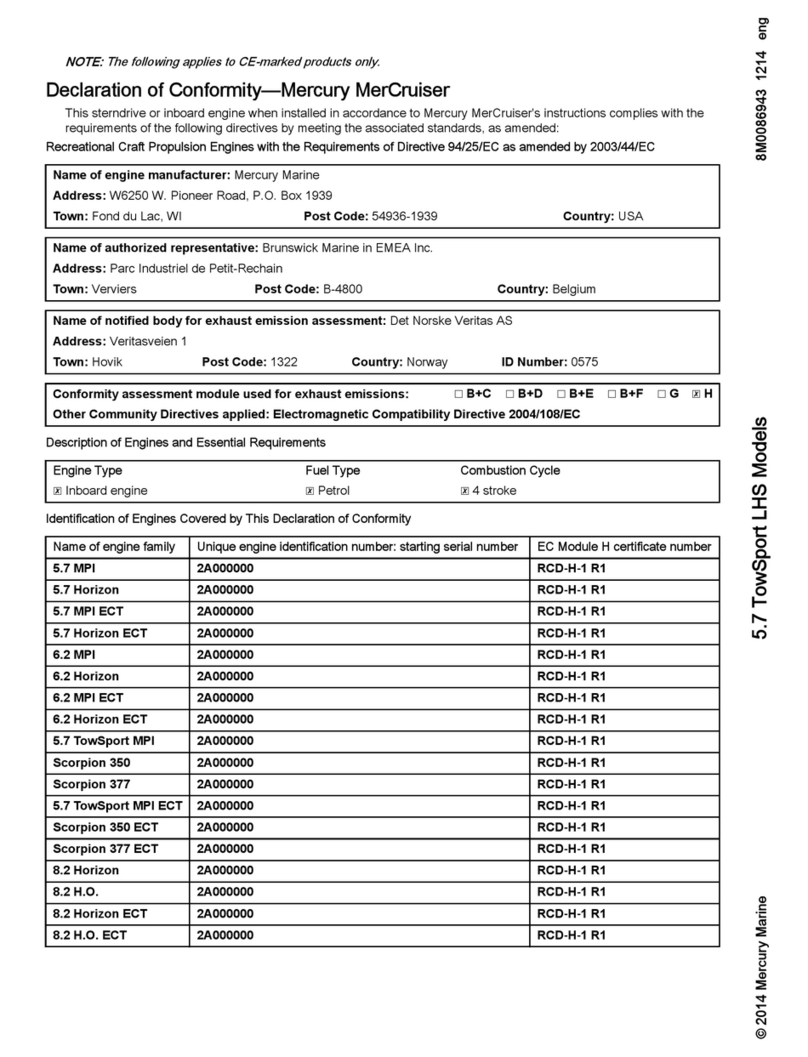

Mercury MerCruiser Tow Sport 5.7 LHS manual

MTD

MTD SX800 owner's manual

Siemens

Siemens SIMOTICS TN N-compact 1LH8 Operating instructions & installation instructions

Nakayama

Nakayama SP9700 user manual