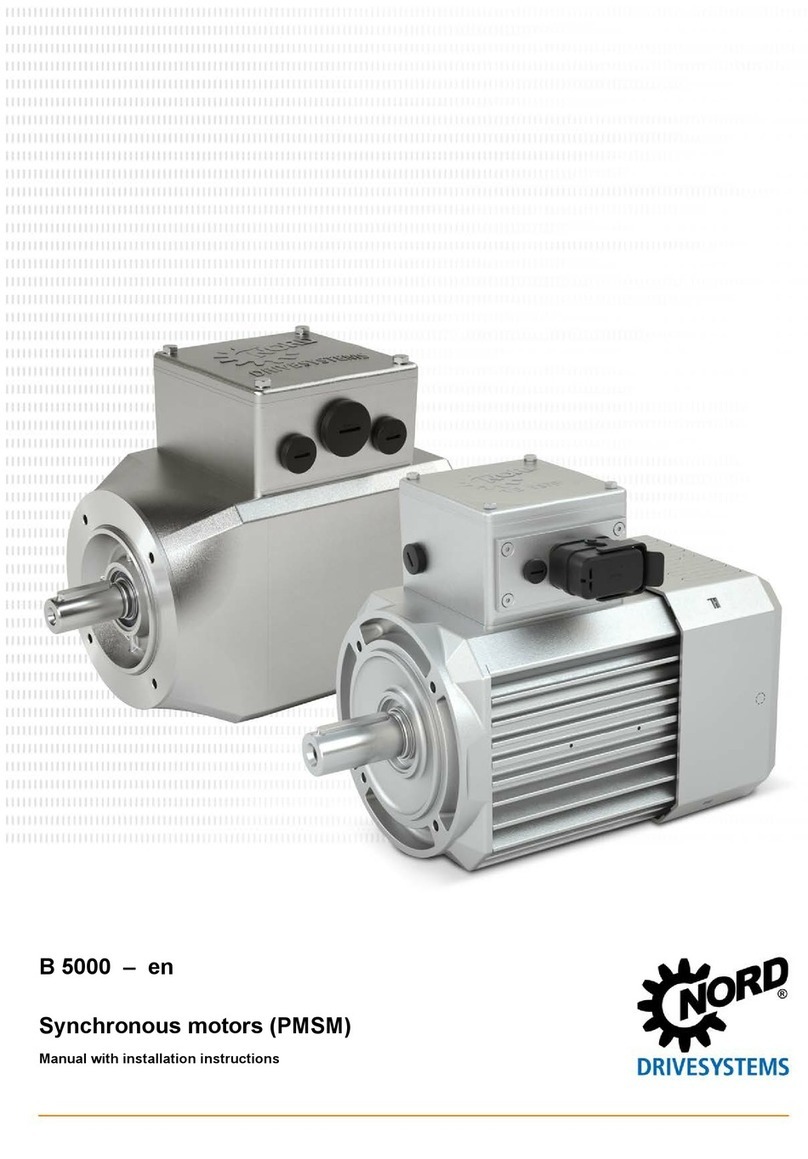

Nord Drivesystems B1091 Manual

Intelligent Drivesystems, Worldwide Services

B1091

Operating and Maintenance Instructions

GB

Three-phase Asynchronous Motors – Standard Design

Explosion-proof Motors with Type of Protection „e“

Dust Explosion-proof Motors (Zone 21+ Zone 22)

-2- B1091-GB-3212 www.nord.com

Contents

1. General information ........................................................................................................... 3

2. Description............................................................................................................................4

2.1 Range of application...............................................................................................................4

3. Information on the designated use of electric motors ....................................................4

3.1 Transport, storage..................................................................................................................4

3.2 Installation...............................................................................................................................5

3.3 Balancing, output components...............................................................................................5

3.4 Alignment................................................................................................................................5

3.5 Electrical connection...............................................................................................................5

3.6 Checking insulation resistance...............................................................................................6

3.7 Commissioning.......................................................................................................................6

4. Maintenance/servicing.........................................................................................................7

5. Motors with type of protection Increased Safety Exe.......................................................8

6. Motors for use in Zone 21 and Zone 22............................................................................10

6.1 General.................................................................................................................................10

6.2 Safety instructions................................................................................................................10

6.3 Commissioning instructions/range of application.................................................................10

6.4 Design and method of operation ..........................................................................................11

6.5 Minimum cross-sections of protective earth wires................................................................11

6.6 Maintenance.........................................................................................................................12

7. IE2-ATEX Motors for use in Zone 21 and Zone 22 ..........................................................13

7.1 General information..............................................................................................................13

7.1.2 Impact test............................................................................................................................13

7.2 Safety information.................................................................................................................13

7.3 Commissioning information / Field of application / Extended ambient temperature range...........13

7.3.1 Electrical connection.............................................................................................................14

7.3.2 Cable and wiring glands.......................................................................................................15

7.3.3 Permissible ambient temperature range ..............................................................................16

7.3.4 Painting.................................................................................................................................16

7.3.5 IEC-B14 Motors....................................................................................................................16

7.4 Structure and method of use................................................................................................17

7.5 Minimum cross section of bonding conductors ....................................................................17

7.6 Maintenance.........................................................................................................................17

8. Options for motors for use in Zone 22.............................................................................18

8.1 Option inverter operation......................................................................................................18

8.2 Option external fan...............................................................................................................18

8.3 Option return stop.................................................................................................................18

8.4 Option brake.........................................................................................................................18

9. Spare parts drawing and spare parts list.........................................................................19

10. Conformity declarations....................................................................................................20

Safety and information signs

Please comply with the following safety and information signs!

Danger!

Danger to life and risk of

injury for humans

Attention!

Damage to the machine possible

Danger!

Important information

for explosion protection

Information!

www.nord.com B1091-GB-3212 -3-

1. Information

1. General information

These Operating Instructions must be read before you transport, assemble, commission,

maintain or repair NORD motors. All persons who are involved with such tasks must observe

these Operating Instructions. All safety instructions provided in these Operating Instructions

must be strictly observed for reasons of personal protection and protection of property.

Information and instructions provided in the manual supplied, safety and commissioning

information and all other manuals must be observed.

This is absolutely essential in order to avoid hazards and damage!

Any applicable national, local and system-specific regulations and requirements must also be

observed!

Custom designs and design variants may differ on technical details. If any points are

not clear, it is urgently recommended that you consult the manufacturer stating the

type designation and motor number or have the maintenance work performed by

NORD.

Qualified staff are persons who, owing to their training, experience, instruction received, and

their knowledge of relevant standards, accident prevention regulations and the appropriate

operating conditions, are entitled to perform the activities necessary in order to put the motor

into operation.

That also calls for knowledge of First Aid and local rescue facilities. It is assumed that the

work for transport, assembly, installation, commissioning, maintenance and repair will be

performed by qualified staff.

The following points in particular must be observed:

Specifications and information about permissible use, assembly, connection, ambient

and operating conditions, which are included in the catalogue, the order

documentation and any other product documentation

The local, system-specific regulations and requirements

Expert use of tools, hoisting equipment and transport equipment

Use of personal safety equipment

For reasons of simplicity the Operating Instructions cannot contain all detailed information

about possible design variants so they cannot take into consideration every imaginable case

of installation, operation or maintenance.

For this reason these Operating Instructions essentially only contain such instructions as are

required for normal use by qualified staff. To prevent malfunctions it is necessary that the

specified maintenance and inspection work be performed by appropriately trained staff.

The engineering guideline 605 2101 must be included with the operating instructions

when operated with the inverter.

The additional operating instructions must be taken into account if an external fan is

present.

The brake operating instructions must also be taken into account with braking motors.

If, for any reason, the operating instructions or the engineering guidelines are lost, new

documentation must be obtained from Getriebebau NORD.

-4- B1091-GB-3212 www.nord.com

2. Description

3. Information

2.1 Range of application

Use of the motors:

The motors may only be used for their intended purpose.

The motors are designed with at least IP 55 protection (for degree of protection see name

plate). They can be installed in a dusty or moist environment.

The necessary degree of protection and any additional precautions required always depend

on the operating and environmental conditions. For outdoor installation and vertical designs,

e.g. V1 or V5 with shaft pointing down, NORD recommends using the option of the double fan

hood [RDD].The motors must be protected against intense sunlight, e.g. by means of a

protective roof. The insulation is tropic-proof.

Installation height: 1000 m

Ambient temperature: -20°C...+40°C. With standard motors, a greater ambient temperature

range is permitted from -20°C...+60°C. The rated power must however be reduced to 82% of

the catalogue value. If the maximum value of the ambient temperature is between +40°C and

+60°C, the value of the power consumption can be inversely interpolated linearly between

100% and 82%.

The motor connection cables and the cable inlet glands must be suitable for temperatures

90°C.

3. Information on the designated use of electric motors

Work may only be performed if the system is disconnected from the mains supply.

3.1 Transport, storage

For transport use all the hoisting lugs fitted to the motor!

The hoisting lugs are designed for the weight of the motor; do not attach any

additional loads!

To transport machine sets (e.g. gear unit attachments) only use the hoisting lugs and

pins provided!

Machine sets must not be hoisted by attaching to individual machines!

To prevent damage to the motor, the motor must always be lifted with suitable hoisting

equipment. The antifriction bearings should be replaced if the time between delivery and

motor commissioning under favourable conditions (storage in dry, dust-free and vibration-free

rooms) is more than 4 years. Under unfavourable conditions that time is reduced

considerably. It may be necessary to treat unprotected, machine surfaces (flanging surface,

shaft end; ...) with corrosion inhibitor. If necessary, check the insulation resistance of the

winding, see section 3.6.

Changes in normal operation (higher power consumption, higher temperatures or higher

vibrations, unusual noises or smells, response from the monitoring system, etc.) indicate that

operation is impaired. To avoid personal injury and damage to property, the maintenance staff

responsible must be informed about the change immediately.

In case of doubt switch off the motor without delay, as soon as the status of the system

permits.

www.nord.com B1091-GB-3212 -5-

3. Information

3.2 Installation

Screwed-in lifting eyes must either be screwed in fully or removed after erection!

Running smoothness: Precise alignment of the coupling and a well-balanced drive

element (coupling, belt pulleys, fans, etc.) are prerequisites for quiet, low vibration

operation.

Complete balancing of the motor with the drive elements may be necessary.

The upper section of the terminal box and the terminal box position can be rotated by

4 x 90 degrees.

IEC-B14 motors:

All four fixing screws, even if not required, must be screwed into the flanged bearing

plate! The fixing screw threads must be inserted with a sealant, e.g. Loctite 242. The

maximum screw-in depth in the bearing plate is 2 x d.

The motor must be inspected for damage before installation and commissioning. A

damaged motor must not be commissioned.

3.3 Balancing, output components

Fitting and removing output assemblies (coupling, pulleys, gear, ...) must be performed

with a suitable device. The rotors are balanced with half key balancing as standard.

When fitting output assemblies to the motor shaft observe the appropriate type of

balancing! The output assemblies have to be balanced in accordance with

DIN ISO 1940!

Take the general precautions necessary for providing the output assemblies with shock

protection. If a motor is put into operation without an output assembly, prevent the key from

being flung out. This also applies if a second shaft end is fitted. Alternatively, remove the key.

3.4 Alignment

Especially if there is a direct coupling, align the shafts of the motor and the driven machine

with one another axially and radially. Any inaccurate alignment can lead to bearing damage,

excessive vibrations and shaft breakage.

3.5 Electrical connection

Feed the connecting leads into the terminal box with cable glands. The terminal box must be

sealed so that it is dust-tight and water-tight. The mains voltage and mains frequency must

agree with the figures on the name plate. ± 5% voltage deviations or ± 2% frequency

deviations are permissible without any reduction in performance. The connections and

arrangement of the terminal board jumpers must conform to the circuit diagram provided in

the terminal box. Connect the protective earth lead to that protective earth terminal.

Provide the ends of the connecting leads with cable lugs or curved ring eyes and connect

them to the terminal board. That also applies to the protective earth connection and the

external bonding lead.

For tightening torques at the screw connections of electric terminals and the terminal board

connections (apart from terminal strips) refer to the table below:

Tightening torques for terminal board connections

Thread diameter M4 M5 M6 M8

Tightening torque (Nm) 0.6 – 1.2 1.8 – 2.5 2.7 – 4.0 5.5 – 8.0

If the machine has an auxiliary heater, it must not be switched on during operation.

-6- B1091-GB-3212 www.nord.com

3. Information

3.6 Checking insulation resistance

Before putting the motor into operation for the first time, after a lengthy period of storage or

standstill (approx. 6 months), the insulation resistance of the winding has to be determined.

During and directly after measurement the terminals carry hazardous voltages in some cases

and must not be touched.

Insulation resistance

The insulation resistance of new, cleaned, repaired windings against the housing and against

one another is >200 M Ohm.

Measurement

In the case of windings up to an operating voltage of 400 V the insulation resistance against

the housing must be measured with a DC voltage of 500 V. At operating voltages up to 725 V

measure with a DC voltage of 1000 V. When doing this the temperature of the windings

should be 25°C ± 15°C.

Checking

If, in the case of a new, cleaned winding or a repaired motor which has been stored or shut

down for any lengthy period, the insulation resistance of the winding against the housing is

less than 50 MOhm, the cause may be moisture. The windings will then have to be dried.

After any lengthy period of operation the insulation resistance may drop. As long as the

measured value does not fall below the critical insulation resistance of < 50 MOhm, the motor

may continue to be operated. If the value falls below the critical level, the cause must be

established and if necessary, the windings or winding sections must be repaired, cleaned or

dried.

3.7 Commissioning

Note: Electromagnetic compatibility

Emitted interference: If torques are not equal (e.g. drive of a piston compressor) a non-

sinusoidal motor current is bound to develop, the harmonics of which may cause

impermissible mains influence and hence impermissible emitted interference.

If power is fed via an inverter, different levels of emitted interference will occur, depending on

the design of inverter (type, suppression, manufacturer). It is absolutely essential that the

EMC information provided by the inverter manufacturer be observed. If the manufacturer

recommends a screened motor supply lead, screening will be most effective if it is electrically

connected to a large area of the metal terminal box of the motor (with EMC cable gland made

of metal). In the case of motors with built-in sensors (e.g. PTC thermistors) interference

voltages can occur on the sensor line, caused by the inverter.

Interference immunity: In the case of motors with built-in sensors (e.g. PTC thermistors) the

user himself must ensure adequate interference immunity by making a suitable selection of

sensor signal line (possibly with screening, interfacing as with motor supply lead) and the

analysing instrument. Prior to commissioning always observe the information and instructions

in the operating manuals for inverters as well as all other sets of instructions. After attaching

the motors, check them to make sure they are operating properly! In the case of brake motors

also check that the brake operates properly.

www.nord.com B1091-GB-3212 -7-

4. Maintenance

Servicing

Safety precautions

Before commencing any work on the motor or device, but especially before opening covers in

front of live components, always isolate the motor electrically according to the regulations.

Apart from the main circuits also isolate any additional or auxiliary circuits.

The standard "5 safety rules", e.g. according to DIN VDE 0105, are:

Isolate electrically

Prevent equipment from being switched on again

Check that there is no voltage

Earth and short-circuit

Cover any adjacent live components or prevent access with barriers

The above precautions may only be withdrawn when the maintenance work has been

completed and the motor is fully assembled.

Inspect the motors properly at regular intervals. In particular look out for any physical damage,

ensure that cooling passages are free, listen for any unusual noises, and ensure that electrical

connections are performed in a proper manner.

With the exception of standardised, commercial or equivalent parts the only spare parts which

may be used are genuine spare parts!

NOTE: Inasmuch as motors are provided with enclosed condensation ports, they must be

opened from time to time so that any accumulated condensation can drain off. Condensation

ports are always positioned at the lowest point of the motor. When installing the motor ensure

that the condensation holes are at the bottom.

Bearing changes, grease filling

The period for changing bearings in operating hours [h] on IEC motors with coupling drive is

as follows, under normal operating conditions and with the motor installed horizontally,

depending on coolant temperature and motor speed:

25°C 40°C

up to 1800 min-

1

approx. 40000 h approx. 20000 h

up to 3600 min-

1

approx. 20000 h approx. 10000 h

In the case of direct gearbox attachment or under special operating conditions, e.g. vertical

motor, substantial vibrations or shock loads, frequent reversing, etc. the above-mentioned

operating hours will be reduced considerably.

The motor must be subjected to a general overhaul every 5 years!

General overhaul

For this purpose the motor must be dismantled. Perform the following work:

Clean all parts of the motor

Inspect all parts of the motor for damage

Replace all damaged parts

Replace all antifriction bearings

Replace all gaskets and shaft seals

The general overhaul must be performed in a specialised workshop with appropriate

equipment and by qualified staff. We urgently recommend having the general overhaul

performed by NORD Service.

-8- B1091-GB-3212 www.nord.com

5. Motors with protection type

Increased Safety Exe

These motors are subject to the following supplementary or specific information.

The motors are suitable for use in Zone 1 and conform to equipment group II, category 2G, and can be used

for an ambient temperature between -20°C and +40°C.

Type addition: 2G e.g.: 80 L/4 2G TF

The marking is 0102 II 2G Ex e II along with the temperature class

If the motor is connected to a gearbox, the Ex marking of the gearbox must also be observed.

Explosive gas mixtures or concentrations of dust in conjunction with hot, live and moving parts on electrical

machinery can cause serious or lethal injuries.

The increased hazard in explosive areas calls for particularly careful compliance with the general safety and

commissioning instructions. The staff responsible must be trained regarding correct use of motors in

explosive areas.

Explosion-proof electrical machines comply with the standards in series EN 60034 (VDE 0530) as well as

EN 60079-0 and 60079-7. It is the degree of explosion risk which determines zone classification.

DIN EN 60079, Part 10, provides information on this. It is the user who is responsible for zone classification.

If motors are not certified for explosive areas, it is prohibited to use them in explosive areas.

Cable entries must be approved for explosive atmospheres. Ports which are not used must be closed off with

approved blind plugs.

When connecting up the installation lines to the motor terminals and the protective earth lead must be laid

with U-shaped lines under the respective terminals so that the wire clamps and the terminal studs are

subjected to uniform loading and are not deformed under any circumstances. Alternatively, the connections

can be made with a cable lug. The use of aluminium connecting cables is not permissible.

The motor is supplied with a certified cable gland. The clamping nuts of the cable gland must be tightened to

the torque specified in the following table.

Cable gland Clamping nut tightening

torque [Nm]

M20x1.5 6

M25x1.5 8

M32x1.5 12

M40x1.5 16

When connecting up always ensure that the permissible clearance distances of 10 mm and the permissible

creepage distances of 12 mm between live components and housing potential and between individual live

components are observed.

Before the terminal box is closed, make sure that all the nuts on the terminals and the screw on the

protective earth terminal are tight. The terminal box gaskets and the seals on the cable gland must be fitted

properly and must not be damaged in any way.

If the shaft end is at the top, e.g. designs IMV3 or IMV6, and the motor has Exe protection, the user/installer

must fit a cover which prevents foreign bodies from falling into the motor fan hood (see DIN EN 60079-0). It

must not impair cooling of the motor by its fan. A handwheel at the second shaft end is not permitted. If the

shaft end is at the bottom, e.g. designs IMV1 or IMV5, the motors are generally provided with a protective

roof on the fan hood. The motors are designed for continuous duty and normal, non-recurring start-ups in

which no substantial start-up heat develops.

Area A in EN 60034-1 (VDE 0530 Part 1) - voltage ± 5%, frequency ± 2%, characteristic, mains symmetry -

must be observed so that the development of heat remains within the limits permitted. Any major deviations

from the ratings can caused an impermissible increase in the development of heat in the electric machine.

The motor temperature class stated on the name plate must at least conform to the temperature class of any

combustible gas that may be emitted.

www.nord.com B1091-GB-3212 -9-

5. Motors with protection type

Increased Safety Exe

Each machine must be protected against impermissible development of heat by a current-dependent

delayed protective switch tested for operation by an appointed body, with phase-failure protection in

compliance with VDE 0660 or an equivalent system in all phases. The protective system must be set to the

rated current. If windings are connected in a delta circuit the trips must be connected in series with the

winding phases and set to 0.58 times the rated current. If such a configuration is not possible, additional

precautions will be necessary (e.g. thermal machine protection).

If the rotor jams, the protective system must shut down within the tE-time specified for the respective

temperature class.

Electric machines for heavy starting (ramp time > 1.7 x tE-time) must be protected by a start-up monitoring

system in accordance with the provisions of the EC type test certificate.

Thermal machine protection by means of direct thermal monitoring of the winding with PTC thermistor

temperature sensor is permissible if it is certified and stated on the name plate.

Do not connect any voltage higher than 30V to the PTC thermistor temperature sensor!

If the only protection is a PTC thermistor temperature sensor, a performance-tested, certified PTC tripping

unit from an appointed body must be used. The PTC tripping unit must be provided with the following marks

concerning the degree of protection:

II (2) G

In Germany reference is made to DIN 57165/VDE 0165 and ElexV for setting up electrical installations

in explosive areas! In other countries the appropriate national regulations must be observed!

Operation in conjunction with an inverter must be explicitly certified. It is absolutely essential that the

separate manufacturer's instructions be observed. For Exe protection the motor, inverter and protective

systems must be identified as belonging together and the permissible operating data must be defined on the

joint EC type test certificate. The levels of voltage peaks generated by the inverter may be subjected to

unfavourable influences by the connecting cable installed between the inverter and the electric machine. In

the system comprising inverter-cable-electric machine the maximum figure for voltage peaks at the

connecting terminals on the machine must not be less than the figure specified in the separate

manufacturer's instructions. In addition, the EMC Directive must also be observed.

Any repairs must be performed by NORD or accepted by an officially recognised independent expert. The

work must be identified by means of an additional repair plate. With the exception of standardised,

commercial and equivalent parts, the only spare parts which may be used are genuine spare parts (see

spare parts list): this particularly applies to seals and connecting parts.

In the case of motors with closed condensation holes the threads of the plugs must be recoated with

Loctite 242 or Loxeal 82-21 after condensation has been drained off. As soon as that has been done the

plugs must be reinserted. Checking of electrical connections must be performed at regular intervals.

The connection terminals, protective earth terminal and equipotential bonding terminal must be inspected to

make sure they are firm. When doing so, check to make sure that the cable entry, cable gland and terminal

box gaskets are in good condition.

All work on electric machines must be performed with the machine vertical and with all terminals

disconnected from the mains.

If installation resistance is being measured the motor must be removed. Measurement must not be

performed in the explosive area. As soon as measurement has been completed discharge the connecting

terminals again by shorting them in order to prevent any spark discharges occurring in the explosive area.

-10- B1091-GB-3212 www.nord.com

6. Motors for use in Zone 21

and Zone 22

6.1 General information

The following information applies additionally or especially to motors in categories 2D and 3D!

The motors are suitable for use in Zone 21 (category 2D) or Zone 22 – non-conductive dusts (category 3D)

according to their designation.

Type addition: Zone 21:2D e.g.: 80 L/4 2D TF

Zone 22: 3D e.g.: 80 L/4 3D TF

The designation is as follows: 0102 II 2 D T 125°C for category 2 (Zone 21)*

Certification number: BVS 04 ATEX E 037

II 3 D T 125°C for category 3 (Zone 22 non-conductive dust)*

*the details of the surface temperature may deviate from 125°C and may be obtained from the name plate

If the motor is connected to a gear, the Ex designation of the gear must also be taken into account!

6.2 Safety information

The increased danger in areas with combustible dust requires that the general safety and commissioning

instructions are strictly complied with. Explosive dust concentrations can cause explosions if ignited by hot or

sparking objects and this can cause severe or even lethal injuries to persons and significant damage to

property.

It is absolutely essential that the persons authorised to use these motors in hazardous areas are trained in

their correct use.

6.3 Commissioning instructions / application area

The motors are suitable for use in Zone 21 (category 2D) or Zone 22 – non-conductive dusts (category 3D)

according to their designation. If the motors are intended for inverter operation, this must be specified when

ordering. The motors must be protected against overheating with suitable monitoring equipment! The dust

levels must not exceed 5 mm! The motors are designed for the voltage and frequency range A as in

EN 60034 Part 1.

Motors for use in Zone 21 and Zone 22, with labelling TF may be thermally monitored via the built-in PTC in

combination with a suitable triggering device as the sole protection. Electrical equipment for use in areas with

combustible dust complies with the standards EN 50281-1-1, EN 60034 and EN 50014. The level of

explosion hazard is determined by the zone separation. The operator/employer is responsible for zone

separation (guideline 1999/92/EC).

If the designation is supplemented by an X, special documentation in the EC type examination certificate

must be complied with. It is forbidden to use standard motors in hazardous areas that are not authorised for

use in hazardous areas. In Zone 21, the cable entries must be authorised for Ex areas (protection class

minimum IP 66) and must be secured against accidental loosening. Unused apertures must be sealed with

authorised plugs (minimum protection class IP 66).

For Zone 22, the cable glands must as a minimum correspond to the protection type specified on the name

plate. Unused openings must be closed with plugs, which as a minimum correspond to the protection class

of the motor.

The motor must not be opened under hazardous atmospheres to connect the electrical cables or for any

other work. The voltage must always be switched off and secured against being switched on again before

opening the motor!

www.nord.com B1091-GB-3212 -11-

6. Motors for use in Zone 21

and Zone 22

If the motor is supplied with a certified cable gland, the clamping nuts of the cable gland must be tightened to

the torque specified in the following table.

Cable gland Clamping nut tightening

torque [Nm]

M20x1.5 6

M25x1.5 8

M32x1.5 12

M40x1.5 16

The permissible ambient temperature range for all motors is -20°C...+40°C. A greater ambient temperature

range of -20°C...+60°C is permissible with motors for operation in Zones 21 and 22. This does not however

apply with the option brake and external fans! The rated power must then be reduced to 72% of the

catalogue value. If the maximum value of the ambient temperature is between +40°C and +60°C, the value

of the power consumption can be inversely interpolated linearly between 100% and 72%. Thermal motor

protection with a PTC temperature sensor is essential here. The motor connection cables and the cable

glands must be suitable for temperatures

90°C.

IEC-B14 motors

The B14 flanged bearing plate must be covered with a protective foil which must be removed before the

motor is fastened in place. All four fixing screws, even if not required, must be screwed into the flanged

bearing plate! The fixing screw threads must be inserted with a sealant, e.g. Loctite 242. The maximum

screw-in depth in the bearing plate is 2 x d.

If the shaft end faces upwards, e.g. models IMV3, IMV6, a cover must be positioned on the motor by the

operator/installer to prevent foreign bodies from falling into the motor ventilation cover (see

DIN EN 50 280-1-1). It must not hinder the motor from being cooled by the fans. Where shaft ends face

down, e.g. models IMV1, IMV5, the motors for Zone 21 are generally equipped with a protective roof on the

ventilation cover. A handwheel on the second shaft end is not permitted.

Unless otherwise specified for operating modes and tolerances in the test certificate or name plate, electrical

machinery is designed for continuous operation and normal infrequent start-ups where insignificant start-up

heating occurs. The motors may only be used for the operating mode specified on the name plate.

The installation regulations must be complied with!

6.4 Structure and operating mode

The motors are self-cooling. Rotary shaft seals are fitted both on the drive side (DS) and on the ventilation

side (VS).

Motors for Zone 21 and Zone 22 have metal fans. The motors are designed for protection class IP 55

(Zone 22 – non-conductive dust) or IP 66 (Zone 21). Under normal operating conditions the surface

temperature does not exceed that stated on the name plate.

6.5 Minimum cross-sections of ground leads

Cross-section of phase conductor

in installation S in mm2Minimum cross-section of the associated

ground lead SPin mm2

S ≤16

16 < S ≤35

S > 35

S

16

0.5 S

When connecting a lead to the external ground, the minimum cross-section must be 4 mm2.

-12- B1091-GB-3212 www.nord.com

6. Motors for use in Zone 21

and Zone 22

6.6 Maintenance

The voltage must always be switched off and secured against being switched on again!

Attention! Higher temperatures than the maximum permitted surface temperature of the housing may

be present inside the motor. The motor must therefore never be opened in hazardous dust

atmospheres!

The motors must be checked and tested regularly for functional safety! The applicable national

standards and regulations must be complied with!

Unpermitted high dust deposits > 5 mm may not be allowed to build up! If functional safety cannot be

ensured, the motor may not be operated!

When the ball bearings are replaced, the rotary shaft seals must also be replaced. FKM rotary shaft seals as

specified by Getriebebau NORD must be used. Ensure that they are fitted correctly!

The rotary shaft seals must be lubricated on the external rings and on the seal lips. If an explosion protected

gear is flanged dust-tight to the motor, an NBR rotary shaft seal can be used on the drive side of the motor if

the gear oil temperature does not exceed 85°C.

Only original parts may be used as spare parts with the exception of standardised, commercially available

and equivalent parts. This also applies in particular to seals and connection components. Parts for terminal

boxes or spare parts for external grounding must be ordered as per the spare parts list in the operating

instructions.

The functionality of seals, rotary shaft seals and cable glands must be regularly checked!

Maintaining dust protection for the motors is of paramount importance for explosion protection.

Maintenance must be implemented by qualified personnel in a specialist workshop with suitable equipment.

We urgently recommend that general overhauls are implemented by NORD Service.

www.nord.com B1091-GB-3212 -13-

7. IE2-ATEX Motors for use in

Zone 21 and Zone 22

ATTENTION!

Section 7 of these operating instructions applies as a supplement for IE2-ATEX motors for Zone 21

and Zone 22 as per EN 60079-0 and DIN EN 60079-31. Please disregard Section 6 for these motors.

7.1 General information

The following information applies additionally or especially to motors in categories 2D and 3D!

The motors are suitable for use in Zone 21 (category 2D) or Zone 22 – non-conductive dusts (category 3D)

according to their designation.

Type addition: Zone 21:2D e.g.: 80 L/4 2D TF

Zone 22: 3D e.g: 80 L/4 3D TF

The designation is as follows: 0102 II 2 D Ex tb IIIC T125°C Db for Category 2

(Zone 21)*

II 3 D Ex tc IIIB T125°C Dc for Category 3

(Zone 22, non-conducting dust)*

*the details of the surface temperature may deviate from 125°C and may be obtained from the name plate

If the motor is attached to a gear unit, the EX labelling of the gear unit must also be observed!

7.1.2 Impact test

As per 26.4.2 of EN 60079-0 (2009 version), motors for Category 3D are subjected to an impact test with 4J.

7.2 Safety information

The increased danger in areas with inflammable dust demands the strict observation of the general safety

and commissioning information. Explosive concentrations of dust may cause explosions if ignited by hot or

sparking objects. Such explosions may cause serious or fatal injuries to persons or severe material damage.

It is absolutely essential that the persons responsible for the use these motors and frequency inverters in

explosion hazard areas are trained in their correct use.

7.3 Commissioning information / Field of application

If the motors are required for use with frequency inverters, this must be stated in the order. The motors must

be protected against overheating with suitable monitoring equipment! The thickness of dust deposits must

not exceed 5 mm! The motors are designed for the voltage and frequency range B of EN 60034 Part 1.

Motors for use in Zone 21 and Zone 22, with labelling TF may be thermally monitored via the built-in PTC in

combination with a suitable triggering device as the sole protection.

Electrical equipment for use in areas with combustible dust comply with the standards DIN EN 60079-0,

EN 60079-31 and DIN EN 60034. The valid version of the standard can be seen from the EEC Declaration of

Conformity. The degree of explosion hazard determines the zone categorisation. The operator / employer is

responsible for the assignment of zones (RL 1999/92/EEC)

If the certification is supplemented with an "X" the special conditions in the EEC prototype certification and/or

the relevant documentation must be observed. The use of standard motors which are not certified for

explosion hazard areas in explosion hazard areas is prohibited.

The terminal box cover is covered on one side with a very thin film of grease. This grease film prevents the

seal from adhering to the frame of the terminal box and must not be removed. This grease film must also be

applied using a suitable grease, if the seal is replaced.

-14- B1091-GB-3212 www.nord.com

7. IE2-ATEX Motors for use in

Zone 21 and Zone 22

The terminal box seal is glued into the cover of the terminal box cover. Please only use an original seal when

replacing the seal.

If the terminal box is opened during installation, maintenance, repair, troubleshooting or overhaul, the

terminal box cover must be re-fitted after the work is complete. There must be no dirt on the surface of the

seal or the sealing surface of the terminal box frame.

The screws for the terminal box cover must be tightened with a torque according to the following table.

Tightening torques for terminal box cover screws

Thread Tightening torque [Nm]

M4 0.8 to 1.2

M5 1.2 to 1.8

M6 1.5 to 2.5

M8 3.0 to 5.0

7.3.1 Electrical Connection

The electrical connections of the terminal board are protected against twisting. The voltage supply to the

terminal board must be made by means of suitable ring terminals. The ring terminals are installed between

the two brass washers below the lock washer. The nuts must be tightened with a torque according to the

table below. The contact pressure is permanently maintained by means of the specified torque and the lock

washer. In addition, twisting of the ring terminals of the voltage supply is prevented. The connection

elements are corrosion-proof.

Torques for Electrical

Rated thread diameter Tightening torque [Nm]

M1.6 0.09-0.12

M3 0.35-0.5

M4 0.8-1.2

M5 1.8-2.5

M6 2.7-4.0

M8 5.5-8.0

M10 9.0-13.0

M12 16.0-20.0

M16 36.0-40.0

Electrical connection:

Brass nut

Lock washer

Brass washer

Brass washer

Brass nut

Brass washer

Ring terminal

Brass washer

Brass thread with collar

Mechanical protection against twisting

A

r

www.nord.com B1091-GB-3212 -15-

7. IE2-ATEX Motors for use in

Zone 21 and Zone 22

7.3.2 Cable and wiring glands

In Zone 21, the cable entries must be authorised for Ex areas (protection class minimum IP 66) and must be

secured against accidental loosening. Unused apertures must be sealed with authorised plugs (minimum

protection class IP 66). As delivered, the motors are equipped with a blank screw cap and a plastic cap. The

plastic cap must be replaced with a certified cable gland.

For Zone 22, the cable glands must as a minimum correspond to the protection type specified on the name

plate. Unused openings must be closed with plugs, which as a minimum correspond to the protection class

of the motor and the requirements of EN 60079-0. The cable glands and blank plugs must be suitable for a

temperature of at least 100°C.

The motor must not be opened under hazardous atmospheres to connect the electrical cables or for any

other work. The voltage must always be switched off and secured against being switched on again before

opening the motor!

The motors are equipped with cable glands according to the following overview.

Assignment of Cable Glands to Motor Size

Cable glands for standard motors Cable glands for brake motors

Type Number Thread Number Thread Number Thread Type Number Thread Number Thread Number Thread

63 2 M20x1.5 63 4 M20x1.5 2 M12x1.5

71 2 M20x1.5 71 4 M20x1.5 2 M12x1.5

80 2 M25x1.5 80 4 M25x1.5 2 M12x1.5

90 2 M25x1.5 90 4 M25x1.5 2 M12x1.5

100 2 M32x1.5 100 4 M32x1.5 2 M12x1.5

112 2 M32x1.5 112 4 M32x1.5 2 M12x1.5

132 2 M32x1.5 132 4 M32x1.5 2 M12x1.5 2 M16x1.5

160/

180/..X 2 M40x1.5 2 M12x1.5 2 M16x1.5 160/

180/..X 2 M40x1.5 2 M12x1.5 2 M16x1.5

180/

200/..X 2 M40x1.5 2 M12x1.5 2 M16x1.5 180/

200/..X 2 M40x1.5 2 M12x1.5 2 M16x1.5

200 2 M40x1.5 2 M12x1.5 2 M16x1.5 200 2 M40x1.5 2 M12x1.5 2 M16x1.5

If the motor is supplied with a certified cable gland, the clamping nuts of the cable gland must be tightened to

the torque specified in the following table.

Cable gland Clamping nut tightening

torque [Nm]

M20x1.5 6

M25x1.5 8

M32x1.5 12

M40x1.5 16

-16- B1091-GB-3212 www.nord.com

7. IE2-ATEX Motors for use in

Zone 21 and Zone 22

7.3.3 Permissible Ambient Temperature Range

The permissible ambient temperature range for all motors is -20°C...+40°C. A greater ambient temperature

range of -20°C...+60°C is permissible with motors for operation in Zones 21 and 22. This does not however

apply with the option brake and external fans! In this case, the rated power must be reduced to 72% of the

value stated in the catalogue. If the maximum ambient temperature is between +40°C and +60°C, the power

output should be inversely linearly interpolated between 100% and 72%. In this case thermal protection of

the motor by means of a thermistor sensor is essential. The motor connection cables and the cable glands

must be suitable for temperatures of at least 100°C.

7.3.4 Painting

Motors for Zone 21 and Zone 22 are provided with suitable painting ex-works.

Subsequent painting may only be carried out after consultation with Getriebebau NORD or a workshop which

is approved for the repair of explosion protected motors. Compliance with the valid standards and regulations

is mandatory.

7.3.5 IEC-B14 Motors

The B14 flanged bearing plate must be covered with a protective foil which must be removed before the mo-

tor is fastened in place. All four fixing screws, even if not required, must be screwed into the flanged bearing

plate! The fixing screw threads must be inserted with a sealant, e.g. Loctite 242. The maximum screw-in

depth in the bearing plate is 2 x d.

If the end of the shaft faces upwards, e.g. version IMV3, IMV6, a cover must be provided by the operator /

installer, which prevents foreign bodies from falling into the fan cover of the motor (see DIN EN 60079-017,

item 17). This must not obstruct the fan from cooling the motor. If the end of the shaft faces downwards, e.g.

versions IMV1, IMV5, motors for Zone 21 and Zone 22 are provided with a protective cover on the fan cover.

A hand wheel on the second end of the shaft is not permitted for versions with the "shaft end downwards".

Unless otherwise specified for operating modes and tolerances in the test certificate or name plate, electrical

machinery is designed for continuous operation and normal infrequent start-ups where insignificant start-up

heating occurs. The motors may only be used for the type of operation stated on the name plate.

The installation instructions must be strictly observed.

www.nord.com B1091-GB-3212 -17-

7. IE2-ATEX Motors for use in

Zone 21 and Zone 22

7.4 Structure and method of use

The motors are self-cooling. Rotary shaft seals are fitted both on the drive side (DS) and on the ventilation

side (VS). Motors for Zone 21 and Zone 22 have metal fans. Motors with brakes for Zone 22 (Category 3D,

non-conducting dust) have a special plastic fan. The motors are produced as protection class IP55,

optionally protection class IP 66, (Zone 22 – non-conducting dust) or IP66 (Zone 21). Under normal

operating conditions, the surface temperature does not exceed the surface temperature stated on the name

plate.

7.5 Minimum cross section of bonding conductors

Cross-section of phase conductor in in-

stallation S in mm2Minimum cross-section of the associated

ground lead SPin mm2

S ≤16

16 < S ≤35

S > 35

S

16

0.5 S

When connecting a lead to the external ground, the minimum cross-section must be 4 mm2.

7.6 Maintenance

The voltage must always be switched off and secured against being switched on again before open-

ing the motor!

Attention! Higher temperatures than the maximum permitted surface temperature of the housing may

be present inside the motor. The motor must therefore never be opened in hazardous dust atmos-

pheres! The motors must be checked and tested regularly for functional safety! The applicable na-

tional standards and regulations must be complied with!

Unpermitted high dust deposits > 5 mm may not be allowed to build up! If functional safety cannot be en-

sured, the motor may not be operated! When the ball bearings are replaced, the rotary shaft seals must also

be replaced. FKM rotary shaft seals as specified by Getriebebau NORD must be used. Ensure that they are

fitted correctly! The rotary shaft seals must be lubricated on the external rings and on the seal lips. If an ex-

plosion protected gear is flanged dust-tight to the motor, an NBR rotary shaft seal can be used on the drive

side of the motor if the gear oil temperature does not exceed 85°C. Only original parts may be used as spare

parts with the exception of standardised, commercially available and equivalent parts. This also applies in

particular to seals and connection components. Parts for terminal boxes or spare parts for external grounding

must be ordered as per the spare parts list in the operating instructions.

The functionality of seals, rotary shaft seals and cable glands must be regularly checked!

Maintaining dust protection for the motors is of paramount importance for explosion protection.

Maintenance must be implemented by qualified personnel in a specialist workshop with suitable equipment.

We urgently recommend that the general overhaul is carried out by NORD Service.

-18- B1091-GB-3212 www.nord.com

8. Options for motors used in

Zone 22

8.1 Option inverter operation

ATEX NORD motors for Zone 22 are suitable for inverter operation due to their insulation system design.

Because of the variable rpm range, temperature monitoring with PTC resistors or temperature monitors is

necessary. For safe engineering and application, comply with the engineering guideline "Operation of ATEX

motors with frequency inverters", No. 605 2101. The engineering guideline provides information about the

necessary requirements for inverter operation and about the permitted rpm ranges.

8.2 Option external fan

Motors with the additional designation F (e.g. 80S/4 3D F) are equipped with an external fan and must be

monitored via the integrated temperature sensor.

Attention!

The motor may only be operated together with the external fan! A failure of the external fan can lead to the

motor overheating and therefore endanger property/persons.

Comply with the operating instructions for the external fan!

The power supply for the external fan is provided independently via the external fan terminal box. The

external fan power supply must be identical to the voltage rating given on the name plate. The external fans

must be protected against overheating with suitable monitoring equipment! The IP protection classes of the

external fan and motor may be different. The lower IP protection class applies to the drive unit. The cable

glands must as a minimum correspond to the protection type specified on the name plate. Unused openings

must be closed with plugs, which as a minimum correspond to the protection class of the motor.

External fans and motors for use in hazardous areas have an Ex designation as per guideline 94/9 EC. This

designation must be present on the external fan and on the motor. If the designations of the external fan and

the motor differ, the lowest designated explosion protection applies to the entire drive. The maximum

specified temperature given in the surface temperature data for the individual components applies for the

entire drive unit In this case, it may be necessary to take into account any gears that may be present.

Contact Getriebebau NORD if there are any doubts.

If any component in the entire drive does not have an Ex designation, then the entire drive may not be

operated in an Ex area.

8.3 Option return stop

Motors with the additional designation RLS (e.g. 80S/4 3D RLS) are equipped with a return stop.

Motors with return stops have an arrow marking the direction of rotation on the ventilation cover. The arrow

points in the rotation direction of the motor. It must be ensured, when connecting the motor and during motor

control, that the motor can only operate in the rotation direction, e.g. by means of a rotary field test.

Switching the motor to the blocked rotation direction, i.e. incorrect rotation direction, can lead to damage.

Return stops operate without wear from a speed of ca. 800 1/min.. Return stops must not be operated at

speeds under 800 l/min to prevent unpermitted heating and rapid wear of the return stop. This must be taken

into account for motors with a frequency of 50 Hz and poles ≥8, and for motors with frequency inverters.

8.4 Option brake

Motors with the additional designation BRE (e.g. 80S/4 3D BRE 10) are equipped with a brake and must be

monitored via the integrated temperature sensor. If the temperature sensor of one of the components (motor

or brake) is triggered, the entire drive must be securely shutdown. The motor and brake PTC's must be

switched in series.

Attention!

The brake DC voltage supply must be implemented via a rectifier located in the motor terminal box or via a

directly supplied voltage. The brake voltage shown on the name plate must be complied with.

The power supply lines must not be laid in a cable together with the temperature sensor circuit. The brake

functionality must be checked before start-up. There should be no grinding noises, as this could lead to

unpermitted excessive heating.

www.nord.com B1091-GB-3212 -19-

Item No. Description Item No. Description

900 Rotor with shaft

902 End shield at drive end

902.1 Cheese-head screw

902.2 Hexagon nut

904 Shaft seal

905 Bearing at drive end

906 Ball bearing shim

907 Terminal box frame

907.1 Chassis connection terminal wire clamp

907.2 Oval-head screw

908 Terminal box lid

908.1 Cheese-head screw

909 Terminal box frame gasket

910 Terminal box lid gasket

911 Terminal board

911.1 Cheese-head screw

911.5 Spring lock washer

912 Mini-terminal

912.1 Oval-head screw

913 Spacer

913.1 Cheese-head screw

913.2 Spring lock washer

916 Stator with winding

916.1 Equipotential bonding terminal

916.2 Spring pin

918 Key

924 Screw-on foot (BG 100-132)

924.1 Hexagon bolt

924.2 Spring lock washer

924.3 Hexagon nut

929 Bearing at ventilation end

932 End shield at ventilation end

932.1 Cheese-head screw

932.2 Hexagon nut

933 Shaft seal

939 Fan

940 Fan hood

940.1 Oval-head screw

940.2 Countersink screw B3

941 Key

942 947 Circlip

948 Circlip

952 Clamping bush

953 Cable gland

955 Blind plug

956 Blind plug

980 Protective roof

988 Ring seal

989 Name plate

989.1 Oval-head screw

9. Spare parts drawing and

spare parts list

-20- B1091-GB-3212 www.nord.com

10. Conformity declaration

Other manuals for B1091

1

Table of contents

Other Nord Drivesystems Engine manuals

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton 310000 VERTICAL SERIES Operator's manual

Nice

Nice E Star ST Instructions for installation and use

Mhouse

Mhouse MhouseKit RM Installation instructions and warnings

Siemens

Siemens SIMOTICS M-1PH818 Operating and installation instructions

Bauer

Bauer MSXH operating manual

Alutech

Alutech AM1/RS Operation manual